Download - Royal Australian Navy

Download - Royal Australian Navy

Download - Royal Australian Navy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

NAVY ENGINEERING BULLETIN AUGUST 2002<br />

55<br />

The Iron Monarch is maintained<br />

in-class under Lloyds Register, in<br />

a 60 monthly Continuous<br />

Machinery Survey (CMS),<br />

similarly to HMAS WESTRALIA.<br />

The Iron Monarch’s propulsion<br />

plant consists of two medium<br />

fixed speed Wartsilla diesels with<br />

pneumatic clutches, a single<br />

reduction gearbox driving a single<br />

propeller shaft and CPP, plus a<br />

shaft alternator, thus giving it a<br />

very similar configuration to<br />

WESTRALIA. Three Diesel<br />

Alternators are fitted for use<br />

alongside and during ‘standby’<br />

(the merchant version of RAN<br />

‘specials’), whereas the shaft<br />

alternator carries the cruising<br />

electrical load.<br />

The ‘Standby’ crew consists of<br />

the Chief and Duty Engineer<br />

closed up in the MCR, and the<br />

Master and 1st Mate on the<br />

Bridge. The on-watch deck officer<br />

will give the Duty Engineer one<br />

hour’s notice prior to departure<br />

or entering harbor. The flash-up is<br />

achieved in around 40 minutes.<br />

The ship is required to achieve<br />

an operational availability of<br />

98%. Allowable maintenance<br />

periods consists of one eight<br />

hour lay period at Port Kembla<br />

per month, an annual 4-5 day<br />

period and a 30-monthly 12 day<br />

docking. Thus it is imperative that<br />

the crew conduct the majority of<br />

the required work, with minimal<br />

shore support. Full advantage is<br />

taken of machinery redundancies<br />

to allow work to take place at<br />

sea, and all windows of<br />

opportunity during cargo<br />

operations. Much maintenance<br />

and repair effort of the cargo<br />

gantries is necessary to minimise<br />

disruption to cargo operations.<br />

Gantry call-outs are the least<br />

favourite of the Duty Engineer,<br />

particularly where operator error<br />

(by the wharfies) is blamed!<br />

Nevertheless, the speed with<br />

which the defect is rectified is<br />

particularly critical.<br />

With the availability focus,<br />

Engineers are not burdened with<br />

ancillary duties, and the Deck<br />

Officers shoulder a large share of<br />

other work. In addition to keeping<br />

four hour 1-in-3 watches at sea,<br />

Deck Officers keep eight hour<br />

cargo watches alongside, are<br />

responsible for ballasting, crew<br />

welfare and administration,<br />

maintenance and lead of<br />

damage control equipment and<br />

exercises, victuals and domestic<br />

supplies, shore water and<br />

telephone connections and ship’s<br />

husbandry.<br />

To conclude, the commercial<br />

shipping environment differs<br />

significantly from RAN practice,<br />

each organisation being driven<br />

by different requirements and<br />

with different stakeholders in<br />

each ship. There are however,<br />

several examples of improved<br />

means of doing business that<br />

would certainly be applicable to<br />

RAN vessels, the auxiliary ships<br />

in particular. The substantial<br />

detail necessary to support such<br />

an argument would constitute<br />

another article.<br />

Footnote:<br />

An opportunity exists for ME<br />

officers to undertake similar<br />

short-term secondments to a<br />

merchant vessel. This<br />

experience will be of most<br />

benefit to Officers with a<br />

minimum of MEOCC<br />

qualification. For further details<br />

see <strong>Navy</strong> Engineering Bulletin<br />

Issue 2 February 2002 (page<br />

13).<br />

About the Author LEUT Raymond Howe<br />

graduated from ADFA in 1999. Awarded<br />

an MEOCC onboard HMAS WESTRALIA in<br />

November 2001, he is currently posted as<br />

the WA Liaison Officer at AASSPO, and<br />

WESTRALIA Maintenance Manager.<br />

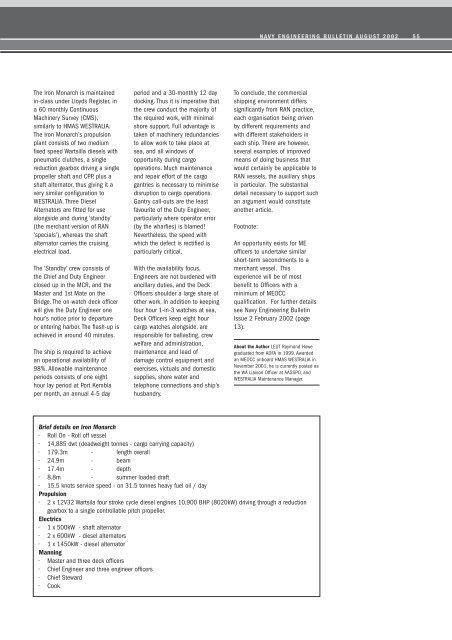

Brief details on Iron Monarch<br />

• Roll On - Roll off vessel<br />

• 14,885 dwt (deadweight tonnes - cargo carrying capacity)<br />

• 179.3m - length overall<br />

• 24.9m - beam<br />

• 17.4m - depth<br />

• 8.8m - summer loaded draft<br />

• 15.5 knots service speed - on 31.5 tonnes heavy fuel oil / day<br />

Propulsion<br />

• 2 x 12V32 Wartsila four stroke cycle diesel engines 10,900 BHP (8020kW) driving through a reduction<br />

gearbox to a single controllable pitch propeller.<br />

Electrics<br />

• 1 x 500kW - shaft alternator<br />

• 2 x 600kW - diesel alternators<br />

• 1 x 1450kW - diesel alternator<br />

Manning<br />

• Master and three deck officers<br />

• Chief Engineer and three engineer officers<br />

• Chief Steward<br />

• Cook