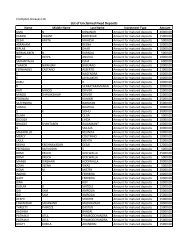

2007-2008 - Cgglobal.com

2007-2008 - Cgglobal.com

2007-2008 - Cgglobal.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

EXECUTIVES OF CG AND MICROSOL UNDERTAKING<br />

TESTING ON THE KANJUR 33KV RTU PROJECT<br />

$ 12 kV, 18.4 kA, vertical isolation vacuum<br />

circuit breaker<br />

$ 12 kV, 26.3 kA, 1600 A Univac porcelain clad<br />

vacuum circuit breaker<br />

$ 12 kV, 20 kA, (next generation) Univac<br />

vacuum circuit breaker<br />

$ Range extension of 24 kV, 25 kA vacuum<br />

interrupter<br />

$ Range extension of 72.5 kV current<br />

transformer and inductive voltage<br />

transformer for 2400 M altitude<br />

$ 69 kV circuit breaker made to ANSI standards<br />

$ 24 kV capacitor voltage transformer with 1.9<br />

voltage factor<br />

$ 245 kV reliable spring spring mechanism in<br />

circuit breaker<br />

$ 242 kV reliable spring mechanism in circuit<br />

breaker<br />

$ 66 kV spring spring circuit breaker with<br />

higher creepage<br />

$ 420 kV gas circuit breaker with higher altitude<br />

$ 36 kV, 25 kA, 200 kV basic insulation level<br />

panel for circuit breaker<br />

$ 145 kV, 4000 A gas circuit breaker<br />

$ 69 kV & 138 kV bushings as per ANSI<br />

standards<br />

R&D FROM POWER SYSTEMS<br />

(OVERSEAS LOCATIONS)<br />

The Company has also benefited from the<br />

research work undertaken at Power Systems<br />

(overseas locations) as under :<br />

$ Development of high temperature super<br />

conducting transformer<br />

$ Implementation of counter-sheilding<br />

winding, and standardized core clam<br />

construction<br />

$ Introduction of silicon fluid production<br />

capabilities in conjunction with NOMEX<br />

materials to serve the need for high<br />

temperature transformers<br />

$ Development of submersible control box for<br />

underground switches<br />

$ Introduction of new protection system for<br />

self-protecting transformers<br />

$ IEC 61850 interface for Xcell product range<br />

$ Development of 145 kV <strong>com</strong>pact gas<br />

insulated switchgear as per latest standard<br />

INDUSTRIAL SYSTEMS<br />

$ Traction motors for 25 kV AC mainline<br />

$ Traction alternator type C1014TA for railways<br />

$ 560 frame industrial duty DC motor<br />

$ Range extension of HT motors above 1500<br />

kW,11 kV range<br />

$ 0.25 HP to 1 HP series of general purpose<br />

motors<br />

$ 0.25 HP to 1 HP motor for wet grinder<br />

$ 0.25 HP motor for cooler kit<br />

$ 0.25 HP motor for temple drum<br />

$ 0.5 HP motor for blowers<br />

$ 400 frame SR 4P/8P slipring motor<br />

$ 500 kVA, 750 V alternators for railways<br />

$ 160 and 200 frame aluminum body<br />

alternators<br />

$ Lamyoke mill duty motors in 808, 810 and<br />

816 frame sizes<br />

CONSUMER PRODUCTS<br />

$ High flow 18” pedestal fan<br />

$ Ceiling fans - Scorpio 1200mm, New Whirl<br />

Wind 1200mm, Silent Breeze 1200mm, Cool<br />

Breeze 900mm, Nebula 1200mm<br />

$ 380mm and 450mm Blast Air exhaust fan<br />

$ Appliances – new models of irons, geysers<br />

and juicer mixer grinders<br />

$ 600 VA and 800 VA Home UPS<br />

$ 0.5 HP, 0.75 HP and 1 HP 3” borewell<br />

submersible pumps<br />

$ 4” borewell submersible pumps (Popular<br />

series and Classic series)<br />

$ 45 HP to 75 HP 8” borewell submersible<br />

pumps with high water discharge<br />

$ LED RGB flood light with controller<br />

$ Energy efficient Slim Gold luminaires for<br />

domestic Interiors<br />

$ Cost effective 70 W deepdrawn streetlight<br />

$ Industrial & Floodlights - integral increased<br />

safety luminaire for better light distribution<br />

$ LED updown lighter 21 W for illuminating<br />

corridors<br />

New Processes Implemented/<br />

Processes Improved<br />

$ Stator coil vulcanization process for<br />

alternators used in diesel lo<strong>com</strong>otives<br />

$ Improvement of 12kV mechanism of M2 class<br />

of vacuum circuit breaker<br />

$ Manufacturing of Fastech tools for punching<br />

laminations<br />

$ Modification of 200 ton and 400 ton clutch<br />

assembly<br />

$ Improvement in winding process for FHP<br />

motors<br />

Technology Competence Achieved<br />

$ Development of nano coating, for various<br />

outdoor applications like transformers, for<br />

improved paint life<br />

$ Substation automation technology at<br />

transmission and distribution level<br />

42 ANNUAL REPORT <strong>2007</strong>–<strong>2008</strong> CROMPTON GREAVES LIMITED