操作級課程

操作級課程

操作級課程

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

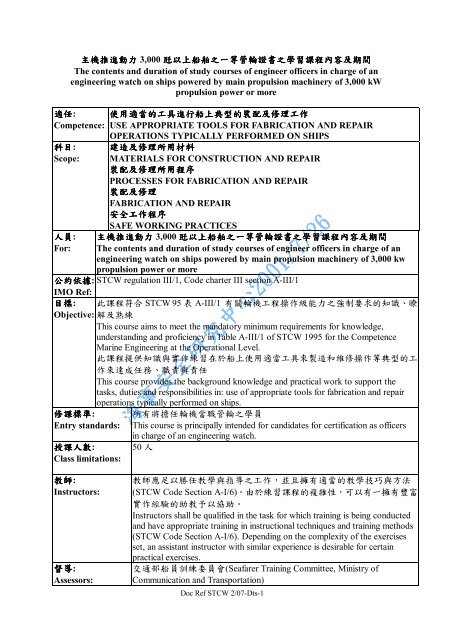

主 機 推 進 動 力 3,000 瓩 以 ㆖ 船 舶 之 ㆒ 等 管 輪 證 書 之 學 習 課 程 內 容 及 期 間<br />

The contents and duration of study courses of engineer officers in charge of an<br />

engineering watch on ships powered by main propulsion machinery of 3,000 kW<br />

propulsion power or more<br />

適 任 :<br />

使 用 適 當 的 工 具 進 行 船 ㆖ 典 型 的 裝 配 及 修 理 工 作<br />

Competence: USE APPROPRIATE TOOLS FOR FABRICATION AND REPAIR<br />

OPERATIONS TYPICALLY PERFORMED ON SHIPS<br />

科 目 :<br />

建 造 及 修 理 所 用 材 料<br />

Scope: MATERIALS FOR CONSTRUCTION AND REPAIR<br />

裝 配 及 修 理 所 用 程 序<br />

PROCESSES FOR FABRICATION AND REPAIR<br />

裝 配 及 修 理<br />

FABRICATION AND REPAIR<br />

安 全 工 作 程 序<br />

SAFE WORKING PRACTICES<br />

㆟ 員 :<br />

主 機 推 進 動 力 3,000 瓩 以 ㆖ 船 舶 之 ㆒ 等 管 輪 證 書 之 學 習 課 程 內 容 及 期 間<br />

For: The contents and duration of study courses of engineer officers in charge of an<br />

engineering watch on ships powered by main propulsion machinery of 3,000 kw<br />

propulsion power or more<br />

公 約 依 據 : STCW regulation III/1, Code charter III section A-III/1<br />

IMO Ref:<br />

目 標 : 此 課 程 符 合 STCW 95 表 A-III/1 有 關 輪 機 工 程 操 作 級 能 力 之 強 制 要 求 的 知 識 、 瞭<br />

Objective: 解 及 熟 練<br />

This course aims to meet the mandatory minimum requirements for knowledge,<br />

understanding and proficiency in Table A-III/1 of STCW 1995 for the Competence<br />

Marine Engineering at the Operational Level.<br />

此 課 程 提 供 知 識 與 實 作 練 習 在 於 船 ㆖ 使 用 適 當 工 具 來 製 造 和 維 修 操 作 等 典 型 的 工<br />

作 來 達 成 任 務 、 職 責 與 責 任<br />

This course provides the background knowledge and practical work to support the<br />

tasks, duties and responsibilities in: use of appropriate tools for fabrication and repair<br />

operations typically performed on ships.<br />

修 課 標 準 : 所 有 將 擔 任 輪 機 當 職 管 輪 之 學 員<br />

Entry standards: This course is principally intended for candidates for certification as officers<br />

in charge of an engineering watch.<br />

授 課 ㆟ 數 : 50 ㆟<br />

Class limitations:<br />

<br />

<br />

教 師 :<br />

Instructors:<br />

督 導 :<br />

Assessors:<br />

教 師 應 足 以 勝 任 教 學 與 指 導 之 工 作 , 並 且 擁 有 適 當 的 教 學 技 巧 與 方 法<br />

(STCW Code Section A-I/6)。 由 於 練 習 課 程 的 複 雜 性 , 可 以 有 ㆒ 擁 有 豐 富<br />

實 作 經 驗 的 助 教 予 以 協 助 。<br />

Instructors shall be qualified in the task for which training is being conducted<br />

and have appropriate training in instructional techniques and training methods<br />

(STCW Code Section A-I/6). Depending on the complexity of the exercises<br />

set, an assistant instructor with similar experience is desirable for certain<br />

practical exercises.<br />

交 通 部 船 員 訓 練 委 員 會 (Seafarer Training Committee, Ministry of<br />

Communication and Transportation)<br />

Doc Ref STCW 2/07-Dts-1

教 學 設 備 及 器 材 :<br />

Teaching facilities<br />

and equipment:<br />

教 具 :<br />

Teaching aids:<br />

證 書 :<br />

Certificate:<br />

教 育 部 (Ministry of Education)(Ministry of Education)<br />

1. 黑 板 或 掛 圖<br />

Blackboard or flipchart<br />

2. 課 桌<br />

Desks<br />

3. 投 影 機<br />

Overhead projector<br />

4. 手 工 具 與 電 動 工 具<br />

Hand and power tools<br />

5. 工 具 機<br />

Machine tools<br />

6. 製 造 、 焊 接 、 接 合 、 切 削 機<br />

Fabrication, welding, joining and cutting<br />

7. 車 床<br />

Engine Lathe<br />

8. 牛 頭 鉋 床<br />

Shaper<br />

9. 銑 床<br />

Milling Machine<br />

10. 鑽 床<br />

Drill Press<br />

11. 磨 床 及 磨 輪<br />

Grinding Machine and Grinding wheel<br />

12. 電 動 磨 床<br />

Electric grinder<br />

13. 氣 焊<br />

Gas Welding<br />

14. 電 焊<br />

Electric Welding<br />

15. 彎 管 器<br />

Pipe Bending Machine<br />

1. 教 師 指 導 手 冊<br />

Instructor guidance<br />

2. 廠 商 說 明 書<br />

Manufacturer’s manuals<br />

3. 錄 影 帶<br />

Video cassette player<br />

4. 投 影 片<br />

Overhead projection film<br />

5. 筆 記<br />

Notebook<br />

6. 掛 圖<br />

flipchart<br />

<br />

<br />

學 員 成 功 的 完 成 課 程 與 評 估 後 , 由 主 管 機 關 發 予 適 任 證 書 以 玆 證 明 其 符<br />

合 或 超 越 STCW1995 表 A-III/1 所 規 定 之 輪 機 操 作 級 知 識 與 適 任 標 準<br />

On successful completion of the course and assessments, a document may be<br />

issued certifying that the holder has successfully completed a course of<br />

Doc Ref STCW 2/07-Dts-2

教 師 手 冊 :<br />

Instructor manual:<br />

課 程 內 容<br />

Course Outline<br />

training which meets or exceeds the level of knowledge and competence<br />

specified in Table A-III/1 of STCW 1995, for the Competence Marine<br />

Engineering at the Operational Level. A certificate may be issued only by<br />

centres approved by the Administration.<br />

Guidance on the implementation of IMO model courses<br />

知 識 、 瞭 解 及 熟 練<br />

Knowledge, Understanding And Proficiency<br />

使 用 適 當 的 工 具 進 行 船 ㆖ 典 型 的 裝 配 及 修 理 工 作<br />

USE APPROPRIATE TOOLS FOR FABRICATION AND<br />

REPAIR OPERATIONS TYPICALLY PERFORMED ON<br />

SHIPS<br />

建 造 及 修 理 所 用 材 料<br />

MATERIALS FOR CONSTRUCTION AND REPAIR<br />

.1 特 性 與 應 用<br />

Properties and uses<br />

.2 程 序<br />

Process<br />

裝 配 及 修 理 所 用 程 序<br />

PROCESSES FOR FABRICATION AND REPAIR<br />

.3 基 本 合 金 學 、 金 屬 及 製 造 過 程<br />

Basic metallurgy, metal and processes<br />

.4 非 金 屬 材 料<br />

Non metallic materials<br />

.5 材 料 之 承 載<br />

Materials under load<br />

.6 震 動<br />

Vibration<br />

裝 配 及 修 理<br />

FABRICATION AND REPAIR<br />

.7 永 久 接 合<br />

Permanent joints<br />

.8 鉚 接<br />

Rivetting<br />

.9 硬 焊<br />

Soldering<br />

.10 軟 焊<br />

Self-secured joints<br />

.11 焊 接 時 安 全 與 健 康<br />

Safety and health when welding<br />

.12 電 弧 焊 原 理<br />

Principles of electric arc welding<br />

<br />

估 計 時 數<br />

Approximate time<br />

(Hours)<br />

授 課 、 示 範 與 實 作<br />

Lectures,<br />

demonstrations and<br />

practical work<br />

9<br />

9<br />

6<br />

3<br />

9<br />

3<br />

1<br />

4<br />

18<br />

4<br />

3<br />

3<br />

Doc Ref STCW 2/07-Dts-3

.13 氣 體 焊 接 原 理<br />

Principles of gas welding<br />

.14 低 碳 鋼 焊 接 點<br />

Welded joints in low-carbon steel<br />

.15 焊 接 之 缺 失<br />

Common faults in welded joints<br />

.16 板 作 - 畫 線<br />

Plate-work - marking out<br />

.17 熱 切 割<br />

Thermal cutting<br />

.18 機 械 切 割<br />

Mechanical cutting<br />

.19 成 形<br />

Forming<br />

.20 塑 膠 材 之 彎 曲<br />

Bonding plastics<br />

.21 檢 驗<br />

Inspection<br />

.22 管 工<br />

Pipework<br />

安 全 工 作 程 序<br />

SAFE WORKING PRACTICES<br />

.23 安 全<br />

Safety<br />

參 考 文 獻<br />

Reference<br />

Sub Totals 163<br />

- International Convention on Standards of Training, Certification and<br />

Watchkeeping for Seafarers (STCW), 1995 (IMO Sales No. 938), and<br />

1997 Amendments to STCW 95 (IMO Sales No. 945)<br />

- International Convention for the Safety of Life at Sea (SOLAS), as<br />

amended (IMO Sales No. 110)<br />

- International Convention forthe Prevention of Pollution from Ships,<br />

1973/78 (MARPOL) (IMO Sales No. 520) and 1994/95 MARPOL<br />

Amendments (IMO Sales No. 640)<br />

<br />

<br />

- IMO/ILO Document for Guidance, 1985 (IMO Sales No. 935)<br />

- International Safety Management Code (ISM Code) (IMO-186)<br />

- 1. Flood, C.R. Fabrication, Welding and Metal Joining Processes.<br />

London, Butterworth, 1981 (ISBN 04-08-00448-7) OUT OF<br />

PRINT 1999<br />

- Hall, D.T. Practical Marine Electrical Knowledge. London, Witherby<br />

& Co. Ltd, 1984. (ISBN 09-00-88687-0)<br />

- Hannah-Hillier.J. Applied Mechanics. Harlow,Longmann. 1995.<br />

(ISBN 05-82-25632-1)<br />

- International Labour Office. Accident Prevention on Board Ship at<br />

Sea and in Port, 2nded. Geneva, ILO, 1996 (ISBN 92-21-09450-2)<br />

- Jackson, L and Morton, T.D. General Engineering Knowledge for<br />

Marine Engineers. 5th ed. London, Thomas Reed Publications Ltd<br />

1990. (ISBN 09-47-63776-1)<br />

- Joel, R. Basic Engineering Thermodynamics in S.I. Units, 5th ed.<br />

5<br />

39<br />

1<br />

3<br />

11<br />

3<br />

9<br />

3<br />

6<br />

7<br />

4<br />

Doc Ref STCW 2/07-Dts-4

課 程 綱 要<br />

Syllabus<br />

Harlow, Longmann, 1996 (ISBN 05-82-25629-1)<br />

- Kraal, E.G.R. Basic Electrotechnology for Engineers, 3rd ed.<br />

London, Thomas Reed Publications Ltd, 1985 (ISBN 09-00-33596-3)<br />

- Morton, TD Motor Engineering Knowledge for Marine Engineers.<br />

London. Thomas Reed Publications Ltd, 1994 (ISBN 09-01-2856-5)<br />

- Pritchard.R.T. Technician Workshop Processes and Materials.<br />

London, Hodder and Stoughton, 1979 (ISBN 0-34022-100-3) OUT<br />

OF PRINT 1999<br />

- Simmonds, C.H. and Maguire, D.E. Progressive Engineering<br />

Drawing for T.E.C. Students, London. Hodder and Stoughton Ltd<br />

1983 (ISBN 03-40-26196-x-O) OUT OF PRINT 1999<br />

- Taylor.D.A. Introduction to Marine Engineering, 2nded. London,<br />

Butterworth. 1990 (ISBN 07-50-6253-9)<br />

- Code of Safe Working Practices for Merchant Seamen. London, The<br />

Stationery Office Publications Centre. 1998 (ISBN 0115518363)<br />

- Blakey, T.N. English for Maritime Studies, 2nd ed. Hemel<br />

Hempstead, Prentice Hall International (UK) Ltd, 1987 (ISBN 0<br />

13281379-3)<br />

- 材 料 力 學 - 楊 廉 編 著 大 ㆗ 國 圖 書 公 司 印 行 ㆗ 華 民 國 七 十 ㆒ 年 八<br />

月 再 版<br />

- 材 料 科 學 工 程 - 陳 文 照 、 游 信 和 編 著 高 立 圖 書 有 限 公 司 ㆗ 華 民 國<br />

89 年 7 月 10 日 初 版 ㆓ 刷<br />

高 職 學 校<br />

VACATIONAL HIGH SCHOOL<br />

1. Properties and Uses<br />

- explains in simple terms what influences the choice of material for a<br />

marine engineering component<br />

- describe in simple terms what is meant by the following mechanical<br />

properties:<br />

- elasticity<br />

- brittleness<br />

- hardness<br />

- strength<br />

- toughness<br />

<br />

<br />

- ductility<br />

- malleability<br />

- Plasticity<br />

- explains what is meant by low-, medium- and high-carbon steels<br />

- compares the tensile strength, ductility and hardness of low-, medium- and<br />

high-carbon steels<br />

- states the uses of low-, medium and high-carbon steels<br />

- describes the properties of cast iron and gives examples of its use<br />

- defines an alloy<br />

- states the uses of aluminum, copper, zinc, lead, tin and antimony<br />

- states the component metals of brass, bronze and white metal states the<br />

uses of the above alloys<br />

- explains why the above alloys are suitable for the uses in the above<br />

objective<br />

- identifies samples of metals described in the above objectives<br />

Doc Ref STCW 2/07-Dts-5

2. Basic Metallurgy, Metals and Processes<br />

- describes in simple terms the production of pig iron from iron<br />

- describes the principles of the open-hearth, the Bessemer and more<br />

modern processes used in the production of steel from pig iron<br />

- explains the principal differences between sand casting, die casting,<br />

centrifugal casting, forgings, cold working and hot-rolled plate, bars and<br />

other sections<br />

- states the normal range of carbon content in mild steel, tool steel, cast steel<br />

and cast iron<br />

- describes the principle difference between ferrous and non-ferrous metals<br />

- gives examples of applications of non-ferrous metals in marine<br />

engineering<br />

- states the purpose of the alloying elements nickel, chromium and<br />

molybdenum in steels used in marine engineering<br />

- identifies the metals used in non-ferrous alloys commonly employed in<br />

marine engineering<br />

3. Permanent Joints<br />

- lists the different ways of making permanent joints<br />

工 程 材 料 學<br />

ENGINEERING MATERIAL<br />

1. Process<br />

- describe, in basic terms, the following heat-treatment processes:<br />

- tempering<br />

- annealing<br />

- normalizing<br />

- hardening<br />

- explains, indicates why the processes in the above objective are used<br />

- states how low-carbon steels can be given a hard case<br />

- states why low-carbon steels are sometimes given a hard case<br />

- describes in basic terms a suitable heat-treatment process for common<br />

carbon steels, given the properties required<br />

2. Non-Metallic Materials (3)<br />

- explains the reasons for using the following fillers in polymers:<br />

- glass fibre<br />

- asbestos<br />

- mica<br />

- states that polymers can be plastic, rigid, semi-rigid or elastomeric<br />

- states the properties and limitations of polymers<br />

- lists polymers and other non-metallic materials in common use<br />

- states applications of polymers and other non-metallic materials on board<br />

ship<br />

<br />

<br />

材 料 力 學<br />

MECHANICS OF MATERIAL<br />

1. Materials Under Load<br />

- defines stress as the internal resistance per unit area of a material to an<br />

externally applied load<br />

- defines strain as the deformation produced in a material by an externally<br />

Doc Ref STCW 2/07-Dts-6

applied load<br />

- describes three types of loading as:<br />

- tensile<br />

- compressive<br />

- shear<br />

- illustrates with the aid of simple sketches, a material under each of the<br />

applied loadings given in the above objective, using arrows to indicate<br />

load and stress and dotted lines to indicate deformation<br />

- explains how stress and strain can be calculated in terms of loading and<br />

material dimensions, for the cases in the above objectives<br />

- defines, for an elastic material subjected to a tensile load:<br />

- elastic limit<br />

- yield point<br />

- ultimate strength<br />

- breaking strength<br />

- states that, within the elastic limit, Hooke's law will apply<br />

- defines Hooke's law as:<br />

stress = a constant strain<br />

strain<br />

- defines the constant contained in Hooke's law as the elastic modulus<br />

- applies the above objectives to simple numerical calculations<br />

- shows, on a sketched graph of load to a base of corresponding extension<br />

values, the behaviour of an elastic material under tensile loading and<br />

indicates the condition points listed above<br />

- states the significance in engineering practice of the four physical<br />

properties in the above objectives<br />

動 力 學<br />

DYNAMICS<br />

1. Vibration<br />

- states that vibration is caused by the effect of a single force or a succession<br />

of forces applied suddenly to elastic materials<br />

- states that the forces causing vibration in a ship usually result from an<br />

imbalance in the machinery<br />

- describes the main sources of ship vibration as:<br />

- machinery with reciprocating components (e.g. pistons etc.)<br />

- ship's propeller blades rotating through water of varying pressure and<br />

velocity<br />

- rotating machinery which has not been balanced (e.g. some crankshafts)<br />

- rotating machinery becoming unbalanced through damage, erosion,<br />

corrosion or deposits (e.g. dirt, scale, etc.)<br />

- unbalanced powers in the cylinders of a diesel engine<br />

- worn bearings in rotating machinery<br />

- states that a ship's structure and machinery are constructed largely of<br />

materials which are elastic<br />

- states that vibrations are transmitted from one elastic material or<br />

component to another<br />

- states that anti-vibration materials are sometimes placed between<br />

connecting parts in order to reduce vibration<br />

<br />

<br />

Doc Ref STCW 2/07-Dts-7

- states that if a component is vibrating then a reversing stress is present in<br />

the material<br />

- states that in normal working conditions the stresses due to vibrations are<br />

well within limits allowed for in the design<br />

- states that vibrations in a component may be from different sources, which<br />

can synchronize and magnify the effect- states that if vibrations<br />

become excessive the stresses induced can cause permanent damage<br />

- states that excessive vibration should not be allowed to continue<br />

- states that when varying the rotational speed of machinery, stages may be<br />

encountered where vibrations become excessive<br />

- explains that the condition described in the above objective is normally<br />

due to a synchronization of vibrations which occurs at what is known as<br />

'critical speeds'<br />

- states that excessive vibration within machinery is not always apparent<br />

- states that critical speeds are predictable and should be clearly marked on<br />

controls and known to engineer officers<br />

- states that machinery should not be allowed to operate either at or close to<br />

a critical speed<br />

- states that critical speed ranges should be passed through as quickly as<br />

possible<br />

- tates that in addition to including stress, vibration may cause securing<br />

devices to work loose<br />

- explains how vibration may be reduced<br />

輪 機 拆 裝<br />

MARINE OF AUXILIARY MACHINERY OVERHAUL PRACTICE<br />

1. Safety and Health when Welding<br />

- states the protective clothing to be worn when welding at a bench<br />

- states the additional protection necessary when welding in more difficult<br />

situations<br />

- states the measures necessary to protect other personnel when welding<br />

- states the precautions related specifically to gas welding<br />

- explains the effect of radiation from welding on the eyes and skin<br />

- describes the dangers of fume from welding and how this should be dealt<br />

with<br />

- explains the principles of the precautions to be taken when welding or<br />

when a similar heating process is to be performed in tanks which have<br />

contained combustibles<br />

- states the precautions to be taken when working in confined spaces<br />

- states the care and precautions necessary when handling and storing<br />

compressed gas cylinders, with particular reference to acetylene and<br />

oxygen<br />

<br />

<br />

2. Principles of Electric Arc Welding<br />

- explains the suitability of low, medium-and high-carbon steels for welding<br />

- sketches the relative positions of the electrode and the base metal when<br />

metallic arc welding manually<br />

- states that ac welding is more common than d.c. welding<br />

- sketches the components and circuit necessary in arc welding describes<br />

how welding electrodes are classified describes the purpose of the<br />

Doc Ref STCW 2/07-Dts-8

electrode covering explains how electrodes should be stored explains how<br />

damp electrodes can be detected states how damp electrodes can be dried<br />

- identifies the tools commonly used when welding<br />

- describes the principle of metal arc gas-shielded welding<br />

- describes the principle of tungsten inert-gas welding<br />

3. Principles of Gas Welding<br />

- explains the basic principles of gas welding<br />

- describes the principle features of a low-pressure system<br />

- explains what is meant by a high-pressure system<br />

- lists the fuel-oxygen/air mixtures<br />

- describes the flame produced when using oxygen and acetylene<br />

- explains the effect on the flame of mixing different proportions of oxygen<br />

and acetylene<br />

- describes the dangers of handling acetylene gas and the methods used for<br />

its storage in cylinders<br />

- explains why the maximum discharge rate should not be exceeded<br />

identifies the safety fittings for an acetylene gas cylinder<br />

- compares the need for control of gas pressure for:<br />

- welding<br />

- cutting<br />

- states that a two-stage gas pressure regulator gives a more precise control<br />

than a single-stage regulator<br />

- identifies the safety features of gas pressure gauges<br />

- states that high-pressure blowpipes are unsuitable for use in a low-pressure<br />

system '<br />

- identifies the principle parts of a high-pressure blowpipe<br />

- explains the care necessary for:<br />

- blowpipe<br />

- hoses<br />

- explains the purpose of hose check valves and flashback arresters<br />

- describes the sequence to be followed if a flashback arrester is triggered<br />

- explains the basic purpose of a cylinder manifold system<br />

- names the gas, states its approximate pressure and describes the cylinder<br />

outlet thread, given the colours of cylinders likely to be encountered<br />

<br />

<br />

- sketches the relative positions of the base metal, the filter wire and the<br />

welding nozzle when using:<br />

- the leftward technique<br />

- the rightward technique<br />

- demonstrates the welding procedure for both techniques in the above<br />

objective<br />

- explains the limitations of leftward welding<br />

- explains the advantage of the rightward technique<br />

4. Thermal Cutting<br />

- states the applications of flame and plasma-arc cutting<br />

- explains the principle upon which oxygen is used to cut iron<br />

- describes the conditions necessary in order to cut when using an<br />

oxygen-fuel gas mixture<br />

- identifies the common engineering metals which can and cannot be cut<br />

Doc Ref STCW 2/07-Dts-9

using an oxygen-fuel gas mixture<br />

- lists the gases commonly used as fuels<br />

- identifies the controls on a gas cutting blowpipe and demonstrates their<br />

purpose<br />

- explains the factors which affect the quality of cutting states the basic<br />

principles of plasma-arc cutting<br />

- uses oxygen-fuel gas cutting torch to cut straight lines and curves in mild<br />

steel plate up to 10 mm thick to crop mild steel sections<br />

5. Mechanical Cutting<br />

- describes the principle upon which mechanical cutting is based<br />

- explains the basic difference between:<br />

- hand shears<br />

- guillotine or bench shears<br />

- a shear machine<br />

- a nibbler<br />

- states the maximum thickness of mild steel plate that can normally be cut<br />

by bench shears<br />

- cuts sheet steel by mechanical means<br />

6. Forming<br />

- describes the principles of the basic methods of plate forming, including:<br />

- pyramid rolls<br />

- initial-pinch bending rolls<br />

- press brake<br />

- hand-operated folding machine<br />

- states the maximum thickness of mild steel which can be bent using a<br />

hand-operated machine<br />

- describes the effect of varying the width of the vee when bending plate<br />

relates the width of the vee to the inside radius of the bent plate<br />

- illustrates by means of a sketch what is meant by the development of a<br />

sheet-metal component<br />

- estimates lengths of plate, to include bending allowances lists equipment<br />

required to bend thin steel plate without a bending machine<br />

- explains the dangers encountered in sheet-metal work and the precautions<br />

to be taken<br />

- designs and constructs simple containers from thin plate<br />

<br />

<br />

7. Bonding Plastics<br />

- describes the principle of bending plastics<br />

- states the range of softening temperature for plastics<br />

- explains the care and safeguards necessary when heating plastics<br />

8. Inspection<br />

- constructs a checklist for visual inspection during:<br />

- electric welding<br />

- gas welding<br />

- constructs a list of the points to check visually after welding is completed<br />

- explains the limitations of visual inspection<br />

- carries out the following destructive tests on welded joints:<br />

Doc Ref STCW 2/07-Dts-10

- bend<br />

- macroscopic<br />

- nick-break<br />

- carries out penetrant tests on welded joints<br />

- describes the principle of:<br />

- ultrasonic inspection<br />

- microscopic inspection<br />

- lists common weld defects and their causes<br />

評 量<br />

Evaluation<br />

9. Pipework<br />

- determines minimum bend radius with regard to pipe diameter, thickness,<br />

material and process to be used<br />

- selects pipe filter<br />

- observes safety precautions<br />

- bends pipes, using both cold and hot techniques removes bulk filler and<br />

residue<br />

- checks for ovality, thinning and other defects<br />

- anneals, normalizes or stress-relieves as necessary<br />

Written examination, Practical examination<br />

<br />

<br />

Doc Ref STCW 2/07-Dts-11

適 任 :<br />

Competence:<br />

使 用 手 工 具 及 量 測 設 備 進 行 船 ㆖ 裝 置 及 設 備 之 拆 卸 、 保 養 、 修 理 及 重 新 裝 配<br />

USE HAND TOOLS AND MEASURING EQUIPMENT FOR<br />

DISMANTLING, MAINTENANCE, REPAIR AND RE-ASSEMBLY OF<br />

SHIPBOARD PLANT AND EQUIPMENT<br />

科 目 :<br />

手 工 具 和 電 動 工 具 使 用<br />

Scope: USE OF HAND AND POWER TOOLS<br />

公 約 依 據 : STCW regulation III/1, Code charter III section A-III/1<br />

IMO Ref:<br />

目 標 : 此 課 程 符 合 STCW 95 表 A-III/1 有 關 輪 機 工 程 操 作 級 能 力 之 強 制 要 求 的 知 識 、 瞭<br />

Objective: 解 及 熟 練<br />

This course aims to meet the mandatory minimum requirements for knowledge,<br />

understanding and proficiency in Table A-III/1 of STCW 1995 for the Competence<br />

Marine Engineering at the Operational Level.<br />

此 課 程 提 供 知 識 與 實 作 練 習 在 於 船 ㆖ 使 用 適 當 工 具 來 製 造 和 維 修 操 作 等 典 型 的 工<br />

作 來 達 成 任 務 、 職 責 與 責 任<br />

This course provides the background knowledge and practical work to support the<br />

tasks, duties and responsibilities in: use of appropriate tools for fabrication and repair<br />

operations typically performed on ships.<br />

修 課 標 準 :<br />

Entry standards:<br />

授 課 ㆟ 數 :<br />

Class limitations:<br />

教 師 :<br />

Instructors:<br />

督 導 :<br />

Assessors:<br />

教 學 設 備 及 器 材 :<br />

Teaching facilities<br />

and equipment:<br />

所 有 將 擔 任 輪 機 當 職 管 輪 之 學 員<br />

This course is principally intended for candidates for certification as officers<br />

in charge of an engineering watch.<br />

50 ㆟<br />

教 師 應 足 以 勝 任 教 學 與 指 導 之 工 作 , 並 且 擁 有 適 當 的 教 學 技 巧 與 方 法<br />

(STCW Code Section A-I/6)。 由 於 練 習 課 程 的 複 雜 性 , 可 以 有 ㆒ 擁 有 豐 富<br />

實 作 經 驗 的 助 教 予 以 協 助 。<br />

Instructors shall be qualified in the task for which training is being conducted<br />

and have appropriate training in instructional techniques and training methods<br />

(STCW Code Section A-I/6). Depending on the complexity of the exercises<br />

set, an assistant instructor with similar experience is desirable for certain<br />

practical exercises.<br />

<br />

<br />

交 通 部 船 員 訓 練 委 員 會 (Seafarer Training Committee, Ministry of<br />

Communication and Transportation)<br />

教 育 部 (Ministry of Education)<br />

1. 黑 板 或 掛 圖<br />

Blackboard or flipchart<br />

2. 投 影 機<br />

Overhead projector<br />

3. 手 工 具 與 電 動 工 具<br />

Hand and power tools<br />

4. 工 具 機<br />

Machine tools<br />

5. 製 造 、 焊 接 、 接 合 、 切 削 機<br />

Fabrication, welding, joining and cutting<br />

6. 掛 圖<br />

Doc Ref STCW 2/07-Dts-12

flipchart<br />

教 具 :<br />

1. 教 師 指 導 手 冊<br />

Teaching aids: Instructor guidance<br />

2. 廠 商 說 明 書<br />

Manufacturer’s manuals<br />

3. 錄 影 帶<br />

Video cassette player<br />

4. 投 影 片<br />

Overhead projection film<br />

5. 筆 記<br />

Notebook<br />

證 書 :<br />

學 員 成 功 的 完 成 課 程 與 評 估 後 , 由 主 管 機 關 發 予 適 任 證 書 以 玆 證 明 其 符<br />

Certificate: 合 或 超 越 STCW1995 表 A-III/1 所 規 定 之 輪 機 操 作 級 知 識 與 適 任 標 準<br />

On successful completion of the course and assessments, a document may be<br />

issued certifying that the holder has successfully completed a course of<br />

training which meets or exceeds the level of knowledge and competence<br />

specified in Table A-III/1 of STCW 1995, for the Competence Marine<br />

Engineering at the Operational Level. A certificate may be issued only by<br />

centres approved by the Administration.<br />

教 師 手 冊 : Guidance on the implementation of IMO model courses<br />

Instructor manual:<br />

估 計 時 數<br />

課 程 內 容<br />

Approximate time<br />

Course Outline<br />

(Hours)<br />

授 課 、 示 範 與 實 作<br />

知 識 、 瞭 解 及 熟 練<br />

Lectures,<br />

Knowledge, Understanding And Proficiency<br />

demonstrations and<br />

practical work<br />

使 用 手 工 具 及 量 測 設 備 進 行 船 ㆖ 裝 置 及 設 備 之 拆 卸 、 保 養 、 修 理<br />

及 重 新 裝 配<br />

USE HAND TOOLS AND MEASURING EQUIPMENT FOR<br />

DISMANTLING, MAINTENANCE, REPAIR AND<br />

RE-ASSEMBLY OF SHIPBOARD PLANT AND EQUIPMENT<br />

<br />

<br />

手 工 具 和 電 動 工 具 使 用<br />

USE OF HAND AND POWER TOOLS<br />

.1 落 樣<br />

Marking out<br />

.2 手 工 具<br />

Hand tools<br />

.3 動 力 工 具<br />

Powered hand tools<br />

.4 量 測<br />

Measurement<br />

.5 鑽 床<br />

Drilling machines<br />

.6 碳 鋼 的 熱 處 理<br />

Heat treatment of carbon steel<br />

10<br />

36<br />

9<br />

13<br />

24<br />

14<br />

Doc Ref STCW 2/07-Dts-13

.7 黏 合 劑 及 黏 合<br />

Adhesives and bonding<br />

參 考 文 獻<br />

Reference<br />

課 程 綱 要<br />

Syllabus<br />

Sub Totals 121<br />

- International Convention on Standards of Training, Certification and<br />

Watchkeeping for Seafarers (STCW), 1995 (IMO Sales No. 938),<br />

and 1997 Amendments to STCW 95 (IMO Sales No. 945)<br />

- International Convention for the Safety of Life at Sea (SOLAS), as<br />

amended (IMO Sales No. 110)<br />

- International Convention forthe Prevention of Pollution from Ships,<br />

1973/78 (MARPOL) (IMO Sales No. 520) and 1994/95 MARPOL<br />

Amendments (IMO Sales No. 640)<br />

- IMO/ILO Document for Guidance, 1985 (IMO Sales No. 935)<br />

- International Safety Management Code (ISM Code) (IMO-186)<br />

- Flood, C.R. Fabrication, Welding and Metal Joining Processes.<br />

London, Butterworth, 1981 (ISBN 04-08-00448-7) OUT OF<br />

PRINT 1999<br />

- Hall, D.T. Practical Marine Electrical Knowledge. London, Witherby<br />

& Co. Ltd, 1984. (ISBN 09-00-88687-0)<br />

- Hannah-Hillier.J. Applied Mechanics. Harlow,Longmann. 1995.<br />

(ISBN 05-82-25632-1)<br />

- International Labour Office. Accident Prevention on Board Ship at<br />

Sea and in Port, 2nded. Geneva, ILO, 1996 (ISBN 92-21-09450-2)<br />

- Jackson, L and Morton, T.D. General Engineering Knowledge for<br />

Marine Engineers. 5th ed. London, Thomas Reed Publications Ltd<br />

1990. (ISBN 09-47-63776-1)<br />

- Joel, R. Basic Engineering Thermodynamics in S.I. Units, 5th ed.<br />

Harlow, Longmann, 1996 (ISBN 05-82-25629-1)<br />

- Kraal, E.G.R. Basic Electrotechnology for Engineers, 3rd ed.<br />

London, Thomas Reed Publications Ltd, 1985 (ISBN<br />

09-00-33596-3)<br />

- Morton, TD Motor Engineering Knowledge for Marine Engineers.<br />

London. Thomas Reed Publications Ltd, 1994 (ISBN 09-01-2856-5)<br />

- Pritchard.R.T. Technician Workshop Processes and Materials.<br />

London, Hodder and Stoughton, 1979 (ISBN 0-34022-100-3) OUT<br />

OF PRINT 1999<br />

<br />

<br />

- Simmonds, C.H. and Maguire, D.E. Progressive Engineering<br />

Drawing for T.E.C. Students, London. Hodder and Stoughton Ltd<br />

1983 (ISBN 03-40-26196-x-O) OUT OF PRINT 1999<br />

- Taylor.D.A. Introduction to Marine Engineering, 2nded. London,<br />

Butterworth. 1990 (ISBN 07-50-6253-9)<br />

- Code of Safe Working Practices for Merchant Seamen. London, The<br />

Stationery Office Publications Centre. 1998 (ISBN 0115518363)<br />

- Blakey, T.N. English for Maritime Studies, 2nd ed. Hemel<br />

Hempstead, Prentice Hall International (UK) Ltd, 1987 (ISBN 0<br />

13281379-3)<br />

- 機 工 學 - 張 甘 棠 著 ㆔ 文 出 版 社 87 年 版<br />

高 職 學 校<br />

VACATIONAL HIGH SCHOOL<br />

1. Marking Out<br />

- demonstrates the care of:<br />

Doc Ref STCW 2/07-Dts-14<br />

10

- a surface plate<br />

- vee blocks<br />

- demonstrates the care of:<br />

- scribers<br />

- dividers<br />

- odd-leg calipers<br />

- explains the uses of 60° and 90° centre punches<br />

- states when a scriber should not be used for marking out<br />

- uses the tools included in the above objectives to mark out simple<br />

exercises, working from:<br />

- datum faces<br />

- datum lines<br />

2. Hand Tools<br />

- explains the use of a hacksaw<br />

- types of hacksaw blade available and describes their application<br />

- explains the general relationship between tooth pitch of a hacksaw blade<br />

and the hardness and thickness of the material to be cut<br />

- selects the correct hacksaw blade for a given job and fits it into a saw<br />

frame with the correct tension<br />

- demonstrates, using a hacksaw, the correct technique, to cut common<br />

materials, including thin-walled pipe<br />

- explains the use of files<br />

- names the correct file section to be used for given situations<br />

- identifies the following files, explaining their use:<br />

- double-cut - rough, second-cut and smooth<br />

- single-cut - smooth and second-cut<br />

- demonstrates the care of, and safety precautions necessary when using,<br />

files<br />

- uses rough and finishing files correctly on given exercises<br />

- describes the uses of flat and half-round scrapers<br />

- demonstrates how scrapers are sharpened and cared for<br />

- uses scrapers correctly on given exercises<br />

- explains the use of chisels<br />

<br />

<br />

- describes the use of the following cold chisels:<br />

- flat<br />

- cross-cut<br />

- diamond-cut<br />

- round-nose<br />

- describes the safety measures necessary when using a chisel<br />

- uses and sharpens the chisels listed in the above objective in a<br />

correct and safe manner<br />

Thread Cutting<br />

- explains the purpose of taper, second and plug taps<br />

- explains what governs the diameter of the hole to be drilled prior to<br />

tapping explains the difference in use of a die nut and a stock and die<br />

- describes the different techniques used when cutting:<br />

- small-diameter threads<br />

- large-diameter and fine threads<br />

Doc Ref STCW 2/07-Dts-15

- cuts internal threads in open-ended and blind holes and external threads on<br />

small- and large-diameter rod<br />

3. Powered Hand Tools<br />

- names the types of power used in hand tools<br />

- identifies the processes for which powered hand tools might be used<br />

- states the practical maximum and minimum capacities of an electrically<br />

powered hand drill<br />

- explains the care necessary for the supply cables of powered hand tools<br />

uses powered hand tools safely and correctly and care required<br />

- explains the principle of operation of a standard dial test indicator<br />

plunger-type comparator<br />

- uses a standard dial test indicator to compare dimensions<br />

4. Drilling Machines<br />

- lists the uses of a drilling machine<br />

- states engineering terms used to describe geometrical surfaces and<br />

vice-versa<br />

- explains briefly how drills are held in a machine<br />

- explains how a workpiece is held in place, emphasizing dangerous<br />

practice and the particular problem when drilling thin plate<br />

- names the types of drilling machine used in engineering workshops<br />

- relates the approximate limits on drill diameters and the uses of each of<br />

the machines listed in the above objective<br />

- states that accurate drilling is very difficult to achieve<br />

- states the general relationships between drill diameter and rotational speed<br />

- explains how feed rates are determined<br />

- explains how the height of the work-table is determined<br />

- lists the operations which can be carried out by using a pillar drilling<br />

machine<br />

- explains how feed is provided to the drill on a pillar machine<br />

- relates spindle speeds to those of a sensitive machine<br />

- describes the care necessary to avoid accidents when using automatic feed<br />

- describes the procedure for inserting and removing drills with parallel and<br />

<br />

<br />

with tapered shanks<br />

- lists the steps taken to:<br />

- set up work<br />

- drill<br />

- conuterbore, ream or countersink<br />

- explains in simple terms the differences between the work-tables used on<br />

pillar machines<br />

- explains briefly why radial drilling machines are used<br />

- describes the care necessary when using automatic feed<br />

Drills<br />

- sketches the cutting face of a twist drill, showing:<br />

- the land<br />

- rake angle<br />

- clearance angle<br />

- explains the care necessary when using twist drills, referring to angles and<br />

Doc Ref STCW 2/07-Dts-16

length of cutting edge<br />

- explains the effect of incorrect sharpening of a twist drill<br />

- explains the principal uses of the following drills and tools:<br />

- parallel-shank jobber series<br />

- stub<br />

- parallel-shank long series<br />

- Morse-taper-shank series<br />

- two-, three- and four-fluted drills<br />

- reamers - hand and machine<br />

- counter sinker<br />

- spotfacer<br />

- states the normal allowance on hole diameter for reaming<br />

- explains how speeds and feeds are affected when:<br />

- reaming<br />

- countersinking<br />

- explains the care necessary when drilling plastics<br />

- uses drilling machines to carry out all of the processes included in the<br />

above objectives correctly<br />

- sharpens twist drills safely and correctly<br />

輪 機 拆 裝<br />

MARINE OF AUXILIARY MACHINERY OVERHAUL PRACTICE<br />

1. Measurement<br />

- explains why dimensional control Is necessary<br />

- states the difference between functional and non-functional dimensions<br />

and the relative tolerances given to each<br />

- demonstrates the use of a common datum when using a steel tube<br />

- states the accuracy obtainable using a steel rule<br />

- uses inside and outside callipers to measure diameters<br />

- uses a try-square to check 90° angles<br />

- checks a try-square for accuracy against a master square<br />

- uses a bevel gauge and a plain protractor to check and to mark out angles<br />

- uses small-scale vernier callipers to measure internal and external<br />

dimensions to an accuracy of 0.02 mm<br />

- explains the principles of the vernier protractor<br />

- explains the purpose of the ratchet fitted to a mechanical micrometer<br />

- states the accuracy of micrometer measurements<br />

- checks and adjusts the zero reading of a micrometer<br />

- lists measuring instruments which use the micrometer principle<br />

- demonstrates the care of micrometer instruments<br />

- uses micrometers correctly and accurately<br />

- states that the vernier principle can be applied to micrometers to give<br />

greater accuracy<br />

- explains briefly why and how dimensions of components are checked by<br />

comparison<br />

- explains the principle of operation of a standard dial test indicator<br />

plunger-type comparator<br />

- uses a standard dial test indicator to compare dimensions<br />

<br />

<br />

2. Drilling Machines<br />

Doc Ref STCW 2/07-Dts-17

- lists the uses of a drilling machine<br />

- states engineering terms used to describe geometrical surfaces and<br />

vice-versa<br />

- explains briefly how drills are held in a machine<br />

- explains how a workpiece is held in place, emphasizing dangerous<br />

practice and the particular problem when drilling thin plate<br />

- names the types of drilling machine used in engineering workshops<br />

- relates the approximate limits on drill diameters and the uses of each of<br />

the machines listed in the above objective<br />

- states that accurate drilling is very difficult to achieve<br />

- states the general relationships between drill diameter and rotational speed<br />

- explains how feed rates are determined<br />

- explains how the height of the work-table is determined<br />

- lists the operations which can be carried out by using a pillar drilling<br />

machine<br />

- explains how feed is provided to the drill on a pillar machine<br />

- relates spindle speeds to those of a sensitive machine<br />

- describes the care necessary to avoid accidents when using automatic feed<br />

- describes the procedure for inserting and removing drills with parallel and<br />

with tapered shanks<br />

- lists the steps taken to:<br />

- set up work<br />

-drill<br />

- conuterbore, ream or countersink<br />

- explains in simple terms the differences between the work-tables used on<br />

pillar machines<br />

- explains briefly why radial drilling machines are used<br />

- describes the care necessary when using automatic feed<br />

Drills<br />

- sketches the cutting face of a twist drill, showing:<br />

- the land<br />

- rake angle<br />

- clearance angle<br />

- explains the care necessary when using twist drills, referring to angles and<br />

<br />

<br />

length of cutting edge<br />

- explains the effect of incorrect sharpening of a twist drill<br />

- explains the principal uses of the following drills and tools:<br />

- parallel-shank jobber series<br />

- stub<br />

- parallel-shank long series<br />

- Morse-taper-shank series<br />

- two-, three- and four-fluted drills<br />

- reamers - hand and machine<br />

- counter sinker<br />

- spotfacer<br />

- states the normal allowance on hole diameter for reaming<br />

- explains how speeds and feeds are affected when:<br />

- reaming<br />

- countersinking<br />

- explains the care necessary when drilling plastics<br />

Doc Ref STCW 2/07-Dts-18

- uses drilling machines to carry out all of the processes included in the<br />

above objectives correctly<br />

- sharpens twist drills safely and correctly<br />

3. Heat Treatment of Carbon Steel<br />

- explains the purpose of heat treatment<br />

- lists four basic heat treatments<br />

- explains the purpose of the four basic heat treatments<br />

- describes the following processes and the types of steel to which they<br />

might be applied:<br />

- annealing<br />

- normalizing<br />

- hardening<br />

- tempering<br />

- completes items of deleted information in a table which gives the<br />

following details for the tempering of high-carbon steel:<br />

- temperatures (230 to 320°C)<br />

- colour<br />

- application conditions<br />

- typical tool applications<br />

- explains how a component is tempered throughoyUtswhole section carries<br />

out the heat treatments listed in the above objective<br />

- tests a hardened and tempered cutting edge, taking the necessary safety<br />

precautions<br />

4. Adhesives and Bonding<br />

Health and safety<br />

- explains the care necessary when using adhesives, to include:<br />

- skin protection<br />

- storage<br />

- fire<br />

- toxicity<br />

- states the advantages and disadvantage of adhesive bonding<br />

- describes the basic principles of joining by using an adhesive<br />

- sketches the four joint configurations<br />

- describes the principles of testing for shear strength and peel strength of<br />

adhesives<br />

- compares the strength of the parent material to that of a well-made joint<br />

- explains the principles of bonding friction linings to steel-shoes or discs<br />

- explains the principles of bonding smooth surfaces and states applications<br />

- identifies a cemented joint<br />

- states the source of early adhesives<br />

- states the purpose of an activator when using an epoxy resin<br />

- states the significance of pot file<br />

- explains the limitations on the service conditions of epoxy resins<br />

- states that special epoxy resins are made to meet particular service<br />

conditions<br />

- lists the steps necessary when bonding together:<br />

- two metal components<br />

- friction material to steel<br />

<br />

<br />

Doc Ref STCW 2/07-Dts-19

評 量<br />

Evaluation<br />

- describes briefly metal-to-metal bonding and applications using:<br />

- liquid or paste<br />

- beads or dry film<br />

Joining Plastics<br />

- states the three methods of joining plastics<br />

- states the need to use the correct adhesive for the plastic to be joined<br />

- describes the principle of solvent welding<br />

- describes the principle of welding plastics<br />

- selects and uses the correct adhesive for a variety of applications for a<br />

variety and strength tests included in the above objectives<br />

Written examination, Practical examination<br />

<br />

Doc Ref STCW 2/07-Dts-20

適 任 :<br />

Competence:<br />

科 目 :<br />

Scope:<br />

㆟ 員 :<br />

For:<br />

使 用 手 工 具 及 量 測 設 備 進 行 船 ㆖ 裝 置 及 設 備 之 拆 卸 、 保 養 、 修 理 及 重 新 裝 配<br />

USE HAND TOOLS AND MEASURING EQUIPMENT FOR<br />

DISMANTLING, MAINTENANCE, REPAIR AND RE-ASSEMBLY OF<br />

SHIPBOARD PLANT AND EQUIPMENT<br />

輪 機 製 圖<br />

MARINE ENGINEERING DRAWING AND DESIGN<br />

主 機 推 進 動 力 3,000 瓩 以 ㆖ 船 舶 之 ㆒ 等 管 輪 證 書 之 學 習 課 程 內 容 及 期 間<br />

The contents and duration of study courses of engineer officers in charge of an<br />

engineering watch on ships powered by main propulsion machinery of 3,000<br />

kw propulsion power or more<br />

公 約 依 據 :<br />

IMO Ref:<br />

目 標 :<br />

Objective:<br />

修 課 標 準 :<br />

Entry standards:<br />

授 課 ㆟ 數 :<br />

Class limitations:<br />

教 師 :<br />

Instructors:<br />

督 導 :<br />

Assessors:<br />

教 學 設 備 及 器 材 :<br />

Teaching facilities<br />

and equipment:<br />

教 具 :<br />

STCW regulation III/1, Code charter III section A-III/1<br />

此 課 程 符 合 STCW 95 表 A-III/1 有 關 輪 機 工 程 操 作 級 能 力 之 強 制 要 求 的 知 識 、<br />

瞭 解 及 熟 練<br />

This course aims to meet the mandatory minimum requirements for knowledge,<br />

understanding and proficiency in Table A-III/1 of STCW 1995 for the Competence<br />

Marine Engineering at the Operational Level.<br />

此 課 程 提 供 知 識 與 實 作 練 習 在 於 船 ㆖ 使 用 適 當 工 具 來 製 造 和 維 修 操 作 等 典 型<br />

的 工 作 來 達 成 任 務 、 職 責 與 責 任<br />

This course provides the background knowledge and practical work to support the<br />

tasks, duties and responsibilities in: use of appropriate tools for fabrication and<br />

repair operations typically performed on ships.<br />

所 有 將 擔 任 輪 機 當 職 管 輪 之 學 員<br />

This course is principally intended for candidates for certification as<br />

officers in charge of an engineering watch.<br />

50 ㆟<br />

教 師 應 足 以 勝 任 教 學 與 指 導 之 工 作 , 並 且 擁 有 適 當 的 教 學 技 巧 與 方 法<br />

(STCW Code Section A-I/6)。 由 於 練 習 課 程 的 複 雜 性 , 可 以 有 ㆒ 擁 有 豐 富<br />

實 作 經 驗 的 助 教 予 以 協 助 。<br />

<br />

<br />

Instructors shall be qualified in the task for which training is being conducted<br />

and have appropriate training in instructional techniques and training methods<br />

(STCW Code Section A-I/6). Depending on the complexity of the exercises<br />

set, an assistant instructor with similar experience is desirable for certain<br />

practical exercises.<br />

交 通 部 船 員 訓 練 委 員 會 (Seafarer Training Committee, Ministry of<br />

Communication and Transportation)<br />

教 育 部 (Ministry of Education)<br />

1. 黑 板 或 掛 圖<br />

Blackboard or flipchart<br />

2. 課 桌<br />

Desks<br />

3. 投 影 機<br />

Overhead projector<br />

1. 教 師 指 導 手 冊<br />

Doc Ref STCW 2/07-Dts-21

Teaching aids:<br />

證 書 :<br />

Certificate:<br />

Instructor guidance<br />

2. 廠 商 說 明 書<br />

Manufacturer’s manuals<br />

3. 投 影 片<br />

Overhead projection film<br />

4. 筆 記<br />

Notebook<br />

學 員 成 功 的 完 成 課 程 與 評 估 後 , 由 主 管 機 關 發 予 適 任 證 書 以 玆 證 明 其 符<br />

合 或 超 越 STCW1995 表 A-III/1 所 規 定 之 輪 機 操 作 級 知 識 與 適 任 標 準<br />

On successful completion of the course and assessments, a document may be<br />

issued certifying that the holder has successfully completed a course of<br />

training which meets or exceeds the level of knowledge and competence<br />

specified in Table A-III/1 of STCW 1995, for the Competence Marine<br />

Engineering at the Operational Level. A certificate may be issued only by<br />

centres approved by the Administration.<br />

教 師 手 冊 : Guidance on the implementation of IMO model courses<br />

Instructor manual:<br />

課 程 內 容<br />

Course Outline<br />

知 識 、 瞭 解 及 熟 練<br />

Knowledge, Understanding And Proficiency<br />

<br />

<br />

估 計 時 數<br />

Approximate time<br />

(Hours)<br />

授 課 、 示 範 與 實 作<br />

Lectures,<br />

demonstrations and<br />

practical work<br />

使 用 手 工 具 及 量 測 設 備 進 行 船 ㆖ 裝 置 及 設 備 之 拆 卸 、 保 養 、 修 理<br />

及 重 新 裝 配<br />

USE HAND TOOLS AND MEASURING EQUIPMENT FOR<br />

DISMANTLING, MAINTENANCE, REPAIR AND<br />

RE-ASSEMBLY OF SHIPBOARD PLANT AND EQUIPMENT<br />

輪 機 製 圖<br />

MARINE ENGINEERING DRAWING AND DESIGN<br />

.1 製 圖 形 式<br />

8<br />

Types of drawing<br />

.2 線 條 及 字 法<br />

6<br />

Linework<br />

.3 規 劃 圖<br />

9<br />

Pictorial projection<br />

.4 展 開 圖<br />

6<br />

Development<br />

.5 螺 紋 與 結 件<br />

2<br />

Screw threads and fasteners<br />

.6 鎖 緊 與 固 定 裝 置<br />

3<br />

Locking and retaining devices<br />

.7 鉚 釘 型 式 與 結 件<br />

1<br />

Rivetted type fastening<br />

.8 焊 接 3<br />

Doc Ref STCW 2/07-Dts-22

Welded connections<br />

.9 尺 寸<br />

Dimensioning<br />

.10 公 差 與 配 合<br />

Limits and fits<br />

.11 幾 何 誤 差<br />

Geometrical tolerancing<br />

.12 凸 輪<br />

Cams<br />

.13 軸 承<br />

Bearings<br />

.14 軸 封<br />

Seals<br />

.15 滾 軸 承 之 潤 滑<br />

Lubrication of ball and roller bearings<br />

.16 繪 圖 練 習<br />

Engineering drawing practice<br />

參 考 文 獻<br />

Reference<br />

Sub Totals 238<br />

- International Convention on Standards of Training, Certification and<br />

Watchkeeping for Seafarers (STCW), 1995 (IMO Sales No. 938), and<br />

1997 Amendments to STCW 95 (IMO Sales No. 945)<br />

- International Convention for the Safety of Life at Sea (SOLAS), as<br />

amended (IMO Sales No. 110)<br />

- International Convention forthe Prevention of Pollution from Ships,<br />

1973/78 (MARPOL) (IMO Sales No. 520) and 1994/95 MARPOL<br />

Amendments (IMO Sales No. 640)<br />

- IMO/ILO Document for Guidance, 1985 (IMO Sales No. 935)<br />

- International Safety Management Code (ISM Code) (IMO-186)<br />

- Flood, C.R. Fabrication, Welding and Metal Joining Processes.<br />

London, Butterworth, 1981 (ISBN 04-08-00448-7) OUT OF<br />

PRINT 1999<br />

- Hall, D.T. Practical Marine Electrical Knowledge. London, Witherby<br />

& Co. Ltd, 1984. (ISBN 09-00-88687-0)<br />

- Hannah-Hillier.J. Applied Mechanics. Harlow,Longmann. 1995.<br />

<br />

<br />

(ISBN 05-82-25632-1)<br />

- International Labour Office. Accident Prevention on Board Ship at<br />

Sea and in Port, 2nded. Geneva, ILO, 1996 (ISBN 92-21-09450-2)<br />

- Jackson, L and Morton, T.D. General Engineering Knowledge for<br />

Marine Engineers. 5th ed. London, Thomas Reed Publications Ltd<br />

1990. (ISBN 09-47-63776-1)<br />

- Joel, R. Basic Engineering Thermodynamics in S.I. Units, 5th ed.<br />

Harlow, Longmann, 1996 (ISBN 05-82-25629-1)<br />

- Kraal, E.G.R. Basic Electrotechnology for Engineers, 3rd ed.<br />

London, Thomas Reed Publications Ltd, 1985 (ISBN 09-00-33596-3)<br />

- Morton, TD Motor Engineering Knowledge for Marine Engineers.<br />

London. Thomas Reed Publications Ltd, 1994 (ISBN 09-01-2856-5)<br />

- Pritchard.R.T. Technician Workshop Processes and Materials.<br />

London, Hodder and Stoughton, 1979 (ISBN 0-34022-100-3) OUT<br />

OF PRINT 1999<br />

Doc Ref STCW 2/07-Dts-23<br />

3<br />

2<br />

2<br />

6<br />

3<br />

1<br />

63<br />

120

課 程 綱 要<br />

Syllabus<br />

- Simmonds, C.H. and Maguire, D.E. Progressive Engineering<br />

Drawing for T.E.C. Students, London. Hodder and Stoughton Ltd<br />

1983 (ISBN 03-40-26196-x-O) OUT OF PRINT 1999<br />

- Taylor.D.A. Introduction to Marine Engineering, 2nded. London,<br />

Butterworth. 1990 (ISBN 07-50-6253-9)<br />

- Code of Safe Working Practices for Merchant Seamen. London, The<br />

Stationery Office Publications Centre. 1998 (ISBN 0115518363)<br />

- Blakey, T.N. English for Maritime Studies, 2nd ed. Hemel<br />

Hempstead, Prentice Hall International (UK) Ltd, 1987 (ISBN 0<br />

13281379-3)<br />

- 機 械 製 圖 (㆖、㆘ 冊 )_ 康 鳳 梅 著 作 ,㆔ 民 書 局 出 版<br />

- 機 械 設 計 , 正 文 書 局 編 譯 委 員 會 譯 編 , 正 文 書 局 ,㆗ 華 民 國 七 十<br />

㆒ 年 九 月 ㆒ 日 出 版<br />

- 機 械 設 計 , 譯 述 者 , 黃 俊 雯 , 科 技 圖 書 股 份 有 限 公 司 ,㆗ 華 民 國<br />

八 十 ㆒ 年 ㆒ 月 ㆓ 版<br />

高 職 學 校<br />

VACATIONAL HIGH SCHOOL<br />

1. Types of Drawing<br />

- explains briefly the method of microfilming to store drawings<br />

- explains the purpose of a general arrangement<br />

- explains the purpose of assembly drawings<br />

- explains the purpose of component drawings<br />

- explains the use of collective single-part drawings<br />

- explains the use of pictorial drawings<br />

- states that there are several standard sizes of drawing paper<br />

- lists the standard/routine information and references commonly given on<br />

drawings<br />

2. Linework<br />

- relates examples of lines to applications and vice-versa<br />

- draws tangents as required in practice<br />

- demonstrates what is meant by:<br />

- first-angle projection<br />

- third-angle projection<br />

and sketches the correct symbol for both cases<br />

- using given examples, completes first- and third-angle projections with:<br />

- missing lines<br />

- missing views<br />

- simple plotted curves<br />

- re-draws given simple components and provides sufficient dimensions for<br />

their manufacture<br />

- completes orthographic projections of solids<br />

- completes sectional views in orthographic projection<br />

- draws a third-angle projection with hidden detail<br />

- explains the use of auxiliary projection<br />

<br />

<br />

3. Pictorial Projection<br />

- draws isometric projections of simple solids<br />

- draws oblique projections of simple solids<br />

Doc Ref STCW 2/07-Dts-24

4. Development<br />

- draws the development of a 90° intersection of circular trunking<br />

- draws the development of a cone<br />

- draws the development of a square pyramid<br />

- draws the development of a square-to-round transition piece<br />

5. Screw Threads and Fasteners<br />

- identifies left- and right-hand screw threads<br />

- describes, with the aid of a sketch, the following terminology related to<br />

screw threads:<br />

- pitch<br />

- outside diameter<br />

- root diameter<br />

- crest<br />

- root<br />

- flank<br />

- lead<br />

- lists the names of the threads which are common on nuts and bolts<br />

- names the threads which are common on pipes<br />

- names the threads used for power transmission and gives simple<br />

applications<br />

- identifies the thread commonly used on valves spindles<br />

- draws threads, using a standard convention (including sections), for the<br />

following applications:<br />

- male thread cut by dies, with undercut and when rolled<br />

- female thread through a collar<br />

- female thread in a blind hole, both plain and when undercut<br />

- explains what is meant by a multiple thread and its use<br />

- draws a hexagonal nut, using an approximate construction<br />

- draws a nut, stud and washer assembly in a tapped hole<br />

- identifies the difference between a tapping drill and a clearance drill<br />

- identifies a range of sockets-head screws, to include:<br />

- cap screws<br />

- countersunk head<br />

<br />

<br />

- button head<br />

- shoulder screws<br />

- set screws<br />

- identifies a range of machine screws, to include cross and slotted head:<br />

- countersunk<br />

- raised countersunk<br />

- cheese<br />

- pan<br />

6. Locking and Retaining Devices<br />

- sketches a locking plate<br />

- sketches a Simmonds lock-nut<br />

- identifies and describes the use of:<br />

- lock washers<br />

- spring washers<br />

Doc Ref STCW 2/07-Dts-25

- tab washers<br />

- describes locking by:<br />

- adhesives, giving applications<br />

- peening<br />

- wire<br />

- identifies and knows the use of:<br />

- taper pins<br />

- bifurcated taper pins<br />

- parallel pins<br />

- split pins<br />

- identifies and knows the use of locking rings, to include internal and<br />

external:<br />

- wire rings<br />

- air clips<br />

- draws/sketches the cross section of the grove for each of the above rings<br />

7. Rivetted-type Fastening<br />

- identifies the following rivet heads:<br />

- snap<br />

- flat<br />

- universal<br />

- countersunk<br />

- raised countersunk<br />

- identifies the material of rivets to that of the material to be joined<br />

- sketches the following rivetted joints:<br />

- single lap<br />

- double lap<br />

- single-strap butt<br />

- double-strap butt<br />

- describes briefly the fitting and uses of blind rivet nuts and blind screw<br />

anchors<br />

- describes briefly the fitting and removal of "Hucbolf fasteners<br />

8. Welded Connections<br />

- given symbols for various welded connections, describes, with the aid of<br />

sketches, the specified connection<br />

<br />

<br />

9. Dimensioning<br />

- dimensions a simple component, applying all correct standards<br />

- explains the advantage of datum dimensioning<br />

10. Limits and Fits<br />

- explains the need for limits and fits<br />

- given various ways of indicating limits of size, explains their meaning<br />

- explains the meaning of:<br />

- tolerance<br />

- actual size<br />

- basic size<br />

- nominal size<br />

- explains hole basis fits<br />

Doc Ref STCW 2/07-Dts-26

- explains shaft basis fit<br />

- explains, using examples:<br />

- clearance fits<br />

- transition fits<br />

- interference fits<br />

- describes, using examples, the cumulative effect of tolerances<br />

- explains what is meant by selective assembly<br />

- lists the factors which influence the selection of tolerances<br />

11. Geometrical Tolerancing<br />

- explains briefly what is meant by geometrical tolerancing<br />

- relates symbols for geometrical tolerancing to the intended characteristics<br />

- using given reference material, applies tolerancing data to engineering<br />

drawings, to include examples of:<br />

- straightness<br />

- flatness<br />

- roundness<br />

- cylindricity<br />

- concentricity<br />

- squareness<br />

- parallelism<br />

- angularity<br />

- position<br />

12. Cams<br />

- constructs cam profiles to give uniform velocities and a dwell period to<br />

the cam follower<br />

13. Seals<br />

- explains the purpose of a bearing seal<br />

- lists the factors which influence the choice of seal<br />

- describes the general application of non-rubbing seals and sketches a<br />

non-rubbing seal<br />

- explains the principle of rubbing seals<br />

- sketches a simple felt seal, and identifies its applications and limitations<br />

- identifies the principle feature of lip seals suitable for peripheral speeds<br />

between 4 m/s and 8 m/s and when more than 8 m/s<br />

- identifies the principle of a V-ring seal and its applications<br />

<br />

<br />

14. Lubrication of Ball and Roller Bearings<br />

- describes how ball and roller bearings are lubricated<br />

- states the proportion of available volume to be filled when using grease<br />

- states the maximum height of lubricant in a stationary bearing when using<br />

oil<br />

15. Engineering Drawing Practice<br />

- makes engineering drawings employing the following:<br />

- sections in two parallel planes<br />

- revolved sections<br />

- thin sections<br />

Doc Ref STCW 2/07-Dts-27

- part sections<br />

- half sections<br />

- hidden detail<br />

- machinery symbols<br />

- surface finish<br />

- angular dimensions<br />

- arrow heads<br />

- auxiliary dimensions<br />

- centre lines<br />

- pitch-circle diameters<br />

- threads<br />

- thick chain-lines<br />

- enlarged views<br />

- hatching<br />

- leader lines<br />

- using reference material, applies abbreviations to drawings<br />

- applies conventional representation of the following features<br />

- external and internal threads<br />

- squares on shafts<br />

- serrated and splined shafts<br />

- holes on a linear and on a circular pitch<br />

- bearings<br />

- interrupted views<br />

- tension and compression springs<br />

- uses applications as appropriate from subject areas 2.1 to 2.14 above<br />

機 械 設 計<br />

MACHINE DESIGN<br />

1. Bearings<br />

Plain Bearings<br />

- explains the limitations of direct-lined bearings<br />

- describes solid and lined inserts<br />

- describes briefly:<br />

- thick-walled<br />

- medium-walled liners<br />

- thin-walled liners<br />

- wrapped bushes<br />

- lists the ideal properties of a lubrication oil for plain bearings<br />

- describes the reasons for using white metal, copper-lead alloys, lead<br />

bronzes, tin bronzes, gun metals and aluminium-based alloys for plain<br />

bearings<br />

- lists the types of bearing normally selected for small and large diameter<br />

shafts<br />

Ball and Roller Bearings<br />

- compares the load-carrying abilities of ball and roller bearings<br />

- compares the ability of ball and roller bearings to carry radial and axial<br />

loads<br />

- states the type of bearing suitable for shafts subject to angular<br />

misalignment<br />

<br />

<br />

Doc Ref STCW 2/07-Dts-28

評 量<br />

Evaluation<br />

- sketches the types of bearing suitable for the following applications:<br />

- light and medium radial loads<br />

- heavy radial loads<br />

- radial loads in restricted radial space<br />

- axial loads<br />

- combined loads<br />

- angular misalignment<br />

- rigidity<br />

- ease of mounting<br />

- indicates the range of deep-groove ball bearings and their characteristics<br />

- explains the basic principles of the application of bearings to rotating<br />

machinery<br />

- describe how bearings are located on shafts and in housings, referring to<br />

the need for interference fits<br />

- explains how rising temperature affects the fit of bearings<br />

- describes the effect of movement of a bearing ring on the fitted surface<br />

- describes the applications where clearance fits are suitable<br />

- explains why tapered-bore bearings are sometimes used<br />

- describes how bearings are located<br />

Written examination, Practical examination<br />

<br />

<br />

Doc Ref STCW 2/07-Dts-29

適 任 :<br />

Competence:<br />

科 目 :<br />

Scope:<br />

㆟ 員 :<br />

For:<br />

公 約 依 據 :<br />

IMO Ref:<br />

目 標 :<br />

Objective:<br />

修 課 標 準 :<br />

Entry standards:<br />

授 課 ㆟ 數 :<br />

Class limitations:<br />

使 用 手 工 具 、 電 力 與 電 子 量 測 及 測 試 設 備 以 探 測 瑕 疵 、 進 行 保 養 及 修 理 工 作<br />

USE OF HAND TOOLS, ELECTRICAL AND ELECTRONIC MEASURING<br />

AND TEST EQUIPMENT FOR FAULT FINDING, MAINTENANCE AND<br />

REPAIR<br />

電 力 系 統 之 安 全 設 備<br />

SAFETY REQUIREMENTS FOR ELECTRICAL SYSTEMS<br />

船 舶 電 力 系 統 的 特 性<br />

CHARACTERISTICS OF SHIPBOARD ELECTRICAL SYSTEMS<br />

電 力 試 驗 及 量 測 之 設 備<br />

ELECTRICAL TESTS AND MEASURING EQUIPMENT<br />

主 機 推 進 動 力 3,000 瓩 以 ㆖ 船 舶 之 ㆒ 等 管 輪 證 書 之 學 習 課 程 內 容 及 期 間<br />

The contents and duration of study courses of engineer officers in charge of an<br />

engineering watch on ships powered by main propulsion machinery of 3,000<br />

kw propulsion power or more<br />

STCW regulation III/1, Code charter III section A-III/1<br />

此 課 程 符 合 STCW 95 表 A-III/1 有 關 輪 機 工 程 操 作 級 能 力 之 強 制 要 求 的 知 識 、<br />

瞭 解 及 熟 練<br />

This course aims to meet the mandatory minimum requirements for knowledge,<br />

understanding and proficiency in Table A-III/1 of STCW 1995 for the Competence<br />

Marine Engineering at the Operational Level.<br />

此 課 程 提 供 知 識 與 實 作 練 習 在 於 船 ㆖ 使 用 適 當 工 具 來 製 造 和 維 修 操 作 等 典 型<br />

的 工 作 來 達 成 任 務 、 職 責 與 責 任<br />

This course provides the background knowledge and practical work to support the<br />

tasks, duties and responsibilities in: use of appropriate tools for fabrication and<br />

repair operations typically performed on ships.<br />

所 有 將 擔 任 輪 機 當 職 管 輪 之 學 員<br />

This course is principally intended for candidates for certification as officers<br />

in charge of an engineering watch.<br />

50 ㆟<br />

<br />

<br />

教 師 :<br />

Instructors:<br />

督 導 :<br />

Assessors:<br />

教 學 設 備 及 器 材 : 1. 黑 板 或 掛 圖<br />

教 師 應 足 以 勝 任 教 學 與 指 導 之 工 作 , 並 且 擁 有 適 當 的 教 學 技 巧 與 方 法<br />

(STCW Code Section A-I/6)。 由 於 練 習 課 程 的 複 雜 性 , 可 以 有 ㆒ 擁 有 豐 富<br />

實 作 經 驗 的 助 教 予 以 協 助 。<br />

Instructors shall be qualified in the task for which training is being conducted<br />

and have appropriate training in instructional techniques and training methods<br />

(STCW Code Section A-I/6). Depending on the complexity of the exercises<br />

set, an assistant instructor with similar experience is desirable for certain<br />

practical exercises.<br />

交 通 部 船 員 訓 練 委 員 會 (Seafarer Training Committee, Ministry of<br />

Communication and Transportation)<br />

教 育 部 (Ministry of Education)<br />

Doc Ref STCW 2/07-Dts-30

Teaching facilities<br />

and equipment:<br />

教 具 :<br />

Teaching aids:<br />

證 書 :<br />

Certificate:<br />

授 課 時 程 :<br />

Course schedule:<br />

Blackboard or flipchart<br />

2. 課 桌<br />

Desks<br />

3. 投 影 機<br />

Overhead projector<br />

4. 手 工 具 與 電 動 工 具<br />

Hand and power tools<br />

5. 電 器 設 備<br />

Electrical equipment<br />

6. 電 表<br />

electric meter<br />

7. 示 波 器<br />

oscilloscope<br />

1. 教 師 指 導 手 冊<br />

Instructor guidance<br />

2. 廠 商 說 明 書<br />

Manufacturer’s manuals<br />

3. 錄 影 帶<br />

Video cassette player<br />

4. 投 影 片<br />

Overhead projection film<br />

5. 筆 記<br />

Notebook<br />

學 員 成 功 的 完 成 課 程 與 評 估 後 , 由 主 管 機 關 發 予 適 任 證 書 以 玆 證 明 其 符<br />

合 或 超 越 STCW1995 表 A-III/1 所 規 定 之 輪 機 操 作 級 知 識 與 適 任 標 準<br />

On successful completion of the course and assessments, a document may be<br />

issued certifying that the holder has successfully completed a course of<br />

training which meets or exceeds the level of knowledge and competence<br />

specified in Table A-III/1 of STCW 1995, for the Competence Marine<br />

Engineering at the Operational Level. A certificate may be issued only by<br />

centres approved by the Administration.<br />

<br />

<br />

教 師 手 冊 : Guidance on the implementation of IMO model courses<br />

Instructor manual:<br />

課 程 內 容<br />

Course Outline<br />

知 識 、 瞭 解 及 熟 練<br />

Knowledge, Understanding And Proficiency<br />

使 用 手 工 具 、 電 力 與 電 子 量 測 及 測 試 設 備 以 探 測 瑕 疵 、 進 行 保 養<br />

及 修 理 工 作<br />

USE OF HAND TOOLS, ELECTRICAL AND ELECTRONIC<br />

估 計 時 數<br />

Approximate time<br />

(Hours)<br />

授 課 、 示 範 與 實 作<br />

Lectures,<br />

demonstrations and<br />

practical work<br />

Doc Ref STCW 2/07-Dts-31

MEASURING AND TEST EQUIPMENT FOR FAULT<br />

FINDING, MAINTENANCE AND REPAIR<br />

電 力 系 統 之 安 全 設 備<br />

SAFETY REQUIREMENTS FOR ELECTRICAL SYSTEMS<br />

.1 基 本 安 全<br />

Basic safety<br />

船 舶 電 力 系 統 的 特 性<br />

CHARACTERISTICS OF SHIPBOARD ELECTRICAL<br />

SYSTEMS<br />

.2 電 子 理 論<br />

Electron theory<br />

.3 線 圖 及 符 號<br />

Diagrams and symbols<br />

.4 簡 單 電 路 及 歐 姆 定 律<br />

Simple circuits and ohm's law<br />

.5 串 聯 及 並 聯 電 路<br />

Series and parallel circuits<br />

.6 安 培 表 及 伏 特 表<br />

Ammeters and voltmeters<br />

.7 功 、 能 及 功 率<br />

Work, energy and power<br />

.8 電 功 率 供 應<br />

Electrical power supply<br />

.9 導 體<br />

Conductors<br />

.10 絕 緣<br />

Insulation<br />

.11 維 護 的 原 理<br />

Principles of maintenance<br />

.12 電 池 組<br />

Batteries<br />

.13 磁 導 與 電 磁<br />

Magnetism and electromagnetism<br />

.14 電 磁 感 應<br />

Electromagnetic induction<br />

.15 發 電 機 及 電 動 機 之 基 本 原 理<br />

Fundamentals of generators and motors<br />

.16 交 流 電 路<br />

Alternating current<br />

.17 配 電<br />

Distribution<br />

.18 變 壓 器<br />

Transformers<br />

.19 油 氣 及 化 學 油 輪 : 電 氣 要 求<br />

Oil, gas and chemical tanker: electrical requirements<br />

電 力 試 驗 及 量 測 之 設 備<br />

ELECTRICAL TESTS AND MEASURING EQUIPMENT<br />

<br />

Doc Ref STCW 2/07-Dts-32<br />

1<br />

4<br />

3<br />

6<br />

9<br />

3<br />

6<br />

2<br />

5<br />

4<br />

1<br />

5<br />

6<br />

6<br />

4<br />

4<br />

6<br />

2<br />

4

.20 試 驗 及 量 測<br />

Testing and measuring<br />

參 考 文 獻<br />

Reference<br />

課 程 綱 要<br />

Syllabus<br />

Sub Totals 90<br />

- International Convention on Standards of Training, Certification and<br />

Watchkeeping for Seafarers (STCW), 1995 (IMO Sales No. 938), and<br />

1997 Amendments to STCW 95 (IMO Sales No. 945)<br />

- International Convention for the Safety of Life at Sea (SOLAS), as<br />

amended (IMO Sales No. 110)<br />

- International Convention forthe Prevention of Pollution from Ships,<br />

1973/78 (MARPOL) (IMO Sales No. 520) and 1994/95 MARPOL<br />

Amendments (IMO Sales No. 640)<br />

- IMO/ILO Document for Guidance, 1985 (IMO Sales No. 935)<br />

- International Safety Management Code (ISM Code) (IMO-186)<br />

- Flood, C.R. Fabrication, Welding and Metal Joining Processes.<br />

London, Butterworth, 1981 (ISBN 04-08-00448-7) OUT OF<br />

PRINT 1999<br />

- Hall, D.T. Practical Marine Electrical Knowledge. London, Witherby<br />

& Co. Ltd, 1984. (ISBN 09-00-88687-0)<br />

- Hannah-Hillier.J. Applied Mechanics. Harlow,Longmann. 1995.<br />

(ISBN 05-82-25632-1)<br />

- International Labour Office. Accident Prevention on Board Ship at<br />

Sea and in Port, 2nded. Geneva, ILO, 1996 (ISBN 92-21-09450-2)<br />

- Jackson, L and Morton, T.D. General Engineering Knowledge for<br />

Marine Engineers. 5th ed. London, Thomas Reed Publications Ltd<br />

1990. (ISBN 09-47-63776-1)<br />

- Joel, R. Basic Engineering Thermodynamics in S.I. Units, 5th ed.<br />

Harlow, Longmann, 1996 (ISBN 05-82-25629-1)<br />

- Kraal, E.G.R. Basic Electrotechnology for Engineers, 3rd ed.<br />

London, Thomas Reed Publications Ltd, 1985 (ISBN 09-00-33596-3)<br />

- Morton, TD Motor Engineering Knowledge for Marine Engineers.<br />

London. Thomas Reed Publications Ltd, 1994 (ISBN 09-01-2856-5)<br />

- Pritchard.R.T. Technician Workshop Processes and Materials.<br />

London, Hodder and Stoughton, 1979 (ISBN 0-34022-100-3) OUT<br />

OF PRINT 1999<br />

- Simmonds, C.H. and Maguire, D.E. Progressive Engineering<br />

<br />

<br />

Drawing for T.E.C. Students, London. Hodder and Stoughton Ltd<br />

1983 (ISBN 03-40-26196-x-O) OUT OF PRINT 1999<br />

- Taylor.D.A. Introduction to Marine Engineering, 2nded. London,<br />

Butterworth. 1990 (ISBN 07-50-6253-9)<br />