Combinatorial and High-Throughput Screening of Materials ...

Combinatorial and High-Throughput Screening of Materials ...

Combinatorial and High-Throughput Screening of Materials ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ACS <strong>Combinatorial</strong> Science<br />

REVIEW<br />

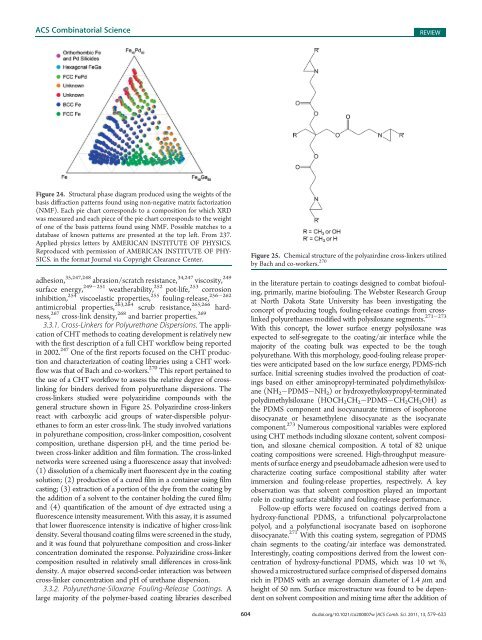

Figure 24. Structural phase diagram produced using the weights <strong>of</strong> the<br />

basis diffraction patterns found using non-negative matrix factorization<br />

(NMF). Each pie chart corresponds to a composition for which XRD<br />

was measured <strong>and</strong> each piece <strong>of</strong> the pie chart corresponds to the weight<br />

<strong>of</strong> one <strong>of</strong> the basis patterns found using NMF. Possible matches to a<br />

database <strong>of</strong> known patterns are presented at the top left. From 237.<br />

Applied physics letters by AMERICAN INSTITUTE OF PHYSICS.<br />

Reproduced with permission <strong>of</strong> AMERICAN INSTITUTE OF PHY-<br />

SICS. in the format Journal via Copyright Clearance Center.<br />

adhesion, 35,247,248 abrasion/scratch resistance, 34,247 viscosity, 249<br />

surface energy, 249 251 weatherability, 252 pot-life, 253 corrosion<br />

inhibition, 254 viscoelastic properties, 255 256 262<br />

fouling-release,<br />

antimicrobial properties, 263,264 scrub resistance, 265,266 hardness,<br />

267 cross-link density, 268 <strong>and</strong> barrier properties. 269<br />

3.3.1. Cross-Linkers for Polyurethane Dispersions. The application<br />

<strong>of</strong> CHT methods to coating development is relatively new<br />

with the first description <strong>of</strong> a full CHT workflow being reported<br />

in 2002. 247 One <strong>of</strong> the first reports focused on the CHT production<br />

<strong>and</strong> characterization <strong>of</strong> coating libraries using a CHT workflow<br />

was that <strong>of</strong> Bach <strong>and</strong> co-workers. 270 This report pertained to<br />

the use <strong>of</strong> a CHT workflow to assess the relative degree <strong>of</strong> crosslinking<br />

for binders derived from polyurethane dispersions. The<br />

cross-linkers studied were polyaziridine compounds with the<br />

general structure shown in Figure 25. Polyazirdine cross-linkers<br />

react with carboxylic acid groups <strong>of</strong> water-dispersible polyurethanes<br />

to form an ester cross-link. The study involved variations<br />

in polyurethane composition, cross-linker composition, cosolvent<br />

composition, urethane dispersion pH, <strong>and</strong> the time period between<br />

cross-linker addition <strong>and</strong> film formation. The cross-linked<br />

networks were screened using a fluorescence assay that involved:<br />

(1) dissolution <strong>of</strong> a chemically inert fluorescent dye in the coating<br />

solution; (2) production <strong>of</strong> a cured film in a container using film<br />

casting; (3) extraction <strong>of</strong> a portion <strong>of</strong> the dye from the coating by<br />

the addition <strong>of</strong> a solvent to the container holding the cured film;<br />

<strong>and</strong> (4) quantification <strong>of</strong> the amount <strong>of</strong> dye extracted using a<br />

fluorescence intensity measurement. With this assay, it is assumed<br />

that lower fluorescence intensity is indicative <strong>of</strong> higher cross-link<br />

density. Several thous<strong>and</strong> coating films were screened in the study,<br />

<strong>and</strong> it was found that polyurethane composition <strong>and</strong> cross-linker<br />

concentration dominated the response. Polyaziridine cross-linker<br />

composition resulted in relatively small differences in cross-link<br />

density. A major observed second-order interaction was between<br />

cross-linker concentration <strong>and</strong> pH <strong>of</strong> urethane dispersion.<br />

3.3.2. Polyurethane-Siloxane Fouling-Release Coatings. A<br />

large majority <strong>of</strong> the polymer-based coating libraries described<br />

Figure 25. Chemical structure <strong>of</strong> the polyazirdine cross-linkers utilized<br />

by Bach <strong>and</strong> co-workers. 270<br />

in the literature pertain to coatings designed to combat bi<strong>of</strong>ouling,<br />

primarily, marine bi<strong>of</strong>ouling. The Webster Research Group<br />

at North Dakota State University has been investigating the<br />

concept <strong>of</strong> producing tough, fouling-release coatings from crosslinked<br />

polyurethanes modified with polysiloxane segments.<br />

271 273<br />

With this concept, the lower surface energy polysiloxane was<br />

expected to self-segregate to the coating/air interface while the<br />

majority <strong>of</strong> the coating bulk was expected to be the tough<br />

polyurethane. With this morphology, good-fouling release properties<br />

were anticipated based on the low surface energy, PDMS-rich<br />

surface. Initial screening studies involved the production <strong>of</strong> coatings<br />

based on either aminopropyl-terminated polydimethylsiloxane<br />

(NH 2 PDMS NH 2 ) or hydroxyethyloxypropyl-terminated<br />

polydimethylsiloxane (HOCH 2 CH 2 PDMS CH 2 CH 2 OH) as<br />

the PDMS component <strong>and</strong> isocyanaurate trimers <strong>of</strong> isophorone<br />

diisocyanate or hexamethylene diisocyanate as the isocyanate<br />

component. 273 Numerous compositional variables were explored<br />

using CHT methods including siloxane content, solvent composition,<br />

<strong>and</strong> siloxane chemical composition. A total <strong>of</strong> 82 unique<br />

coating compositions were screened. <strong>High</strong>-throughput measurements<br />

<strong>of</strong> surface energy <strong>and</strong> pseudobarnacle adhesion were used to<br />

characterize coating surface compositional stability after water<br />

immersion <strong>and</strong> fouling-release properties, respectively. A key<br />

observation was that solvent composition played an important<br />

role in coating surface stability <strong>and</strong> fouling-release performance.<br />

Follow-up efforts were focused on coatings derived from a<br />

hydroxy-functional PDMS, a trifunctional polycarprolactone<br />

polyol, <strong>and</strong> a polyfunctional isocyanate based on isophorone<br />

diisocyanate. 271 With this coating system, segregation <strong>of</strong> PDMS<br />

chain segments to the coating/air interface was demonstrated.<br />

Interestingly, coating compositions derived from the lowest concentration<br />

<strong>of</strong> hydroxy-functional PDMS, which was 10 wt %,<br />

showed a microstructured surface comprised <strong>of</strong> dispersed domains<br />

rich in PDMS with an average domain diameter <strong>of</strong> 1.4 μm <strong>and</strong><br />

height <strong>of</strong> 50 nm. Surface microstructure was found to be dependent<br />

on solvent composition <strong>and</strong> mixing time after the addition <strong>of</strong><br />

604 dx.doi.org/10.1021/co200007w |ACS Comb. Sci. 2011, 13, 579–633