02-a Wet etching - Caltech Micromachining Laboratory

02-a Wet etching - Caltech Micromachining Laboratory

02-a Wet etching - Caltech Micromachining Laboratory

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

l eaN ;,..~;;1.,: -.~~.~<br />

~ Vol. ~, o.~. '.:J~-~."~:;~ ..'.,~...';,~.:,."'-""Q~~~IA --".~~-,:",;',::£~ CAL.'. "';i~~~::'" ETCHIN~ DF.SILICO~ ,'.' c-~', ~t':: ;;:'~..:~~""'::.r.. ~~. '- ,~~j~':';""~:i-.7 "i;--i,.:..",l9.Qb,;:---~.:.,<br />

.~.,.,~" ..'~<br />

high H<br />

NOf/-CATALYZED RATES faces<br />

-CATALYZED RATES 80<br />

Hz (~46%)<br />

HF (59<br />

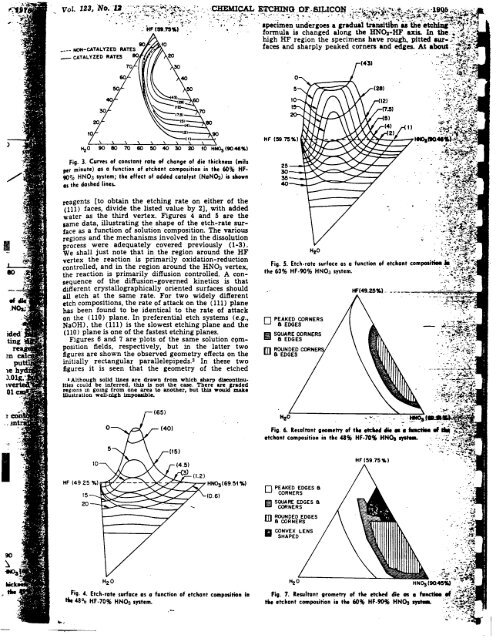

Fig. 3. Curyes of constont rate of change of die thickness (mils<br />

per minute) as 0 function of etchant composition in the 60% HF. ~<br />

9O~o HNO3 system; the effect of added catalyst (NaN~) is shown 35<br />

os the dashed lines. 40<br />

reagents [to obtain the <strong>etching</strong> rate on either of the<br />

(Ill) faces, divide the listed value by 2], with added .<br />

water as the third vertex. Figures 4 and 5 are the<br />

same data, illustrating the shape of the etch-rate surface<br />

as a function of solution composition. The various<br />

I regions and the mechanisms involved in the dissolution<br />

process were adequately covered previously (1-3).<br />

..We shall just note that in the region around the HF<br />

vertex the reaction is primarily oxidation-reduction F' 5<br />

controlled, and in the region around the HNO3 vertex, Ig. .<br />

the reaction is primarily diffusion controlled. A con- the 60%<br />

sequence of the diffusion-governed kinetics is that<br />

different all etch at crystallographically the same rate. For oriented two widely surfaces different' should - .<br />

etch compositions, the rate of attack on the (Ill) plane<br />

has been found to be identical to the rate of attack<br />

on the (110) plane. In preferential etch systems (e.g., 0 PEAKED CORNERS<br />

NaOH), the (Ill) is the slowest <strong>etching</strong> plane and the 6 EDGES<br />

(110) plane is one of the fastest <strong>etching</strong> planes. m SQUARE CORNERS<br />

Figures 6 and 7 are plots of the same solution com- ~ 6 EDGES<br />

position fields, respectively, but in the latter two<br />

m ROUNDED ~N<br />

figures are shown the observed geometry effects on the 6 EDGES<br />

initially rectangular parallelepipeds.3 In these two<br />

figures it is seen that the geometry of the etched<br />

I Although solid tines are drawn from which sharp d!8COntinu.<br />

Itles could be inferred, this Is not the C&.se. Tbere are ended<br />

regIons in going from one area to another, but this would make<br />

Wustration well-n1ib imposaible.<br />

~,<br />

..etchant<br />

~<br />

c ,I<br />

co HF (492 H~(6951%)<br />

Hz<br />

Fig. 6.<br />

0 PEAKED EDGES 6<br />

15 (0.6) CORNERS<br />

20 ~ SQUAREDGES 8<br />

EO! CORNERS<br />

m ROUNDED EDGES<br />

6 CORNERS<br />

-CONVEX<br />

-SHAPED<br />

LENS<br />

H2O<br />

,. Fig. 4. Etch-rate surface as a function of etchant composition in Fig. 7<br />

~ 48% HF-70% HNOa system. the etch<br />

~ --~,:.- ;"~-