Gladiator Admittance Manual - Hawk Measurement

Gladiator Admittance Manual - Hawk Measurement

Gladiator Admittance Manual - Hawk Measurement

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INSTRUCTION MANUAL<br />

<strong>Admittance</strong> Smart Switch Series<br />

- An all-round point level switch -<br />

A higher level of performance

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

INTRODUCTION<br />

CONTENTS<br />

PROPRIETARY NOTICE<br />

The information contained in this publication<br />

is derived in part from proprietary and patent<br />

data. This information has been prepared for<br />

the express purpose of assisting operating and<br />

maintenance personnel in the efficient use of<br />

the instrument described herein. Publication of<br />

this information does not convey any rights to<br />

use or reproduce it, or to use for any purpose<br />

other than in connection with the installation,<br />

operation and maintenance of the equipment<br />

described herein.<br />

WARNING<br />

This instrument contains electronic components<br />

that are susceptible to damage by static<br />

electricity. Proper handling procedures must<br />

be observed during the removal, installation, or<br />

handling of internal circuit boards or devices:<br />

Handling Procedure:<br />

1. Power to unit must be removed prior to<br />

commencement of any work.<br />

2. Personnel must be grounded, via wrist strap<br />

or other safe, suitable means, before any<br />

printed circuit board or other internal devices<br />

are installed, removed or adjusted.<br />

3. Printed circuit boards must be transported<br />

in a conductive bag or other conductive<br />

container. Boards must not be removed from<br />

protective container until the immediate time<br />

of installation. Removed boards must be<br />

placed immediately in a protective container<br />

for transport, storage, or return to factory.<br />

Comments:<br />

This instrument is not unique in its content<br />

of ESD (electrostatic discharge) sensitive<br />

components. Most modern electronic designs<br />

contain components that utilize metal oxide<br />

technology (NMOS, CMOS, etc.). Experience<br />

has proven that even small amounts of static<br />

electricity can damage or destroy these<br />

devices. Damaged components, even though<br />

they appear to function properly, exhibit early<br />

failure.<br />

<br />

General Description<br />

Features 2<br />

Typical Applications 3<br />

Dimensions 5<br />

Mounting 9<br />

Flexile Cable Probe Adjustment 11<br />

Wiring<br />

- Smart Probe 2<br />

- Remote Probe 3<br />

- Relay Functions 4<br />

- Multidrop Connections 15<br />

- <strong>Hawk</strong>Link GSM 6<br />

- Test Terminal 8<br />

Smart Probe Setup Procedure 19<br />

Remote Setup Procedure 22<br />

Remote Software Menu 24<br />

- Software Tree 25<br />

- QuickSet 26<br />

- Advanced Menu 27<br />

- Diagnostic Displays 30<br />

Multidrop Communication 32<br />

Remote Communication 33<br />

Troubleshooting 34<br />

Part Numbering 35<br />

Specifications 37<br />

Dielectric Constant 38<br />

CE Declaration 39<br />

Contact Information (back cover)<br />

Sultan 234 Series

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

GENERAL DESCRIPTION<br />

FEATURES<br />

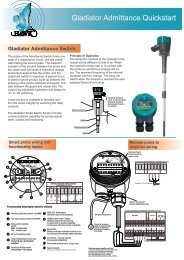

The <strong>Gladiator</strong> Smart <strong>Admittance</strong> Switch<br />

is a third generation, state-of-the-art<br />

level probe, designed to operate in<br />

tough industrial environments. The<br />

probe of the <strong>Admittance</strong> Switch forms<br />

one plate of a capacitance circuit, with<br />

the vessel wall making the second plate.<br />

The dielectric constant of the product<br />

between the probe and the vessel wall<br />

will cause a capacitive change as the<br />

level approaches the probe, and the<br />

output will switch in response. A special<br />

circuit is used to ignore product build-up<br />

between the sensing probe (active element)<br />

and guard, and also between the<br />

guard and vessel wall. The output has<br />

adjustable hysteresis and delays for ‘on’<br />

or ‘off’ switching.<br />

A test function is available to remotely<br />

confirm the probe integrity by switching<br />

the relay contacts.<br />

The <strong>Gladiator</strong> Smart Switch Series<br />

includes communications flatten roof capability for<br />

remote adjustment, control and monitoring.<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Excellent immunity to product build-up<br />

Excellent temperature stability - no<br />

false trips<br />

Simple ‘1-minute’ set-up<br />

Relay outputs: Smart probe (1)<br />

Remote (2)<br />

Remote test function<br />

Adjustable ON and OFF delays (0-20 sec)<br />

Smart communication options:<br />

Gos<strong>Hawk</strong>, Modbus, HART, Profibus<br />

DP, DeviceNet<br />

Remote GSM Connection option<br />

Remote amplifier to probe separation<br />

up to 500 m (1640 ft)<br />

Bright visual status indication on<br />

Probe<br />

LCD Diagnostic for Remote version<br />

Independant housing alignment after<br />

mounting thread locked<br />

Non contact switching possible with<br />

many materials<br />

Principle of Operation<br />

The dielectric constant of the material<br />

in the vessel will be different to that of<br />

air. When the material comes near or in<br />

contact with the probe an admittance<br />

change will occur. The resonant frequency<br />

of the internal oscillator will then<br />

change. The relay will switch when the<br />

frequency reaches the user selected<br />

Switch Point value.<br />

Material build up<br />

Guard<br />

Probe Insulation<br />

> 100mm<br />

Ground the housing to<br />

vessel, if vessel is metallic.<br />

Ground the housing to<br />

plant ground, if vessel is<br />

non-metallic.<br />

Probe

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

TYPICAL APPLICATIONS<br />

High level switch in plastic pellet silo<br />

High level switch in grain application<br />

Cyclone bin level switch<br />

<br />

Sultan 234 Series

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

TYPICAL APPLICATIONS<br />

Continuous filling with build-up<br />

on probe<br />

High and low level switch in a hopper<br />

High level<br />

(top mounted)<br />

Low level<br />

(top mounted)<br />

Probe<br />

If impact from falling material is<br />

expected, mount a protection plate<br />

above the probe to ensure no<br />

physical damage can occur to the<br />

probe in normal operation. If it is not<br />

possible to do this or to move the<br />

probe to an alternative position, use<br />

a microwave switch.<br />

Low level<br />

(side mounted)<br />

See www.hawkmeasure.com for<br />

further information on Microwave<br />

switches and other level products.

10mm (0.4<br />

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

DIMENSIONS<br />

REMOTE AMPLIFIER ENCLOSURE<br />

192mm (7.6”)<br />

106mm (4.2”)<br />

76.5 (3”)<br />

DIN Rail Mounting<br />

(clips included)<br />

Front Side Back<br />

192mm (7.6”)<br />

145mm (5.7”)<br />

10.5mm (0.4”)<br />

160mm (6.3”)<br />

106mm (4.2”)<br />

160mm (6.3”)<br />

142mm (5.6”)<br />

38mm (1.5”)<br />

83mm (3.3”)<br />

3 x 20mm (0.7”), 1x16mm (0.6”)<br />

Knock outs<br />

166mm (6.5”)<br />

61mm (2.4”) 8mm (0.3”)<br />

151mm (5.9”)<br />

166mm (6.5”)<br />

10mm (0.4”)<br />

OPTIONAL FLANGE<br />

HIGH TEMPERATURE<br />

EXTENSIONS (

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

DIMENSIONS<br />

REMOTE PROBE<br />

SMART PROBE<br />

Window for<br />

viewing status<br />

LEDs<br />

85mm (3.3”)<br />

Window for<br />

viewing status<br />

LEDs<br />

85mm (3.3”)<br />

M20 cable gland<br />

or 3/4” NPT adaptor<br />

50mm (2”)<br />

90mm (3.5”)<br />

2 x M20<br />

cable glands<br />

or 3/4” NPT adaptors<br />

50mm (2”)<br />

90mm (3.5”)<br />

Ground 100mm (3.9”)<br />

Mounting<br />

thread<br />

Ground 100mm (3.9”)<br />

Optional Flange<br />

Active (mm)<br />

Guard 150mm (5.9”)<br />

probe length<br />

Active (mm)<br />

Guard 150mm (5.9”)<br />

probe length<br />

16mm (0.6”)<br />

16mm (0.6”)<br />

Probe Length (mm, inch) Active + Guard + Ground<br />

P30 (300mm,11.8”)<br />

P50 (500mm, 19.7”)<br />

P100 (1000mm, 39.4”)<br />

= 50mm, 2”<br />

= 250mm, 9.8”<br />

= 750mm, 29.5”<br />

+<br />

+<br />

+<br />

250mm, 9.8”<br />

250mm, 9.8”<br />

250mm, 9.8”

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

DIMENSIONS<br />

FLEXIBLE CABLE PROBE<br />

M20 x 1.5<br />

or 3/4” NPT adaptor<br />

115mm<br />

Mounting Thread<br />

(1.5” NPT or BSP only)<br />

100mm (3.9”)<br />

Ground<br />

SS 316<br />

Teflon<br />

150mm (5.9”)<br />

Guard<br />

SS 316<br />

215mm (8.4”)<br />

Teflon<br />

83mm (3.3”)<br />

Cable Length<br />

Ø 8mm (0.3”)<br />

SS 316<br />

Rope<br />

Active<br />

83mm (3.3”)<br />

Removable grub screws<br />

for cable adjustment<br />

SS 316<br />

250mm (9.8”)<br />

Weight<br />

Ø 40mm (1.6”)<br />

Cable Length (mm, inch) Active + Guard + Ground (Rope Length)<br />

C100 (1000mm, 39.3”) = 750mm, 29.5” + 250mm, 9.8” 451mm, 17.8”<br />

C200 (2000mm, 78.7”) = 1750mm, 68.9” + 250mm, 9.8” 1451mm, 57.1”<br />

C300 (3000mm, 118.1”) = 2750mm, 108.3” + 250mm, 9.8” 2451mm, 96.5”<br />

<br />

Sultan 234 Series

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

DIMENSIONS<br />

HIGH TEMPERATURE PROBES<br />

HIGH TEMP PROBE (

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

MOUNTING<br />

Probes can be mounted from the top,<br />

side and bottom.<br />

Points to consider when mounting:<br />

A. Material Infeed Clearance<br />

Install the probe away from the infeed to<br />

minimize the influence of build-up and<br />

impact forces, and to avoid false triggering<br />

from product flow.<br />

B. Wall Clearance<br />

Install the probe far enough away from<br />

the wall to prevent the probe or cable<br />

from coming into contact with the vessel<br />

wall. Avoid creating a confined area<br />

where material could build-up over time.<br />

See note <br />

C. Nozzle Clearance<br />

Where possible, ensure the probe guard<br />

has at least 100mm clearance from the<br />

nozzle.<br />

Correct Mounting in a Nozzle<br />

Recommended 50mm (2”)<br />

min. 100mm (4”)<br />

D. Top mounting<br />

When top mounting, ensure adequate<br />

clearance is provided between probe<br />

and wall. Avoid creating a confined area<br />

where material could build-up over time.<br />

In the case of cable probe versions,<br />

ensure enough clearance is provided<br />

between the probe and wall to allow for<br />

build-up of material occurring on the<br />

wall.<br />

See note <br />

E. Side mounting<br />

It is highly recommended to install any<br />

side mounted probe at a downward<br />

angle of 30-45º. Use a protection plate<br />

for side mounting where the probe may<br />

be subject to impact strain or collapsing<br />

material.<br />

F. Bottom mounting<br />

Bottom mounting is not recommended.<br />

Only mount from the bottom if no buildup<br />

of material occurs. If low level mounting<br />

is required, suitable options are<br />

shown in the diagram on page 10.<br />

CORRECT MOUNTING NOTES:<br />

(Refer to picture on page 10)<br />

Select correct probe for high temperature<br />

applications.<br />

Allow adequate air flow for cooling extensions<br />

dissipate heat.<br />

INCORRECT MOUNTING NOTES:<br />

Incorrect mounting because the<br />

probe is too close to the wall or roof.<br />

Positioning too close to a wall or roof<br />

will limit probe sensitivity. Material may<br />

build-up between the probe and the<br />

vessel.<br />

Incorrect mounting because the<br />

probe’s guard is mounted inside the<br />

nozzle. The correct arrangement is for<br />

the guard to protrude out of the mounting<br />

pipe at least 100mm. Product will buildup<br />

in the nozzle.<br />

<br />

Sultan 234 Series

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

MOUNTING<br />

Correct<br />

1<br />

2<br />

Incorrect<br />

If necessary mount a<br />

protection plate to<br />

prevent direct impact<br />

or to prevent pull<br />

from down feed.<br />

Possible product<br />

build-up<br />

Correct Correct<br />

Flexible cable<br />

1<br />

Correct<br />

Incorrect<br />

3<br />

Incorrect<br />

2<br />

Possible<br />

product<br />

build-up<br />

Correct<br />

30-45º<br />

Correct<br />

Housing can be rotated<br />

within 200º after the<br />

mounting thread is<br />

tightened, to allow cable<br />

entries to face downwards<br />

or allow optimal cable<br />

clearance.<br />

Correct<br />

Incorrect<br />

3<br />

Correct (non-preferred<br />

low level mounting)<br />

10

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

FLEXIBLE CABLE PROBE ADJUSTMENT<br />

Notes for adjusting probe rope length<br />

The <strong>Gladiator</strong> rope type probe can be<br />

altered to any sensing length between<br />

approx. 750mm and 3m by cutting down<br />

from the standard sizes as required.<br />

If a new rope is to be used, the rope<br />

should be cut to:<br />

Cable probe length - 549mm = new wire rope<br />

length (total sensing length - 549mm)<br />

For example, within a 1000mm (1m) cable:<br />

1000 = [rope + 549]<br />

So rope length = 451mm<br />

465mm (18.3”)<br />

Remove or install the probe weight grub<br />

screws with a 4mm allen key.<br />

When fastening the rope, apply threadlocking<br />

adhesive onto grub screws<br />

before re-installation.<br />

83mm<br />

83mm<br />

Concealed<br />

rope<br />

Concealed<br />

rope<br />

Rope<br />

Cable Probe Length<br />

Removable SS grub screws<br />

for cable adjustment<br />

250mm (9.8”)<br />

Weight<br />

11<br />

Sultan 234 Series

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

WIRING<br />

SMART PROBE<br />

Remove Plug-In<br />

terminal block for<br />

easier wiring.<br />

SENSITIVITY<br />

HI FSH CAL TEST<br />

DELAY<br />

1 2 3 4 5 6 7 8 9 10<br />

!<br />

The AC earth/ground<br />

cable must be connected<br />

to the ground screw<br />

inside the housing when<br />

using AC power.<br />

Hole for securing of<br />

optional identification tag<br />

If only one cable is used for both<br />

power and output signal, then the<br />

second entry port must be<br />

plugged or blinded. Every Smart<br />

unit is supplied with two M20<br />

glands (or 3/4”NPT adaptors)<br />

mounted on the unit and one<br />

blind plug loose.<br />

1. NC<br />

Ground the housing to<br />

vessel, if vessel is metallic.<br />

Ground the housing to<br />

plant ground, if vessel is<br />

non-metallic.<br />

RELAY<br />

2. COM<br />

M4 grounding screw<br />

GLADIATOR SMART PROBE TERMINAL LAYOUT<br />

3. NO<br />

4. Test<br />

COMMS DC-IN AC-IN<br />

A<br />

5.<br />

B<br />

6.<br />

<br />

7.<br />

8.<br />

N<br />

9.<br />

L1<br />

10.<br />

RS 485 12-30VDC 80-265 VAC<br />

-<br />

12

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

WIRING<br />

REMOTE PROBE TO AMPLIFER<br />

Remove Plug-In<br />

terminal block for<br />

easier wiring.<br />

GLADIATOR REMOTE PROBE TERMINAL LAYOUT<br />

TRANSDUCER<br />

1 2 3 4 5 6 7 8 9 10<br />

1. 2. 3. 4. 5. 6. 7. 8. 9. 10.<br />

WHITE<br />

BLUE<br />

RED<br />

BLACK<br />

Terminals 1, 2, 3, 4, 9, 10 not used.<br />

Hole for securing of<br />

optional identification tag<br />

GLADIATOR REMOTE AMPLIFIER TERMINAL LAYOUT<br />

M4 grounding screw<br />

NOT USED<br />

Test in<br />

RELAY 1<br />

NC<br />

COM<br />

NO<br />

RELAY 2<br />

(FAIL SAFE)<br />

NC<br />

COM<br />

NO<br />

Ground the housing to<br />

vessel, if vessel is metallic.<br />

Ground the housing to<br />

plant ground, if vessel is<br />

non-metallic.<br />

CURRENT<br />

SENSOR<br />

COMMS<br />

DC-IN<br />

AC-IN<br />

Is<br />

+ –<br />

RED<br />

BLACK<br />

BLUE<br />

WHITE<br />

NOT USED<br />

B<br />

A<br />

– +<br />

N<br />

L1<br />

24 VDC 80-265 VAC<br />

Cable type between Amplifier and Probe<br />

4 conductor shielded twisted pair instrument cable.<br />

Conductor size dependent on cable length.<br />

BELDEN 3084A, DEKORON or equivalent.<br />

Max: BELDEN 3084A = 500m (1640 ft)<br />

Max: DEKORON IED183AA002 = 350m (1150 ft)<br />

13<br />

Sultan 234 Series

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

WIRING<br />

RELAY FUNCTIONS<br />

Level Switch Contact Action<br />

FailSafe Low<br />

FSL<br />

Relay Action<br />

FailSafe High<br />

FSH (default)<br />

Relay - for Smart Probe Version<br />

(Set Relay Action selection switch<br />

pages 19 and 20)<br />

State 1<br />

1 2 3<br />

NC COM NO<br />

1 2 3<br />

NC COM NO<br />

Relay Status<br />

Smart Probe<br />

terminal numbers<br />

Remote Amplifier<br />

terminal function<br />

labels<br />

Relay 1 - for Remote Version<br />

(Set ‘Relay Action’ parameter<br />

pages 23 and 26)<br />

RISING LEVEL<br />

(not detected)<br />

LED Status<br />

*It is possible for the <strong>Gladiator</strong> to<br />

switch state before actual product<br />

contact with the probe. State 2 represents<br />

product being detected by<br />

the probe, even if it occurs without<br />

contact.<br />

State 2<br />

CONTACT LEVEL<br />

(detected)<br />

1 2 3<br />

NC COM NO<br />

1 2 3<br />

NC COM NO<br />

State 1<br />

1 2 3<br />

NC COM NO<br />

1 2 3<br />

NC COM NO<br />

FALLING LEVEL<br />

(not detected)<br />

POWER FAILURE<br />

1 2 3<br />

NC COM NO<br />

1 2 3<br />

NC COM NO<br />

FailSafe Switch Contact Action<br />

Relay 2 - Remote version only.<br />

For Smart Probes the Test terminal<br />

can act as a solid state output<br />

with a similar function.<br />

(see page 18)<br />

POWER FAILURE<br />

OR<br />

INTERNAL FAILURE<br />

SYSTEM OPERATING<br />

NORMALLY<br />

NC COM NO NC COM NO<br />

NC COM NO<br />

NC COM NO<br />

14

1 2 3 4 5 6 7 8 9 10<br />

HI FSH<br />

ON<br />

HI FSH<br />

ON<br />

HI FSH<br />

ON<br />

1 2 1 2<br />

LO FSL OFF OFF<br />

CAL TEST<br />

ON<br />

1 2 1 2<br />

LO FSL OFF OFF<br />

CAL TEST<br />

ON<br />

1 2 1 2<br />

LO FSL OFF OFF<br />

CAL TEST<br />

ON<br />

1 2 3 4 5 6 7 8 9 10<br />

1 2 3 4 5 6 7 8 9 10<br />

HI FSH<br />

ON<br />

CAL TEST<br />

ON<br />

1 2 1 2<br />

LO FSL OFF OFF<br />

HI FSH<br />

ON<br />

HI FSH<br />

ON<br />

1 2 3 4 5 6 7 8 9 10<br />

CAL TEST<br />

ON<br />

1 2 1 2<br />

LO FSL OFF OFF<br />

CAL TEST<br />

ON<br />

1 2 1 2<br />

LO FSL OFF OFF<br />

1 2 3 4 5 6 7 8 9 10<br />

1 2 3 4 5 6 7 8 9 10<br />

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

WIRING<br />

MULTIDROP CONNECTIONS<br />

Multidrop Connection Using <strong>Hawk</strong>Link USB*<br />

SENSITIVITY<br />

DELAY<br />

SENSITIVITY<br />

DELAY<br />

A B Gnd<br />

A B Gnd<br />

A B Gnd<br />

White<br />

Blue<br />

Black<br />

<strong>Hawk</strong>link<br />

USB<br />

Laptop or PC Communications using<br />

<strong>Hawk</strong>link USB or RS485 / 232 converter<br />

with Gos<strong>Hawk</strong> software.<br />

Multidrop GSM/CDMA Connection*<br />

<strong>Hawk</strong>Link<br />

GSM/CDMA unit<br />

SENSITIVITY<br />

DELAY<br />

SENSITIVITY<br />

DELAY<br />

A B Gnd<br />

A B Gnd<br />

A B Gnd<br />

Laptop or PC Communications using<br />

PCMCIA card or wired (PSTN) modem<br />

and remote GSM/CDMA connection<br />

with Gos<strong>Hawk</strong> software.<br />

Multidrop Connection to PLC/DCS/SCADA*<br />

SENSITIVITY<br />

DELAY<br />

SENSITIVITY<br />

DELAY<br />

A B Gnd<br />

A B Gnd<br />

A B Gnd<br />

PLC / DCS / SCADA for Remote<br />

Communication with Modbus.<br />

* Wiring installation should follow<br />

RS-485 standards for layout and<br />

termination.<br />

15<br />

Sultan 234 Series

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

WIRING<br />

HAWKLINK GSM - CONNECTING POWER AND COMMS<br />

USING DC POWER DERIVED FROM AC POWERED REMOTE GLADIATOR<br />

GSM<br />

COMMS DC-IN<br />

AC-IN<br />

REMOTE AMP<br />

COMMS DC-IN<br />

AC-IN<br />

B<br />

A<br />

<br />

N<br />

L1<br />

B<br />

A<br />

<br />

N<br />

L1<br />

RS 485 12-30VDC 80-265VAC<br />

RS 485 12-30VDC 80-265VAC<br />

1 2 3 4 1 2 3 4<br />

!<br />

NOT POSSIBLE WITH<br />

GLADIATOR SMART<br />

PROBES. INTERNAL<br />

POWER SUPPLY HAS IN-<br />

SUFFICIENT CAPACITY.<br />

Existing AC power<br />

supply (GSM will be<br />

powered by DC<br />

generated by the <strong>Gladiator</strong>)<br />

Connect shield to<br />

DC “-” only at this end.<br />

USING DC POWER FROM REMOTE GLADIATOR<br />

GSM<br />

COMMS DC-IN<br />

AC-IN<br />

REMOTE AMP<br />

COMMS DC-IN<br />

AC-IN<br />

RS 485<br />

B<br />

A<br />

<br />

12-30VDC<br />

N<br />

L1<br />

80-265VAC<br />

RS 485<br />

B<br />

A<br />

<br />

12-30VDC<br />

N<br />

L1<br />

80-265VAC<br />

1 2 3 4<br />

1 2 3 4<br />

Existing DC power supply<br />

-<br />

<br />

!<br />

Connect shield to<br />

DC “-” only at this end.<br />

TERMINAL ORDER VARIES BETWEEN GLADIATOR SMART PROBE<br />

AND REMOTE AMPLIFIER. ENSURE CORRECT LAYOUT IS USED.<br />

USING DC POWER FROM GLADIATOR SMART PROBE<br />

GSM<br />

COMMS DC-IN<br />

AC-IN<br />

SMART PROBE<br />

COMMS<br />

DC-IN<br />

B<br />

A<br />

<br />

RS 485 12-30VDC<br />

1 2 3 4<br />

N<br />

L1<br />

80-265VAC<br />

-<br />

RS 485 12-30VDC<br />

A<br />

B<br />

<br />

2 1 4 3<br />

- Existing DC power supply<br />

<br />

Connect shield to<br />

DC “-” only at this end.<br />

16

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

WIRING<br />

HAWKLINK GSM - CONNECTING POWER AND COMMS<br />

USING SEPARATE AC OR DC POWER WITH SMART PROBE<br />

GSM<br />

COMMS DC-IN<br />

AC-IN<br />

SMART PROBE<br />

COMMS DC-IN AC-IN<br />

B<br />

A<br />

RS 485<br />

<br />

12-30VDC<br />

N<br />

L1<br />

80-265VAC<br />

Separate AC power supply<br />

for the GSM module<br />

or<br />

DC power<br />

supply<br />

1 2 2 1<br />

-<br />

RS 485 12-30VDC 80-265VAC<br />

A<br />

B<br />

<br />

N<br />

L1<br />

Existing AC<br />

or<br />

DC power<br />

supply<br />

*<br />

Connect shield to<br />

DC “-” only at this end.<br />

!<br />

TERMINAL ORDER VARIES BETWEEN GLADIATOR SMART PROBE<br />

AND REMOTE AMPLIFIER. ENSURE CORRECT LAYOUT IS USED.<br />

USING SEPARATE AC OR DC POWER WITH REMOTE GLADIATOR<br />

GSM<br />

COMMS DC-IN<br />

AC-IN<br />

REMOTE AMP<br />

COMMS DC-IN AC-IN<br />

B<br />

A<br />

RS 485<br />

<br />

12-30VDC<br />

N<br />

L1<br />

80-265VAC<br />

Separate AC power supply<br />

for the GSM module<br />

or<br />

DC power<br />

supply<br />

1 2 1 2<br />

B<br />

A<br />

RS 485<br />

-<br />

<br />

12-30VDC<br />

N<br />

L1<br />

80-265VAC<br />

Existing AC<br />

or<br />

DC power<br />

supply<br />

*<br />

Connect shield to<br />

DC “-” only at this end.<br />

*Ensure separate DC supplies have the same ground potential<br />

17<br />

Sultan 234 Series

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

WIRING<br />

TEST TERMINAL FUNCTION SELECTION<br />

TEST INPUT MODE<br />

Test switch must be in ‘TEST’ (ON) position on Smart Probe - function always enabled on Remote Amplifier.<br />

Test terminal acts as an input for remote testing of the instrument’s switching function.<br />

Used to check for malfunction of unit from a remote position, PLC, SCADA etc. For more<br />

information see page 21.<br />

TEST INPUT FROM PLC/SCADA/DCS DIGITAL OUTPUT<br />

Terminal Block<br />

PLC / SCADA / DCS Output<br />

Test<br />

OPERATOR CONTROLLED PRESS TO TEST<br />

!<br />

PLC/SCADA/DCS GROUND MUST<br />

CONNECT BACK TO GLADIATOR<br />

GROUND OR DC ‘-’ TERMINALS<br />

Terminal Block<br />

Externally provided<br />

test button<br />

Test<br />

!<br />

EXTERNAL PUSH BUTTON GROUND<br />

MUST CONNECT BACK TO GLADIATOR<br />

GROUND OR DC ‘-’ TERMINALS<br />

FAILSAFE OUTPUT MODE (Test switch must be in the ‘OFF’ position - default setting)<br />

Test terminal will provide an output which is able to switch an external failsafe relay or PLC/SCADA/DCS input.<br />

During normal system operation this terminal will internally switch a solid state output to ground (or DC ‘-’).<br />

If power fails or an internal system failure occurs, the terminal will act as an open circuit.<br />

To switch an external relay<br />

To a PLC input<br />

Test<br />

+12-24Vdc<br />

Coil rating<br />

500mW max<br />

or 50mA max<br />

Relay will turn on during<br />

normal system operation<br />

or off in failed or unpowered<br />

conditions.<br />

Test<br />

18<br />

max 50mA<br />

12-24Vdc<br />

Pull up<br />

PLC<br />

SCADA<br />

DCS Input<br />

Input will detect ‘0’ state during normal system<br />

operation, or ‘1’ in failed or unpowered conditions.

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

SETUP PROCEDURE<br />

SMART PROBE FUNCTIONALITY LAYOUT<br />

9<br />

3<br />

6<br />

12<br />

4<br />

SENSITIVITY<br />

signal<br />

HI FSH CAL TEST<br />

ON<br />

ON<br />

1 2 1 2<br />

LO FSL OFF OFF<br />

1 2 3 4 5 6 7 8 9 10<br />

DELAY<br />

1<br />

5<br />

2<br />

8<br />

10<br />

7<br />

11<br />

SMART PROBE REMOVABLE<br />

TERMINAL BLOCK<br />

RELAY COMMS DC-IN AC-IN<br />

1. NC<br />

2. COM<br />

3. NO<br />

4. Test<br />

A<br />

B<br />

+ -<br />

N<br />

L1<br />

5.<br />

6.<br />

7.<br />

8.<br />

9.<br />

10.<br />

RS 485<br />

12-30VDC<br />

80-265 VAC<br />

Functionality Description (bold is default)<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

Mounting Calibration switch CAL/OFF<br />

Test input function select TEST/OFF<br />

Relay action selection<br />

switch (see page 14)<br />

FSH - FailSafe High<br />

FSL - FailSafe Low<br />

HI / LO sensitivity switch<br />

Delay Potentiometer (0-20 sec)<br />

(Default 0 sec. at minimum<br />

position)<br />

Sensitivity Potentiometer<br />

Default 50% = 12 o’clock<br />

7<br />

8<br />

9<br />

10<br />

11<br />

RED LED: Relay status<br />

ON when relay coil is energised<br />

GREEN LED: Power / Status<br />

Blinks to indicate the functioning<br />

is correct and no media is detected.<br />

Continuously ON when media is detected.<br />

BLUE LED:<br />

Blinking indicates calibration function is on.<br />

Continuously ON indicates failed calibration.<br />

AC Ground - must be used for<br />

AC powered installations<br />

Removable terminal block - plug in type<br />

12 Signal indicator - Not used in <strong>Gladiator</strong> <strong>Admittance</strong> products<br />

19<br />

Sultan 234 Series

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

SETUP PROCEDURE<br />

SMART PROBE VERSION<br />

1. Mount the unit in its actual position.<br />

(See mounting procedure - pages 9-10)<br />

Make sure that external ground wire is connected<br />

between the outside ground screw on<br />

the <strong>Gladiator</strong> housing and the roof/wall/side<br />

of the silo/tank/vessel/chute. (For non metallic<br />

tanks make sure that external ground<br />

wire is connected between the same outside<br />

ground screw on the housing and the general<br />

plant ground potential).<br />

2. Check where the actual level is relative<br />

to the probe.<br />

Make sure that product is not touching the<br />

probe - ideally it needs to be > 500mm away.<br />

(If the silo/vessel/tank/chute is very small<br />

you must ensure that the material is as far<br />

away as possible - it must not be touching<br />

the probe).<br />

3. Turn the power on.<br />

The green LED will either stay on for 2 seconds<br />

then begin flashing or stay on permanently<br />

to indicate operation.<br />

4. Select the required relay contact action.<br />

The Relay can switch ‘ON’ or ‘OFF’ as the<br />

product approaches the probe and switch<br />

‘ON’ or ‘OFF’ in response to an instrument<br />

failure (for details see page 14). Set the relay<br />

action selection switch position (FSL or FSH)<br />

depending on your requirements.<br />

5. Cancel influence of mounting and/or<br />

build up.<br />

Do not proceed with this step unless the<br />

product is not touching the probe. Ideally the<br />

level needs to be > 500mm away.<br />

Switch the Mounting Calibration switch to<br />

‘CAL’ (ON) position. The Blue LED will blink<br />

to indicate that mounting calibration is<br />

now in progress.<br />

Wait for at least 10 sec. then switch the<br />

mounting calibration switch to ‘OFF’ position.<br />

The blue LED should turn off after a short<br />

time. The Blue LED will stay on if there<br />

was a calibration error. If this is the case<br />

please check that the probe is not touching<br />

the product or the mounting, then try the<br />

calibration again. If mounting calibration was<br />

successful the blue LED should be off and<br />

the Green LED should blink every 2 sec.<br />

Unit is now able to cancel influence of<br />

mounting and/or build-up and probe history<br />

has been cleared.<br />

6. Select the sensitivity.<br />

There are two adjustments controlling the<br />

sensitivity of the switch point:<br />

6.1. The ‘HI/LO’ sensitivity switch is used<br />

to set your unit depending on the dielectric<br />

properties of the product to be measured.<br />

This switch sets the range of adjustment<br />

possible with the sensitivity potentiometer.<br />

If the material to be detected has a lower<br />

dielectric constant than 10 - set the switch to<br />

‘HI’ (ON) - default.<br />

If material to be detected has a higher dielectric<br />

constant than 10 - set switch to ‘LO’<br />

If you are not aware of your material dielectric<br />

constant – set the switch to ‘HI’ (ON)<br />

- default.<br />

6.2 The sensitivity potentiometer.<br />

Set the potentiometer according to your<br />

requirements. A 12 o’clock setting (50%)<br />

- default, will cover the majority of instances<br />

- for the remaining instances, turning the<br />

potentiometer anti clockwise will decrease<br />

sensitivity. Switch point will then occur with<br />

the material nearer to the probe or more<br />

in contact with the probe than before. The<br />

reverse is also true.<br />

20

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

SETUP PROCEDURE<br />

SMART PROBE VERSION<br />

7. Select the time delay<br />

Set the required delay using the Delay<br />

potentiometer. (Default is 0 sec. at minimum<br />

position) Turn the potentiometer clockwise if<br />

any delay is required. Maximum rotation is<br />

¾ of a revolution. Max delay is 20 sec. The<br />

selected delay will be used for both an ON<br />

delay and an OFF delay.*<br />

8. Test function (used to check for<br />

malfunction of unit from remote position,<br />

PLC, SCADA etc)<br />

Select the desired Test function by switching<br />

the ‘Test’ switch (Default = ‘OFF’).<br />

‘TEST’ (ON) Position: Test function is<br />

selected. Test terminal (terminal number 4 of<br />

Smart probe) is used as an input to the unit.<br />

The test function allows you to check the<br />

functionality of the unit. Applying a ground<br />

wire to the Test terminal will change the<br />

state of the relay. It will hold this state until<br />

the ground is removed, then it will change<br />

back to the standard running mode.<br />

If the unit was in a Fail mode then the relay<br />

will not change status.<br />

‘OFF’ (Default) Position: Fail safe output<br />

function is selected. Test terminal (terminal<br />

number 4 of Smart probe) will function as an<br />

open drain drive. This can be used to drive a<br />

relay or an active low PLC input to detect a<br />

Fail condition. In normal operation mode the<br />

Test terminal will output Zero Volts (Short to<br />

GND). In Fail or unpowered mode the Test<br />

terminal will be open circuit.<br />

See page 18 for further information.<br />

* Setting of different time ranges for the delay potentiometer for ON delay and OFF delay is possible using<br />

a PC connected via Gos<strong>Hawk</strong>2 software. By default, both will have the same time adjustment range<br />

(20 sec max) and adjustment will result in equal ON delay and OFF delay.<br />

21<br />

Sultan 234 Series

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

SETUP PROCEDURE<br />

REMOTE FUNCTIONALITY LAYOUT<br />

4<br />

1<br />

1<br />

Calibrate button<br />

2<br />

Run button<br />

3<br />

Down button<br />

4<br />

Up button<br />

5<br />

Relay LEDs 1 and 2<br />

3<br />

RELAY 1<br />

RELAY 2<br />

STATUS A<br />

STATUS B<br />

6 Display (LCD with backlight)<br />

5<br />

6<br />

7<br />

2<br />

7 Status LEDs A and B<br />

- Status A flashes with probe to amplifier communications<br />

- Status B has no function in this product<br />

REMOVABLE REMOTE PROBE TERMINAL BLOCK<br />

TRANSDUCER<br />

8<br />

REMOTE<br />

STATUS<br />

1. 2. 3. 4. 5. 6. 7. 8. 9. 10.<br />

1 2 3 4 5 6 7 8 9 10<br />

9<br />

WHITE<br />

BLUE<br />

RED<br />

BLACK<br />

Terminals 1, 2, 3, 4, 9, 10 not used.<br />

8<br />

9<br />

GREEN LED: Power / Status<br />

Blinks every 1/2 second to indicate that functioning<br />

is correct and no medium is detected.<br />

LED on continuously indicates correct functioning and media is detected.<br />

Removable terminal block - plug in type<br />

22

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

SETUP PROCEDURE<br />

REMOTE VERSION<br />

1. Mount the unit in its actual position. (see mounting procedure - page 9-10)<br />

Make sure that external ground wire is connected between the outside ground screw on the <strong>Gladiator</strong><br />

housing and the roof/wall/side of the silo/tank/vessel/chute. (For non metallic tanks make sure<br />

that external ground wire is connected between the same outside ground screw on the housing<br />

and the general plant ground potential.)<br />

2. Check where the actual level is relative to the probe.<br />

Make sure that product is not touching the probe - ideally it needs to be > 500mm away.<br />

(If the silo/vessel/tank/chute is very small you must ensure that the material is as far away as possible<br />

- it must not be touching the probe).<br />

3. Turn the power on<br />

The display will turn on and the failsafe relay will switch. The display will scroll through the following<br />

messages: <strong>Hawk</strong>, Amp SerialNo, Type, Amp Soft Ver, Device ID, SensorSerial, SensorModel,<br />

Sens SoftVer, Sensor Addrs, <strong>Gladiator</strong> System Amp.<br />

The unit will then go into operational mode displaying ‘Switch’ with a % value. This % value represents<br />

the changing admittance reading.<br />

4. Simple “1-minute” Setup - Follow the flow chart<br />

Press<br />

Press<br />

Press<br />

Press<br />

Press<br />

Press<br />

Press<br />

Press<br />

Press<br />

Sensor Value<br />

0.0%<br />

CAL<br />

UnLock<br />

0<br />

CAL<br />

QuickSet<br />

CAL<br />

Cal Mounting<br />

Yes / No<br />

CAL<br />

CAL<br />

CAL<br />

CAL<br />

CAL<br />

CAL<br />

Relay Action<br />

FailSafe Hi<br />

Press<br />

CAL<br />

Press<br />

Twice<br />

RUN<br />

Yes<br />

Switch Point<br />

50%<br />

50%<br />

Delay Adjust<br />

0.1S<br />

0.1S<br />

FailSafe Hi<br />

FailSafe Low<br />

Cancel Influence of Mounting and/or Buildup<br />

Do not proceed with this step unless the product is not touching the<br />

probe. Ideally it needs to be > 500mm away.<br />

Select ‘Yes’ to start the mounting calibration. ‘Wait’ will be displayed<br />

during the calibration for up to 30 seconds.<br />

Unit is now able to cancel the influence of the mounting and/or<br />

build-up. The % reading has been zeroed with the existing process<br />

conditions and probe history log has been cleared.<br />

Select the Switch point (sensitivity)<br />

The output relay will switch at the entered % value. The default value of<br />

50% will be suitable for detecting most media. For detection of products<br />

having low dieletric constant, select a lower % value and vice versa. A<br />

higher % value will require the product to come nearer to the probe or<br />

cover more of the probe before switching will occur. When the level falls<br />

the relay will switch back at half of the entered switch point % value.<br />

Select the Time Delay<br />

Set the time to be used for both switch on and switch off delays<br />

(default: 0.1 seconds). Maximum Delay is 40 seconds.<br />

Select the required relay action<br />

The Relay can switch ‘ON’ or ‘OFF’ as the product approaches the<br />

probe and switch ‘ON’ or ‘OFF’ in response to an instrument failure.<br />

For details see page 14. Set the parameter to FailSafe Low or<br />

FailSafe Hi depending on your requirements.<br />

23<br />

Sultan 234 Series

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

SOFTWARE MENU<br />

REMOTE AMPLIFIER<br />

ENTERING DATA<br />

All software adjustments are achieved via the four PUSHBUTTONS on the front<br />

panel.<br />

In Run Mode<br />

(A) Press and hold - interrupts normal operations and allows access<br />

to software menu headings.<br />

In Calibrate Mode<br />

(B) Steps into a menu selection to allow editing (down one level)<br />

(C) Saves selected value and moves onto the next menu item.<br />

In Run Mode<br />

(A) Scrolls up through operating diagnostics on display LCD.<br />

In Calibrate Mode<br />

(B) Scrolls up through software parameters when browsing the<br />

menus.<br />

(C) Increases display value when editing a parameter.<br />

In Run Mode<br />

(A) Scrolls down through operating diagnostics on LCD display.<br />

In Calibrate Mode<br />

(B) Scrolls down through software parameters when browsing the<br />

menus.<br />

(C) Decreases display value when editing a parameter.<br />

In Run Mode<br />

(A) Hides diagnostics if they are in view and returns to the standard<br />

running display.<br />

In Calibrate Mode<br />

(B) Steps out of a menu or selection (up one level). Parameter value<br />

will be stored automatically when stepping up.<br />

(C) Returns to running mode from the top level menu.<br />

24

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

FLOW CHART<br />

SOFTWARE TREE<br />

SOFTWARE VERSION 7.14<br />

Sensor Value<br />

0.0%<br />

Normal Running Display<br />

Press<br />

CAL<br />

To Calibrate<br />

On first start up there is<br />

no security code protection.<br />

Press<br />

UnLock<br />

0<br />

CAL<br />

Press<br />

Press<br />

Press<br />

To QuickSet<br />

QuickSet<br />

Advanced<br />

flow chart CAL<br />

CAL To Advanced<br />

flow chart<br />

See page 26<br />

QuickSet Menu<br />

Advanced Menu<br />

See page 27<br />

covers all parameters covers less commonly<br />

required for standard used or advanced<br />

setups.<br />

parameters.<br />

Press<br />

RUN<br />

to return to normal operation<br />

25<br />

Sultan 234 Series

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

FLOW CHART<br />

QUICKSET<br />

QuickSet<br />

*When CAL is pressed ‘ edit’ will flash on the<br />

bottom line of the display for a short time to indicate<br />

that the parameter is being opened for editing.<br />

CAL<br />

Cal Mounting<br />

No<br />

CAL<br />

CAL<br />

Calibrate mount will cancel the mounting influence<br />

and zero the % reading with the existing process<br />

conditions. Probe history log will be cleared.<br />

Vessel must be empty before calibration. Yes / No<br />

Switch Point<br />

50%<br />

CAL<br />

CAL<br />

Relay 1 will switch at the entered Switch Point<br />

value (default 50%) and switch back at half of this<br />

value. <strong>Manual</strong> will be displayed if you<br />

have set the parameter ‘Switch Mode’ to <strong>Manual</strong> in<br />

Advanced menu. The <strong>Manual</strong> setting can only be<br />

removed or adjusted from the Advanced menu.<br />

Delay Adjust<br />

0.1S<br />

CAL<br />

CAL<br />

Set switch delay time 0.1-40sec (default 0.1 sec).<br />

Relay Action<br />

FailSafe Hi<br />

CAL<br />

CAL<br />

Relay Action (FailSafe Hi or FailSafe Low)<br />

(see page 14)<br />

Lock Code<br />

0<br />

CAL<br />

CAL<br />

Security code lock<br />

Adjustable 0-200<br />

Default 0<br />

Default values/settings in bold and underlined<br />

26

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

FLOW CHART<br />

ADVANCED MENU<br />

Advanced<br />

Default values/settings<br />

in bold and underlined<br />

Switch Mode<br />

Auto<br />

CAL<br />

Auto<br />

(view only)<br />

CAL<br />

Auto - Switch point is set in QuickSet by the ‘Switch Point’ parameter.<br />

‘Switch On’ = ‘Switch Point’, ‘Switch Off’ = Half of ‘Switch Point’ value (by default).<br />

‘Switch On’ and ‘Switch Off’ can not be changed (view only) in Auto.<br />

<strong>Manual</strong> - ‘Switch On’ and ‘Switch Off’ values can be edited in <strong>Manual</strong><br />

mode. <strong>Manual</strong> editing over-rides the QuickSet selected<br />

values.<br />

<strong>Manual</strong><br />

(editable) *Only possible if manual selected<br />

Switch On<br />

50%<br />

CAL CAL Relay switch point On (Default 50%)<br />

*Output relay in ‘State 2’ above this value.<br />

Switch Off<br />

25%<br />

CAL CAL Relay switch point Off (Default 25%)<br />

*Output relay in ‘State 1’ below this value.<br />

View Log<br />

CAL<br />

CAL<br />

Yes<br />

View history log of probe<br />

% and temperature Yes / No<br />

No<br />

Min Sensor %<br />

0.0%<br />

Minimum Sensor % since last<br />

Reset Log (not adjustable).<br />

Max Sensor %<br />

288.4%<br />

Maximum Sensor % since last<br />

Reset Log (not adjustable).<br />

Min Temp<br />

20.0C<br />

Minimum temperature value since<br />

last Reset Log (not adjustable).<br />

Max Temp<br />

26.9C<br />

Maximum temperature value since<br />

last Reset Log (not adjustable).<br />

Continued next<br />

page (Reset Log)<br />

*Switch points are refered to as ‘On’ and ‘Off’ to<br />

reflect the most simply understood performance in FailSafe Low<br />

mode. Actual relay state may be different according<br />

to setting of relay contact action. (see page 14)<br />

27<br />

Sultan 234 Series

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

From previous page<br />

FLOW CHART<br />

ADVANCED MENU<br />

Reset Log<br />

No<br />

Comms Type<br />

Modbus<br />

CAL<br />

CAL<br />

CAL<br />

CAL<br />

Reset probe history log<br />

(Yes / No)<br />

Log will automatically reset when Cal Mounting is used in<br />

QuickSet to cancel mounting influences and re-zero the % reading.<br />

Modbus<br />

HART<br />

Profibus DP<br />

DeviceNet<br />

Selection should not be changed<br />

unless required hardware is<br />

present. (see part numbers - page 34-35)<br />

Device ID<br />

1<br />

CAL<br />

CAL<br />

1-255<br />

Baud Rate<br />

19200<br />

CAL<br />

CAL<br />

1200<br />

4800<br />

9600<br />

19200<br />

38400<br />

57600<br />

Default values/settings<br />

in bold and underlined<br />

Back Light<br />

On<br />

CAL<br />

CAL<br />

Display Backlight<br />

On/Off<br />

Display Span<br />

3<br />

CAL<br />

CAL<br />

Display Span: 0-100% change in displayed value will occur with the<br />

selected change of raw internal units.<br />

Changing of this parameter will change the value of the Switch Point<br />

(Switch On and Switch Off) values.<br />

0. 0 - 40000 2. 0 - 20000 4. 0 - 5000<br />

1. 0 - 30000 3. 0 - 10000 5. 0 - 1000<br />

28

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

FLOW CHART<br />

DIAGNOSTIC DISPLAYS (Remote type only)<br />

The diagnostic displays appear on the top line of the LCD, after pressing the Up or<br />

Down push button when the <strong>Gladiator</strong> switch is in its normal running mode.<br />

The diagnostics provide the user with valuable performance feedback on how the<br />

instrument is performing whilst in operation.<br />

The measured reading Sensor Value (%) continues to be displayed on the second<br />

line of the LCD during diagnostic viewing on the top line. Ouput relays will continue to<br />

operate during diagnostic viewing.<br />

Press<br />

Sensor Value<br />

0.0%<br />

Normal<br />

0.0%<br />

Operation Mode<br />

Normal / Comms Retry / Fail<br />

Press<br />

Temp: 23.3C<br />

0.0%<br />

Current temperature inside probe housing (ºCelsius).<br />

Press<br />

Delay: 0.1S<br />

0.0%<br />

Programmed switch On / switch Off delay (seconds).<br />

Press<br />

Min: 0.0%<br />

0.0%<br />

Minimum captured Sensor Value % since last history<br />

log reset, or last Cal Mounting operation.<br />

(Continued next page)<br />

29<br />

Sultan 234 Series

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

FLOW CHART<br />

DIAGNOSTIC DISPLAYS<br />

Max: 72.9%<br />

0.0%<br />

Maximum captured Sensor Value % since last<br />

history log reset, or last Cal Mounting operation.<br />

Press<br />

SwOff: 25%<br />

0.0%<br />

Percentage below which the Relay will be in<br />

State 1*.<br />

Press<br />

SwOn: 50%<br />

0.0%<br />

Percentage above which the Relay will be in<br />

State 2*.<br />

Press<br />

Returns to<br />

Sensor Value<br />

0.0%<br />

*Switch points are refered to as ‘On’ and ‘Off’ to<br />

reflect the most simply understood performance in<br />

FailSafe Low mode. Actual relay state may be different<br />

according to setting of relay contact action. (see page 14)<br />

30

SULTAN 234<br />

SULTAN 234<br />

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

MULTIDROP CONNECTIONS<br />

<strong>Gladiator</strong><br />

<strong>Admittance</strong><br />

Switch<br />

<strong>Gladiator</strong><br />

<strong>Admittance</strong><br />

Switch<br />

<strong>Gladiator</strong><br />

<strong>Admittance</strong><br />

Switch<br />

<strong>Gladiator</strong><br />

<strong>Admittance</strong><br />

Switch<br />

Sultan Acoustic<br />

Wave Transmitter<br />

Slurries<br />

Sultan Acoustic<br />

Wave Transmitter<br />

Floatation Cells<br />

GLadiator<br />

Microwave<br />

Low Level<br />

Sultan Acoustic Wave Transmitter<br />

Silo, bin levels, coal, plastic powder,<br />

woodchip, sawdust, cement,<br />

clinker, iron ore, lime etc.<br />

<strong>Gladiator</strong><br />

Microwave<br />

Low Level<br />

<strong>Gladiator</strong><br />

Vibration<br />

Switch<br />

<strong>Gladiator</strong><br />

Conductivity<br />

Switch<br />

Sultan Smart Transducer<br />

Farm Tanks, Grain Terminals<br />

<strong>Gladiator</strong><br />

Conductivity<br />

Switch<br />

Orca Sonar Interface<br />

Thickener, CCD<br />

Sultan Acoustic<br />

Wave Switch<br />

Blocked Chute Detection<br />

Orca Sonar Interface<br />

Clarifier<br />

GSM Network<br />

or<br />

CDMA Network<br />

Sultan Master/Slave Positioning System<br />

Sultan Acoustic Wave Transmitter<br />

Stockpiles, Stackers,<br />

Reclaimers<br />

GSM or CDMA Network<br />

• Typically up to 31 transmitters or switches per string.<br />

• Maximum 250 transmitters or switches.<br />

• Using GSM/CDMA network, transmitters and switches can be<br />

monitored, calibrated remotely.<br />

• Alarm status, diagnostics can be monitored.<br />

• Support from factory engineering for customer application problems.<br />

Laptop or PC Communications<br />

or PLC / DCS with<br />

MODBUS RTU Port<br />

Gos<strong>Hawk</strong> Software for<br />

inventory monitoring on PC<br />

(Limited Modbus query rate for Switches only)<br />

31<br />

Sultan 234 Series

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

ADVANCED REMOTE COMMUNICATION<br />

GSM/CDMA<br />

<strong>Hawk</strong>Link GSM/CDMA communication<br />

device allows any authorized computer<br />

with a standard modem and Gos<strong>Hawk</strong>II<br />

software to dial in and calibrate, test<br />

or check in on the performance of the<br />

connected <strong>Hawk</strong> product. The <strong>Hawk</strong>Link<br />

device can be wired to the standard<br />

communication terminals of the <strong>Hawk</strong><br />

products.<br />

Remote technical support and complete<br />

commissioning of equipment in applications<br />

is possible via our GSM/CDMA<br />

module and allows monitoring and<br />

adjustment of settings no matter what<br />

corner of the world.<br />

Remote connection worldwide!<br />

32

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

TROUBLESHOOTING<br />

REMOTE VERSION<br />

Operation Setup Check<br />

After final adjustment it is advisable to<br />

check the performance of the probe<br />

relative to your entered settings.<br />

Ensure there is no mounting influence.<br />

When calibrating the mounting of the<br />

unit, there should be no product within<br />

at least 500mm of the probe. After calibrating<br />

the unit the Sensor Value (%)<br />

should read approximately 0.0% with<br />

no product near or touching the probe.<br />

Allow infeed to occur and note the Sensor<br />

Value (%) change (if there is any) -<br />

as the level gets closer to the probe the<br />

Sensor Value (%) number will increase<br />

and continue to increase as the product<br />

gets closer to, touches and covers the<br />

probe.<br />

The <strong>Gladiator</strong> is capable of switching<br />

repeatably and reliably without product<br />

contacting the probe for a wide variety<br />

of materials. Some very low dielectric<br />

materials may need to touch the probe<br />

to be detected.<br />

The Sensor Value (%) will reach its<br />

maximum after the probe is covered<br />

- but the Switch Point can be set at any<br />

value less then the maximum. It is recommended<br />

to select the set point more<br />

than 10% below the maximum value<br />

seen with material touching the probe.<br />

For instance the following readings may<br />

occur during filling:<br />

Sensor Value (%)<br />

- Before filling 0.0%<br />

- Filling starts 0.7%<br />

- Filling continue 4.9%<br />

- Filling continue 27.5%<br />

- Material approaching probe 48.5%<br />

- Material contacts probe 96.5%<br />

- Material covers probe 285.7%<br />

A. You may choose to leave the Switch<br />

Point at the default 50%. The <strong>Gladiator</strong><br />

will switch reliably without contact of<br />

the material to the probe.<br />

B. You may choose to adjust the Switch<br />

Point to 100% to switch when the product<br />

contacts the probe.<br />

By default the Switch Off % is set at 1/2<br />

of the Switch Point. You may wish to<br />

adjust this to a higher or lower number.<br />

This is adjustable in the Advanced<br />

Menu by selecting Switch Mode - <strong>Manual</strong>.<br />

You can then manually select your<br />

Switch On and Switch Off values.<br />

In general, you should not choose the<br />

Max Sensor % (Max) value nor the Min<br />

Sensor % (Min) value as the Switch<br />

Point.<br />

If possible, always have the Switch On<br />

% at a value of at least 10% less than<br />

the Max Sensor % (Max) value and<br />

Switch Off at least 10% more than the<br />

Min Sensor % (Min).<br />

If the % change on the display is too<br />

small then the Display Span parameter<br />

in the Advanced menu can expand the<br />

display resolution (select a larger number<br />

- smaller raw range) and vice versa.<br />

Changing the Display Span will change<br />

Switch Point value.<br />

33<br />

Sultan 234 Series

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

PART NUMBERING<br />

SMART PROBE VERSION<br />

AS2100 <strong>Gladiator</strong> <strong>Admittance</strong> Switch - Smart Probe<br />

Power Supply<br />

B 24 Vdc standard (7-30Vdc)<br />

U Universal AC power supply (80-260Vac input) and 7-30Vdc<br />

Output Options<br />

S Switch only, 1 level relay, Modbus<br />

Z Special Request<br />

Housing<br />

S Standard Powder Coated, Diecast with glass lid<br />

C Corrosion Resistant, stainless steel housing<br />

Guard Length (excludes 100mm ground length)<br />

1 150 mm (5.9”)<br />

Z Special Request<br />

Temperature<br />

1 Maximum 80ºC (176ºF)<br />

2 Maximum 150ºC (302ºF) Temperature extension length 150 mm (5.9”), Teflon<br />

3 Maximum 250ºC (482ºF) Temperature extension length 250 mm (9.8”), Teflon<br />

4 Maximum 450ºC (842ºF) Temperature extension length 350 mm (13.7”), Ceramic<br />

Probe Type<br />

1 Standard rod (non-insulated)<br />

2 Insulated rod<br />

3 Cable (non-insulated)<br />

Mounting<br />

TN07 3/4” NPT Thread (not available with high temp ceramic version)<br />

TB07 3/4” BSP Thread (not available with high temp ceramic version)<br />

TN10 1” NPT Thread (not available with high temp ceramic version)<br />

TB10 1” BSP Thread (not available with high temp ceramic version)<br />

TN15 1.5” NPT Thread<br />

TB15 1.5” BSP Thread<br />

TZ Special Thread Request<br />

FA2 2” Flange ANSI (Class 150)<br />

FD2 2” Flange DIN 50 (PN 40)<br />

FJ2 2” Flange JIS (10K)<br />

FZ Special flange request<br />

Approvals<br />

A22 ATEX 22 (Pending)<br />

X Standard CE Approved<br />

(P)Probe (C)Cable Length<br />

P30 - 300mm (11.8”)<br />

P50 - 500mm (19.6”)<br />

P100 - 1000mm (39.3”)<br />

C100 - 1000mm (39.3”)<br />

C200 - 2000mm (78.7”)<br />

C300 - 3000mm (118.1”)<br />

For longer consult factory<br />

AS2100 B S S 1 1 1 TB15 X P30<br />

34

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

PART NUMBERING<br />

REMOTE VERSION<br />

Remote Amplifier<br />

GSA Remote <strong>Gladiator</strong> System Amplifier<br />

Housing<br />

S Standard polycarbonate electronics housing<br />

Power Supply<br />

B 24 Vdc standard (12-30Vdc)<br />

C 48Vdc<br />

U Universal AC power supply (80-260Vac input) and 7-30Vdc<br />

Output Options<br />

S Switch only, 1 level relay, 1 failsafe relay, Modbus<br />

I HART Isolated, 1 level relay, 1 failsafe relay<br />

D Profibus DP, 1 level relay, 1 failsafe relay<br />

P Devicenet, 1 level relay, 1 failsafe relay<br />

Z Special Request<br />

GSA S B S<br />

Remote Probe<br />

AS2200 Remote <strong>Gladiator</strong> <strong>Admittance</strong> Probe<br />

Housing<br />

S Standard Powder Coated, Diecast with glass lid<br />

C Corrosion Resistant, stainless steel housing<br />

Guard Length (excludes 100mm ground length)<br />

1 150 mm (5.9”)<br />

Z Special Request<br />

Temperature<br />

1 Maximum 80ºC (176ºF)<br />

2 Maximum 150ºC (302ºF), temperature extension length 150 mm (5.9”), Teflon<br />

3 Maximum 250ºC (482ºF), temperature extension length 250 mm (9.8”), Teflon<br />

4 Maximum 450ºC (842ºF), temperature extension length 350 mm (13.7”), Ceramic<br />

Probe Type<br />

1 Standard rod (non-insulated)<br />

2 Insulated rod<br />

3 Cable (non-insulated)<br />

Mounting<br />

TN07 3/4” NPT Thread (not available with high temp ceramic version)<br />

TB07 3/4” BSP Thread (not available with high temp ceramic version)<br />

TN10 1” NPT Thread (not available with high temp ceramic version)<br />

TB10 1” BSP Thread (not available with high temp ceramic version)<br />

TN15 1.5” NPT Thread<br />

TB15 1.5” BSP Thread<br />

TZ Special Thread Request<br />

FA2 2” Flange ANSI (Class 150)<br />

FD2 2” Flange DIN 50 (PN 40)<br />

FJ2<br />

FZ<br />

AS2200 S 1 1 1 TB15 X P30<br />

2” Flange JIS (10K)<br />

Special flange request<br />

Approvals<br />

A22 ATEX 22 (Pending)<br />

X Standard CE Approved<br />

(P)Probe (C)Cable Length<br />

P30 - 300mm (11.8”)<br />

P50 - 500mm (19.6”)<br />

P100 - 1000mm (39.3”)<br />

C100 - 1000mm (39.3”)<br />

C200 - 2000mm (78.7”)<br />

C300 - 3000mm (118.1”)<br />

For longer consult factory<br />

35<br />

Sultan 234 Series

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

SPECIFICATIONS<br />

Operating Voltage<br />

• 7 - 30Vdc (residual ripple no greater than<br />

100mV)<br />

• 80 - 260Vac 50/60Hz<br />

Power Consumption<br />

•

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

DIELECTRIC CONSTANTS TABLE<br />

For other materials contact the factory<br />

Dielectric<br />

Material Constant<br />

Acetal 3.6<br />

Acetic Acid 6.1<br />

Acetone 17.7<br />

Acetyl Acetone 23.1<br />

Acetyl Bromide 16.5<br />

Allyl Alcohol 21.0<br />

Allyl Bromide 7.0<br />

Allyl Choloride 8.2<br />

Allyl lodide 6.1<br />

Ammonia 15.5<br />

Amyl Alcohol 11.2<br />

Amyl Bromide 6.3<br />

Amyl Choloride 6.6<br />

Amyl Ether 3.1<br />

Amyl lodide 6.9<br />

Amyl Nitrate 9.1<br />

Arsenic Tribromide 9.0<br />

Arsenic Trichloride 12.4<br />

Arsenic Triiodide 7.0<br />

Asphalt 2.65<br />

Benzene 2.3<br />

Benzil 13.0<br />

Benzoyl Chloride 22.1<br />

Benzyl Alcohol 13.0<br />

Benzyl Chloride 6.4<br />

Boron Bromide 2.6<br />

Bromine 3.1<br />

Butane 1.4<br />

Butyl Chloride 9.6<br />

N Butyl lodide 6.1<br />

Iso Butyl lodide 5.8<br />

Cable Oil 2.2<br />

Camphene 2.7<br />

Carbon Dioxide 1.6<br />

Carbon Disulphide 2.6<br />

Carbon Tetrachloride 2.2<br />

Dielectric<br />

Material Constant<br />

Castor Oil 2.6<br />

Camphene 2.3<br />

Cement 2.1<br />

Chloracetic acid 12.3<br />

Chlorine 2.0<br />

Chloroform 5.5<br />

Cr eosol 10.6<br />

Cyclohexane 2.0<br />

Deuterium 1.3<br />

Deuterium Oxide 78.3<br />

Dichloracetone 14.0<br />

Dichlorobenzene 2.8<br />

Dichloroethane 16.7<br />

Diethyl Sulfide 7.2<br />

Dimethyl Ethyl 11.7<br />

Dimethyl Sulfide 6.3<br />

Dimethyl Sulfate 55.0<br />

Dowtherm 3.3<br />

Ethanol 24.3<br />

Ethyl Acetate 6.4<br />

Ethyl Amyl Ether 4.0<br />

Ethyl Benzene 2.5<br />

Ethyl Benzoate 6.0<br />

Ethyl Cyclobutane 1.9<br />

Ethylene Chloride 10.5<br />

Ethylene Cyanide 58.3<br />

Ethylene Glycol 37.0<br />

Ethylene Oxide 13.9<br />

Ethyl lodide 7.4<br />

Ethyl Nitrate 19.7<br />

Ethyl Silicate 4.1<br />

Fly Ash 2.6<br />

Formic Acid 58.5<br />

Freon 12 2.4<br />

Freon 11 3.1<br />

Freon 113 2.6<br />

Dielectric<br />

Material Constant<br />

Glycerine 47.0<br />

Glycer ol 43.0<br />

Glycol 35.6<br />

Heptane 1.9<br />

Heptanoic Acid 2.5<br />

Hexane 1.9<br />

Hydrogen Bromide 3.8<br />

Hydrogen Chloride 4.6<br />

Hydrogen Cyanide 95.4<br />

Hydrogen Fluoride 84.0<br />

Hydrogen lodide 2.9<br />

Hydrogen Peroxide 84.2<br />

Hydrogen Sulfide 5.8<br />

Hydrazine 52.9<br />

lodine 118.0<br />

Isobutyl Alcohol 18.7<br />

Kerosene 1.8<br />

Lead Oleate 3.2<br />

Lonone 10.0<br />

Menthol 3.95<br />

Mesityl Oxide 15.4<br />

Methanol 33.6<br />

Methyl Alcohol 33.0<br />

Methyl Ether 5.0<br />

Methyl Ether Ketone 18.4<br />

Mineral Oil 2.1<br />

Nephthyl Ethyl Ether 3.2<br />

Nitroethane 19.7<br />

Nitromethane 39.4<br />

Octane 1.96<br />

Octyl Alcohol 3.4<br />

Octylene 4.1<br />

Oleic Acid 2.46<br />

Oil, Oiive 3.1<br />

Oil, Peanut 2.2<br />

Oil, Transformer 2.2<br />

Dielectric<br />

Material Constant<br />

Palmitic Acid 2.3<br />

Pentane 1.8<br />

Phenol 9.9<br />

Phenol Acetate 6.9<br />

Phosgene 4.7<br />

Phosphorus 4.1<br />

Polyethylene chips 1.3<br />

Polyethylene powder 1.4<br />

Propyl Acetate 6.3<br />

Propyl Alcohol 21.8<br />

Propyl Benezene 2.4<br />

Pyridine 12.5<br />

Reburned Lime 2.2<br />

Sand (Dry) 4.8<br />

Sodium Chloride 6.1<br />

Sodium Oleate 2.7<br />

Succinic Acid 2.4<br />

Sodium Chloride 6.1<br />

Sulphur 3.4<br />

Sulphur Dioxide 17.6<br />

Sulfuryl Chloride 10.0<br />

Sulphur Trioxide 3.6<br />

Teflon Powder 1.3<br />

Teterabromiethane 7.1<br />

Thionyl Bromide 9.1<br />

Thionyl Chloride 9.3<br />

Titanium Tetrachloride 2.8<br />

Toluene 2.4<br />

Trichloroxoluene 6.9<br />

Trimetylbenzene 2.2<br />

Trimethyl Borate 8.2<br />

Urethane 3.2<br />

Valeric Acid 2.6<br />

Vinyl Ether 3.9<br />

Water 80.0<br />

Xylene 2.4<br />

37<br />

Sultan 234 Series

<strong>Admittance</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.3, Feb 2009<br />

HAWK MEASUREMENT SYSTEMS<br />

PTY. LTD. A.C.N. 006 782 449<br />

15-17 MAURICE COURT<br />

NUNAWADING VIC. 3131<br />

P.O. BOX 286 NUNAWADING<br />

VIC. 3131 AUSTRALIA<br />

EMAIL: <strong>Hawk</strong>Sales@hawk.com.au<br />

PH: +61-3 9873 4750<br />

FAX: +61-3 9873 4538 (Sales/Engineering)<br />

FAX: +61-3 9873 4384 (Accounts/Production)<br />

DECLARATION OF CONFORMITY<br />

Manufacturer’s Name:<br />

Manufacturer’s Address:<br />

declares that the product<br />

Models<br />

HAWK MEASUREMENT SYSTEMS PTY LTD<br />

5–7 Maurice Court<br />

Nunawading, Vic.<br />

Australia 33<br />

<strong>Gladiator</strong> Variable <strong>Admittance</strong> Level Switch series<br />

AS2000, AS200, AS2200, AS220, and GARP.<br />

conform to the following product specifications:<br />

Low Voltage Directive:<br />

Amendment Directive:<br />

EMC Directive:<br />

ATEX Directive:<br />

73/23/EEC<br />

93/68/EEC<br />

89/336/EEC<br />

94/9/EEC<br />

Standards in whole or in part to which conformity is declared:<br />

Normative Documents: EN 6326: 997 +Amendment : 998 + Amendment 2:200<br />

EN 600-:200<br />

BS EN 5004:998<br />

EN 5028--:998<br />

Standards:<br />

Supplemental Information:<br />

IEC 000-3-2: 995<br />

IEC 000-3-3: 994<br />

IEC 000-4-2: 995<br />

IEC 000-4-3: 995<br />

IEC 000-4-4: 995<br />

IEC 000-4-5: 995<br />

IEC 000-4-6: 996<br />

IEC 000-4-: 994<br />

The product herewith complies with the requirements of Low Voltage Directive 73/23/EEC, Amendment<br />

Directive 93/68/EEC, and EMC Directive 89/336/EEC, when the probe is installed to monitor material in a<br />

closed metal vessel, and carries the CE-marking accordingly. The Remote amplifier is safe for operation<br />

in Category 3 hazardous locations (Zone 2/22) and the Integral and Remote Probes have been designed<br />

to operate in Cat and 2 (Zone 20/2) dust locations. The ATEX marking code is II 3 GD IP67 T65ºC.<br />

Signature:<br />

Name:<br />

Position:<br />

Colin Prohasky<br />

Engineering Manager<br />

Date: 0 October 2007<br />

Place:<br />

Melbourne, Australia.<br />

38

Contacts<br />

Rev 1.3, Feb 2009<br />

<strong>Hawk</strong> <strong>Measurement</strong> Systems (Head Office)<br />

15-17 Maurice Court<br />

Nunawading VIC 3131<br />

Australia<br />

Phone: +61 3 9873 4750<br />

Fax: +61 3 9873 4538<br />

info@hawk.com.au<br />

<strong>Hawk</strong> <strong>Measurement</strong><br />

7 River Street<br />

Middleton, MA 01949<br />

USA<br />

Phone: +1 888 HAWKLEVEL (1-888-429-5538)<br />

Phone: +1 978 304 3000<br />

Fax: +1 978 304 1462<br />

info@hawkmeasure.com<br />

For more information and global<br />

representatives:<br />

www.hawkmeasure.com<br />

Represented by:<br />

Part no. DOC-ADMITTANCE-MAN