00 Contents - Hilti Svenska AB

00 Contents - Hilti Svenska AB

00 Contents - Hilti Svenska AB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Hilti</strong> X-CR / X-BT stainless steel<br />

fastener (CR5<strong>00</strong> material)<br />

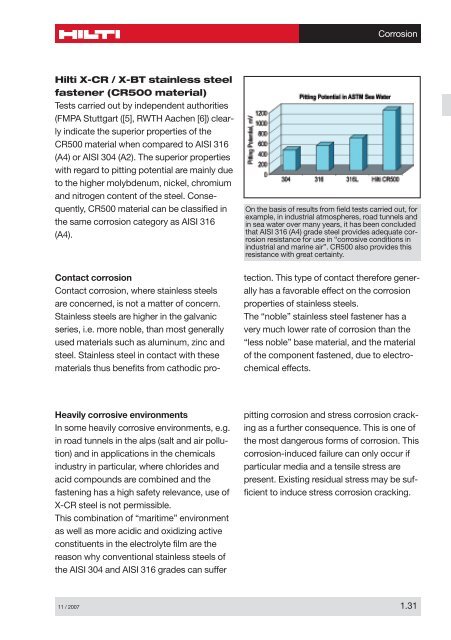

Tests carried out by independent authorities<br />

(FMPA Stuttgart ([5], RWTH Aachen [6]) clearly<br />

indicate the superior properties of the<br />

CR5<strong>00</strong> material when compared to AISI 316<br />

(A4) or AISI 304 (A2). The superior properties<br />

with regard to pitting potential are mainly due<br />

to the higher molybdenum, nickel, chromium<br />

and nitrogen content of the steel. Consequently,<br />

CR5<strong>00</strong> material can be classified in<br />

the same corrosion category as AISI 316<br />

(A4).<br />

Contact corrosion<br />

Contact corrosion, where stainless steels<br />

are concerned, is not a matter of concern.<br />

Stainless steels are higher in the galvanic<br />

series, i.e. more noble, than most generally<br />

used materials such as aluminum, zinc and<br />

steel. Stainless steel in contact with these<br />

materials thus benefits from cathodic pro-<br />

Heavily corrosive environments<br />

In some heavily corrosive environments, e.g.<br />

in road tunnels in the alps (salt and air pollution)<br />

and in applications in the chemicals<br />

industry in particular, where chlorides and<br />

acid compounds are combined and the<br />

fastening has a high safety relevance, use of<br />

X-CR steel is not permissible.<br />

This combination of “maritime” environment<br />

as well as more acidic and oxidizing active<br />

constituents in the electrolyte film are the<br />

reason why conventional stainless steels of<br />

the AISI 304 and AISI 316 grades can suffer<br />

Corrosion<br />

On the basis of results from field tests carried out, for<br />

example, in industrial atmospheres, road tunnels and<br />

in sea water over many years, it has been concluded<br />

that AISI 316 (A4) grade steel provides adequate corrosion<br />

resistance for use in “corrosive conditions in<br />

industrial and marine air”. CR5<strong>00</strong> also provides this<br />

resistance with great certainty.<br />

tection. This type of contact therefore generally<br />

has a favorable effect on the corrosion<br />

properties of stainless steels.<br />

The “noble” stainless steel fastener has a<br />

very much lower rate of corrosion than the<br />

“less noble” base material, and the material<br />

of the component fastened, due to electrochemical<br />

effects.<br />

pitting corrosion and stress corrosion cracking<br />

as a further consequence. This is one of<br />

the most dangerous forms of corrosion. This<br />

corrosion-induced failure can only occur if<br />

particular media and a tensile stress are<br />

present. Existing residual stress may be sufficient<br />

to induce stress corrosion cracking.<br />

11 / 2<strong>00</strong>7 1.31