Anvol HP5046D B1607/02 - Castrol TDS

Anvol HP5046D B1607/02 - Castrol TDS

Anvol HP5046D B1607/02 - Castrol TDS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

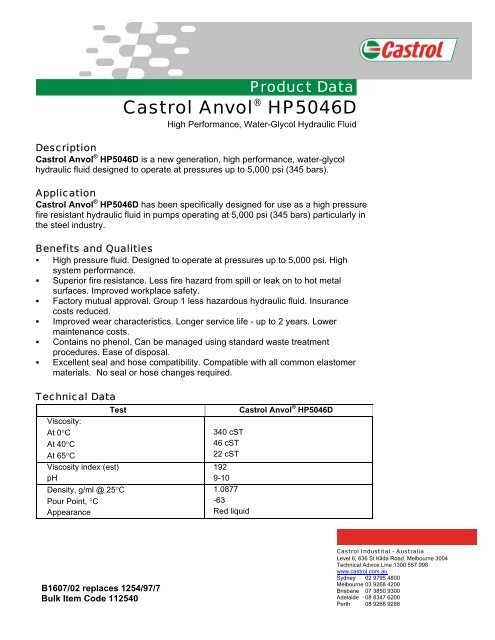

Product Data<br />

<strong>Castrol</strong> <strong>Anvol</strong> ® <strong>HP5046D</strong><br />

High Performance, Water-Glycol Hydraulic Fluid<br />

Description<br />

<strong>Castrol</strong> <strong>Anvol</strong> ® <strong>HP5046D</strong> is a new generation, high performance, water-glycol<br />

hydraulic fluid designed to operate at pressures up to 5,000 psi (345 bars).<br />

Application<br />

<strong>Castrol</strong> <strong>Anvol</strong> ® <strong>HP5046D</strong> has been specifically designed for use as a high pressure<br />

fire resistant hydraulic fluid in pumps operating at 5,000 psi (345 bars) particularly in<br />

the steel industry.<br />

Benefits and Qualities<br />

• High pressure fluid. Designed to operate at pressures up to 5,000 psi. High<br />

system performance.<br />

• Superior fire resistance. Less fire hazard from spill or leak on to hot metal<br />

surfaces. Improved workplace safety.<br />

• Factory mutual approval. Group 1 less hazardous hydraulic fluid. Insurance<br />

costs reduced.<br />

• Improved wear characteristics. Longer service life - up to 2 years. Lower<br />

maintenance costs.<br />

• Contains no phenol. Can be managed using standard waste treatment<br />

procedures. Ease of disposal.<br />

• Excellent seal and hose compatibility. Compatible with all common elastomer<br />

materials. No seal or hose changes required.<br />

Technical Data<br />

Test<br />

Viscosity:<br />

At 0°C<br />

At 40°C<br />

At 65°C<br />

Viscosity index (est)<br />

pH<br />

Density, g/ml @ 25°C<br />

Pour Point, °C<br />

Appearance<br />

340 cST<br />

46 cST<br />

22 cST<br />

192<br />

9-10<br />

1.0877<br />

-63<br />

Red liquid<br />

<strong>Castrol</strong> <strong>Anvol</strong> ® <strong>HP5046D</strong><br />

<strong>B1607</strong>/<strong>02</strong> replaces 1254/97/7<br />

Bulk Item Code 112540<br />

<strong>Castrol</strong> Industrial - Australia<br />

Level 6, 636 St Kilda Road, Melbourne 3004<br />

Technical Advice Line 1300 557 998<br />

www.castrol.com.au<br />

Sydney <strong>02</strong> 9795 4800<br />

Melbourne 03 9268 4200<br />

Brisbane 07 3850 9300<br />

Adelaide 08 8347 6200<br />

Perth 08 9268 9288

Seal and Hose Compatibility<br />

Historically, water glycol fluids have exhibited excellent compatibility and service life<br />

with standard hydraulic seals and hose elastomers. <strong>Castrol</strong> <strong>Anvol</strong> ® <strong>HP5046D</strong><br />

affords similar elastomer compatibility with commonly used materials such as<br />

“Viton”, high-nitrile Buna N, EPDM, butyl, silicone, and halogenated elastomers (eg<br />

Aflas, “Kalrez” etc). Urethanes and Buna S (SBR) elastomers are not compatible<br />

with <strong>Castrol</strong> <strong>Anvol</strong> ® <strong>HP5046D</strong>.<br />

Pump Wear Performance ASTM D-2882<br />

As the data in Table 1 indicates, <strong>Castrol</strong> <strong>Anvol</strong> ® <strong>HP5046D</strong> is significantly superior<br />

to conventional water-glycol fluids and exhibits wear characteristics similar to those<br />

of phosphate/polyol esters and AW oil.<br />

Table 1<br />

Comparative ASTM D2882 Pump Wear Test Results<br />

Test Standard<br />

ASTM D-2882<br />

Vickers Vane<br />

104-C pump (30 l/min ),<br />

1200 rmp<br />

2,000 psi (13.8 Mpa)<br />

100 hrs<br />

Pass criteria:<br />

1mg/hr wear<br />

Water glycol<br />

0.65<br />

Wear Rates of Typical Fluids mg/hr<br />

<strong>Castrol</strong> <strong>Anvol</strong> ®<br />

<strong>HP5046D</strong><br />

0.1<br />

Phos/Polyol Ester<br />

0.05/0.1<br />

AW Oil<br />

0.24<br />

High Pressure Axial Piston Pump Test Results<br />

<strong>Castrol</strong> <strong>Anvol</strong> ® <strong>HP5046D</strong> was also evaluated independently in a Sundstrand series<br />

22 axial piston pump using a modified Water Stability Test. As shown in Table 2, no<br />

significant flow degradation (0.8%) was observed over the full duration. (A flow<br />

degradation of 10% constitutes failure.) Furthermore, test parts showed negligible<br />

wear after running 225 hours with <strong>Castrol</strong> <strong>Anvol</strong> ® HP5046Q.<br />

Table 2<br />

High Pressure Piston Pump Results<br />

High Pressure Piston Pump<br />

Sunstrand 22-2132<br />

Variable Displacement<br />

Axial Piston Pump<br />

Input speed 3100 rpm<br />

Load pressure 5,000 psi (345) bars<br />

Reservoir Temp 49°C<br />

Loop Temp 77°C<br />

Pass Criteria:,10% flow rate decrease<br />

Flow Rate (litres/min)<br />

Time (hrs) 1 75 125 225<br />

Flow Rate 24.9 24.9 24.9 24.9

Table 3<br />

High Pressure Hydrostatic Drive Simulation<br />

High Pressure Hydrostatic Drive Simulation<br />

Sunstrand Series 20 Motor & Pump<br />

Case Drain Flow 19 Umin<br />

600 set Pressure Cycle:<br />

1,300 psi (90 bars) to 4,500 psi (310 bars).<br />

Duration: 500 hrs 5 days/week<br />

16 hrs/day<br />

Operating temp variation<br />

+14°C to - 21°C.<br />

Pass criteria: 5% flow rate decrease.<br />

Visual inspection of pump parts fluid integrity.<br />

Observation<br />

Sunstrand pump and motor performed<br />

well. Visual inspection before and after<br />

the test did not indicate unusual wear or<br />

stress.<br />

No significant change in flow rate<br />

occurred during the test period.<br />

Fluid exhibited excellent shear stability.<br />

All chemical and physical properties of<br />

the fluid remained virtually inchanged.<br />

Conclusion: <strong>Castrol</strong> <strong>Anvol</strong> ® <strong>HP5046D</strong><br />

is a very stable fluid with excellent<br />

lubrication properties under high<br />

pressure conditions.<br />

Health, Safety and Environment<br />

<strong>Castrol</strong> <strong>Anvol</strong> ® <strong>HP5046D</strong> presents no significant hazard to the operator. However,<br />

it is a good safety procedure to minimize skin contact and breathing vapour.<br />

<strong>Castrol</strong> <strong>Anvol</strong> <strong>HP5046D</strong> is classified R22 – harmful if swallowed.<br />

Spillage:<br />

Disposal:<br />

SMALL - 20 LITRES OR LESS<br />

Soak up on <strong>Castrol</strong> Diatomaceous Earth or similar inert oil<br />

absorbent. Arrange for disposal through an approved facility.<br />

LARGE - GREATER THAN 20 LITRES<br />

Increase ventilation. Evacuate all unnecessary personnel. Wear full<br />

protective equipment and clothing to minimise exposure. If possible<br />

contain the spill. Place inert absorbent material such as vermiculite,<br />

sand or dirt onto spillage. Use clean non-sparking tools to collect the<br />

material and place into a suitable labelled container. Do not dilute<br />

material but contain. If large quantities of this material enter the<br />

waterways contact the Environmental Protection Authority, or your<br />

local Waste Management Authority.<br />

Dispose of waste according to federal, E.P.A., state and local<br />

regulations. Assure conformity with all applicable regulations.<br />

All reasonable care has been taken to ensure that the information contained in this publication is accurate as of<br />

the date of printing. However, such information may, nevertheless, be affected by changes in the blend<br />

formulation occurring subsequent to the date of printing. Material Safety Data Sheets are available for all<br />

<strong>Castrol</strong> Industrial Australia Inc. products. The MSDS must be consulted for appropriate information regarding<br />

storage, safe handling and disposal of a product.<br />

30-Jan-05<br />

<strong>Castrol</strong> <strong>Anvol</strong> ® <strong>HP5046D</strong><br />

Page 3 of 3