IBC Cylindrical Roller Bearings - Spekuma Kullager AB

IBC Cylindrical Roller Bearings - Spekuma Kullager AB

IBC Cylindrical Roller Bearings - Spekuma Kullager AB

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

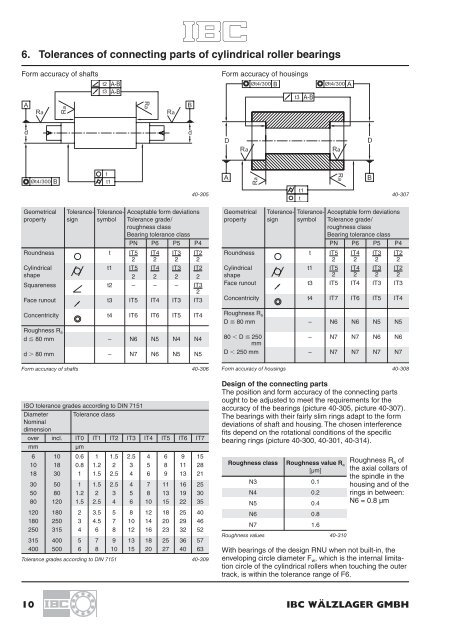

6. Tolerances of connecting parts of cylindrical roller bearings<br />

Form accuracy of shafts<br />

Form accuracy of housings<br />

40-305 40-307<br />

Geometrical Tolerance- Tolerance- Acceptable form deviations<br />

property sign symbol Tolerance grade/<br />

roughness class<br />

Bearing tolerance class<br />

PN P6 P5 P4<br />

Roundness t IT5 IT4 IT3 IT2<br />

2 2 2 2<br />

<strong>Cylindrical</strong> t1 IT5 IT4 IT3 IT2<br />

shape<br />

2 2 2 2<br />

Squareness t2 – – – IT3<br />

2<br />

Face runout t3 IT5 IT4 IT3 IT3<br />

Concentricity t4 IT6 IT6 IT5 IT4<br />

Roughness R a<br />

d 80 mm – N6 N5 N4 N4<br />

d 80 mm – N7 N6 N5 N5<br />

Form accuracy of shafts 40-306<br />

ISO tolerance grades according to DIN 7151<br />

Diameter Tolerance class<br />

Nominal<br />

dimension<br />

over incl. IT0 IT1 IT2 IT3 IT4 IT5 IT6 IT7<br />

mm<br />

μm<br />

6 10 0.6 1 1.5 2.5 4 6 9 15<br />

10 18 0.8 1.2 2 3 5 8 11 28<br />

18 30 1 1.5 2.5 4 6 9 13 21<br />

30 50 1 1.5 2.5 4 7 11 16 25<br />

50 80 1.2 2 3 5 8 13 19 30<br />

80 120 1.5 2.5 4 6 10 15 22 35<br />

120 180 2 3.5 5 8 12 18 25 40<br />

180 250 3 4.5 7 10 14 20 29 46<br />

250 315 4 6 8 12 16 23 32 52<br />

315 400 5 7 9 13 18 25 36 57<br />

400 500 6 8 10 15 20 27 40 63<br />

Tolerance grades according to DIN 7151 40-309<br />

Geometrical Tolerance- Tolerance- Acceptable form deviations<br />

property sign symbol Tolerance grade/<br />

roughness class<br />

Bearing tolerance class<br />

PN P6 P5 P4<br />

Roundness t IT5 IT4 IT3 IT2<br />

2 2 2 2<br />

<strong>Cylindrical</strong> t1 IT5 IT4 IT3 IT2<br />

shape<br />

2 2 2 2<br />

Face runout t3 IT5 IT4 IT3 IT3<br />

Concentricity t4 IT7 IT6 IT5 IT4<br />

Roughness R a<br />

D 80 mm – N6 N6 N5 N5<br />

80 D 250 – N7 N7 N6 N6<br />

mm<br />

D 250 mm – N7 N7 N7 N7<br />

Form accuracy of housings 40-308<br />

Design of the connecting parts<br />

The position and form accuracy of the connecting parts<br />

ought to be adjusted to meet the requirements for the<br />

accuracy of the bearings (picture 40-305, picture 40-307).<br />

The bearings with their fairly slim rings adapt to the form<br />

deviations of shaft and housing. The chosen interference<br />

fits depend on the rotational conditions of the specific<br />

bearing rings (picture 40-300, 40-301, 40-314).<br />

Roughness class Roughness value R a<br />

[μm]<br />

N3 0.1<br />

N4 0.2<br />

N5 0.4<br />

N6 0.8<br />

N7 1.6<br />

Roughness values 40-310<br />

Roughness R a of<br />

the axial collars of<br />

the spindle in the<br />

housing and of the<br />

rings in between:<br />

N6 = 0.8 μm<br />

With bearings of the design RNU when not built-in, the<br />

enveloping circle diameter F w , which is the internal limitation<br />

circle of the cylindrical rollers when touching the outer<br />

track, is within the tolerance range of F6.<br />

10 <strong>IBC</strong> WÄLZLAGER GMBH