Caution: This document contains mixed page sizes ... - Cummins Onan

Caution: This document contains mixed page sizes ... - Cummins Onan

Caution: This document contains mixed page sizes ... - Cummins Onan

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WARNING Accidental or remote starting can<br />

cause severe personal injury or death. Before<br />

removing a housing panel or access door, disconnect<br />

the negative (−) cable at the battery to<br />

prevent the engine from starting.<br />

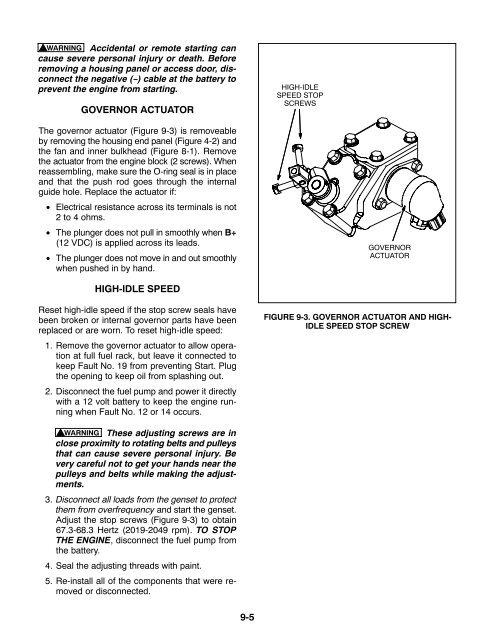

GOVERNOR ACTUATOR<br />

HIGH-IDLE<br />

SPEED STOP<br />

SCREWS<br />

The governor actuator (Figure 9-3) is removeable<br />

by removing the housing end panel (Figure 4-2) and<br />

the fan and inner bulkhead (Figure 8-1). Remove<br />

the actuator from the engine block (2 screws). When<br />

reassembling, make sure the O-ring seal is in place<br />

and that the push rod goes through the internal<br />

guide hole. Replace the actuator if:<br />

• Electrical resistance across its terminals is not<br />

2 to 4 ohms.<br />

• The plunger does not pull in smoothly when B+<br />

(12 VDC) is applied across its leads.<br />

• The plunger does not move in and out smoothly<br />

when pushed in by hand.<br />

GOVERNOR<br />

ACTUATOR<br />

HIGH-IDLE SPEED<br />

Reset high-idle speed if the stop screw seals have<br />

been broken or internal governor parts have been<br />

replaced or are worn. To reset high-idle speed:<br />

1. Remove the governor actuator to allow operation<br />

at full fuel rack, but leave it connected to<br />

keep Fault No. 19 from preventing Start. Plug<br />

the opening to keep oil from splashing out.<br />

2. Disconnect the fuel pump and power it directly<br />

with a 12 volt battery to keep the engine running<br />

when Fault No. 12 or 14 occurs.<br />

FIGURE 9-3. GOVERNOR ACTUATOR AND HIGH-<br />

IDLE SPEED STOP SCREW<br />

WARNING These adjusting screws are in<br />

close proximity to rotating belts and pulleys<br />

that can cause severe personal injury. Be<br />

very careful not to get your hands near the<br />

pulleys and belts while making the adjustments.<br />

3. Disconnect all loads from the genset to protect<br />

them from overfrequency and start the genset.<br />

Adjust the stop screws (Figure 9-3) to obtain<br />

67.3-68.3 Hertz (2019-2049 rpm). TO STOP<br />

THE ENGINE, disconnect the fuel pump from<br />

the battery.<br />

4. Seal the adjusting threads with paint.<br />

5. Re-install all of the components that were removed<br />

or disconnected.<br />

9-5