Arrow Bowen GAs Project - Arrow Energy

Arrow Bowen GAs Project - Arrow Energy

Arrow Bowen GAs Project - Arrow Energy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Arrow</strong> <strong>Bowen</strong> Gas <strong>Project</strong> EIS | Executive summary<br />

Water treatment and storage infrastructure at the IPFs are<br />

expected to include:<br />

• 600 ML feedwater dam(s);<br />

• 600 ML treated water dam(s);<br />

• Reverse osmosis plant; and<br />

• Two 960 ML brine storage dams.<br />

Reverse osmosis technology is currently being considered as<br />

the most appropriate treatment process coupled with some<br />

form of suitable pre-treatment such as membrane or media<br />

filtration and hardness removal. With reverse osmosis, water<br />

passes under pressure through a selective membrane and the<br />

dissolved salts are retained as concentrated brine. Treated<br />

water may also be amended through the addition of trace<br />

elements so that it is suitable for a variety of beneficial end uses.<br />

4.4.2 Management of CSG Water<br />

<strong>Arrow</strong> has developed a strategy for the management of CSG<br />

water in line with the Queensland EHP’s Coal Seam Gas Water<br />

Management Policy (DERM, 2010). This policy is implemented<br />

through the EA conditions imposed upon <strong>Arrow</strong>’s operations<br />

and projects.<br />

<strong>Arrow</strong>’s water management strategy seeks to maximise<br />

beneficial use of CSG water and minimise the environmental<br />

impacts associated with its use and disposal. The strategy also<br />

seeks (where possible) to manage CSG water in such a way as<br />

to mitigate the impacts of groundwater depressurisation on<br />

groundwater users. In order to achieve these objectives, the<br />

CSG water produced as a result of undertaking CSG extraction<br />

activities will be managed through a hierarchy of management<br />

options.<br />

<strong>Arrow</strong> expects to implement a number of beneficial use<br />

options including the agricultural (irrigation), industrial and<br />

urban uses in addition to the current uses already employed at<br />

its existing operations.<br />

Another option is to inject water to offset the impacts of<br />

groundwater depressurisation on users and to provide a<br />

disposal means for any water that cannot be accommodated<br />

through beneficial use. <strong>Arrow</strong> will conduct an injection<br />

feasibility study and is preparing EA applications to conduct<br />

aquifer injection trials in the <strong>Project</strong> area. The purpose of<br />

the trials is to determine the suitability of the formations for<br />

injection, and to identify the volumes and rates of water that<br />

can be sustainably injected.<br />

Figure 10 shows the <strong>Project</strong> water management concept and<br />

a range of end uses for CSG water.<br />

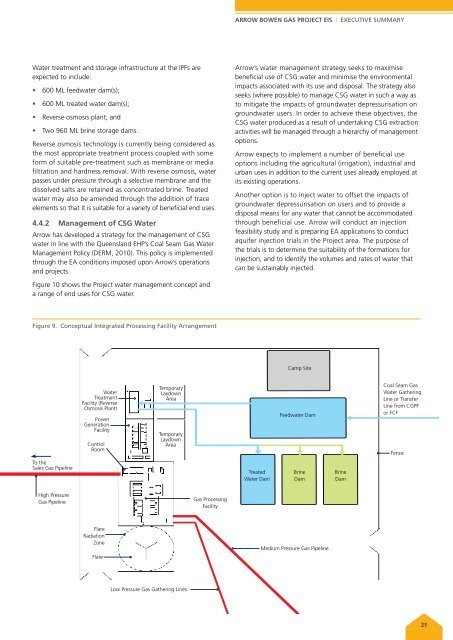

Figure 9. Conceptual Integrated Processing Facility Arrangement<br />

Camp Site<br />

Water<br />

Treatment<br />

Facility (Reverse<br />

Osmosis Plant)<br />

Power<br />

Generation<br />

Facility<br />

Control<br />

Room<br />

Temporary<br />

Laydown<br />

Area<br />

Temporary<br />

Laydown<br />

Area<br />

Feedwater Dam<br />

Coal Seam Gas<br />

Water Gathering<br />

Line or Transfer<br />

Line from CGPF<br />

or FCF<br />

Fence<br />

To the<br />

Sales Gas Pipeline<br />

Treated<br />

Water Dam<br />

Brine<br />

Dam<br />

Brine<br />

Dam<br />

High Pressure<br />

Gas Pipeline<br />

Gas Processing<br />

Facility<br />

Flare<br />

Radiation<br />

Zone<br />

Flare<br />

Medium Pressure Gas Pipeline<br />

Low Pressure Gas Gathering Lines<br />

21