HA-655 Series - Harmonic Drive LLC

HA-655 Series - Harmonic Drive LLC

HA-655 Series - Harmonic Drive LLC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 1Outlines of the <strong>HA</strong>-<strong>655</strong> driver<br />

Chapter 1Outlines of <strong>HA</strong>-<strong>655</strong> driver<br />

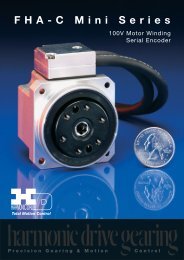

The <strong>HA</strong>-<strong>655</strong> series are dedicated servo drivers for F<strong>HA</strong> -C series actuators, which are axially compact<br />

and feature a large through-hole. The actuators utilize <strong>Harmonic</strong> <strong>Drive</strong>® gear components for precise<br />

motion control and super flat AC servomotors.<br />

The <strong>HA</strong>-<strong>655</strong> drivers provide many superior functions to allow the F<strong>HA</strong>-C actuators to excel in<br />

performance.<br />

1-1 Main features<br />

Easy parameter setting<br />

Parameters have been set to match the driver with the F<strong>HA</strong> -C series actuator you have ordered. No<br />

setting for the actuator is necessary by users.<br />

The <strong>HA</strong>-<strong>655</strong> series provides four modes that can be adjusted by end users: monitor mode, tune mode,<br />

parameter mode, and test mode. Parameters of these modes are indicated on a front panel of the driver<br />

using a 7-segment LED display and are easily set.<br />

Substantial monitoring functions<br />

The monitor mode indicates various operational parameters and makes it possible to indicate the<br />

required parameters for the servo system; such as commands, feedback, or an error counter.<br />

Up to eight previous alarms are also indicated as alarm history that is helpful for diagnosis.<br />

Individual control power supply<br />

It is possible to troubleshoot safely because the control power supply is individuated from the main.<br />

Easy test operation<br />

The test mode helps testing a servo system by JOG operation with keys on the front panel.<br />

Monitoring and operating I/O ports with the keys also help checking command sequences of a host<br />

without actuator motions.<br />

Complex encoder cable<br />

Improvement of data transmission with an encoder saves its wires resulted in increased reliability and<br />

simplified wiring.<br />

Optional absolute encoder<br />

The optional encoder system surely keeps its current position all the time, even in power failure.<br />

Electronic gear suitable for mechanical system<br />

The electronic gear function adjusts commands to a feed pitch of a driven mechanism such as gears or<br />

lead screws.<br />

Three types of input signals for position commands<br />

Three types of input signals for the position command are selectable: two-pulse train (Forward Pulse,<br />

Reverse Pulse), single-pulse train (Step and Direction), and two phase pulse train (Quadrature Input<br />

Signals).<br />

- 1 -