Eclipse Combustion Engineering Guide - Burnerparts

Eclipse Combustion Engineering Guide - Burnerparts

Eclipse Combustion Engineering Guide - Burnerparts

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

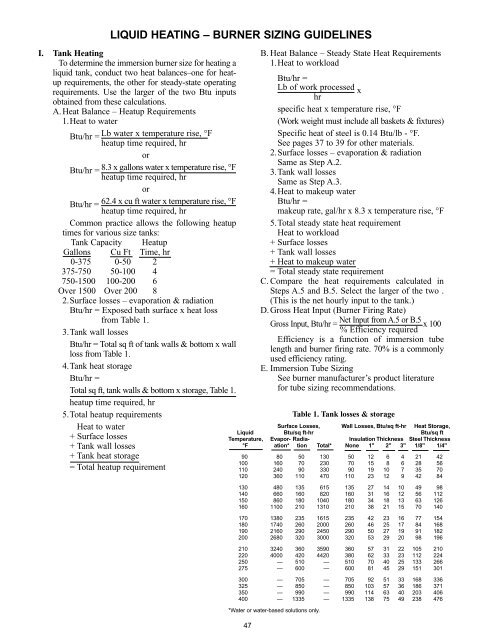

LIQUID HEATING – BURNER SIZING GUIDELINES<br />

I. Tank Heating<br />

To determine the immersion burner size for heating a<br />

liquid tank, conduct two heat balances–one for heatup<br />

requirements, the other for steady-state operating<br />

requirements. Use the larger of the two Btu inputs<br />

obtained from these calculations.<br />

A. Heat Balance – Heatup Requirements<br />

1.Heat to water<br />

Btu/hr = Lb water x temperature rise, °F<br />

heatup time required, hr<br />

or<br />

Btu/hr = 8.3 x gallons water x temperature rise, °F<br />

heatup time required, hr<br />

or<br />

Btu/hr = 62.4 x cu ft water x temperature rise, °F<br />

heatup time required, hr<br />

Common practice allows the following heatup<br />

times for various size tanks:<br />

Tank Capacity Heatup<br />

Gallons Cu Ft Time, hr<br />

0-375 0-50 2<br />

375-750 50-100 4<br />

750-1500 100-200 6<br />

Over 1500 Over 200 8<br />

2.Surface losses – evaporation & radiation<br />

Btu/hr = Exposed bath surface x heat loss<br />

from Table 1.<br />

3.Tank wall losses<br />

Btu/hr = Total sq ft of tank walls & bottom x wall<br />

loss from Table 1.<br />

4.Tank heat storage<br />

Btu/hr =<br />

Total sq ft, tank walls & bottom x storage, Table 1.<br />

heatup time required, hr<br />

5.Total heatup requirements<br />

Heat to water<br />

+ Surface losses<br />

+ Tank wall losses<br />

+ Tank heat storage<br />

= Total heatup requirement<br />

47<br />

B. Heat Balance – Steady State Heat Requirements<br />

1.Heat to workload<br />

Btu/hr =<br />

Lb of work processed x<br />

hr<br />

specific heat x temperature rise, °F<br />

(Work weight must include all baskets & fixtures)<br />

Specific heat of steel is 0.14 Btu/lb - °F.<br />

See pages 37 to 39 for other materials.<br />

2.Surface losses – evaporation & radiation<br />

Same as Step A.2.<br />

3.Tank wall losses<br />

Same as Step A.3.<br />

4.Heat to makeup water<br />

Btu/hr =<br />

makeup rate, gal/hr x 8.3 x temperature rise, °F<br />

5.Total steady state heat requirement<br />

Heat to workload<br />

+ Surface losses<br />

+ Tank wall losses<br />

+ Heat to makeup water<br />

= Total steady state requirement<br />

C. Compare the heat requirements calculated in<br />

Steps A.5 and B.5. Select the larger of the two .<br />

(This is the net hourly input to the tank.)<br />

D. Gross Heat Input (Burner Firing Rate)<br />

Gross Input, Btu/hr = Net Input from A.5 or B.5 x 100<br />

% Efficiency required<br />

Efficiency is a function of immersion tube<br />

length and burner firing rate. 70% is a commonly<br />

used efficiency rating.<br />

E. Immersion Tube Sizing<br />

See burner manufacturer’s product literature<br />

for tube sizing recommendations.<br />

Table 1. Tank losses & storage<br />

Surface Losses, Wall Losses, Btu/sq ft-hr Heat Storage,<br />

Liquid Btu/sq ft-hr Btu/sq ft<br />

Temperature, Evapor- Radia- Insulation Thickness Steel Thickness<br />

°F ation* tion Total* None 1" 2" 3" 1/8" 1/4"<br />

90 80 50 130 50 12 6 4 21 42<br />

100 160 70 230 70 15 8 6 28 56<br />

110 240 90 330 90 19 10 7 35 70<br />

120 360 110 470 110 23 12 9 42 84<br />

130 480 135 615 135 27 14 10 49 98<br />

140 660 160 820 160 31 16 12 56 112<br />

150 860 180 1040 180 34 18 13 63 126<br />

160 1100 210 1310 210 38 21 15 70 140<br />

170 1380 235 1615 235 42 23 16 77 154<br />

180 1740 260 2000 260 46 25 17 84 168<br />

190 2160 290 2450 290 50 27 19 91 182<br />

200 2680 320 3000 320 53 29 20 98 196<br />

210 3240 360 3590 360 57 31 22 105 210<br />

220 4000 420 4420 380 62 33 23 112 224<br />

250 — 510 — 510 70 40 25 133 266<br />

275 — 600 — 600 81 45 29 151 301<br />

300 — 705 — 705 92 51 33 168 336<br />

325 — 850 — 850 103 57 36 186 371<br />

350 — 990 — 990 114 63 40 203 406<br />

400 — 1335 — 1335 138 75 49 238 476<br />

*Water or water-based solutions only.