Souvenir Containing Abstracts - YMCA University of Science ...

Souvenir Containing Abstracts - YMCA University of Science ...

Souvenir Containing Abstracts - YMCA University of Science ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

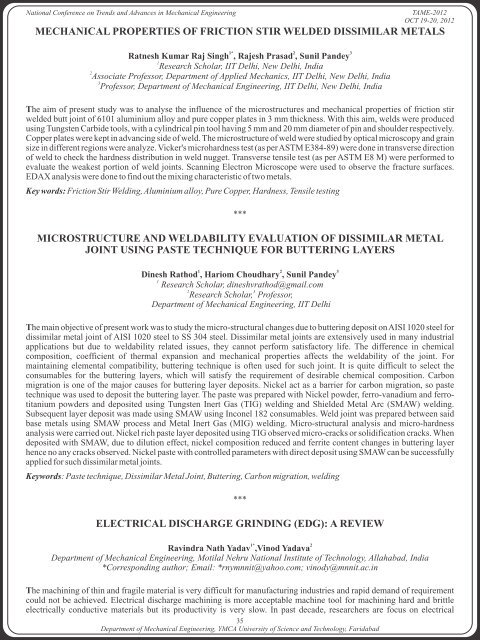

National Conference on Trends and Advances in Mechanical Engineering<br />

MECHANICAL PROPERTIES OF FRICTION STIR WELDED DISSIMILAR METALS<br />

1* 2 3<br />

Ratnesh Kumar Raj Singh , Rajesh Prasad , Sunil Pandey<br />

1<br />

Research Scholar, IIT Delhi, New Delhi, India<br />

2<br />

Associate Pr<strong>of</strong>essor, Department <strong>of</strong> Applied Mechanics, IIT Delhi, New Delhi, India<br />

3<br />

Pr<strong>of</strong>essor, Department <strong>of</strong> Mechanical Engineering, IIT Delhi, New Delhi, India<br />

TAME-2012<br />

OCT 19-20, 2012<br />

The aim <strong>of</strong> present study was to analyse the influence <strong>of</strong> the microstructures and mechanical properties <strong>of</strong> friction stir<br />

welded butt joint <strong>of</strong> 6101 aluminium alloy and pure copper plates in 3 mm thickness. With this aim, welds were produced<br />

using Tungsten Carbide tools, with a cylindrical pin tool having 5 mm and 20 mm diameter <strong>of</strong> pin and shoulder respectively.<br />

Copper plates were kept in advancing side <strong>of</strong> weld. The microstructure <strong>of</strong> weld were studied by optical microscopy and grain<br />

size in different regions were analyze. Vicker's microhardness test (as per ASTM E384-89) were done in transverse direction<br />

<strong>of</strong> weld to check the hardness distribution in weld nugget. Transverse tensile test (as per ASTM E8 M) were performed to<br />

evaluate the weakest portion <strong>of</strong> weld joints. Scanning Electron Microscope were used to observe the fracture surfaces.<br />

EDAX analysis were done to find out the mixing characteristic <strong>of</strong> two metals.<br />

Key words: Friction Stir Welding, Aluminium alloy, Pure Copper, Hardness, Tensile testing<br />

***<br />

MICROSTRUCTURE AND WELDABILITY EVALUATION OF DISSIMILAR METAL<br />

JOINT USING PASTE TECHNIQUE FOR BUTTERING LAYERS<br />

1 2 3<br />

Dinesh Rathod , Hariom Choudhary , Sunil Pandey<br />

1<br />

Research Scholar, dineshvrathod@gmail.com<br />

2 3<br />

Research Scholar, Pr<strong>of</strong>essor,<br />

Department <strong>of</strong> Mechanical Engineering, IIT Delhi<br />

The main objective <strong>of</strong> present work was to study the micro-structural changes due to buttering deposit on AISI 1020 steel for<br />

dissimilar metal joint <strong>of</strong> AISI 1020 steel to SS 304 steel. Dissimilar metal joints are extensively used in many industrial<br />

applications but due to weldability related issues, they cannot perform satisfactory life. The difference in chemical<br />

composition, coefficient <strong>of</strong> thermal expansion and mechanical properties affects the weldability <strong>of</strong> the joint. For<br />

maintaining elemental compatibility, buttering technique is <strong>of</strong>ten used for such joint. It is quite difficult to select the<br />

consumables for the buttering layers, which will satisfy the requirement <strong>of</strong> desirable chemical composition. Carbon<br />

migration is one <strong>of</strong> the major causes for buttering layer deposits. Nickel act as a barrier for carbon migration, so paste<br />

technique was used to deposit the buttering layer. The paste was prepared with Nickel powder, ferro-vanadium and ferrotitanium<br />

powders and deposited using Tungsten Inert Gas (TIG) welding and Shielded Metal Arc (SMAW) welding.<br />

Subsequent layer deposit was made using SMAW using Inconel 182 consumables. Weld joint was prepared between said<br />

base metals using SMAW process and Metal Inert Gas (MIG) welding. Micro-structural analysis and micro-hardness<br />

analysis were carried out. Nickel rich paste layer deposited using TIG observed micro-cracks or solidification cracks. When<br />

deposited with SMAW, due to dilution effect, nickel composition reduced and ferrite content changes in buttering layer<br />

hence no any cracks observed. Nickel paste with controlled parameters with direct deposit using SMAW can be successfully<br />

applied for such dissimilar metal joints.<br />

Keywords: Paste technique, Dissimilar Metal Joint, Buttering, Carbon migration, welding<br />

***<br />

ELECTRICAL DISCHARGE GRINDING (EDG): A REVIEW<br />

1* 2<br />

Ravindra Nath Yadav ,Vinod Yadava<br />

Department <strong>of</strong> Mechanical Engineering, Motilal Nehru National Institute <strong>of</strong> Technology, Allahabad, India<br />

*Corresponding author; Email: *rnymnnit@yahoo.com; vinody@mnnit.ac.in<br />

The machining <strong>of</strong> thin and fragile material is very difficult for manufacturing industries and rapid demand <strong>of</strong> requirement<br />

could not be achieved. Electrical discharge machining is more acceptable machine tool for machining hard and brittle<br />

electrically conductive materials but its productivity is very slow. In past decade, researchers are focus on electrical<br />

35<br />

Department <strong>of</strong> Mechanical Engineering, <strong>YMCA</strong> <strong>University</strong> <strong>of</strong> <strong>Science</strong> and Technology, Faridabad