Eclipse Combustion Engineering Guide - Burnerparts

Eclipse Combustion Engineering Guide - Burnerparts

Eclipse Combustion Engineering Guide - Burnerparts

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FUME INCERATION – SELECTION & SIZING GUIDELINES<br />

I. Process Information Required<br />

A. Fume stream flow rate, scfm or acfm. (If acfm,<br />

specify temperature at which flow is measured.)<br />

Maximum and minimum flow rates are required.<br />

B. Fume stream temperature at inlet to burner at<br />

maximum and minimum flow rates.<br />

C. Oxygen content of fume stream.<br />

D. Amount of particulates or other non-volatile<br />

matter in fume stream.<br />

E. Incineration temperature required, typically:<br />

600-900°F for catalytic incinerators<br />

1200-1500°F for thermal incinerators.<br />

F. Residence time required in combustion chamber,<br />

typically, 0.3 to 0.7 seconds.<br />

II. Burner Type Selection<br />

Two basic types of burners are used to fire fume incinerators:<br />

raw gas burners, which obtain their combustion<br />

air from the incoming fume stream, and fresh air burners,<br />

which obtain theirs from an external source.<br />

Raw gas burners permit higher fuel efficiency, but they<br />

can’t be used under as wide a variety of operating conditions.<br />

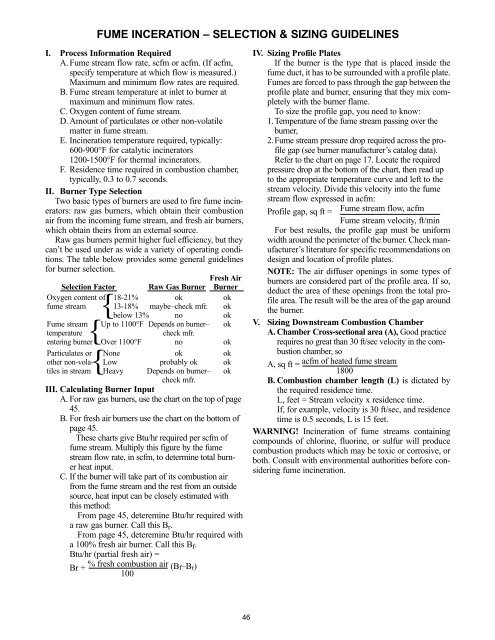

The table below provides some general guidelines<br />

for burner selection.<br />

Fresh Air<br />

Selection Factor Raw Gas Burner Burner<br />

Oxygen content of 18-21% ok ok<br />

fume stream 13-18% maybe–check mfr. ok<br />

below 13% no ok<br />

Fume stream Up to 1100°F Depends on burner– ok<br />

{<br />

{<br />

{<br />

temperature<br />

check mfr.<br />

entering burner Over 1100°F no ok<br />

Particulates or None ok ok<br />

other non-vola- Low probably ok ok<br />

tiles in stream Heavy Depends on burner– ok<br />

check mfr.<br />

III. Calculating Burner Input<br />

A. For raw gas burners, use the chart on the top of page<br />

45.<br />

B. For fresh air burners use the chart on the bottom of<br />

page 45.<br />

These charts give Btu/hr required per scfm of<br />

fume stream. Multiply this figure by the fume<br />

stream flow rate, in scfm, to determine total burner<br />

heat input.<br />

C. If the burner will take part of its combustion air<br />

from the fume stream and the rest from an outside<br />

source, heat input can be closely estimated with<br />

this method:<br />

From page 45, deteremine Btu/hr required with<br />

a raw gas burner. Call this B r .<br />

From page 45, deteremine Btu/hr required with<br />

a 100% fresh air burner. Call this B f .<br />

Btu/hr (partial fresh air) =<br />

Br + % fresh combustion air (Bf–Br)<br />

100<br />

IV. Sizing Profile Plates<br />

If the burner is the type that is placed inside the<br />

fume duct, it has to be surrounded with a profile plate.<br />

Fumes are forced to pass through the gap between the<br />

profile plate and burner, ensuring that they mix completely<br />

with the burner flame.<br />

To size the profile gap, you need to know:<br />

1.Temperature of the fume stream passing over the<br />

burner,<br />

2.Fume stream pressure drop required across the profile<br />

gap (see burner manufacturer’s catalog data).<br />

Refer to the chart on page 17. Locate the required<br />

pressure drop at the bottom of the chart, then read up<br />

to the appropriate temperature curve and left to the<br />

stream velocity. Divide this velocity into the fume<br />

stream flow expressed in acfm:<br />

Profile gap, sq ft = Fume stream flow, acfm<br />

Fume stream velocity, ft/min<br />

For best results, the profile gap must be uniform<br />

width around the perimeter of the burner. Check manufacturer’s<br />

literature for specific recommendations on<br />

design and location of profile plates.<br />

NOTE: The air diffuser openings in some types of<br />

burners are considered part of the profile area. If so,<br />

deduct the area of these openings from the total profile<br />

area. The result will be the area of the gap around<br />

the burner.<br />

V. Sizing Downstream <strong>Combustion</strong> Chamber<br />

A. Chamber Cross-sectional area (A), Good practice<br />

requires no great than 30 ft/sec velocity in the combustion<br />

chamber, so<br />

A, sq ft =<br />

acfm of heated fume stream<br />

1800<br />

B. <strong>Combustion</strong> chamber length (L) is dictated by<br />

the required residence time.<br />

L, feet = Stream velocity x residence time.<br />

If, for example, velocity is 30 ft/sec, and residence<br />

time is 0.5 seconds, L is 15 feet.<br />

WARNING! Incineration of fume streams containing<br />

compounds of chlorine, fluorine, or sulfur will produce<br />

combustion products which may be toxic or corrosive, or<br />

both. Consult with environmental authorities before considering<br />

fume incineration.<br />

46