02-a Wet etching - Caltech Micromachining Laboratory

02-a Wet etching - Caltech Micromachining Laboratory

02-a Wet etching - Caltech Micromachining Laboratory

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

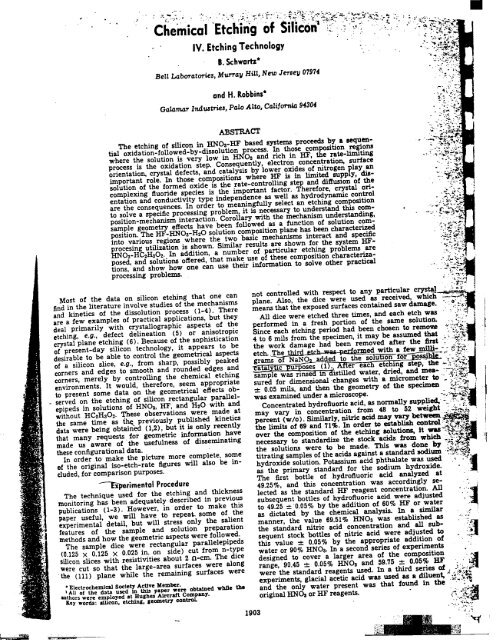

, '., ...: Chemical ""~.:.:::'; ~ :'- ',...~;."': Etchin'g ,.;.~.-;:':..:-f.:. of ;:,~~~;~~~.-:..:i~~~:~.:::=~-~;;.;',::'-~:~,;'-:~:;.~ Silicon ..::~-'.. -~ ~..,;. --',~.: ~ ~.; ;..,.::::~~?~~~~~.<br />

, ; ."<br />

..-, -.; '-:-,,"':<br />

IV. Etching Technology ...'- ~:~Z~",<br />

.":, ~::'"~Z~tJ<br />

B, Schwartz _:".~.'~~".."(.<br />

..' ...<br />

Bell Laboratories, Murrau Hill, New JerBe'j 07974 :;';;'-:~.{~<br />

d H R bb ' .--; --<br />

an ,0 Ins:.~;'" i'~:<br />

:1'. .;<br />

Galamar Industries, Palo Alto, California 94304 .-',~ :.:";-:<br />

ABSTRACT<br />

, .-"."<br />

-.;"~.::; ~;<br />

.:~::;~k;;<br />

The <strong>etching</strong> of silicon in HNOa-HF based systems proceeds by a sequ.en- --.~ :,.-#~~~.<br />

tial oxidation-fo.11o",:ed-by-dissol~tion process. ~ ~ose composition ~~~ns 7 .:.~~;:.~::;;:':<br />

where the solution 15 very low m HNOa and nch m HF, the rate-limiting .' .: ~'~~.<br />

process .is the oxidation step. Conseq~ently, electro~ concen~ration, surface '- ~-~: ~t'<br />

,?rientatlon, crystal defects, and c~t,alYSIS by lower I?Xl.des ~f .nItrogen play .an -;::;.:1,<br />

lInportant role. In those composItIons where ~ 15 m 1imi~ su?ply, dis- :..~~"'-<br />

solution of the formed oxide is the rate-contro11mg step and diffusIon of the .::;.~.:<br />

complexing fluoride species is the important factor. Therefore, cr,:stal ori- :::.::<br />

entation and conductivity type independ.ence as well as hydrodynan1lc co~t;rol -);.;~,;'..<br />

are the consequences. In order to mearongfully select an <strong>etching</strong> COmI;>oSltlon ,; :'"-' --f:,<br />

to solve a specific processing problem, it is necessary to un.derstand this CO;m- .--""t.:-~~-:~<br />

position-mechanism interaction. Corollary with the mec~m under.standing, -,.; -.;.:~:~'~)J<br />

sample geometry effects have be~n follow~ .as a functIon of solution c«;,m- ., -;'.".;;<br />

position. The HF-HNO3-H20 solution coml?osltion pl~e h~ been characte~ '.::OJ:.[~:<br />

into various regions where the two haslC mechanlSms mteract and specific ,:,::;:'d:;~<br />

procesing utilization is shown. Similar results a~ shown fo~ the system HF- .:~..;.:i<br />

HNOa-HC2H3<strong>02</strong>. In addition, a number of particular <strong>etching</strong> problems .are ::!;':",,?<br />

posed, and solutions offered, that make. u~e of the~e composition characterl;U- :..,: ~'._~:. '.<br />

tions, a.nd show how one can use theIr Information to solve other practical .'. :.~-~~-;~<br />

processIng problems. ~';'"<br />

..-:. .,.,<br />

, ...~i:;,;j: i<br />

Most of the data on silicon <strong>etching</strong> that one can not controlled with respect to any partic.war c~ :-::~~:i, 1<br />

~<br />

find and kinetics the literature of the involve dissolution studies process of the (1-4). mechanisms There plane. means that Also, the the exposed dice were surfaces used contamed as. receIved, saw damage. which :-:',:;i-" :'~~.~:-!-"<br />

are a few examples of practical applications, but they All dice were etched three times, and each etch was ' -;.'. :--/<br />

deal primarily with crystallographic aspects of the performed in a fresh portion of the same solution. '-.. ;~;:<br />

<strong>etching</strong>, e.g., defect delineation (5) or anisotropic Since each <strong>etching</strong> period had been chosen to remov~ :.:::-::-1,;<br />

crystal plane <strong>etching</strong> (6). Because of the sophistication 4 to 6 mils from the specimen, it may be assumed that ;.; ~l::~<br />

of present-day silicon technology, it appears to be the work damage had been removed after the first : _.:~.::<br />

desirable to be able to control the geometrical aspects etch. The third--.etch-was p~rformed with a few ~:-- .~:.t-,=~of<br />

a silicon slice, e.g., from sharp, possibly peaked gramss=~ NaNQ;2~tO the ~~ssi-PJL ':-:.,:;'f;..,<br />

corners and edges to smooth and rounded edges and a lC u oses (1). er eac <strong>etching</strong> step, the '-:~'.~~~:;'.;,<br />

corners, merely by controlling the chemical <strong>etching</strong> sample was rins m istilled water, dried, and mea- .._",::;.::..~..<br />

environments. It would, therefore, seem appropriate sured for dimensional changes with a micrometer to '- ,~ ~:,~<br />

to present some d~ta on t,h.e geometrical effects ob- :t. 0.05 ~s, and then ~e geometry of the specimen -~J~;~ . '<br />

-served on the etchIng of silicon rectangular parallel- was exammed under a IDlcroscope. -~.:, ,O;i:,:.;<br />

e~ipeds in solutions of HNOa, HF,. and H2O with and Concentra~ed hydrofluoric acid, as normally SUPP1!ed. .:... "~-.~; ,<br />

without H~2H3<strong>02</strong>. 'I;'hese ob~ervatlons ~ere m~de ,at may vary m concentration from 48 to 52 weIght :~':'-':~"'~<br />

the same tiJ?e as t~ preVIously ~u~lished kinetics percent (w/o). SimnA1'ly, nitric acid may vary betwe81.~<br />

data were beIng obtain"ed (1,2), b';lt 1: 15 onlY,recently the limIts of 69 and 71%. In order to estab;1ish control~"iI!1<br />

that many requests for geometnc info~tio~ h~ve over the composition of the <strong>etching</strong> solutions, it was"':.:4=1'!~made<br />

us aware of the usefulness of disselDlnating necessary to standardize the stock -acids from which .;.~"'::~..<br />

these configurational data. the solutions were to be made, This was done by .~;f~<br />

In orde,!, ,to m.ake the picture more ~omplete, s°!De titrating samples of the acids against a standard sodium ;~:"~~:~1<br />

of the ongmal Is~-etch-rate figures will also be m- hydroxide solution. Potassium acid phthalate was used ;. .4<br />

cluded, for companson purposes, as the primary standard for the sodium hydroxide. .I<br />

~_. The bottle of hydrofluoric acid analyzed first at '<br />

p~<br />

Lxt'golmental Proced~re .49.25%, and this concentration was accordingly se- -;<br />

The technique used for the etchm~ an~ thlck~ess lected as the standard HF reagent concentration. All ..-<br />

monitoring has been adequatel~ descnbed m prevlo~s subsequent bottles of hydrofluoric acid were adjusted '.'"<br />

publications (1-3). However, m order to make thiS to 49.25 :t 0.05% by the addition of 60% HF or water.<br />

paper useful, we will have to repeat- some of. the as dictated by the chemical analysis, In a similar ."' ,<br />

experimental detail, but will stress only the sall~nt manner, the value 69.51 % HNOa was established as " '::.<br />

features of the sample and solution preparatIon the standard nitric acid concentration and all sub- .::':<br />

methods and h°v.: the geometric aspects were fo11o",:",ed. sequent stock bottles of nitric acid ~ere adj\,1s.ted to _:~ 1<br />

The sample dIce were rectangular parallelepIpeds this value :t. 0.05% by the appropnate addItIon of .<br />

~<br />

(0.125 X 0.125 X 0.<strong>02</strong>5 in. on side) cut from n-t~pe water or 90% HNOa. In a second series of experiments .<br />

silicon slices with resistivities about 2 {l-cm. The dice designed to cover a larger area of the composition . ~.<br />

were cut so that the large-area ~u,rfaces were along range, 90.45 :t. 0.05% HNOa and 59.75 :t 0.05% HF -.: j.<br />

the (111) plane while the remaInIng surfaces were were the standard reagents used. In a third series of .-~ '~':.f~<br />

.Electrochemical Society Active Member. experiments, glacial acetic acid was used as a ~uent, .:I.:~!~~_~i<br />

1 All of the daU used In this paper were obtained whfie the and the only water present was that found In the -.~<br />

authors were employed at Hughes Aircraft Company. original HNOs or HF reagents. ..;;.':-<br />

Key words: I1l1con, <strong>etching</strong>, geometry control. i' : =-"'( ,", ~<br />

1903 .'.":~';~,'~<br />

" ,.<br />

---,<br />

."c.~