Somerford Mini Ltd. Ordering Parts Using This Catalogue

Somerford Mini Ltd. Ordering Parts Using This Catalogue

Somerford Mini Ltd. Ordering Parts Using This Catalogue

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

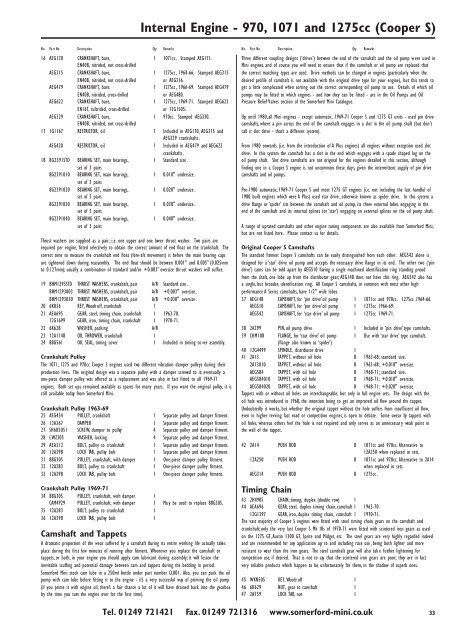

Internal Engine - 970, 1071 and 1275cc (Cooper S)<br />

No. Part No. Description Qty. Remarks No. Part No. Description Qty. Remarks<br />

16 AEG170 CRANKSHAFT, bare, 1 1071cc . Stamped AEG171.<br />

EN40B, nitrided, not cross-drilled<br />

AEG315 CRANKSHAFT, bare, 1 1275cc , 1964-66. Stamped AEG315<br />

EN40B, nitrided, not cross-drilled or AEG316.<br />

AEG479 CRANKSHAFT, bare, 1 1275cc , 1966-69. Stamped AEG479<br />

EN40B, nitrided, cross-drilled<br />

or AEG480.<br />

AEG622 CRANKSHAFT, bare, 1 1275cc , 1969-71. Stamped AEG623<br />

EN16T, tuftrided, cross-drilled or 12G1505.<br />

AEG329 CRANKSHAFT, bare, 1 970cc . Stamped AEG330.<br />

EN40B, nitrided, not cross-drilled<br />

17 1G1167 RESTRICTOR, oil 1 Included in AEG170, AEG315 and<br />

AEG329 crankshafts .<br />

AEG420 RESTRICTOR, oil 1 Included in AEG479 and AEG622<br />

crankshafts .<br />

18 8G2391STD BEARING SET, main bearings, 1 Standard size .<br />

set of 3 pairs<br />

8G2391010 BEARING SET, main bearings, 1 0.010" undersize.<br />

set of 3 pairs<br />

8G2391020 BEARING SET, main bearings, 1 0.020" undersize.<br />

set of 3 pairs<br />

8G2391030 BEARING SET, main bearings, 1 0.030" undersize.<br />

set of 3 pairs<br />

8G2391040 BEARING SET, main bearings, 1 0.040" undersize.<br />

set of 3 pairs<br />

Thrust washers are supplied as a pair; i.e. one upper and one lower thrust washer. Two pairs are<br />

required per engine, fitted selectively to obtain the correct amount of end float on the crankshaft. The<br />

correct time to measure the crankshaft end float (fore-aft movement) is before the main bearing caps<br />

are tightened down during reassembly. The end float should be between 0.001” and 0.005” (0.025mm<br />

to 0.127mm); usually a combination of standard and/or +0.003” oversize thr ust washers will suffice.<br />

19 BHM1293STD THRUST WASHERS, crankshaft, pair A/R Standard size .<br />

BHM1293003 THRUST WASHERS, crankshaft, pair A/R +0.003" oversize .<br />

BHM1293030 THRUST WASHERS, crankshaft, pair A/R +0.030" oversize .<br />

20 6K836 KEY, Woodr uff, crankshaft 1<br />

21 AEA695 GEAR, steel, timing chain, crankshaft 1 1963-70.<br />

12G1699 GEAR, iron, timing chain, crankshaft 1 1970-71.<br />

22 6K628 WASHER, packing A/R<br />

23 12A1148 OIL THROWER, crankshaft 1<br />

24 88G561 OIL SEAL, timing cover 1 Included in timing co ver assembly.<br />

Crankshaft Pulley<br />

The 1071, 1275 and 970cc Cooper S engines used two different vibration damper pulleys during their<br />

production lives. The original design was a separate pulley with a damper screwed to it; eventually a<br />

one-piece damper pulley was offered as a replacement and was also in fact fitted to all 1969-71<br />

engines. Both set ups remained available as spares for many years. If you want the original pulley, it is<br />

still available today from <strong>Somerford</strong> <strong>Mini</strong>.<br />

Crankshaft Pulley 1963-69<br />

25 AEG454 PULLEY, crankshaft 1 Separate pulley and damper fitment.<br />

26 12A367 DAMPER 1 Separate pulley and damper fitment.<br />

27 SH605051 SCREW, damper to pulley 4 Separate pulley and damper fitment.<br />

28 LWZ305 WASHER, locking 4 Separate pulley and damper fitment.<br />

29 AEA312 BOLT, pulley to crankshaft 1 Separate pulley and damper fitment.<br />

30 12A398 LOCK TAB, pulley bolt 1 Separate pulley and damper fitment.<br />

31 88G305 PULLEY, crankshaft, with damper 1 One-piece damper pulley fitment.<br />

32 12A283 BOLT, pulley to crankshaft 1 One-piece damper pulley fitment.<br />

33 12A398 LOCK TAB, pulley bolt 1 One-piece damper pulley fitment.<br />

Three different coupling designs (‘drives’) between the end of the camshaft and the oil pump were used in<br />

<strong>Mini</strong> engines, and of course you will need to ensure that if the camshaft or oil pump are replaced that<br />

the correct matching types are used. Drive methods can be changed in engines (particularly when the<br />

desired profile of camshaft is not available with the original drive type for your engine), but this tends to<br />

get a little complicated when sorting out the correct corresponding oil pump to use. Details of which oil<br />

pumps may be fitted to which engines - and how they can be fitted - are in the Oil Pumps and Oil<br />

Pressure Relief Valves section of the <strong>Somerford</strong> <strong>Mini</strong> <strong>Catalogue</strong>.<br />

Up until 1980,all <strong>Mini</strong> engines - except automatic , 1969-71 Cooper S and 1275 GT units - used pin drive<br />

camshafts, where a pin across the end of the camshaft engages in a slot in the oil pump shaft (but don’t<br />

call it slot drive - that’s a different system).<br />

From 1980 onwards (i.e. from the introduction of A Plus engines) all engines without exception used slot<br />

drive. In this system the camshaft has a slot in the end which engages with a spade shaped lug on the<br />

oil pump shaft. Slot drive camshafts are not original for the engines detailed in this section, although<br />

finding one in a Cooper S engine is not uncommon these days, given the intermittent supply of pin drive<br />

camshafts and oil pumps.<br />

Pre-1980 automatic, 1969-71 Cooper S and most 1275 GT engines (i.e. not including the last handful of<br />

1980 built engines which were A Plus) used star drive , otherwise known as spider drive. In this system a<br />

drive flange or ‘spider’ sits between the camshaft and oil pump, its three external lobes engaging in the<br />

end of the camshaft and its internal splines (or ‘star’) engaging on external splines on the oil pump shaft.<br />

A range of uprated camshafts and other engine tuning components are also available from <strong>Somerford</strong> <strong>Mini</strong>,<br />

but are not listed here. Please contact us for details.<br />

Original Cooper S Camshafts<br />

The standard fitment Cooper S camshafts can be easily distinguished from each other. AEG542 alone is<br />

designed for a ‘star’ drive oil pump and accepts the necessary drive flange in its end. The other two (‘pin<br />

drive’) cams can be told apart by AEG510 having a single machined identification ring standing proud<br />

from the shaft, one lobe up from the distributor gear; AEG148 does not have this ring. AEG542 also has<br />

a single, but broader, identification ring. All Cooper S camshafts, in common with most other high<br />

performance A Series camshafts, have 1/2" wide lobes.<br />

37 AEG148 CAMSHAFT, for ‘pin drive’oil pump 1 1071cc and 970cc . 1275cc 1964-66.<br />

AEG510 CAMSHAFT, for ‘pin drive’oil pump 1 1275cc 1966-69.<br />

AEG542 CAMSHAFT, for ‘star drive’ oil pump 1 1275cc 1969-71.<br />

38 2A299 PIN, oil pump drive 1 Included in ‘pin drive’type camshafts.<br />

39 CHM108 FLANGE, for ‘star drive’ oil pump 1 Use with ‘star drive’ type camshaft.<br />

(flange also known as ‘spider’)<br />

40 12G4499 SPINDLE, distributor drive 1<br />

41 2A13 TAPPET, without oil hole 8 1963-68; standard size.<br />

2A13010 TAPPET, without oil hole 8 1963-68; +0.010" oversize.<br />

AEG584 TAPPET, with oil hole 8 1968-71; standard size.<br />

AEG584010 TAPPET, with oil hole 8 1968-71; +0.010" oversize.<br />

AEG584020 TAPPET, with oil hole 8 1968-71; +0.020" oversize.<br />

Tappets with or without oil holes are interchangeable, but only in full engine sets. The design with the<br />

oil hole was introduced in 1968, the intention being to get an improved oil flow around the tappet.<br />

Undoubtedly it works, but whether the original tappet without the hole suffers from insufficient oil flow,<br />

even in higher revving fast road or competition engines, is open to debate. Some swear by tappets with<br />

oil holes, whereas others feel the hole is not required and only serves as an unnecessar y weak point in<br />

the wall of the tappet.<br />

42 2A14 PUSH ROD 8 1071cc and 970cc. Alternative to<br />

12A250 when replaced in sets.<br />

12A250 PUSH ROD 8 1071cc and 970cc. Alternative to 2A14<br />

when replaced in sets.<br />

AEG314 PUSH ROD 8 1275cc .<br />

Crankshaft Pulley 1969-71<br />

34 88G305 PULLEY, crankshaft, with damper 1<br />

CAM4929 PULLEY, crankshaft, with damper 1 May be used to replace 88G305.<br />

35 12A283 BOLT, pulley to crankshaft 1<br />

36 12A398 LOCK TAB, pulley bolt 1<br />

Camshaft and Tappets<br />

A dramatic proportion of the wear suffered by a camshaft during its entire working life actually takes<br />

place during the first few minutes of running after fitment. Whenever you replace the camshaft or<br />

tappets, or both, in your engine you should apply cam lubricant during assembly; it will lessen the<br />

inevitable scuffing and potential damage between cam and tappets during the bedding in period.<br />

<strong>Somerford</strong> <strong>Mini</strong> stock cam lube in a 250ml bottle under part number CL001. Also, you can pack the oil<br />

pump with cam lube before fitting it to the engine - it’s a very successful way of priming the oil pump<br />

(if you prime it with engine oil, there’s a fair chance a lot of it will have drained back into the gearbox<br />

by the time you turn the engine over for the first time).<br />

Timing Chain<br />

43 2H4905 CHAIN, timing, duplex (double row) 1<br />

44 AEA696 GEAR, steel, duplex timing chain,camshaft 1 1963-70.<br />

12G1397 GEAR, iron, duplex timing chain, camshaft 1 1970-71.<br />

The vast majority of Cooper S engines were fitted with steel timing chain gears on the camshaft and<br />

crankshaft;only the very last Cooper S Mk IIIs of 1970-71 were fitted with scintered iron gears as used<br />

on the 1275 GT,Austin 1300 GT, Sprite and Midget, etc. The steel gears are very highly regarded indeed<br />

and are recommended for any application up to and including race use, being both lighter and more<br />

resistant to wear than the iron gears. The steel camshaft gear will also tak e further lightening for<br />

competition use, if desired. That is not to say that the scintered iron gears are poor; they are in fact<br />

very reliable products which happen to be, unfortunately for them, in the shadow of superb ones.<br />

45 WKN505 KEY, Woodr uff 1<br />

46 6K629 NUT, gear to camshaft 1<br />

47 2A759 LOCK TAB, nut 1<br />

Tel. 01249 721421 Fax. 01249 721316 www.somerford-mini.co.uk<br />

33