CARB® toroidal roller bearings â a revolutionary ... - Acorn Bearings

CARB® toroidal roller bearings â a revolutionary ... - Acorn Bearings

CARB® toroidal roller bearings â a revolutionary ... - Acorn Bearings

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1 Product information 2 Recommendations 3 Product data<br />

Page ............. 3 Grease lubrication Page ............. 37<br />

Lubrication<br />

CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong> can be<br />

lubricated with grease as well as oil.<br />

There is no strict rule for when grease<br />

or oil should be used.<br />

Grease has the advantage over oil<br />

that it is more easily retained in the<br />

bearing than oil and grease is better if<br />

the shaft is at an angle or arranged<br />

vertically.<br />

On the other hand, oil lubrication<br />

allows higher operating speeds and<br />

temperatures and can contribute to<br />

heat removal from the bearing position,<br />

which is particularly important where<br />

external heating is involved. Very small<br />

quantities of lubricant are required to<br />

lubricate the bearing surfaces.<br />

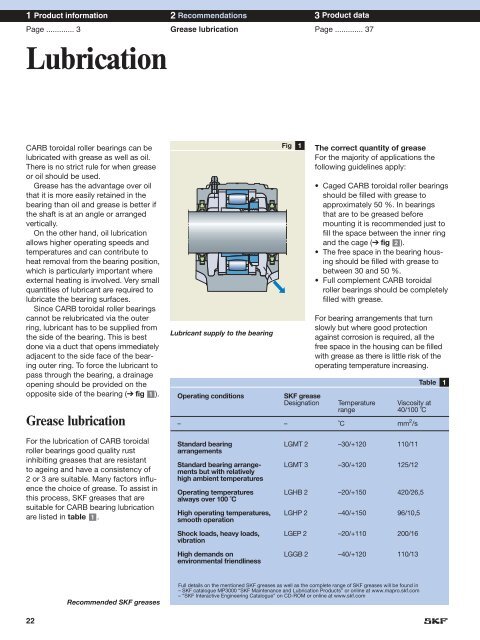

Since CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong><br />

cannot be relubricated via the outer<br />

ring, lubricant has to be supplied from<br />

the side of the bearing. This is best<br />

done via a duct that opens immediately<br />

adjacent to the side face of the bearing<br />

outer ring. To force the lubricant to<br />

pass through the bearing, a drainage<br />

opening should be provided on the<br />

opposite side of the bearing (➔ fig 1 ).<br />

Grease lubrication<br />

For the lubrication of CARB <strong>toroidal</strong><br />

<strong>roller</strong> <strong>bearings</strong> good quality rust<br />

inhibiting greases that are resistant<br />

to ageing and have a consistency of<br />

2 or 3 are suitable. Many factors influence<br />

the choice of grease. To assist in<br />

this process, SKF greases that are<br />

suitable for CARB bearing lubrication<br />

are listed in table 1 .<br />

Lubricant supply to the bearing<br />

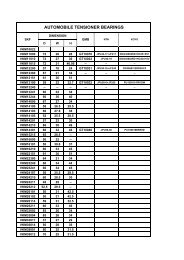

Operating conditions<br />

Fig<br />

1<br />

The correct quantity of grease<br />

For the majority of applications the<br />

following guidelines apply:<br />

• Caged CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong><br />

should be filled with grease to<br />

approximately 50 %. In <strong>bearings</strong><br />

that are to be greased before<br />

mounting it is recommended just to<br />

fill the space between the inner ring<br />

and the cage (➔ fig 2 ).<br />

• The free space in the bearing housing<br />

should be filled with grease to<br />

between 30 and 50 %.<br />

• Full complement CARB <strong>toroidal</strong><br />

<strong>roller</strong> <strong>bearings</strong> should be completely<br />

filled with grease.<br />

For bearing arrangements that turn<br />

slowly but where good protection<br />

against corrosion is required, all the<br />

free space in the housing can be filled<br />

with grease as there is little risk of the<br />

operating temperature increasing.<br />

SKF grease<br />

Designation Temperature Viscosity at<br />

range<br />

40/100 ˚C<br />

– – ˚C mm 2 /s<br />

Standard bearing LGMT 2 –30/+120 110/11<br />

arrangements<br />

Standard bearing arrange- LGMT 3 –30/+120 125/12<br />

ments but with relatively<br />

high ambient temperatures<br />

Operating temperatures LGHB 2 –20/+150 420/26,5<br />

always over 100 ˚C<br />

High operating temperatures, LGHP 2 –40/+150 96/10,5<br />

smooth operation<br />

Table<br />

1<br />

Shock loads, heavy loads, LGEP 2 –20/+110 200/16<br />

vibration<br />

High demands on LGGB 2 –40/+120 110/13<br />

environmental friendliness<br />

Recommended SKF greases<br />

Full details on the mentioned SKF greases as well as the complete range of SKF greases will be found in<br />

– SKF catalogue MP3000 “SKF Maintenance and Lubrication Products” or online at www.mapro.skf.com<br />

– “SKF Interactive Engineering Catalogue” on CD-ROM or online at www.skf.com<br />

22