The Zebra Cell Concept - ISC Konstanz

The Zebra Cell Concept - ISC Konstanz

The Zebra Cell Concept - ISC Konstanz

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

optimized technique in the fabrication process”, Energy Procedia<br />

8, 2011, p. 421<br />

[6]: L. J. Koduvelikulathu, V. M. Mihailetchi, A. Edler, C.<br />

Comparotto, A. Halm, R. Kopecek, K. Peter, “Metallization and<br />

firing process impact on the V OC – a simulation study”,<br />

proceedings of this conference<br />

[7]: K. Mangersnes “Back-contacted back-junction silicon solar<br />

cells”, PhD. thesis, University of Oslo, October 2010<br />

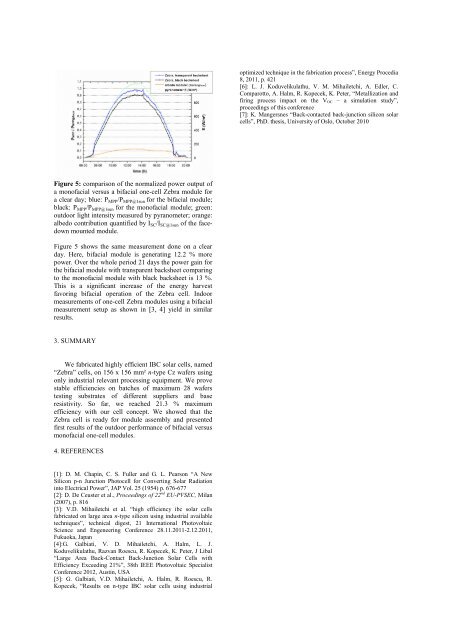

Figure 5: comparison of the normalized power output of<br />

a monofacial versus a bifacial one-cell <strong>Zebra</strong> module for<br />

a clear day; blue: P MPP /P MPP@1sun for the bifacial module;<br />

black: P MPP /P MPP@1sun for the monofacial module; green:<br />

outdoor light intensity measured by pyranometer; orange:<br />

albedo contribution quantified by I SC /I SC@1sun of the facedown<br />

mounted module.<br />

Figure 5 shows the same measurement done on a clear<br />

day. Here, bifacial module is generating 12.2 % more<br />

power. Over the whole period 21 days the power gain for<br />

the bifacial module with transparent backsheet comparing<br />

to the monofacial module with black backsheet is 13 %.<br />

This is a significant increase of the energy harvest<br />

favoring bifacial operation of the <strong>Zebra</strong> cell. Indoor<br />

measurements of one-cell <strong>Zebra</strong> modules using a bifacial<br />

measurement setup as shown in [3, 4] yield in similar<br />

results.<br />

3. SUMMARY<br />

We fabricated highly efficient IBC solar cells, named<br />

“<strong>Zebra</strong>” cells, on 156 x 156 mm² n-type Cz wafers using<br />

only industrial relevant processing equipment. We prove<br />

stable efficiencies on batches of maximum 28 wafers<br />

testing substrates of different suppliers and base<br />

resistivity. So far, we reached 21.3 % maximum<br />

efficiency with our cell concept. We showed that the<br />

<strong>Zebra</strong> cell is ready for module assembly and presented<br />

first results of the outdoor performance of bifacial versus<br />

monofacial one-cell modules.<br />

4. REFERENCES<br />

[1]: D. M. Chapin, C. S. Fuller and G. L. Pearson “A New<br />

Silicon p-n Junction Photocell for Converting Solar Radiation<br />

into Electrical Power”, JAP Vol. 25 (1954) p. 676-677<br />

[2]: D. De Ceuster et al., Proceedings of 22 nd EU-PVSEC, Milan<br />

(2007), p. 816<br />

[3]: V.D. Mihailetchi et al. “high efficiency ibc solar cells<br />

fabricated on large area n-type silicon using industrial available<br />

techniques”, technical digest, 21 International Photovoltaic<br />

Science and Engeneering Conference 28.11.2011-2.12.2011,<br />

Fukuoka, Japan<br />

[4]:G. Galbiati, V. D. Mihailetchi, A. Halm, L. J.<br />

Koduvelikulathu, Razvan Roescu, R. Kopecek, K. Peter, J Libal<br />

“Large Area Back-Contact Back-Junction Solar <strong>Cell</strong>s with<br />

Efficiency Exceeding 21%”, 38th IEEE Photovoltaic Specialist<br />

Conference 2012, Austin, USA<br />

[5]: G. Galbiati, V.D. Mihailetchi, A. Halm, R. Roescu, R.<br />

Kopecek, “Results on n-type IBC solar cells using industrial