CARB® toroidal roller bearings â a revolutionary ... - Acorn Bearings

CARB® toroidal roller bearings â a revolutionary ... - Acorn Bearings

CARB® toroidal roller bearings â a revolutionary ... - Acorn Bearings

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1 Product information 2 Recommendations 3 Product data<br />

Page ............. 3 Page ............. 12 Bearing data<br />

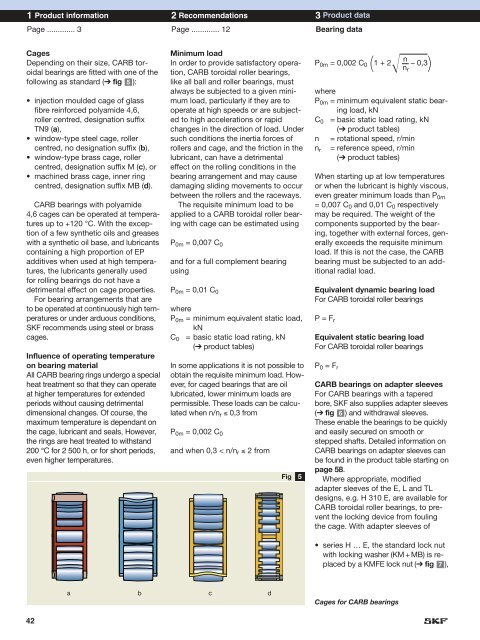

Cages<br />

Depending on their size, CARB <strong>toroidal</strong><br />

<strong>bearings</strong> are fitted with one of the<br />

following as standard (➔ fig 5 ):<br />

• injection moulded cage of glass<br />

fibre reinforced polyamide 4,6,<br />

<strong>roller</strong> centred, designation suffix<br />

TN9 (a),<br />

• window-type steel cage, <strong>roller</strong><br />

centred, no designation suffix (b),<br />

• window-type brass cage, <strong>roller</strong><br />

centred, designation suffix M (c), or<br />

• machined brass cage, inner ring<br />

centred, designation suffix MB (d).<br />

CARB <strong>bearings</strong> with polyamide<br />

4,6 cages can be operated at temperatures<br />

up to +120 °C. With the exception<br />

of a few synthetic oils and greases<br />

with a synthetic oil base, and lubricants<br />

containing a high proportion of EP<br />

additives when used at high temperatures,<br />

the lubricants generally used<br />

for rolling <strong>bearings</strong> do not have a<br />

detrimental effect on cage properties.<br />

For bearing arrangements that are<br />

to be operated at continuously high temperatures<br />

or under arduous conditions,<br />

SKF recommends using steel or brass<br />

cages.<br />

Influence of operating temperature<br />

on bearing material<br />

All CARB bearing rings undergo a special<br />

heat treatment so that they can operate<br />

at higher temperatures for extended<br />

periods without causing detrimental<br />

dimensional changes. Of course, the<br />

maximum temperature is dependant on<br />

the cage, lubricant and seals, However,<br />

the rings are heat treated to withstand<br />

200 °C for 2 500 h, or for short periods,<br />

even higher temperatures.<br />

Minimum load<br />

In order to provide satisfactory operation,<br />

CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong>,<br />

like all ball and <strong>roller</strong> <strong>bearings</strong>, must<br />

always be subjected to a given minimum<br />

load, particularly if they are to<br />

operate at high speeds or are subjected<br />

to high accelerations or rapid<br />

changes in the direction of load. Under<br />

such conditions the inertia forces of<br />

<strong>roller</strong>s and cage, and the friction in the<br />

lubricant, can have a detrimental<br />

effect on the rolling conditions in the<br />

bearing arrangement and may cause<br />

damaging sliding movements to occur<br />

between the <strong>roller</strong>s and the raceways.<br />

The requisite minimum load to be<br />

applied to a CARB <strong>toroidal</strong> <strong>roller</strong> bearing<br />

with cage can be estimated using<br />

P 0m = 0,007 C 0<br />

and for a full complement bearing<br />

using<br />

P 0m = 0,01 C 0<br />

where<br />

P 0m = minimum equivalent static load,<br />

kN<br />

C 0 = basic static load rating, kN<br />

(➔ product tables)<br />

In some applications it is not possible to<br />

obtain the requisite minimum load. However,<br />

for caged <strong>bearings</strong> that are oil<br />

lubricated, lower minimum loads are<br />

permissible. These loads can be calculated<br />

when n/n r ≤ 0,3 from<br />

P 0m = 0,002 C 0<br />

and when 0,3 < n/n r ≤ 2 from<br />

Fig<br />

5<br />

P<br />

n<br />

0m = 0,002 C 0 ( 1 + 2 n – 0,3 r<br />

)<br />

where<br />

P 0m = minimum equivalent static bearing<br />

load, kN<br />

C 0 = basic static load rating, kN<br />

(➔ product tables)<br />

n = rotational speed, r/min<br />

n r = reference speed, r/min<br />

(➔ product tables)<br />

When starting up at low temperatures<br />

or when the lubricant is highly viscous,<br />

even greater minimum loads than P 0m<br />

= 0,007 C 0 and 0,01 C 0 respectively<br />

may be required. The weight of the<br />

components supported by the bearing,<br />

together with external forces, generally<br />

exceeds the requisite minimum<br />

load. If this is not the case, the CARB<br />

bearing must be subjected to an additional<br />

radial load.<br />

Equivalent dynamic bearing load<br />

For CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong><br />

P = F r<br />

Equivalent static bearing load<br />

For CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong><br />

P 0 = F r<br />

CARB <strong>bearings</strong> on adapter sleeves<br />

For CARB <strong>bearings</strong> with a tapered<br />

bore, SKF also supplies adapter sleeves<br />

(➔ fig 6 ) and withdrawal sleeves.<br />

These enable the <strong>bearings</strong> to be quickly<br />

and easily secured on smooth or<br />

stepped shafts. Detailed information on<br />

CARB <strong>bearings</strong> on adapter sleeves can<br />

be found in the product table starting on<br />

page 58.<br />

Where appropriate, modified<br />

adapter sleeves of the E, L and TL<br />

designs, e.g. H 310 E, are available for<br />

CARB <strong>toroidal</strong> <strong>roller</strong> <strong>bearings</strong>, to prevent<br />

the locking device from fouling<br />

the cage. With adapter sleeves of<br />

• series H … E, the standard lock nut<br />

with locking washer (KM + MB) is replaced<br />

by a KMFE lock nut (➔ fig 7 ),<br />

a b c d<br />

Cages for CARB <strong>bearings</strong><br />

42