CARB® toroidal roller bearings â a revolutionary ... - Acorn Bearings

CARB® toroidal roller bearings â a revolutionary ... - Acorn Bearings

CARB® toroidal roller bearings â a revolutionary ... - Acorn Bearings

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1 Product information 2 Recommendations 3 Product data<br />

Page ............. 3 Grease lubrication Page ............. 37<br />

Deviating conditions<br />

Operating temperature<br />

To account for the accelerated ageing<br />

of grease in hot running applications,<br />

SKF recommends halving the intervals<br />

obtained from the diagram for every<br />

15 °C increase in bearing temperature<br />

above 70 °C.<br />

The relubrication interval t f may be<br />

extended at temperatures below 70 °C.<br />

In many cases the interval may also be<br />

prolonged if the load is low (C/P = 30 to<br />

50). Extending the relubrication interval<br />

t f by more than a factor of two is not<br />

recommended.<br />

For full complement <strong>bearings</strong>, t f<br />

values obtained from the diagram<br />

should not be prolonged.<br />

Moreover, it is not advisable to use<br />

relubrication intervals in excess of<br />

30 000 hours.<br />

For many applications, there are<br />

practical grease lubrication limits,<br />

when the bearing ring with the highest<br />

temperature reaches an operating temperature<br />

of 100 °C. Above this temperature<br />

special greases should be used.<br />

In addition,temperature stability of the<br />

bearing and premature seal failure<br />

should be taken into consideration.<br />

For high temperature applications,<br />

contact the SKF application engineering<br />

service.<br />

Vertical shafts<br />

For <strong>bearings</strong> on vertical shafts, the<br />

intervals obtained from the diagram<br />

should be halved.<br />

The use of a good seal or retaining<br />

shield is a prerequisite or grease will<br />

leak from the bearing arrangement.<br />

Vibrations<br />

Mild vibrations will not have a negative<br />

effect on grease life, but high vibration<br />

and shock levels, such as those in<br />

vibrating screen applications, will cause<br />

the grease to churn. In these cases the<br />

relubrication interval should be reduced.<br />

If the grease becomes too soft, a<br />

grease with a better mechanical stability<br />

(e.g. LGHB 2) and/or a stiffer grease<br />

(NLGI 3) should be used.<br />

Outer ring rotation<br />

In applications where there is outer ring<br />

rotation, the value of the bearing factor<br />

n × d m is calculated by applying the<br />

value of the bearing outside diameter D<br />

instead of d m . The use of a good sealing<br />

mechanism is a prerequisite in order<br />

to avoid grease loss.<br />

Under conditions of high outer ring<br />

speeds (i.e. > 50 % of the speed rating<br />

in the bearing tables), greases with<br />

a reduced bleeding tendency should<br />

be selected (e.g. lithium complex and<br />

polyurea).<br />

Contamination<br />

In case of ingress of contamination, a<br />

more frequent relubrication interval will<br />

reduce the negative effects of foreign<br />

particles on the bleeding characteristics<br />

of grease while reducing the damaging<br />

effects caused by overrolling of particles.<br />

Fluid contaminants (water, process<br />

fluids) also call for a reduced interval.<br />

In case of severe contamination,<br />

continuous relubrication should be<br />

considered.<br />

Requisite grease quantities<br />

for relubrication<br />

The used grease in a CARB <strong>toroidal</strong><br />

<strong>roller</strong> bearing should be replaced by<br />

fresh grease. The quantity of grease<br />

required for this depends on the bearing<br />

size; this can be determined using<br />

G p = 0,005 D B<br />

where<br />

G p = grease quantity required for<br />

periodic lubrication, g<br />

D = bearing outside diameter, mm<br />

B = bearing width, mm<br />

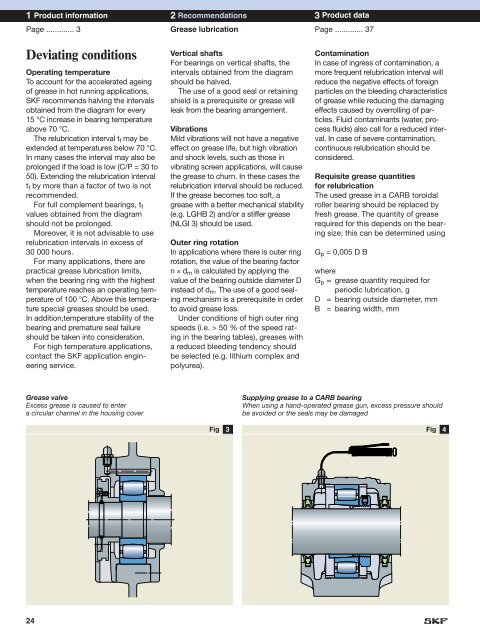

Grease valve<br />

Excess grease is caused to enter<br />

a circular channel in the housing cover<br />

Supplying grease to a CARB bearing<br />

When using a hand-operated grease gun, excess pressure should<br />

be avoided or the seals may be damaged<br />

Fig 3<br />

Fig 4<br />

24