CovEr STory - Mjunction

CovEr STory - Mjunction

CovEr STory - Mjunction

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chief Editor<br />

Rakesh Dubey, Tel: +91 91633 48159, Email: rakesh.dubey@mjunction.in<br />

Executive Editor<br />

Arindam Bandyopadhyay, Tel: +91 91633 48016<br />

Email: arindam.bandyopadhyay@mjunction.in<br />

Editorial Board<br />

Alok Srivastava, General Manager, MMTC Ltd<br />

Amitabh Panda, Group Director (Shipping & Logistics Operations), Tata Steel<br />

Group<br />

Anirudha Gupta, Director, P&H JoyMining Equipment India Ltd<br />

Ashok Jain, Managing Director, Saumya Mining Ltd<br />

Deepak Bhattacharyya, Head – coaljunction, mjunction services ltd<br />

Ganesan Natarajan, WT Director, President & CEO, Ennore Coke Ltd<br />

Lawrence Metzroth, Vice President – Analysis & Strategy, Arch Coal Inc<br />

M K Palanivel, President – All India Bulk, Samsara Group<br />

P S Bhattacharyya, Managing Director, Haldia Petrochemicals Ltd<br />

S N Choubey, Head – Commercial, ABG Cement Ltd<br />

Sandeep Kumar, Managing Director, S & T Mining Co Pvt Ltd<br />

Suresh Thawani, Managing Director, Tata Sponge Iron Ltd<br />

Advertising<br />

Soumitra Bose, Tel: +91 92310 00232, Email: soumitra.bose@mjunction.in<br />

Sumit Jalan, Tel: +91 91633 48243, Email: sumit.jalan@mjunction.in<br />

Subscription<br />

Rachita Das, Tel: +91 91633 48045, Email: rachita.das@mjunction.in<br />

Design<br />

Debal Ray, Ishawer Kumar Sriwastva, Sobhan Jas<br />

For suggestions, feedback and queries, please write to<br />

coalinsights@mjunction.in<br />

Registered Office<br />

mjunction services limited, Tata Centre, 43 J L Nehru Rd, Kolkata 700 071<br />

Website: www.mjunction.in<br />

Corporate Head Quarters: Godrej Waterside, 3rd Floor, Tower 1, Plot V, Block DP, Sector<br />

V, Salt Lake, Kolkata 700091, Tel: +91 33 6610 6100, Fax: +91 33 6610 6187 Bhilai: Room<br />

321, 3rd Floor, Ispat Bhavan, Bhilai Steel Plant, Bhilai 490001, Tel: +91 788 6451066, Tele/Fax:<br />

+91 788 2221071 Bokaro: Room 19, Old Admin Bldg., Bokaro Steel Plant, Bokaro 827001,<br />

Tel/Fax: +91 654 2226132 Burnpur: SAIL - IISCO Steel Plant, Materials Building, Order<br />

Department, Ground Floor, Burnpur 713325, Telfax: +91 341 2240107 Chennai: Basement,<br />

Begum Ispahani Complex, New No 91, Old No 44, Armenian Street, Chennai 600 001, Tel: +91<br />

44 64624733-35, Fax: +91 44 25216536 Durgapur: Room 618, Ispat Bhavan, Durgapur Steel<br />

Plant, Durgapur 713203, Tel: +91 343 6510185, Tele/Fax: +91 343 2586946 Jamshedpur:<br />

Kashi Kunj, Ground Floor, Road No. 02, Contractors Area, Bistupur, Jamshedpur 831001, Tel:<br />

+91 657 6519985/86/90/91, Fax: +91 657 2230040 Mumbai: Jolly Bhavan II, 403, 4th Floor, 7<br />

New Marine Lines, Mumbai 400002, Tel: +91 22 66510663, Tele/Fax: +91 22 66510662 New<br />

Delhi: C127, 2nd Floor, A One Plaza, Naraina Industrial Area, Phase I, New Delhi 110028,<br />

Tel: +91 11 65661774/65413288, Tele/Fax: +91 11 25897000 Noamundi: C/o TATA Steel<br />

Limited, Mines Purchase Cell, PO: Noamundi, Singbhum (West), Jharkhand 833 217, Tel: +91<br />

9204791638/9234368606 Rourkela: Administrative Bldg., Room 624, 6th Flr, Rourkela Steel<br />

Plant, Rourkela 769011, Tel: +91 661 6514142/6511412<br />

mjunction believes that all junctionites, customers, suppliers, partners, etc should<br />

practice the highest ethical standards in their daily operations.<br />

Report a concern to ethics@mjunction.in<br />

Copyright: All rights reserved. No part of Coal Insights can be reproduced or copied in any<br />

form or by any means without the prior permission of mjunction services limited. Please<br />

inform us if any copyright has been inadvertently infringed.<br />

Disclaimer: This document is for information purpose only. Certain information herein has<br />

been acquired from various external sources believed to be reliable. While we have taken<br />

reasonable care to compile this report, we in no way assume any responsibility for any error<br />

or discrepancy in regards to information contained herein. Readers are requested to make<br />

appropriate judgment without any prejudice or compulsion.<br />

EDITORIAL<br />

Dear Readers,<br />

Welcome back to your senses after Budget 2012…!<br />

This year, as in most years, there was something for<br />

everybody…the progressive, the regressive, the moderate,<br />

the excessive. And also for those who are bored with Budget.<br />

Opening the session, the Railway Budget (allegedly) dished<br />

out a ‘drama’ and then the Finance Minister quoted a<br />

(Shakespearean) play. All for the aam admi…!<br />

On a serious note, the Budget 2012 had precious little<br />

for the mining and mineral sector. But of course, the long<br />

standing demand from power producers for removal of duty<br />

on thermal coal import was paid heed to, much to the dismay<br />

of Coal India Ltd (CIL). This could be a turn-off for the coal<br />

miner before an imminent increase in domestic prices planned<br />

for April-May. Leaving this aside, there was hardly any<br />

impact of the Budget on other pure-play miners such as Sesa<br />

Goa, NMDC and MOIL.<br />

As for the power utilities, there are perhaps some reasons<br />

to rejoice. The Budget permitted power companies to tap<br />

external commercial borrowings (ECB) – a welcome move.<br />

The FM, hence the government, also recognised that the power<br />

sector is under duress because of high prices of coal. Why not<br />

straightway provide cheaper domestic coal, then, instead of<br />

trying to make imports cheaper<br />

For CIL, the change in guard is a few days away. If there is<br />

no further twist in the tale, S Narsing Rao would step into the<br />

company headquarters in Kolkata in the first week of April.<br />

The industry is looking up for the quiet man from Singareni<br />

to deliver on the production front. Incidentally, production at<br />

SCCL jumped 40 percent during his tenure.<br />

The ministry, meanwhile, is doing its best to adopt the<br />

carrot and stick approach for the captive blocks. Unfortunately,<br />

it can neither offer nor take away much, except for the notso-attractive<br />

coal blocks. It will be interesting to see how<br />

the companies respond to the auction of around 50 blocks<br />

the MoC has identified for allocation. Talking about captive<br />

allocation, one cannot but be amused at the recent furore in<br />

Parliament over block allocations. The allegations that the<br />

government lost Rs 1,000,000 crore by allocating blocks free<br />

could have some merit. But the fact that these blocks produce<br />

38 million tons (mt) after 15-20 years of allocation makes light<br />

of such accusations.<br />

And still, not every hope is lost. This issue of Coal Insights<br />

brings out a report on the prospects of underground coal<br />

gasification (UCG) in India. UCG is a clean, efficient and ecofriendly<br />

way of using coal that is unmineable. Although there<br />

was not much success initially, the technology holds promise<br />

for the future.<br />

Happy reading,<br />

Warm Regards<br />

Rakesh Dubey<br />

Chief Editor

Contents<br />

16 UCG only way to exploit India’s deep coal<br />

seams<br />

18 Wrong site selection foiled India’s UCG<br />

efforts<br />

24 Thermal coal import prices subdued in<br />

March<br />

25 Spot coking coal prices ease in March<br />

27 CIL may raise prices in April-May<br />

30 Govt. may start auction of new blocks in<br />

May<br />

32 MoC may deallocate 58 blocks<br />

38 Trans Damodar coal block starts<br />

production<br />

39 MoEF may revise norms for washed coal<br />

used in TPPs<br />

40 Union Budget a mixed bag for metals,<br />

mining sectors<br />

41 Budget proposes slew of steps for crisishit<br />

power sector<br />

42 Indian plants generate 70,988.48 MU in<br />

Feb<br />

44 Power utilities’ coal import target for FY13<br />

raised to 70 mt<br />

45 India’s Jan cement production up nearly<br />

10.9%<br />

51 JSPL Odisha coal gasification unit by July<br />

52 RCF, CIL JV to set up coal gasification<br />

unit at Talcher<br />

54 BKT plans 32% hike in production<br />

59 Allocation of coal blocks to non-CIL<br />

companies a national blunder<br />

63 Concern over India’s coal future<br />

64 US coal consumption, production to<br />

decline in 2012: EIA<br />

66 New coking coal mines to benefit Indian<br />

market<br />

68 UK mining equipment makers flock to<br />

Indian shore<br />

70 Dedicated Freight Corridor to be ready by<br />

end of 2017<br />

71 Indian Railways April-Feb commodity<br />

freight revenue up 9.17%<br />

72 Port traffic down 0.74% y-o-y in April-Feb<br />

73 Power sector update<br />

84 E-auction<br />

85 Port data<br />

46 | SPECIAL FEATURE<br />

On the threshold of infinite energy<br />

A new innovation shows the way to<br />

extract carbon from flue gas emitted by<br />

thermal power plants.<br />

Publisher’s Statement<br />

06 | Cover Story<br />

Fuel for the Future<br />

India’s baby steps into the segment of<br />

underground coal gasification hold<br />

promise for the future.<br />

49 | Technology<br />

New biochemical syngas cleaning<br />

mechanism<br />

Innovative offers solutions for<br />

biodesuphurization of H 2<br />

S from syngas<br />

for coal gasification.<br />

Statement about ownership and other particulars about Coal Insights required to be<br />

published under Rule 8 of the Registration of Newspapers (Central) Rule, 1956.<br />

FORM IV<br />

(See Rule 8)<br />

1. Place of publication : Kolkata<br />

2. Periodicity of publication : Monthly<br />

3. Printer’s Name : CDC Printers<br />

Whether citizen of India<br />

: Yes<br />

4. Publisher’s Name : Rajarshi Chattopadhyay<br />

Whether citizen of India<br />

: Yes<br />

Address<br />

: Tata Centre, 43 Jawaharlal Nehru Road<br />

Kolkata 700071<br />

5. Editor’s Name : Rakesh Dubey<br />

Whether citizen of India<br />

: Yes<br />

Address<br />

: Tata Centre, 43 Jawaharlal Nehru Road<br />

Kolkata 700071<br />

6. Names and addresses of individuals : mjunction services ltd,<br />

who own the newspaper and partners Tata Centre, 43 Jawaharlal Nehru Road<br />

or shareholders holding more than Kolkata – 700071<br />

one per cent of the total capital<br />

I, Rajarshi Chattopadhyay, hereby declare that the particulars given above are true to the<br />

best of my knowledge and belief.<br />

Sd/-<br />

Rajarshi Chattopadhyay<br />

Dated: March 2012<br />

Publisher<br />

COAL INSIGHTS 4 March 2012

Cover Story<br />

India’s quest for UCG<br />

Fuel for the future<br />

Arindam Bandyopadhyay<br />

COAL INSIGHTS 6 March 2012

Cover Story<br />

There’s an interesting anecdote about the first discovery<br />

of crude oil in India, at Digboi in Assam, way back in<br />

the late nineteenth century.<br />

In 1867, a large number of ‘natives’ were camping in the<br />

forests of north-eastern tip of Assam to lay railway tracks<br />

for Assam Railway and Trading Co. Ltd. Except for a tiny<br />

habitat nearby, the area was marked as having virgin forest<br />

cover. One day, the loggers who deployed elephants for<br />

hauling found stains of a sticky brown fluid on the feet and<br />

tail of the pachyderm. As they followed the footprints of<br />

the animal, legend has it, the natives discovered a bubbling<br />

liquid oozing out of the forest floor ponging a heavy odour.<br />

Some propounded that the area was not suitable for human<br />

habitation; “Look into the ground, it doesn’t even hold water.”<br />

Some went a step ahead and fancied the land was actually<br />

cursed. It was not until the Canadian engineer overseeing<br />

the project caught sight of the seepage that the crude was<br />

identified and a historic discovery made!<br />

This may be partly true, partly a legend. But such initial<br />

doubts and suspicion are a little too common in case of many<br />

new discoveries and technology applications in this country.<br />

Be it nuclear power, information technology or economic<br />

liberalisation, they have always come with a tag of fear<br />

and apprehension, even though they were tried and tested<br />

elsewhere. Underground coal gasification (UCG) could be the<br />

latest addition to that list.<br />

In common parlance, UCG is an industrial in-situ<br />

gasification process, which is carried out in non-mined coal<br />

seams using injection of oxidants, and bringing the product gas<br />

to surface through production wells drilled from the surface.<br />

The product gas could be used as a chemical feedstock or as<br />

fuel for power generation.<br />

At a time when India is facing stagnation in coal production,<br />

hampering its power sector growth, coal gasification comes as a<br />

viable alternative source of fuel. To go by the experts, only a third<br />

of India’s proven coal reserves is mineable. Coal gasification<br />

technology can help extract the gas tapped in such deposits. By<br />

converting its coal reserves into enough gas and oil, India can<br />

surmount chronic power shortages and halve its energy import<br />

bill of $110 billion a year. Also, UCG has numerous other<br />

usages for chemicals and fertiliser industries and, according to<br />

industry sources, could “ensure future sustainability”.<br />

Unfortunately, the country has been a rather late entrant<br />

into the field. While the technology is decades old, India’s<br />

first commercial coal gasification plant is just about to start<br />

production. In terms of usage of UCG, India lags far behind<br />

China and also some other neighbours. Worse, the country as<br />

a whole seems still not convinced.<br />

UCG and its merits<br />

In simple words, UCG technology converts coal into a<br />

combustible gas underground. The in-situ gasification<br />

produces syngas, which is a mixture of carbon-monoxide,<br />

hydrogen and carbon-dioxide. It has a lesser energy density<br />

than natural gas and is used as a fuel source or feedstock for<br />

the production of other chemicals.<br />

The use of UCG is as old as 150 years or more. The world,<br />

especially Europe and the US, widely used this “spirit of<br />

the coal” for street lighting, set up gas plants, discovered<br />

the chemical composition and refined the technology. Over<br />

the years, a wide variety of appliances and uses for gas was<br />

developed.<br />

As of today, the coal gas has a number of by-products that<br />

are useful for the industry. These include coal tar, sulphur and<br />

ammonia. Dyes, medicines, including sulfa drugs, saccharine<br />

and many organic compounds are derived from coal gas. Coal<br />

tar is subjected to fractional distillation to recover various<br />

products including tar (used in roads), phenol (used in the<br />

manufacture of plastics), cresols (disinfectants), creosote<br />

(wood preservative) and benzole (motor fuel).<br />

By-products of coal gas manufacture<br />

♦♦<br />

Coal tar is a thick black liquid<br />

with high viscosity. It can be<br />

used for roofing jobs; Coal tar<br />

is sometimes used for heating<br />

or to fire boilers. It also has<br />

medical uses.<br />

♦♦<br />

Benzole is obtained from coal tar or coal gas. It is<br />

sometimes mixed with petrol<br />

and is sold as a motor fuel.<br />

♦♦<br />

Creosote is obtained from high<br />

temperature distillation of coal<br />

tar, and is used as a fungicide,<br />

insecticide, miticide, and<br />

sporicide to protect wood and<br />

is applied by pressure methods<br />

to wood products.<br />

♦♦<br />

Phenol is used to make chemical<br />

intermediates for a wide range<br />

of applications, ranging from<br />

plastics to pharmaceuticals and<br />

agricultural chemicals.<br />

♦♦<br />

Cresol is usually derived from<br />

coal tar and wood tar and is<br />

used primarily as a disinfectant.<br />

It also has uses in fermentation<br />

and molecular biology.<br />

COAL INSIGHTS 8 March 2012

DIG DOWN, AND YOU’LL FIND<br />

IT’S A VOLVO TO THE CORE.<br />

Volvo builds better excavators, loaders<br />

and articulated haulers and we are also<br />

one of the world’s largest engine<br />

makers. Engines built to work harder,<br />

for longer.<br />

To need less maintenance. To deliver<br />

more power at lower rpm. So if you’re<br />

using a Volvo excavator, for example,<br />

you don’t have to slow down as you dig<br />

down. With a Volvo under the hood, you<br />

know you’ve got your hands on higher<br />

productivity, lower costs - and more<br />

profit.<br />

Corporate Office:<br />

Volvo India Pvt. Ltd.<br />

Volvo Construction Equipment<br />

#65/1, Parin Building, Bagmane Tech Park,<br />

C V Raman Nagar, Bangalore 560 093<br />

Tel: +91 80 6691 2000<br />

Fax: +91 80 6691 2287<br />

www.volvoce.com<br />

Authorized Dealers<br />

Infra Equip Pvt. Ltd., Dhanbad<br />

Tel: +91 6540 262575<br />

Email: dineshpandey@infraequip.com<br />

Pollutech Engineering, Bhubaneshwar<br />

Tel: +91 674 258 5477<br />

Email: dilip@pollutech.in<br />

Suchita Earthmoving Solutions, Guwahati<br />

Tel: +91 99540 89208<br />

Email: amitabhuwalka@suchitagroup.com<br />

Suchita Millenium Projects Pvt. Ltd., Kolkata<br />

Tel +91 33 2219 7951<br />

Email: raghupatibhuwalka@suchitagroup.com<br />

volvo construction equipment

Cover Story<br />

Sulphur is used in the manufacture of sulphuric acid and<br />

ammonia is used in the manufacture of fertilisers. In fact, coal<br />

gasification is a route for a viable urea-ammonia plant. It is<br />

also an alternative source of fuel for DRI plants and thus can<br />

be used in the secondary steelmaking process.<br />

The major benefit of the UCG technology, as already<br />

mentioned, is that it can be applied to mining resources that<br />

are otherwise not economical to extract. Improved UCG<br />

technology could increase the amount of exploitable reserves<br />

as it helps to gasify deep, thin and low-grade coal seams.<br />

Not only in India, this process could greatly help other coal<br />

producing countries to exploit maximum their coal reserves.<br />

“UCG could increase recoverable coal reserves in the US by<br />

as much as 300 to 400 percent,” said Julio Friedman, who led<br />

the Carbon Management Program of Livermore National<br />

Laboratory, US.<br />

To go by an analyst’s estimate, the syngas produced by<br />

UCG contains about 80 percent of the energy in the coal, while<br />

another 15 percent of the useful energy can be recovered<br />

as steam. “Thus when used in combined cycle mode, the<br />

energy losses during the gasification process are only about<br />

5 percent.” According to some other estimate, about 350 cubic<br />

metres of gas can be produced per ton of coal. The by-products<br />

of significant commercial value are hydrocarbons, phenols,<br />

ammonia and clean water.<br />

UCG also offers an alternative to conventional coal mining<br />

methods. The environmental impact of UCG is less than that<br />

of traditional coal mining, experts said.<br />

Rediscovering the wheel<br />

In India, UCG was never tried on a significant scale. But<br />

globally, the technology saw its ups and downs over the last<br />

150 years. In the late nineteenth and early twentieth century,<br />

Advantages of UCG<br />

♦♦<br />

Tapping energy from vast coal reserves which are not<br />

commercially viable to mine<br />

♦♦<br />

Back of the envelope calculations indicate huge energy<br />

potential of about 1,000 MW power generation from a<br />

small block of 25 sq. km, having 10 m thick coal seam<br />

♦♦<br />

Increases worker safety as no mining operations<br />

involved<br />

♦♦<br />

Low environmental impact<br />

• No atmospheric pollution; coal mines involves<br />

coal dust pollution<br />

• No appreciable change in landscape<br />

• Less subsidence than conventional mining<br />

• Less Resettlement and Rehabilitation (R&R) issues<br />

• No surface disposal of ash and coal tailings<br />

• Potential GHG reduction activity (CO 2<br />

sequestration in cavity)<br />

Linc Energy’s UCG plant at Chinchilla, Australia<br />

the world used coal gas to good measure for street lighting,<br />

but discarded it following the advent of electric power.<br />

Another reason for the withdrawal of the technology was<br />

its growing reputation as “ugly duckling”, especially in the<br />

US. The hydrogen gas that is yielded by the process was then<br />

considered as an environmental hazard.<br />

It is interesting to note that the same technology made<br />

a comeback decades later, in the late 20th century, as an<br />

environmentally sustainable process of ensuring energy<br />

security. Much of the world had, meanwhile, changed its<br />

outlook on crude oil, given the depleting reserves and volatile<br />

prices. Oil price spike was seen as an event that would<br />

become more frequent by the day. Many countries without<br />

significant crude reserves started looking for ways to replace<br />

imported oil with secure domestic energy sources, primarily<br />

coal. Hydrogen fuel gained prominence as a prospective<br />

clean energy source. And the world started rediscovering the<br />

potential of UCG.<br />

During the oil crisis of the 1970s, the US Department of<br />

Energy (DoE) took it up on itself to invest heavily in alternative<br />

energy sources, including coal gasification technologies. More<br />

than 30 UCG pilot tests were run across the country. Two sites<br />

in Centralia (Washington) and Hoe Creek (Wyoming) were<br />

developed by Livermore Laboratory, which pioneered in the<br />

study of UCG.<br />

Along with the US, the former USSR made substantial<br />

investment in the technology over the decades and achieved<br />

commercial success too. But it is China which has taken the<br />

lead in UCG of late. The country started investing in UCG<br />

since the 1980s and currently boasts of the largest operating<br />

UCG programme.<br />

With the Middle East crisis flaring up from time to time,<br />

and uncertainty looming over supply of crude and natural gas<br />

from conflict regions, more and more countries are focusing<br />

on this technology. Overall, there are an increasing number of<br />

UCG projects emerging around the world including Australia,<br />

UK, Canada, China, USA, India, Vietnam, Pakistan, Hungary,<br />

Chile and South Africa.<br />

COAL INSIGHTS 10 March 2012

Cover Story<br />

The UCG process<br />

The UCG process has improved<br />

over the years. Earlier, the old<br />

coal gasification processes were<br />

carried out in the absence of air,<br />

partially converting the coal to<br />

town gas with a large residue of<br />

Air Injection<br />

coke. Modern processes convert<br />

all the carbon to a mixture of CO<br />

and hydrogen, commonly called<br />

syngas.<br />

50% Nitrogen<br />

There are three general types 50% CO, H 2<br />

, CH 4<br />

, CO 2<br />

of coal gasifiers, namely fixed 100-180 BTU/SCF<br />

bed, entrained flow and fluidised<br />

bed. All these technologies are<br />

based on partial oxidation or Electrical power genration<br />

gasification of a carbonaceous<br />

& Industrial fuel<br />

feed material.<br />

100-180 BTU/SCF<br />

The partial oxidation reaction<br />

produces syngas containing<br />

CO, H 2<br />

and CO 2<br />

. It also contains<br />

H 2<br />

O, CH 4<br />

, H 2<br />

S, NH 3<br />

and<br />

particulates. In case a fixed bed<br />

gasification technology is used, the syngas will also contain<br />

some organic compounds. There are various technologies for<br />

coal gasification, but essentially all of them employ the same<br />

chemical processes.<br />

Gasification technologies may vary in the way the blowing<br />

is supplied. In case of ‘direct blowing’, the coal and oxidizer<br />

are supplied towards each other from the opposite sides of the<br />

reactor channel.<br />

In contrast, in ‘reversed blowing’, the coal and the oxidizer<br />

are supplied from the same side of the reactor. In this case,<br />

there is no chemical interaction between coal and oxidizer<br />

before the reaction zone.<br />

In the power sector, the Integrated Gasification<br />

Combined Cycle (IGCC) plants use a combined-cycle design<br />

UCG salient features<br />

• Under the process of UCG, gasification of coal happens<br />

insitu by controlled burning<br />

• About 350 m3gas can be produced per tonne of coal<br />

• By-products of significant commercial value will be<br />

hydrocarbons, phenols, anhydrous NH3and clean<br />

water<br />

• UCG overcomes hazards of underground and open<br />

cast mining operations.<br />

• In UCG process, ash/ slug removal is not required as<br />

they remain in the cavities<br />

• Cost of production for this energy resource could be as<br />

low as US$ 1.0-1.5 per mmbtu<br />

UCG process diagram<br />

Coal resources<br />

insitu<br />

CO 2<br />

removal<br />

Synthesis Gas<br />

(Chemical feedstock)<br />

300-400 BTU/SCF<br />

(incorporating both gas and steam turbines) to maximise the<br />

benefits of coal gasification. The gas turbine is driven by the<br />

combustion of syngas, while the by-product steam is used<br />

to heat exchange with water/steam to generate superheated<br />

steam to drive the steam turbine.<br />

Current status of UCG<br />

Steam/Oxygen<br />

Injection<br />

100% CO, H 2<br />

, CH 4<br />

, CO 2<br />

200-300 BTU/SCF<br />

CO shift and<br />

Methanation<br />

Synthetic Pipeline Gas<br />

900-1000 BTU/SCF<br />

As mentioned above, China is leading the field in terms of the<br />

number of operating UCG programmes. Currently, there are<br />

more than 12 trials are bring conducted in closed underground<br />

mines in the country.<br />

Elsewhere, the major commercially operated projects<br />

of UCG include Angren in Uzbekistan, Chinchilla in West<br />

Brisbane, Australia and Majuba in South Africa. In the last<br />

10-15 years, a number of European countries including<br />

Netherlands, Spain, Germany and Italy have commissioned<br />

demonstration projects for coal gasification.<br />

In India, the effort to set up coal based industries dates<br />

back to the 1940s. However, the early efforts of UCG did not<br />

taste much success.<br />

Along with technology issues, the pricing of natural gas<br />

affected UCG projects. The commercial success of UCG was<br />

doubted by the coal miners as well as the industry.<br />

The situation started changing for the better in the last<br />

few years. The stagnated supply of coal and limited supply of<br />

natural gas in India prompted the project planners to opt for<br />

this technology.<br />

As of today, the first commercially operated UCG projects<br />

in India are just about to commence, thanks to the pioneering<br />

ventures of JSPL and Reliance. JSPL is going to commence<br />

its Angul plant in Odisha shortly. The Angul project would<br />

COAL INSIGHTS 12 March 2012

Cover Story<br />

Gasification technologies<br />

combine the Lurgi coal gasification technology with a Midrex<br />

plant to use coal gas for producing DRI. JSPL has plans to set<br />

up similar such projects in future, company sources said.<br />

Reliance, on its part, is going to use pet coke for its<br />

upcoming coal gasification project. Another Indian company,<br />

Rashtriya Chemicals & Fertiliser (RCF) has planned to take<br />

up an UCG project at Talcher, Odisha based on Lurgi fixed<br />

bed technology. As for the technology, Indian PSU BHEL has<br />

Major market drivers<br />

According to a report by Frost & Sullivan, the high price<br />

of natural gas is the major driver for the development<br />

of this technology. “It is believed that as long as the<br />

natural gas prices exceed $4 per mmbtu, the technology<br />

could compete with the natural gas based generation<br />

technologies. Also, given the abundant supply of<br />

coal, the prices of coal would be much more stable as<br />

compared to natural gas.”<br />

The high efficiency potential coupled with the low<br />

level of emissions from the IGCC systems has also<br />

attracted the interest of various companies. “Their<br />

efficiency is above 40 percent. Furthermore, these<br />

systems produce little solid waste and close to zero<br />

SOx and NOx emissions. Around 99 percent of the<br />

sulphur present in the coal can be recovered and sold.<br />

The carbon monoxide produced can be reacted with<br />

steam to produce hydrogen and carbon dioxide and<br />

after “sequestrating” the carbon dioxide, the remaining<br />

hydrogen can be used in a fuel cell,” the report said.<br />

developed a technology for fluidbased<br />

gasification process for highash<br />

coal.<br />

Fuel for the future<br />

In a country like India, UCG can open<br />

up new avenues of energy security for<br />

fuel-hungry economy.<br />

For India, the stagnated coal<br />

production, huge unmineable<br />

deposits of non-coking coal, limited<br />

availability of natural gas and<br />

bulging oil import bills are reason<br />

enough to give a serious look into this<br />

technology, which some analysts tag<br />

as the fuel for the future.<br />

“Coal gasification is a very<br />

important technology from many<br />

perspectives – fuel, emissions and<br />

efficiency,” said an analyst. “It is a<br />

perfect technology, once completely<br />

developed and commercialised,<br />

to hedge against the uncertain<br />

availability and price of natural gas. The coal is likely to<br />

become a very attractive fuel for the hydrogen production and<br />

could emerge as a critical bridge towards hydrogen economy<br />

in the coming years,” he said.<br />

Except for the threat to ground water contamination, UCG<br />

is much more environment-friendly when compared with<br />

conventional mining methods.<br />

In fact, coal gasification offers one of the most versatile<br />

and clean ways to covert coal into electricity, hydrogen and<br />

other valuable energy products. A number of coal gasification<br />

electric power plants are currently operating commercially in<br />

the US and other countries. Many experts believe UCG will<br />

be “at the heart of future generations of clean coal technology<br />

plants”.<br />

UCG can achieve extremely low SOx, NOx and particulate<br />

emissions from burning coal-derived gases. In an IGCC, the<br />

syngas produced is virtually free of fuel-bound nitrogen. If<br />

oxygen is used in a coal gasifier instead of air, carbon dioxide<br />

is emitted as a concentrated gas stream in syngas at high<br />

pressure. In this form, it can be captured and sequestrated<br />

more easily and at lower costs.<br />

In terms of efficiency too, UCG scores over typical coal<br />

combustion based power plants, where heat from burning<br />

coal is used to boil water, making steam that converts only a<br />

third of the energy value of coal into electricity.<br />

The India Inc. is slowly looking up to these prospects of<br />

a new form of fuel. Although the government remains tardy<br />

as ever, the corporate sector – both public and private – are<br />

slowly shedding their slackness to peep into the future of the<br />

fuel, or perhaps the fuel for the future!<br />

COAL INSIGHTS 14 March 2012

Cover Story<br />

UCG only way to exploit India’s<br />

deep coal seams<br />

Underground coal gasification (UCG) could be an<br />

alternative source of fuel for some countries, but for<br />

India it is perhaps the only way to exploit the country’s<br />

huge deposit of coal that lies below mineable depths. To go by<br />

a study by the Central Institute of Mining and Fuel Research<br />

(CIMFR), the coal deposits lying below the mineable depth of<br />

600 mtrs may be nearly as voluminous as the deposits lying<br />

above the mineable depth.<br />

“In India, the mineable depth is 600 metres. But there are vast<br />

resources below the mineable depth,” said a leading scientist of<br />

CIMFR. While the Geological Survey of India (GSI) estimates 285<br />

billion (bn) tons of coal reserves in the country up to a depth of<br />

1,200 metres, total reserves could be as much as 475 bn tons.<br />

“Altogether, there are 285 bn tons of coal reserves up to<br />

1,200 metres of depth. There is another 60 bn tons of reserves<br />

in another basin below 1,500 metres. There is also substantial<br />

coal in Bengal basin below 2-3 km depth. Overall, India is<br />

estimated to have 475 bn tons of coal reserves, of which only<br />

100 bn tons is recoverable by conventional method mining,”<br />

he said. This coal lying below mineable depth can only be<br />

used via underground coal gasification.<br />

UCG is the partial combustion of coal below to produce a<br />

combustible gas known as syn-gas for use as an energy source.<br />

It is achieved by drilling two wells from the surface, one to<br />

supply air/oxygen, another well to produce syn-gas to the<br />

Coal Insights Bureau<br />

surface. Apart from syn-gas, by-products are hydrocarbon<br />

liquids, ammonia, among others, sources in CIMFR informed.<br />

Hot prospects<br />

Open pit mine Bingham Canyon copper mine in Utah, USA. At 4 km wide and 1.2 km<br />

deep, it is the world’s deepest open-pit mine. It began operations in 1906.<br />

UCG efforts in India<br />

Mehasana in Gujarat in 1980s;<br />

Merta road in Rajasthan in late 1980s;<br />

Bihar (now Jharkhand) in late 1980s;<br />

Gas Authority of India in Rajasthan since 1998;<br />

Neyveli Lignite Corporation since 2002.<br />

In India, Chinakuri coal mine of Eastern Coalfields Ltd (ECL)<br />

is known as the deepest mine, located at a depth 1,400 metres.<br />

There are deeper levels at North and South Karanpura and<br />

Raniganj as well.<br />

There is also huge gas potential at Jharia coalfield, where<br />

the deposit below 600 metres depth is not really explored.<br />

According to some estimate, the reserves up to 600 metres is<br />

14.2 bn tons while the deposit in the range 600-1,200 metres is<br />

5.2 bn tons. Altogether, 19.4 bn tons of reserves are estimated<br />

up to the depth of 1,200 metres.<br />

“All these deeper levels are of interest to us as gas can be<br />

extracted from these levels,” the scientist said.<br />

To explore the potential of UCG in<br />

India, CIMFR has entered into an MoU<br />

with University of California for a trial of<br />

UCG. This, however, requires substantial<br />

funds and institutes like CIMFR are<br />

looking forward to the MoC to grant funds<br />

for UCG trials in the Twelfth Plan budget.<br />

Sources said initially there was a conflict<br />

between MoC and Ministry of Petroleum<br />

and Natural Gas over the ownership of gas<br />

obtained from deep coal seams. While the<br />

MoC maintained that the gas coming off<br />

coal is its property, the petroleum ministry<br />

claimed it should have the ownership<br />

of any gas containing hydrocarbon. An<br />

amicable solution was arrived at later on<br />

whereby the gas available up to mineable<br />

depth will belong to MoC, and the rest<br />

to the petroleum ministry. The mineable<br />

area, as already mentioned, is 600 metres<br />

below ground level.<br />

COAL INSIGHTS 16 March 2012

Cover Story<br />

Wrong site selection foiled<br />

India’s UCG efforts<br />

Coal Insights Bureau<br />

Notwithstanding its rich coal reserves, India is<br />

yet to achieve commercial success in the field of<br />

underground coal gasification (UCG). In fact, the<br />

country is lagging even behind its neighbouring countries<br />

in this respect. While there are various reasons cited for<br />

this failure – technological and economic – a consensus<br />

view is that the project planners failed to make proper site<br />

selection.<br />

In a vastly populated country like India, this was all<br />

the more important given the environmental implications<br />

of this kind of projects. One of the major concerns for<br />

UCG projects is the risk of ground water contamination.<br />

Before taking further steps to tap this resource, the country<br />

therefore needs to mind this important step so as not to<br />

repeat the mistakes.<br />

“All sites are not suitable for UCG. In case of pilots which<br />

failed in the past, wrong site selection was the dominant<br />

reason,” said A.K. Shrivastava, group director, Abhijeet<br />

Group.<br />

“Experience shows that proper site selection, based on<br />

detailed site characterisation, plays a very important role<br />

in the success of UCG. Detailed investigations enhance the<br />

chances of success. But detailed investigations cost a lot of<br />

money. Therefore a suitable primary screening criteria is<br />

needed,” he said.<br />

Echoing his views, Dr P.B. Rastogi, director, Ministry of<br />

Environment and Forests (MoEF), said UCG projects often<br />

lead to groundwater contamination, not only in India but in<br />

sparsely populated countries as well. For instance, he said<br />

the Chinchilla coal gasification pilot project in Australia had<br />

tried to limit outflow of contaminants by maintaining negative<br />

pressure inside the coal combustion chamber, but the attempt<br />

was rather unsuccessful.<br />

“This is a problem that perhaps cannot be solved….there is<br />

no site in India where there is no ground water or water that<br />

will not be consumed,” said Rastogi.<br />

Shrivastava, however, said that risks can be mitigated<br />

through proper site selection. For this, a selection criterion<br />

needs to be chalked out, taking inputs from other countries<br />

and giving due importance to problems specific to the Indian<br />

perspective.<br />

Selection criterion<br />

Shrivastava laid down a number of surface features that may<br />

affect UCG projects. These may include distance from human<br />

habitat, distance from water sources, nature of deposit,<br />

resource base, geology of the deposit,<br />

hydrology of the deposit area,<br />

distance from working or abandoned<br />

mines, and nature and position of the<br />

aquifers.<br />

One of the site characterisation<br />

objectives is to reduce risk of UCG<br />

to acceptable levels. For this, the<br />

project planner needs to use proper<br />

assessment tools for selection and<br />

screening.<br />

Also, plan operations and facilities<br />

are to be based on site-specific risk<br />

profiles. The planners need to evolve<br />

and set operations guidelines based<br />

on verified site parameters. He<br />

also needs to identify the operating<br />

ranges that limit production of<br />

syn-gas, contaminant compounds,<br />

prevent contaminant migration out<br />

of the cavity during and post UCG.<br />

Economics appropriate to UCG site<br />

COAL INSIGHTS 18 March 2012

Cover Story<br />

and appropriate technology for well linking are also crucial,<br />

he said.<br />

Factors that affect UCG design<br />

Thickness, dip and depth<br />

Coal seam geology<br />

Permeability to gas and liquid<br />

Rank (Ash, VM, Carbon content)<br />

Properties of coal<br />

Chemical composition (H2 & S)<br />

Geology, hydrology<br />

Strata & over burden properties<br />

Geo-mechanics & drilling Properties<br />

Operating Pressure, well layout<br />

Operating conditions<br />

Injection composition & flow rates<br />

Thermal, chemical<br />

Process & efficiency<br />

Resource recovery<br />

Volume, flow rate, composition<br />

Product gas<br />

Calorific value, temperature<br />

Impact on environment<br />

Thermal, chemical, subsidence<br />

Selection factors<br />

The various selection factors would affect the projects<br />

undertaken in a number of ways. These could be summarised<br />

under the following heads:<br />

Depth of coal seam: Shallow seams are not suitable for UCG<br />

due to high gas losses, potential for connection to surface and<br />

possible contamination of ground water. Deeper seams allow<br />

higher operating pressure due to higher hydrostatic pressure<br />

which enhances the methane content and thus heating value<br />

of the gas. Deeper seams require guided drilling resulting in<br />

higher cost. Deeper seams are less likely to be linked with<br />

potable aquifers thus avoiding water contamination. The<br />

syn-gas pressure may be adequate for direct use in turbines<br />

resulting in saving on cost of compression. Also, deeper seams<br />

minimise risk of subsidence.<br />

Location<br />

UCG trials – date, depth, thickness<br />

Coal type<br />

Thickness<br />

(m)<br />

Depth<br />

(m)<br />

Year<br />

Lisichanskaya Bituminous 0.44-2 60-250 1948-65<br />

Yuzhno-Abinskaya Bituminous 2.2-9 50-300 1999-current<br />

Angrensikaya Lignite 2-22 120-250 1957-current<br />

Podmoskovnaya Lignite 2.5 30-80 1946-53<br />

Shatskaya Lignite 2.6-4 30-60 1956-63<br />

Sinelnikovsy Lignite 3.6-6 80 -<br />

Chinchilla (Australia) - 8-10 130 1999-2004<br />

Tremeda (Spain)<br />

Sub-bituminous,<br />

lignite<br />

2-5 530-580 1989-98<br />

France Anthracite - 1200 1981-86<br />

Belgium Anthracite - 860 1979-87<br />

Newman Spinney (UK) Sub-bituminous 0.75 75 1959<br />

USA (Hanna 2) Sub-bituminous 6.8 90-120 1973-74<br />

USA (Hoe Creek) Sub-bituminous 7.6 38 1976-79<br />

Australian site selection criteria<br />

♦♦<br />

Seam thickness more than 5 m<br />

♦♦<br />

Coal Ash less than 40% (ADB)<br />

♦♦<br />

Seam dip less than 200<br />

♦♦<br />

Seam depth 200-400 m<br />

♦♦<br />

Minimum faulting – no dip/sills<br />

♦♦<br />

Roof thermally stable with minimal permeability.<br />

Preferably structured to encourage even caving<br />

♦♦<br />

Hydraulic gradient >200 m<br />

♦♦<br />

Adjacent aquifers may contain poor quality water<br />

and are of minimal permeability<br />

Other notes<br />

♦♦<br />

Limited Human activity<br />

♦♦<br />

No waterways over lying the site<br />

♦♦<br />

Subsidence acceptable at the location<br />

♦♦<br />

Coal resource suitable for long time operation<br />

US selection criteria<br />

♦♦<br />

Seam thickness greater than one meter or 0.6 m for<br />

steeply dipping seams<br />

♦♦<br />

Avoid variable thickness seams<br />

♦♦<br />

Avoid seams with overlying coal within 15m that is<br />

thicker than 0.6 m<br />

♦♦<br />

Minimum Resource of 3.5 million tons<br />

♦♦<br />

Minimum over burden of 100 m<br />

♦♦<br />

Minimum distance of 1.6 km from populated area<br />

(>100 people)<br />

♦♦<br />

Minimum distance of 0.8 Km mtrs from major faults<br />

♦♦<br />

Minimum distance of 1.6 Km from oil & Gas<br />

recovery development<br />

♦♦<br />

Minimum distance of 0.4 Km from major highways<br />

and rail<br />

♦♦<br />

Minimum distance of 1.6 Km from rivers and lakes<br />

♦♦<br />

Minimum distance of 3.2 Km from active mines<br />

♦♦<br />

Minimum distance of 1.6 Km from abandoned<br />

mines<br />

♦♦<br />

Steeply dipping seams preferred<br />

♦♦<br />

Floor & roof conditions need closer examination<br />

Porosity & permeability: Higher permeability makes it<br />

easy to link injection and production wells. It increases the<br />

rate of gasification by making transport of reactants easier.<br />

COAL INSIGHTS 20 March 2012

Cover Story<br />

Higher porosity and permeability also increases the influx of<br />

water. Higher porosity increases product gas losses.<br />

Coal seam thickness & dip: Thicker seams contain more<br />

resources for the same area; hence need fewer wells. In such<br />

cases, the drilling costs are lower. In thicker seams it is difficult<br />

to inter link injection and production wells due to drill head<br />

deviation problems. In thin seams, on the contrary, the heat<br />

losses are more and this leads to<br />

lower thermal efficiency and lower product gas quality. It<br />

is difficult to gasify seams less than 2 m in thickness. UCG is<br />

easier to sustain in dipping seams as tars and fluids fly away<br />

from the gasification zone.<br />

Rank, ash, VM & carbon content: The rank of coal plays an<br />

important part. Lignite<br />

and sub-bituminous coals are easier to gasify. Swelling<br />

properties of bituminous coals obstruct the gas passage and<br />

can increase gas losses; hence generally not preferred for UCG.<br />

Higher ash content means lower calorific value of the in-situ<br />

material; hence lower calorific value of gas. The gasification<br />

characteristics of coal play an important role on the volume<br />

and quality of the syn-gas.<br />

Process selection: UCG requires use of coupled process.<br />

Hydrological, geochemical and geo-mechanical models to<br />

capture:<br />

♦♦<br />

balancing gasifier operational pressure against<br />

hydrologic pressure and other gradients in the field to<br />

prevent outward contaminant migration;<br />

♦♦<br />

impact of gasifier operating conditions on creation and<br />

behavior of contaminants within the burn Chamber;<br />

♦♦<br />

enhanced vertical hydraulic conductivity of the rock<br />

matrix above the burn chamber as a result of collapse<br />

and fracturing; and<br />

♦♦<br />

buoyancy-driven upward flow of groundwater in the<br />

vicinity of the burn chamber toward potable water<br />

resources at shallower depth.<br />

Selection criteria in other countries<br />

Shrivastava said the other major coal producing countries<br />

which have pursued UCG have built their own criteria<br />

depending on the local geology and environment conditions.<br />

Among these countries, US, UK and Australia have well<br />

laid down selection criteria for UCG projects. The various<br />

parameters accounted for by these countries include seam<br />

thickness, nature of seams, minimum resource base, minimum<br />

over burden, minimum distance from populated area,<br />

hydraulic gradient, permeability of adjacent aquifers, among<br />

others.<br />

While there are some features common with these<br />

countries, the Indian coal has some peculiarities that are to be<br />

considered while laying down such a list of criteria for Indian<br />

conditions.<br />

“The Indian coals are mostly Permian Gondwana coals.<br />

Tertiary coals are found mostly in the North East. Gondwana<br />

coals are found along distinct river valleys, viz Damodar-Koel,<br />

Son-Mahanadi, Pranhita-Godawari, Wardha , Pench- Kanhan<br />

Valley. Indian coal has high ash content, low sulphur<br />

content, high ash fusion temperature, refractory nature of ash,<br />

low iron content in ash, low chlorine content, and low toxic<br />

trace elements,” said Shrivastava.<br />

Considering these features of Indian coal, the following<br />

selection criteria may be considered for Indian UCG projects:<br />

♦♦<br />

Seam thickness more than 1 m. For banded seams, coal<br />

thickness excluding bands > 1m<br />

♦Minimum ♦ resource of 5 million tons<br />

♦Minimum ♦ depth > 300<br />

♦Inter ♦ seam parting > 30 m for<br />

overlying seam thickness >0.5 m<br />

♦Should ♦ be at a distance of 3Km from<br />

nearest habitat (population >100)<br />

♦Minimum ♦ distance of 1.5 km from<br />

rivers, lakes, reservoirs<br />

♦Minimum ♦ distance of 3.0 km from<br />

working mines<br />

♦Minimum ♦ distance of 1.5 km from<br />

abandoned mines<br />

♦Area ♦ free of excessive faulting<br />

♦Preferably ♦ overlying sealing layer of<br />

clay<br />

♦No ♦ over lying waterways, highways,<br />

Railways<br />

♦Thermally ♦<br />

stable roof for even<br />

caving<br />

COAL INSIGHTS 22 March 2012

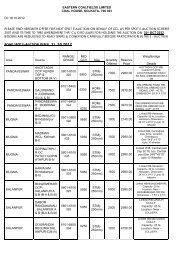

coal market fundamentals<br />

Thermal coal import prices subdued in March<br />

The Indian thermal coal market remained subdued<br />

despite some enquiries that took place in March,<br />

according to market participants. Both consumers and<br />

traders are not bullish or ready to take a position in this market<br />

mainly because of financial problems.<br />

The power prices remained low, while coal prices were<br />

high, with the local currency, the Rupee, hovering around 50-<br />

51 to the US dollar, acting as a deterrent to imports.<br />

Australian thermal coal of heating value of 6,300 kcal GAR<br />

is currently being offered at around $106 per ton against $114<br />

per ton quoted at the beginning of March. Offers of South<br />

African thermal coal of heating value of 6,000 kcal NAR fell by<br />

$2 per ton to $103 per ton in March from February end levels.<br />

Offers for Indonesian coal of heating value of 5,900 kcal GAR<br />

is hovering around $92 per ton, while that of heating value of<br />

5,000 kcal GAR is at $72 per ton.<br />

Traders said deals are done only if the coal is required on<br />

an urgent basis. No one is buying to stock the coal, and small<br />

power projects are also buying low grade coal with high ash.<br />

Another reason for the lack of buying interest is that players<br />

Thermol coal price trend in March 2012<br />

Date<br />

South<br />

African<br />

Coal (6000<br />

Kcal NAR)<br />

Australian<br />

Thermal<br />

coal (6300<br />

GAR)<br />

Indonesian<br />

(5900 Kcal<br />

GAR)<br />

Indonesian<br />

(5000 Kcal/<br />

GAR)<br />

Freight<br />

from SA<br />

to West<br />

Coast<br />

From<br />

Indonesian<br />

to West<br />

Coast<br />

Coal Insights Bureau<br />

From<br />

SA to<br />

East<br />

Coast<br />

From<br />

Indonesia<br />

to East<br />

Coast<br />

2-Mar 103.5 113.1 95 73.4 18.7 10.7 20.9 10.2<br />

5-Mar 103.75 111 94.75 73 19.3 10.6 21.8 10.2<br />

6-Mar 103.5 109 94.25 73 19.3 10.6 21.8 10.2<br />

12-Mar 103.25 105 92.8 72.2 19.5 10.75 22 10.2<br />

15-Mar 103 105.8 91.75 71.8 19.5 10.75 22 10.2<br />

are busy closing their financial year which ends on March 31<br />

and preparing their budget allocation for 2012-13.<br />

Indian buyers are quoting prices way below market rates,<br />

citing bids of around $100 per ton fob, for prompt Richards<br />

Bay cargoes against offers of around $105 per ton.<br />

However, according to analysts, thermal coal prices will<br />

remain at relatively high levels over the long term despite<br />

aggressive mine expansions to meet the growth in Asian<br />

demand, particularly from China and India.<br />

Analysts at a recent coal conference felt although there will<br />

be “aggressive” thermal coal supply expansions, steam coal<br />

prices in the long term will defy expectations of a drop and<br />

will instead remain at high levels.<br />

There may be short-term seasonal fluctuations such as the<br />

drop in prices in the current quarter, but the Newcastle reference<br />

coal price for Australian coal will increase progressively,<br />

analysts said. Cost pressures, infrastructure bottlenecks and a<br />

decrease in export coal quality will combine to hold prices at<br />

traditionally high levels and China and India will be the top<br />

two demand drivers. India’s seaborne steam coal demand by<br />

2030 will be 400 million tons (mt) per year from 80 mt in<br />

Critical coal crisis in 18 power units<br />

Coal Insights Bureau<br />

2011, overtaking Japan, according to analysts.<br />

India’s thermal coal demand may be even higher<br />

if domestic coal supply is constrained by delays in<br />

associated rail and port infrastructure projects. Cost<br />

pressures from changing fiscal regimes such as the<br />

carbon tax in Australia and the minimum export price<br />

regulations in Indonesia will also support high thermal<br />

coal prices.<br />

As many as 18 power plants in the country are faced<br />

with critical level of coal shortage, according to<br />

minister of State for Power, K.C. Venugopal.<br />

Of the 89 thermal power projects being monitored, 34<br />

had fuel (coal) stock less than seven days and 25 had less<br />

than four days stock, he said, while speaking in the Rajya<br />

Sabha (the upper house of Parliament).<br />

“None of the power utilities in the country has reported<br />

that any of their thermal power stations are stuck for want<br />

of coal, although inadequate availability of coal vis-a-vis<br />

requirement has affected electricity generation in some of<br />

the power plants,” he said.<br />

Power utilities, he said, have reported a generation loss<br />

of 8.7 billion units in 2011-12 (up to February, 2012) due to<br />

shortage of coal. Listing steps being taken by the government<br />

to mitigate shortage of coal for thermal power plants in<br />

the country, he said Coal India is being asked to enhance<br />

coal production while power utilities have been advised to<br />

import coal to bridge the domestic supply deficit.<br />

As many as 11 plants of state-owned NTPC lost 7.8<br />

billion units because of shortage of coal during the current<br />

fiscal. Other utilities that lost on generation of electricity<br />

included ones in Madhya Pradesh, Maharashtra and<br />

Andhra Pradesh, he added.<br />

The budget announced cuts in import duties on coal.<br />

The basic customs duty on steam coal was cut to zero from<br />

5 percent with countervailing duty reduced to 1 percent<br />

from 5 percent for fiscal 2012-13 or 2013-14. Analysts say<br />

that the effective reduction in import coal cost is close to 9<br />

percent.<br />

COAL INSIGHTS 24 March 2012

coal market fundamentals<br />

Spot coking coal prices ease<br />

Coal Insights Bureau<br />

Spot coking coal prices from Australia eased by about 1<br />

percent in March 2012 when compared with February<br />

2012 owing to lack of buying support from India and<br />

China.<br />

However, the fall was restricted to some extent towards<br />

the end of March owing to heavy rainfall and significant<br />

disruption at several coking coal mines in the Moranbah<br />

region of the Bowen Basin, in Australia’s Queensland.<br />

Premium Low Vol prices slid to $209 per ton fob Australia<br />

in March against $211 per ton at the end of February. HCC 64<br />

Mid Vol, however, also fell by $8 per ton to $189 per ton fob in<br />

one month’s time. The semi soft variety slid by $4 per ton to<br />

$139 per ton in one month’s time.<br />

There was talk that a number of mines in the region were<br />

being impacted, including high-quality coking coal and PCI<br />

mines owned by BHP Billiton-Mitsubishi Alliance, Anglo<br />

American, Peabody and Rio Tinto.<br />

Haulage was being affected by wet mining pits and ramps,<br />

and mines may have to close due to access being cut off for the<br />

next work shift to get to site, according to reports.<br />

The rainfall comes at a crucial time in coking coal contract<br />

negotiations for April-June 2012, between miner Anglo<br />

American and large steelmakers in South Korea and Japan.<br />

The Goonyella rail system in Queensland, a key<br />

COAL INSIGHTS 25 March 2012

coal market fundamentals<br />

Price fixed for Q1<br />

Coal Insights Bureau<br />

An agreement has been reached after price<br />

negotiations with regard to hard coking coal and<br />

LV PCI coal for blast furnace for the first quarter<br />

(April to June) of FY2012.<br />

Out of the above, the first quarter contract price of highgrade<br />

hard coking coal of Queensland, Australian and<br />

Canadian origins is around $205-210 per ton fob, nearly 11<br />

percent less from the previous term (January to March). On<br />

the other hand, the first quarter contract price of LV PCI<br />

coal of Queensland and Canadian origins is around $153.30<br />

per ton fob, 10.4 percent less from the previous term.<br />

As a result of these, the prices of both hard coking coal<br />

and LV PCI coal have been reduced in four consecutive<br />

terms since second quarter (July to September) of FY2011.<br />

Incidentally, the contract prices of high-grade hard coking<br />

coal and LV PCI coal for first quarter of FY2011 were $330<br />

per per ton fob and $275 per ton fob respectively.<br />

The prices have been reduced because of the worldwide<br />

dwindling demand on the steel products attributed to the<br />

economic crisis in the European Union.<br />

The contract price for the fourth quarter of 2011-<br />

12 (January to March in 2012) was $230-235 per ton fob<br />

Australia. Therefore, it becomes a price reduction by around<br />

$25 (nearly 11 percent) from the one for the previous term.<br />

The contract for third quarter (October-December) was<br />

signed at around $285 a ton, but since then the spot prices<br />

had dipped sharply on low demand from European, US<br />

and Chinese steel makers. The contract for second quarter<br />

(July-September) was signed at $315 a ton compared with<br />

$330 for the first quarter (April-June) of 2011-12.<br />

Coking coal prices, which was earlier fixed on yearly<br />

basis, was around $97 per ton fob during 2007-08. The<br />

prices touched a higher of $300 per ton in 2008-09 before<br />

dropping to $129 per ton in 2009-10.<br />

However, prices started rising again from 2010-11 and<br />

the miners started quarterly contract from Q1 of 2010-11<br />

and touched a high of $225 per ton for the fourth quarter<br />

of the year.<br />

Prices peaked to $330 per ton in the first quarter of 2011-<br />

12 owing to floods in the Queensland region of Australia,<br />

but gradually fell to current levels as supply became<br />

normal over time.<br />

Met coke import prices rise<br />

in March<br />

Met coke import prices rose in March on some<br />

rebound in demand from steel mills and<br />

supply constraints of coking coal following<br />

the bad weather in Queensland region of Australia.<br />

The import prices of met coke were hovering<br />

around $385 per ton currently, up from $372 per ton at<br />

the end of February.<br />

LAM coke demand, which is currently at 33 million<br />

tons per annum (mtpa) domestically, is expected to<br />

shoot up to 58 mtpa in the next five years, as steel<br />

makers increase capacity, according to industry<br />

estimates.<br />

transportation link for Bowen Basin coking coal mines was<br />

shut on March 20 after heavy rainfall caused flooding on a<br />

section of the track, operator QR National said. According to<br />

reports, the world’s largest coking coal export port Dalrymple<br />

Bay Coal Terminal was also closed. The likely duration of the<br />

rail closure was unclear.<br />

The Goonyella system links 30 mines to DBCT and Hay<br />

Coking coal & Met coke price trend in March 2012<br />

Date<br />

HCC Peak<br />

Down fob<br />

Australia<br />

($ per ton)<br />

Premium hard<br />

coking coal prices<br />

(premium low vol)<br />

fob Australia ($<br />

per ton)<br />

HCC 64<br />

Mid Vol fob<br />

Australia ($<br />

per ton)<br />

Low Vol<br />

PCI fob<br />

Australia ($<br />

per ton)<br />

Semi soft<br />

coking coal<br />

rates fob<br />

Australia ($<br />

per ton)<br />

Met coke<br />

price cfr<br />

India (($<br />

per ton)<br />

02-Mar 211 211.5 187 149.5 138.5 370<br />

05-Mar 210 210 186 148.5 137.5 367<br />

06-Mar 209 209.5 186 148.5 136.5 366<br />

12-Mar 208 208.5 187 145 134 385<br />

15-Mar 209 209.5 187 145.5 136 385<br />

Point Coal Terminal. However, operations west of Coppabella<br />

remained open, and the Newlands and Blackwater systems<br />

also remained open.<br />

Separately, Peak Downs Highway, the main artery for<br />

shipping fuel and other supplies to the Bowen Basin coal<br />

mines, has also been cut off by the rain, according to reports.<br />

The low demand from India was attributed to a scarcity of<br />

iron ore facing the steel sector. The Indian steel plants are still<br />

reeling under a shortage of iron ore and have reduced its coal<br />

consumption substantially. In 2010-11, domestic steelmakers<br />

imported close to 27 mt of the raw material.<br />

COAL INSIGHTS 26 March 2012

feature<br />

CIL may raise prices in April-May<br />

Coal Insights Bureau<br />

Asked about the likely movement of prices post review,<br />

Perti said, “Whether prices will go up or come down cannot<br />

be said at this point. For that we have to analyse the data first.”<br />

CIL acting chairperson Zohra Chatterji however indicated<br />

the industry may expect a price rise sometime in April. The<br />

industry on its part also expected an upward revision around<br />

that time.<br />

The company was earlier forced to roll back an average<br />

12.5 percent price rise under Gross Calorific Value (GCV)-<br />

based system, on January 31 following severe protests from<br />

domestic consumers led by the power industry. The miner<br />

had decided to do away with the system of pricing based on<br />

useful heat value (UHV) to align with global practices. Under<br />

the UHV system, the highest quality coal in A-grade – with<br />

heat value exceeding 6,200 Kcal/kg – was sold at `4,100 per<br />

ton. Under the GCV system, the highest band coal – with a<br />

calorific value exceeding 7,000 Kcal/kg – cost `4,900 per ton.<br />

After the roll-back, this price was brought down to `4,870 per<br />

ton.<br />

Zohra Chatterji, Chairperson, Coal India Limited<br />

The proposed review of GCV-based pricing system by<br />

Coal India Ltd (CIL) is likely to be delayed by around<br />

a month and may take place in late April or early May<br />

2012, coal secretary Alok Perti told Coal Insights.<br />

“The data will start coming in only from the middle or end<br />

of April. We will analyse the data and then come to a decision<br />

(about a possible revision in prices),” Perti said.<br />

Earlier, the coal ministry (MoC) had announced it would<br />

review the impact of the revised prices on CIL’s revenue<br />

after March. The review was proposed as CIL was compelled<br />

to partially withdraw a “substantial” hike in coal prices<br />

on January 31 due to large scale protest from consumers,<br />

especially the power sector. The problem started after CIL<br />

switched over to gross calorific value (GCV) based pricing<br />

from useful heat value (UHV) based pricing which led to a<br />

sharp increase in coal prices with effect from January 1, 2012.<br />

Analysts foresee 12% rise<br />

CIL, which partly withdrew its coal price hike in February,<br />

may again go for another round of price increase during the<br />

first quarter of 2012-13, an analyst report by BNP Paribas said.<br />

The report stated that CIL may increase its coal prices<br />

by around 12 percent by June 2012. However, “one industry<br />

participant believed that 1QFY13 price hike by CIL will be<br />

limited to 5-6 percent only (vs. our assumption of 12 percent),”<br />

the report said.<br />

“There was also a clear consensus that CIL will be forced to<br />

reduce the supply of higher priced linkage coal to non-power<br />

customers and e-auction volumes to improve availability for<br />

power sector, thus negatively impacting ASPs and margins,”<br />

it added.<br />

Hike needed to offset wage cost<br />

The roll-back in prices on January 31 had eroded CIL’s cushion<br />

against the `6,500-crore impact of wage hike for over 360,000<br />

workers. Some estimates showed the new grading system<br />

would have given CIL an additional `6,250 crore annually.<br />

CIL’s new wage pact signed on January 31 saw an 88<br />

percent increase in minimum basic of its employees to `15,712<br />

per month, as against `8,360 per month during the previous<br />

deal. The other important highlights of the agreement were a<br />

special allowance of 4 percent of revised basic; and HRA of 2<br />

percent of the basic pay for those who have not been provided<br />

with residential accommodation in other than urban area. Post<br />

retirement, medicare scheme for retired non-executives and<br />

COAL INSIGHTS 27 March 2012

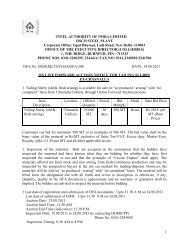

Feature<br />

The new and effective prices of CIL following revision<br />

S<br />

No<br />

GCV<br />

Bands<br />

(Kcal/kg)<br />

New Price after<br />

revision on Jan 31,<br />

2012 (For Power<br />

Sector) but effective<br />

from Jan 1, 2012<br />

New Price after<br />

revision on Jan 31,<br />

2012 (for nonpower<br />

sectors), but<br />

effective from Jan<br />

1, 2012<br />

Indicative Grades<br />

(as per previous<br />

classification)<br />

Price/Range as on Feb<br />

27, 2011 (Power Sector)<br />

as per Grades and mine<br />

to mine<br />

Price/Range as on<br />

Feb 27,2011 for nonpower<br />

sectors as per<br />

grades (mine to mine)<br />

Change for<br />

Power Sector<br />

Change for<br />

Other Sectors<br />

1 7000+ * *<br />

2 6700-7000 4870 4870<br />

A 3690 4100 730 to 1180 320 to 770<br />

3 6400-6700 4420 4420<br />

4 6100-6400 3970 3970<br />

5 5800-6100 2800 2800<br />

B 3590 3990 (-)790 to (+) 380 (-)20 to (-)1110<br />

6 5500-5800 1450 1960 C 1050 to 1500 1300 to 1860 (-)50 to (+)450 100 to 660<br />

7 5200-5500 1270 1720<br />

8 4900-5200 1140 1540<br />

D 790 to 1240 1110 to 1560 30 to 480 430 to 610<br />

9 4600-4900 880 1180<br />

10 4300-4600 780 1050<br />

E 730 to 1020 870 to 1080<br />

50 to 150 and<br />

in some cases<br />

(-) 240<br />

100 to 180<br />

11 4000-4300 640 870<br />

12 3700-4000 600 810<br />

F 570 to 610 630 to 860 30 to 70 10 to 240<br />

13 3400-3700 550 740<br />

14 3100-3400 500 680<br />

G 350 to 700 440 to 650 150 to 200 90 to 300<br />

15 2800-3100 460 620<br />

16 2500-2800 410 550<br />

Ungraded NA NA NA<br />

17 2200-2800 360 490<br />

Note: * For GCV exceeding 7000 Kcal/kg, the price shall be increase by Rs 150/- per ton over and above the price applicable for GCV band<br />

exceeding 6700 but not exceeding 7000 Kcal/Kg, for increase in GCV by every 100 Kcal/kg or part thereof.<br />

For WCL, there shall be a 10% add on over and above the price mentioned above for GCV bands not exceeding 5800 Kcal/Kg and below.<br />

All other elements of the ex-colliery delivered price as are presently applicable in terms of the last coal price notification circulated vide ref. no S<br />

& M: GM(F): Pricing: 1907 Dated 26.02.2011 will continue to remain applicable.<br />

For coal produced by the coal companies of CIL including NEC other than non-coking coal, the prices as are presently applicable in terms of<br />

the coal price notification circulated vide ref no. CIL: S&M: GM (F) Pricing 1907 dated 26.02.2011 will continue to remain applicable shown<br />

as under.<br />

COAL INSIGHTS 28 March 2012

Feature<br />

their spouses was to be finalised within three months, ie. April<br />

2012. Overall, the wage hike would result in around 60 percent<br />

increase in CIL’s wage bill (salary, wages and allowances),<br />

union sources said. They said that along with the increase in<br />

basic salary, the annual increment would also go up. In line<br />

with unions’ estimates, the company said that the wage hike<br />

would put an additional burden of `6,500 crore on the firm. As<br />

of March 2011, CIL’s total outgo on employees’ salary, wages<br />

and allowances was `11,715 crore.<br />

“As per the NCWA VIII, which came into effect from July 1,<br />

2006 workers got a raise of 24 percent in the wages, which had<br />

an impact of around `2,500 crore, so this was more than what<br />

they had expected,” R. Mohandas, director (personnel) of CIL<br />

had said. Initially, CIL had offered a hike of 10 percent when<br />

the talks started, while the workers unions were demanding a<br />

50 percent hike.<br />

Going forward, CIL may face another hike in labour cost as<br />

contract workers wages were expected to be settled in April.<br />

This, if implemented, would put additional burden on CIL<br />

and may call for a significant rise in prices to cover the same.<br />

COAL INSIGHTS 29 March 2012

Feature<br />

Govt may start auction of new blocks in May<br />

Coal Insights Bureau<br />

The ministry<br />

of coal (MoC)<br />

is expected to<br />

appoint a consultant<br />

for the auction of new<br />

blocks within the<br />

next couple of weeks<br />

and start the auction<br />

by May-June, coal<br />

secretary Alok Perti<br />

told Coal Insights.<br />

A pre-selection<br />

meeting of MoC and<br />

interested consultants<br />

who had responded to<br />

Alok Perti, Coal Secretary<br />

the EoI floated by the<br />

ministry was held in<br />

Delhi on March 12, he said. The ministry had floated the EoI to<br />

appoint a consultant who would come out with a transparent<br />

and efficient way of conducting the auction.<br />

Asked when the auction process will start, Perti said,<br />

“We would like to<br />

start it as soon as<br />

possible, but we<br />

have to examine the<br />

suggestions provided<br />

by the consultants.”<br />

Overall, the entire<br />

process may take<br />

another two months<br />

to complete, he said,<br />

indicating that the<br />

auction may actually<br />

start in May-June.<br />

MoC identifies 54<br />

Vinod Rai, CAG<br />

blocks<br />

The MoC has identified 54 coal blocks for allotment through<br />

government dispensation route and auction route to public<br />

and private sector companies. “In the first lot, 54 blocks will<br />

be put up for auction and allotment,” Perti said.<br />

COAL INSIGHTS 30 March 2012

fEATURE<br />

However, it was not known how many of these blocks<br />

would be allotted through each route. “I don’t have the breakup<br />

of the numbers right now,” he said.<br />

The ministry has been considering allotment of new blocks<br />

through auction route for quite sometime now, as the previous<br />

system of allotting blocks for captive mining was questioned<br />

from some quarters.<br />

As of today, only 29 blocks of around 194 blocks allotted<br />

for captive production have come to the production stage.<br />

The ministry, on review of the development of the blocks,<br />

found a number of block owners lacking in action to achieve<br />

milestones. This prompted MoC to de-allocate some blocks<br />

and consider auctioning the new blocks so as to attract only<br />

the serious players.<br />

Uproar over CAG report<br />

Meanwhile, a draft report by the Comptroller and Auditor<br />

General (CAG) on allocation of captive blocks by the<br />

government created a furore in Parliament on March 22,<br />

but was later watered down by the statutory authority as<br />

‘preliminary observations’.<br />

A media report which quoted the report titled ‘Performance<br />

Audit of Coal Block Allocations’ said the government extended<br />

undue benefits totalling Rs 10.67 lakh crore to commercial<br />