Somerford Mini Ltd. Ordering Parts Using This Catalogue

Somerford Mini Ltd. Ordering Parts Using This Catalogue

Somerford Mini Ltd. Ordering Parts Using This Catalogue

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

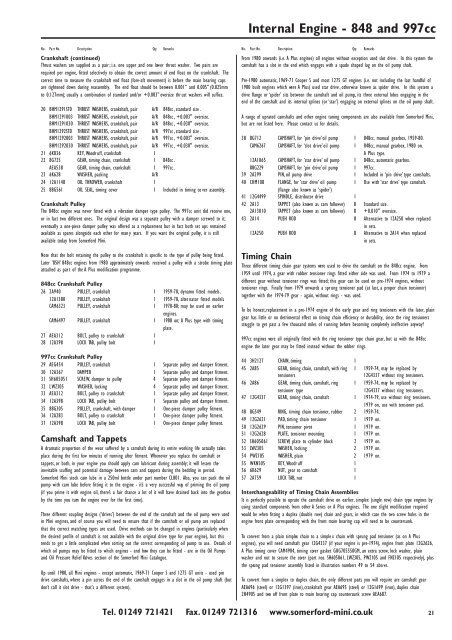

Internal Engine - 848 and 997cc<br />

No. Part No. Description Qty. Remarks No. Part No. Description Qty. Remarks<br />

Crankshaft (continued)<br />

Thrust washers are supplied as a pair; i.e. one upper and one lower thrust washer. Two pairs are<br />

required per engine, fitted selectively to obtain the correct amount of end float on the crankshaft. The<br />

correct time to measure the crankshaft end float (fore-aft movement) is before the main bearing caps<br />

are tightened down during reassembly. The end float should be between 0.001” and 0.005” (0.025mm<br />

to 0.127mm); usually a combination of standard and/or +0.003” oversize thr ust washers will suffice.<br />

20 BHM1291STD THRUST WASHERS, crankshaft, pair A/R 848cc , standard size.<br />

BHM1291003 THRUST WASHERS, crankshaft, pair A/R 848cc , +0.003" oversize.<br />

BHM1291030 THRUST WASHERS, crankshaft, pair A/R 848cc , +0.030" oversize.<br />

BHM1292STD THRUST WASHERS, crankshaft, pair A/R 997cc , standard size.<br />

BHM1292003 THRUST WASHERS, crankshaft, pair A/R 997cc , +0.003" oversize.<br />

BHM1292030 THRUST WASHERS, crankshaft, pair A/R 997cc , +0.030" oversize.<br />

21 6K836 KEY, Woodr uff, crankshaft 1<br />

22 8G725 GEAR, timing chain, crankshaft 1 848cc .<br />

AEA538 GEAR, timing chain, crankshaft 1 997cc .<br />

23 6K628 WASHER, packing A/R<br />

24 12A1148 OIL THROWER, crankshaft 1<br />

25 88G561 OIL SEAL, timing cover 1 Included in timing co ver assembly.<br />

Crankshaft Pulley<br />

The 848cc engine was never fitted with a vibration damper type pulley. The 997cc unit did receive one,<br />

or in fact two different ones. The original design was a separate pulley with a damper screwed to it;<br />

eventually a one-piece damper pulley was offered as a replacement but in fact both set ups remained<br />

available as spares alongside each other for man y years. If you want the original pulley, it is still<br />

available today from <strong>Somerford</strong> <strong>Mini</strong>.<br />

From 1980 onwards (i.e. A Plus engines) all engines without exception used slot drive . In this system the<br />

camshaft has a slot in the end which engages with a spade shaped lug on the oil pump shaft.<br />

Pre-1980 automatic, 1969-71 Cooper S and most 1275 GT engines (i.e. not including the last handful of<br />

1980 built engines which were A Plus) used star drive , otherwise known as spider drive. In this system a<br />

drive flange or ‘spider’ sits between the camshaft and oil pump, its three external lobes engaging in the<br />

end of the camshaft and its internal splines (or ‘star’) engaging on external splines on the oil pump shaft.<br />

A range of uprated camshafts and other engine tuning components are also available from <strong>Somerford</strong> <strong>Mini</strong>,<br />

but are not listed here. Please contact us for details.<br />

38 8G712 CAMSHAFT, for ‘pin drive’oil pump 1 848cc, manual gearbox, 1959-80.<br />

CAM6267 CAMSHAFT, for ‘slot drive’oil pump 1 848cc, manual gearbox, 1980 on.<br />

A Plus type.<br />

12A1065 CAMSHAFT, for ‘star drive’ oil pump 1 848cc, automatic gearbox.<br />

88G229 CAMSHAFT, for ‘pin drive’oil pump 1 997cc .<br />

39 2A299 PIN, oil pump drive 1 Included in ‘pin drive’type camshafts.<br />

40 CHM108 FLANGE, for ‘star drive’ oil pump 1 Use with ‘star drive’ type camshaft.<br />

(flange also known as ‘spider’)<br />

41 12G4499 SPINDLE, distributor drive 1<br />

42 2A13 TAPPET (also known as cam follower) 8 Standard size .<br />

2A13010 TAPPET (also known as cam follower) 8 +0.010" oversize.<br />

43 2A14 PUSH ROD 8 Alternative to 12A250 when replaced<br />

in sets.<br />

12A250 PUSH ROD 8 Alternative to 2A14 when replaced<br />

in sets.<br />

Note that the bolt retaining the pulley to the crankshaft is specific to the type of pulley being fitted.<br />

Later ’85H’ 848cc engines from 1980 approximately onwards received a pulley with a strobe timing plate<br />

attached as par t of the A Plus modification programme.<br />

848cc Crankshaft Pulley<br />

26 2A940 PULLEY, crankshaft 1 1959-70, dynamo fitted models.<br />

12A1380 PULLEY, crankshaft 1 1959-70, alter nator fitted models.<br />

CAM6323 PULLEY, crankshaft 1 1970-80; may be used on earlier<br />

engines.<br />

CAM6497 PULLEY, crankshaft 1 1980 on; A Plus type with timing<br />

plate .<br />

27 AEA312 BOLT, pulley to crankshaft 1<br />

28 12A398 LOCK TAB, pulley bolt 1<br />

997cc Crankshaft Pulley<br />

29 AEG454 PULLEY, crankshaft 1 Separate pulley and damper fitment.<br />

30 12A367 DAMPER 1 Separate pulley and damper fitment.<br />

31 SH605051 SCREW, damper to pulley 4 Separate pulley and damper fitment.<br />

32 LWZ305 WASHER, locking 4 Separate pulley and damper fitment.<br />

33 AEA312 BOLT, pulley to crankshaft 1 Separate pulley and damper fitment.<br />

34 12A398 LOCK TAB, pulley bolt 1 Separate pulley and damper fitment.<br />

35 88G305 PULLEY, crankshaft, with damper 1 One-piece damper pulley fitment.<br />

36 12A283 BOLT, pulley to crankshaft 1 One-piece damper pulley fitment.<br />

37 12A398 LOCK TAB, pulley bolt 1 One-piece damper pulley fitment.<br />

Camshaft and Tappets<br />

A dramatic proportion of the wear suffered by a camshaft during its entire working life actually takes<br />

place during the first few minutes of running after fitment. Whenever you replace the camshaft or<br />

tappets, or both, in your engine you should apply cam lubricant during assembly; it will lessen the<br />

inevitable scuffing and potential damage between cam and tappets during the bedding in period.<br />

<strong>Somerford</strong> <strong>Mini</strong> stock cam lube in a 250ml bottle under part number CL001. Also, you can pack the oil<br />

pump with cam lube before fitting it to the engine - it’s a very successful way of priming the oil pump<br />

(if you prime it with engine oil, there’s a fair chance a lot of it will have drained back into the gearbox<br />

by the time you turn the engine over for the first time).<br />

Three different coupling designs (‘drives’) between the end of the camshaft and the oil pump were used<br />

in <strong>Mini</strong> engines, and of course you will need to ensure that if the camshaft or oil pump are replaced<br />

that the correct matching types are used. Drive methods can be changed in engines (particularly when<br />

the desired profile of camshaft is not available with the original drive type for your engine), but this<br />

tends to get a little complicated when sorting out the correct corresponding oil pump to use. Details of<br />

which oil pumps may be fitted to which engines - and how they can be fitted - are in the Oil Pumps<br />

and Oil Pressure Relief Valves section of the <strong>Somerford</strong> <strong>Mini</strong> <strong>Catalogue</strong>.<br />

Up until 1980, all <strong>Mini</strong> engines - except automatic, 1969-71 Cooper S and 1275 GT units - used pin<br />

drive camshafts, where a pin across the end of the camshaft engages in a slot in the oil pump shaft (but<br />

don’t call it slot drive - that’s a different system).<br />

Timing Chain<br />

Three different timing chain gear systems were used to drive the camshaft on the 848cc engine. From<br />

1959 until 1974, a gear with rubber tensioner rings fitted either side was used. From 1974 to 1979 a<br />

different gear without tensioner rings was fitted; this gear can be used on pre-1974 engines, without<br />

tensioner rings. Finally from 1979 onwards a sprung tensioner pad (at last, a proper chain tensioner)<br />

together with the 1974-79 gear - again, without rings - was used.<br />

To be honest,replacement in a pre-1974 engine of the early gear and ring tensioners with the later, plain<br />

gear has little or no detrimental effect on timing chain efficiency or durability, since the ring tensioners<br />

struggle to get past a few thousand miles of running before becoming completely ineffective anyway!<br />

997cc engines were all originally fitted with the ring tensioner type chain gear, but as with the 848cc<br />

engine the later gear may be fitted instead without the rubber rings.<br />

44 3H2127 CHAIN, timing 1<br />

45 2A85 GEAR, timing chain, camshaft, with ring 1 1959-74, may be replaced by<br />

tensioners<br />

12G4337 without ring tensioners.<br />

46 2A86 GEAR, timing chain, camshaft, ring 1 1959-74, may be replaced by<br />

tensioner type<br />

12G4337 without ring tensioners.<br />

47 12G4337 GEAR, timing chain, camshaft 1 1974-79, use without ring tensioners.<br />

1979 on, use with tensioner pad.<br />

48 8G549 RING, timing chain tensioner, rubber 2 1959-74.<br />

49 12G2621 PAD,timing chain tensioner 1 1979 on.<br />

50 12G2629 PIN, tensioner pivot 1 1979 on.<br />

51 12G2628 PLATE, tensioner mounting 1 1979 on.<br />

52 SH605061 SCREW, plate to cylinder block 2 1979 on.<br />

53 LWZ305 WASHER, locking 2 1979 on.<br />

54 PWZ105 WASHER, plain 2 1979 on.<br />

55 WKN505 KEY, Woodr uff 1<br />

56 6K629 NUT, gear to camshaft 1<br />

57 2A759 LOCK TAB, nut 1<br />

Interchangeability of Timing Chain Assemblies<br />

It is perfectly possible to uprate the camshaft drive on earlier, simplex (single row) chain type engines by<br />

using standard components from other A Series or A Plus engines. The one slight modification required<br />

would be when fitting a duplex (double row) chain and gears, in which case the two screw holes in the<br />

engine front plate corresponding with the front main bearing cap will need to be countersunk.<br />

To convert from a plain simplex chain to a simple x chain with sprung pad tensioner (as on A Plus<br />

engines), you will need camshaft gear 12G4337 (if your engine is pre-1974), engine front plate 12G2626,<br />

A Plus timing cover CAM4904, timing cover gasket GUG705550GM, an extra screw, lock washer, plain<br />

washer and nut to secure the cover (part nos. SH605061, LWZ305, PWZ105 and FNZ105 respectively), plus<br />

the sprung pad tensioner assembly listed in illustration numbers 49 to 54 abo ve.<br />

To convert from a simplex to duplex chain, the only different parts you will require are camshaft gear<br />

AEA696 (steel) or 12G1397 (iron),crankshaft gear AEA695 (steel) or 12G1699 (iron), duplex chain<br />

2H4905 and two off front plate to main bearing cap countersunk screw AEA687.<br />

Tel. 01249 721421 Fax. 01249 721316 www.somerford-mini.co.uk 21