Distributors - Carburetter Models

Distributors - Carburetter Models

Distributors - Carburetter Models

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

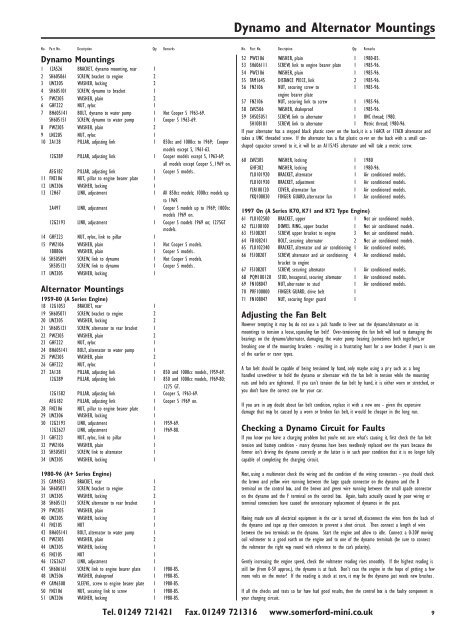

Dynamo and Alternator Mountings<br />

No. Part No. Description Qty. Remarks No. Part No. Description Qty. Remarks<br />

Dynamo Mountings<br />

1 12A526 BRACKET, dynamo mounting, rear 1<br />

2 SH605061 SCREW, bracket to engine 2<br />

3 LWZ305 WASHER, locking 2<br />

4 SH605101 SCREW, dynamo to bracket 1<br />

5 PWZ305 WASHER, plain 2<br />

6 GHF222 NUT, nyloc 1<br />

7 BH605141 BOLT, dynamo to water pump 1 Not Cooper S 1963-69.<br />

SH605151 SCREW, dynamo to water pump 1 Cooper S 1963-69.<br />

8 PWZ305 WASHER, plain 2<br />

9 LNZ205 NUT, nyloc 1<br />

10 2A128 PILLAR, adjusting link 1 850cc and 1000cc to 1969; Cooper<br />

models except S, 1961-63.<br />

12G289 PILLAR, adjusting link 1 Cooper models except S, 1963-69;<br />

all models except Cooper S , 1969 on.<br />

AEG182 PILLAR, adjusting link 1 Cooper S models .<br />

11 FNZ106 NUT, pillar to engine bearer plate 1<br />

12 LWZ306 WASHER, locking 1<br />

13 12H67 LINK, adjustment 1 All 850cc models; 1000cc models up<br />

to 1969.<br />

2A497 LINK, adjustment 1 Cooper S models up to 1969; 1000cc<br />

models 1969 on.<br />

12G2193 LINK, adjustment 1 Cooper S models 1969 on; 1275GT<br />

models.<br />

14 GHF223 NUT, nyloc, link to pillar 1<br />

15 PWZ106 WASHER, plain 1 Not Cooper S models.<br />

1B8806 WASHER, plain 1 Cooper S models.<br />

16 SH505091 SCREW, link to dynamo 1 Not Cooper S models.<br />

SH505121 SCREW, link to dynamo 1 Cooper S models.<br />

17 LWZ305 WASHER, locking 1<br />

Alternator Mountings<br />

1959-80 (A Series Engine)<br />

18 12G1053 BRACKET, rear 1<br />

19 SH605071 SCREW, bracket to engine 2<br />

20 LWZ305 WASHER, locking 2<br />

21 SH605121 SCREW, alternator to rear bracket 1<br />

22 PWZ305 WASHER, plain 2<br />

23 GHF222 NUT, nyloc 1<br />

24 BH605141 BOLT, alternator to water pump 1<br />

25 PWZ305 WASHER, plain 2<br />

26 GHF222 NUT, nyloc 1<br />

27 2A128 PILLAR, adjusting link 1 850 and 1000cc models , 1959-69.<br />

12G289 PILLAR, adjusting link 1 850 and 1000cc models, 1969-80;<br />

1275 GT.<br />

12G1582 PILLAR, adjusting link 1 Cooper S, 1963-69.<br />

AEG182 PILLAR, adjusting link 1 Cooper S 1969 on.<br />

28 FNZ106 NUT, pillar to engine bearer plate 1<br />

29 LWZ306 WASHER, locking 1<br />

30 12G2193 LINK, adjustment 1 1959-69.<br />

12G2627 LINK, adjustment 1 1969-80.<br />

31 GHF223 NUT, nyloc, link to pillar 1<br />

32 PWZ106 WASHER, plain 1<br />

33 SH505051 SCREW, link to alternator 1<br />

34 LWZ305 WASHER, locking 1<br />

52 PWZ106 WASHER, plain 1 1980-85.<br />

53 SH606111 SCREW, link to engine bearer plate 1 1985-96.<br />

54 PWZ106 WASHER, plain 1 1985-96.<br />

55 TAM1645 DISTANCE PIECE, link 2 1985-96.<br />

56 FNZ106 NUT, securing screw to 1 1985-96.<br />

engine bearer plate<br />

57 FNZ106 NUT, securing link to screw 1 1985-96.<br />

58 LWZ506 WASHER, shakeproof 1 1985-96.<br />

59 SH505051 SCREW, link to alternator 1 UNC thread; 1980.<br />

SH108181 SCREW, link to alternator 1 Metric thread; 1980-96.<br />

If your alternator has a stepped black plastic cover on the back,it is a 16ACR or 17ACR alternator and<br />

takes a UNC threaded screw. If the alternator has a flat plastic cover on the back with a small canshaped<br />

capacitor screwed to it, it will be an A115/45 alternator and will take a metric screw.<br />

60 LWZ305 WASHER, locking 1 1980<br />

GHF382 WASHER, locking 1 1980-96.<br />

YLU101920 BRACKET, alternator 1 Air conditioned models.<br />

YLU101930 BRACKET, adjustment 1 Air conditioned models.<br />

YLR100120 COVER, alternator fan 1 Air conditioned models.<br />

YKQ100030 FINGER GUARD,alternator fan 1 Air conditioned models.<br />

1997 On (A Series K70, K71 and K72 Type Engine)<br />

61 YLU102500 BRACKET, upper 1 Not air conditioned models .<br />

62 YLL100100 DOWEL RING , upper bracket 1 Not air conditioned models .<br />

63 FS108207 SCREW, upper bracket to engine 3 Not air conditioned models .<br />

64 FB108241 BOLT, securing alternator 2 Not air conditioned models .<br />

65 YLU102340 BRACKET, alternator and air conditioning 1 Air conditioned models.<br />

66 FS108207 SCREW, alternator and air conditioning 4 Air conditioned models.<br />

bracket to engine<br />

67 FS108207 SCREW, securing alternator 1 Air conditioned models.<br />

68 PQM100120 STUD, hexagonal, securing alternator 1 Air conditioned models.<br />

69 FN108047 NUT,alternator to stud 1 Air conditioned models.<br />

70 PRF100000 FINGER GUARD, drive belt 1<br />

71 FN108047 NUT, securing finger guard 1<br />

Adjusting the Fan Belt<br />

However tempting it may be, do not use a jack handle to lever out the dynamo/alternator on its<br />

mountings to tension a loose, squealing fan belt! Over-tensioning the fan belt will lead to damaging the<br />

bearings on the dynamo/alternator, damaging the water pump bearing (sometimes both together),or<br />

breaking one of the mounting brackets - resulting in a frustrating hunt for a new bracket if yours is one<br />

of the earlier or rarer types.<br />

A fan belt should be capable of being tensioned by hand, only maybe using a pr y such as a long<br />

handled screwdriver to hold the dynamo or alternator with the fan belt in tension while the mounting<br />

nuts and bolts are tightened. If you can’t tension the fan belt by hand, it is either worn or stretched, or<br />

you don’t have the correct one for your car.<br />

If you are in any doubt about fan belt condition, replace it with a new one - given the expensive<br />

damage that may be caused by a worn or broken fan belt, it would be cheaper in the long run.<br />

Checking a Dynamo Circuit for Faults<br />

If you know you have a charging problem but you’re not sure what’s causing it, first check the fan belt<br />

tension and battery condition - man y dynamos have been needlessly replaced over the years because the<br />

former isn’t driving the dynamo correctly or the latter is in such poor condition that it is no longer fully<br />

capable of completing the charging circuit.<br />

1980-96 (A+ Series Engine)<br />

35 CAM4853 BRACKET, rear 1<br />

36 SH605071 SCREW, bracket to engine 2<br />

37 LWZ305 WASHER, locking 2<br />

38 SH605121 SCREW, alternator to rear bracket 1<br />

39 PWZ305 WASHER, plain 2<br />

40 LWZ305 WASHER, locking 1<br />

41 FNZ105 NUT 1<br />

42 BH605141 BOLT, alternator to water pump 1<br />

43 PWZ305 WASHER, plain 2<br />

44 LWZ305 WASHER, locking 1<br />

45 FNZ105 NUT 1<br />

46 12G2627 LINK, adjustment 1<br />

47 SH606161 SCREW, link to engine bearer plate 1 1980-85.<br />

48 LWZ506 WASHER, shakeproof 1 1980-85.<br />

49 CAM6508 SLEEVE, screw to engine bearer plate 1 1980-85.<br />

50 FNZ106 NUT, securing link to screw 1 1980-85.<br />

51 LWZ206 WASHER, locking 1 1980-85.<br />

Next, using a multimeter check the wiring and the condition of the wiring connectors - you should check<br />

the brown and yellow wire running between the large spade connector on the dynamo and the D<br />

terminal on the control box, and the brown and green wire running between the small spade connector<br />

on the dynamo and the F terminal on the control box. Again, faults actually caused by poor wiring or<br />

terminal connections have caused the unnecessary replacement of dynamos in the past.<br />

Having made sure all electrical equipment in the car is turned off, disconnect the wires from the back of<br />

the dynamo and tape up their connectors to prevent a short circuit. Then connect a length of wire<br />

between the two terminals on the dynamo. Start the engine and allow to idle. Connect a 0-20V moving<br />

coil voltmeter to a good earth on the engine and to one of the dynamo terminals (be sure to connect<br />

the voltmeter the right way round with reference to the car’s polarity).<br />

Gently increasing the engine speed, check the voltmeter reading rises smoothly. If the highest reading is<br />

still low (from 0-5V approx.), the dynamo is at fault. Don’t race the engine in the hope of getting a few<br />

more volts on the meter! If the reading is stuck at zero, it may be the dynamo just needs new brushes .<br />

If all the checks and tests so far have had good results, then the control box is the faulty component in<br />

your charging circuit.<br />

Tel. 01249 721421 Fax. 01249 721316 www.somerford-mini.co.uk<br />

9