PDF Download - Glidewell Dental Labs

PDF Download - Glidewell Dental Labs

PDF Download - Glidewell Dental Labs

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

In terms of practical use, how does the clinician who desires<br />

an all-zirconia custom abutment ensure proper seating? For<br />

the lab technician, seating the abutment on a model is easy.<br />

The model can be turned or twisted as needed to achieve<br />

optimal orientation, and there are no other anatomical<br />

structures or tissues to get in the way. A patient in the chair,<br />

however, is another matter. There’s only so much freedom<br />

the clinician has in terms of orientation to gain access to the<br />

implant site. And there are cheeks, teeth, the tongue and<br />

soft tissue to contend with. In addition, the lab technician<br />

is frequently more familiar with the line of draw as a result<br />

of the intimacy gained during the design process. Without<br />

spending the same amount of time relating the abutment to<br />

the patient’s mouth, the doctor cannot be expected to have<br />

this level of familiarity.<br />

To help solve this clinical challenge and ensure proper<br />

seating of the abutment, an acrylic jig can be made, which<br />

serves as a positioning index and placement aid. From<br />

<strong>Glidewell</strong>, this jig is shipped in the case box in a plastic<br />

baggie separate from the abutment (which is seated on the<br />

model). Upon close examination, you will see that both the<br />

jig and the abutment are marked with the appropriate tooth<br />

number along the facial wall (i.e., labial or buccal). Thus, if<br />

your case includes multiple abutments, each abutment can<br />

easily be matched to the correct jig.<br />

Laboratory Example<br />

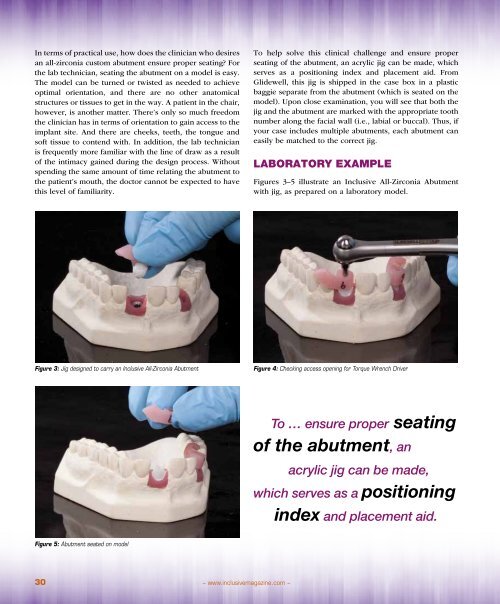

Figures 3–5 illustrate an Inclusive All-Zirconia Abutment<br />

with jig, as prepared on a laboratory model.<br />

Figure 3: Jig designed to carry an Inclusive All-Zirconia Abutment<br />

Figure 4: Checking access opening for Torque Wrench Driver<br />

To … ensure proper seating<br />

of the abutment, an<br />

acrylic jig can be made,<br />

which serves as a positioning<br />

index and placement aid.<br />

Figure 5: Abutment seated on model<br />

30<br />

– www.inclusivemagazine.com –