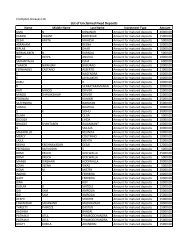

2007-2008 - Cgglobal.com

2007-2008 - Cgglobal.com

2007-2008 - Cgglobal.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

In <strong>2007</strong>-08, Six Sigma was extended to<br />

suppliers to improve and sustain product<br />

quality from the supplier<br />

Six Sigma at Crompton Greaves<br />

Crompton Greaves has defined Six Sigma as, “A<br />

vigorous, scientific, data driven, breakthrough<br />

methodology focused on product quality<br />

improvement as perceived by customers.” The<br />

objective of the Six Sigma drive is to achieve<br />

major quality improvements and, in doing so,<br />

bring about a cultural change from judgmental<br />

to data-based decisions.<br />

The journey started in June 2002 by creating<br />

a core <strong>com</strong>mittee of all Vice Presidents of the<br />

Company, headed by the Managing Director.<br />

Business unit heads were nominated as<br />

Champions, with the role to drive Six Sigma in<br />

their Divisions. 22 best employees of different<br />

Divisions were designated as Black Belts and<br />

were trained for Six Sigma methodology by an<br />

international expert.<br />

The first set of Six Sigma projects have<br />

been directed at elimination of defects<br />

in product, as reported by customers.<br />

Initially, 10 projects were selected involving<br />

transformers, condenser bushings, vacuum<br />

interrupters, motors and fans. In the first year<br />

the improvement was from a base level of 2.3σ<br />

to 4.8σ.<br />

The drive was expanded to all Divisions<br />

by training 25 more employees for the Black<br />

Belt course. By March 2006, the Company<br />

<strong>com</strong>pleted 130 Black Belt projects across a wide<br />

range of products from all its Divisions. In 2006-<br />

07, the Six Sigma initiative was restructured to<br />

speed up the drive to achieve the goal of all<br />

products being of Six Sigma quality.<br />

A new three-step review system was<br />

formalised to monitor the status of Six Sigma<br />

projects. This involved fortnightly review of each<br />

project by the Champions; monthly reviews<br />

by the SBU heads; and quarterly reviews by the<br />

core <strong>com</strong>mittee and the Managing Director. In<br />

addition, the Managing Director visits one of<br />

the Divisions every month to review progress of<br />

the Six Sigma initiatives.<br />

A web based portal has been developed in<br />

the marketing and support services function to<br />

collect data on product performance. Using this<br />

data, 78 Black Belt projects were selected and<br />

<strong>com</strong>pleted in 2006-07.<br />

In <strong>2007</strong>-08, Six Sigma was extended to the<br />

suppliers. To improve and sustain product<br />

quality from the suppliers, a Company-wide<br />

activity called Supplier Quality Policy (SQP) was<br />

begun. SQP is a process for supplier selection<br />

and assessment based on technical parameters.<br />

In the first phase, assessments have been<br />

<strong>com</strong>pleted for 425 critical suppliers across all<br />

Divisions; and wherever warranted, necessary<br />

corrective actions have been taken.<br />

During the year, the Company also undertook<br />

the following initiatives:<br />

$ KNOWLEDGE MANAGEMENT FOR SIX<br />

SIGMA (KMSS) This software was implemented<br />

to monitor the entire cycle of a Six Sigma<br />

Project. It stores data, analysis and results of<br />

projects.<br />

$ TRAINING Crompton Greaves has started its<br />

own Six Sigma Training Centre. During <strong>2007</strong>-08,<br />

20 candidates have been trained as Black Belts<br />

and 84 as Green Belts.<br />

$ ACHIEVEMENTS 20 Black Belts with their<br />

Divisional teams <strong>com</strong>pleted 92 projects in<br />

<strong>2007</strong>-08. Teams used the Six Sigma method to<br />

obtain Five-Star BEE Rating for 36W Power Lux<br />

fluorescent tube light — the first in India to<br />

achieve this.<br />

Improvements in product quality arising out<br />

of Six Sigma initiatives have been recognized<br />

and appreciated by many key customers —<br />

industrial as well as domestic consumers.<br />

For <strong>2008</strong>-09, the team has planned 110 Six<br />

Sigma Black Belt projects, and 650 Green Belt<br />

projects.<br />

VACUUM INTERRUPTERS UNDERGOING VACUUM BRAZING PROCESS AS A PART OF THE SIX SIGMA DRIVE FOR<br />

ENHANCEMENT OF PRODUCT QUALITY<br />

22 ANNUAL REPORT <strong>2007</strong>–<strong>2008</strong> CROMPTON GREAVES LIMITED