Processing and working instructions HPL and HPL elements PR ...

Processing and working instructions HPL and HPL elements PR ...

Processing and working instructions HPL and HPL elements PR ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>PR</strong>ODUCT INFORMATION<br />

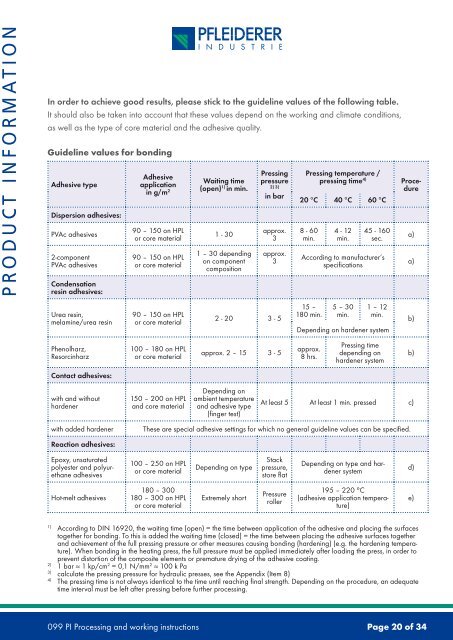

In order to achieve good results, please stick to the guideline values of the following table.<br />

It should also be taken into account that these values depend on the <strong>working</strong> <strong>and</strong> climate conditions,<br />

as well as the type of core material <strong>and</strong> the adhesive quality.<br />

guideline values for bonding<br />

Adhesive type<br />

Dispersion adhesives:<br />

PVAc adhesives<br />

2-component<br />

PVAc adhesives<br />

Condensation<br />

resin adhesives:<br />

Urea resin,<br />

melamine/urea resin<br />

Phenolharz,<br />

Resorcinharz<br />

Contact adhesives:<br />

with <strong>and</strong> without<br />

hardener<br />

Adhesive<br />

application<br />

in g/m 2<br />

90 – 150 on <strong>HPL</strong><br />

or core material<br />

90 – 150 on <strong>HPL</strong><br />

or core material<br />

90 – 150 on <strong>HPL</strong><br />

or core material<br />

100 – 180 on <strong>HPL</strong><br />

or core material<br />

150 – 200 on <strong>HPL</strong><br />

<strong>and</strong> core material<br />

Waiting time<br />

(open) 1) in min.<br />

1 - 30<br />

1 – 30 depending<br />

on component<br />

composition<br />

Pressing<br />

pressure<br />

2) 3)<br />

in bar<br />

approx.<br />

3<br />

approx.<br />

3<br />

2 - 20 3 - 5<br />

approx. 2 – 15 3 - 5<br />

Depending on<br />

ambient temperature<br />

<strong>and</strong> adhesive type<br />

(finger test)<br />

Pressing temperature /<br />

pressing time 4) Proce -<br />

dure<br />

20 °C 40 °C 60 °C<br />

8 - 60<br />

min.<br />

4 - 12<br />

min.<br />

45 - 160<br />

sec.<br />

According to manufacturer’s<br />

specifications<br />

15 –<br />

180 min.<br />

5 – 30<br />

min.<br />

1 – 12<br />

min.<br />

Depending on hardener system<br />

approx.<br />

8 hrs.<br />

Pressing time<br />

depending on<br />

hardener system<br />

At least 5 At least 1 min. pressed c)<br />

with added hardener These are special adhesive settings for which no general guideline values can be specified.<br />

Reaction adhesives:<br />

Epoxy, unsaturated<br />

polyester <strong>and</strong> polyurethane<br />

adhesives<br />

Hot-melt adhesives<br />

100 – 250 on <strong>HPL</strong><br />

or core material<br />

180 – 300<br />

180 – 300 on <strong>HPL</strong><br />

or core material<br />

Depending on type<br />

Extremely short<br />

Stack<br />

pressure,<br />

store flat<br />

Pressure<br />

roller<br />

Depending on type <strong>and</strong> hardener<br />

system<br />

195 – 220 °C<br />

(adhesive application temperature)<br />

1) According to DIN 16920, the waiting time (open) = the time between application of the adhesive <strong>and</strong> placing the surfaces<br />

together for bonding. To this is added the waiting time (closed) = the time between placing the adhesive surfaces together<br />

<strong>and</strong> achievement of the full pressing pressure or other measures causing bonding (hardening) (e.g. the hardening tempera-<br />

ture). When bonding in the heating press, the full pressure must be applied immediately after loading the press, in order to<br />

prevent distortion of the composite <strong>elements</strong> or premature drying of the adhesive coating.<br />

2) 1 bar ≈ 1 kp/cm 2 = 0,1 N/mm 2 ≈ 100 k Pa<br />

3) calculate the pressing pressure for hydraulic presses, see the Appendix (Item 8)<br />

4) The pressing time is not always identical to the time until reaching final strength. Depending on the procedure, an adequate<br />

time interval must be left after pressing before further processing.<br />

099 PI <strong>Processing</strong> <strong>and</strong> <strong>working</strong> <strong>instructions</strong> Page 20 of 34<br />

a)<br />

a)<br />

b)<br />

b)<br />

d)<br />

e)