Apr-Jun.12 - the Nitie

Apr-Jun.12 - the Nitie

Apr-Jun.12 - the Nitie

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Performance of traditional<br />

chart with correlated data<br />

Sukhraj Singh*<br />

Dr. D. R. Prajapati**<br />

Shewhart charts are <strong>the</strong> prominent charts used to detect <strong>the</strong><br />

larger shifts in <strong>the</strong> mean of <strong>the</strong> process. They are widely used in<br />

<strong>the</strong> all type of <strong>the</strong> processes as well as in <strong>the</strong> service industries.<br />

It is usually assumed that <strong>the</strong> observations from <strong>the</strong> process<br />

output are independent and identically distributed (i.i.d.). But<br />

in actual practice, for many processes <strong>the</strong> observations are<br />

<br />

effect on <strong>the</strong> performance of <strong>the</strong> Shewhart (standard) chart.<br />

The performance of <strong>the</strong> traditional (Shewhart) chart is studied<br />

for <strong>the</strong> i.i.d. data and for <strong>the</strong> positively correlated data. The<br />

Average Run Lengths (ARLs) at various sets of parameters of<br />

<strong>the</strong> chart are computed by simulation, using <strong>the</strong> MATLAB<br />

software. The behavior of <strong>the</strong> chart at <strong>the</strong> various shifts in<br />

<strong>the</strong> process mean is studied and analyzed. It is concluded that<br />

when <strong>the</strong> level of correlation increases, both <strong>the</strong> false alarm<br />

rate and out of control ARL increase. In this paper, optimal<br />

schemes of <strong>the</strong> chart for each level of <strong>the</strong> correlation are<br />

suggested.<br />

Key Words: Traditional charts, Average run length,<br />

independent and identically distributed data, Autocorrelation,<br />

MATLAB<br />

INTRODUCTION<br />

Control charts are one of <strong>the</strong> powerful tools of <strong>the</strong><br />

Statistical Process Control (SPC) techniques, which are<br />

widely used in industry for process improvement and<br />

for estimating parameters or monitoring <strong>the</strong> variability<br />

of a given process. Shewhart charts were originally<br />

developed by Walter F. Shewhart (1931). The limits of<br />

<strong>the</strong> chart are known as upper control limit (UCL) and<br />

<br />

LCL = +<br />

<br />

deviation.<br />

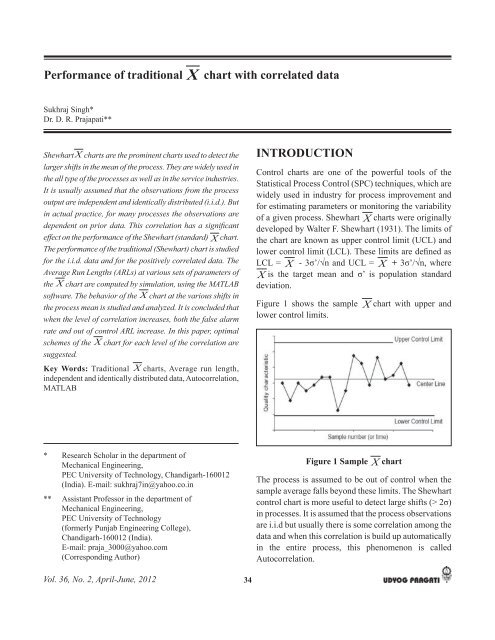

Figure 1 shows <strong>the</strong> sample<br />

lower control limits.<br />

chart with upper and<br />

* Research Scholar in <strong>the</strong> department of<br />

Mechanical Engineering,<br />

PEC University of Technology, Chandigarh-160012<br />

(India). E-mail: sukhraj7in@yahoo.co.in<br />

** Assistant Professor in <strong>the</strong> department of<br />

Mechanical Engineering,<br />

PEC University of Technology<br />

(formerly Punjab Engineering College),<br />

Chandigarh-160012 (India).<br />

E-mail: praja_3000@yahoo.com<br />

(Corresponding Author)<br />

Figure 1 Sample<br />

chart<br />

The process is assumed to be out of control when <strong>the</strong><br />

sample average falls beyond <strong>the</strong>se limits. The Shewhart<br />

<br />

in processes. It is assumed that <strong>the</strong> process observations<br />

are i.i.d but usually <strong>the</strong>re is some correlation among <strong>the</strong><br />

data and when this correlation is build up automatically<br />

in <strong>the</strong> entire process, this phenomenon is called<br />

Autocorrelation.<br />

Vol. 36, No. 2, <strong>Apr</strong>il-June, 2012<br />

34