Combinatorial and High-Throughput Screening of Materials ...

Combinatorial and High-Throughput Screening of Materials ...

Combinatorial and High-Throughput Screening of Materials ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ACS <strong>Combinatorial</strong> Science<br />

REVIEW<br />

Table 2. Continued<br />

materials system instrumentation knowledge ref<br />

one-dimensional fluorescence spectroscopy <strong>and</strong> imaging for the evaluation ranking <strong>of</strong> polymer/UV absorber compositions<br />

333<br />

coiled libraries<br />

<strong>of</strong> polymer/UV<br />

absorber compositions<br />

<strong>of</strong> oxidative stability (weathering) <strong>of</strong> polymer/UV<br />

absorber compositions under accelerated test<br />

conditions. Environmental stress is applied to only local<br />

regions, followed by high-sensitivity spatially<br />

resolved characterization.<br />

equivalent to traditional weathering data while achieved<br />

20 times faster<br />

polyphasic fluid<br />

microreactor for liquid/liquid isomerization <strong>and</strong><br />

reaction rate is proportional to the catalyst concentration; 512<br />

reactions<br />

gas/liquid asymmetric hydrogenation based on<br />

dynamic sequential operation<br />

the rate decreases with increasing surfactant concentration,<br />

no change in the enantiomeric excess was observed<br />

polymer synthesis on-line GPC for reaction optimization determination <strong>of</strong> activation energy <strong>of</strong> polymerization 513<br />

siloxane rubber/<br />

carbon black<br />

nanocomposites<br />

automated scanning probe microscope<br />

study <strong>of</strong> curing rate <strong>of</strong> siloxane rubber matrix on roughness<br />

<strong>and</strong> conductivity <strong>of</strong> composites<br />

514<br />

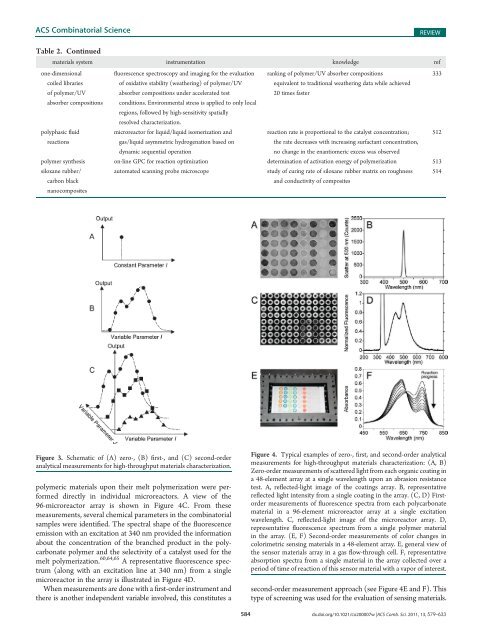

Figure 3. Schematic <strong>of</strong> (A) zero-, (B) first-, <strong>and</strong> (C) second-order<br />

analytical measurements for high-throughput materials characterization.<br />

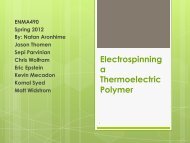

polymeric materials upon their melt polymerization were performed<br />

directly in individual microreactors. A view <strong>of</strong> the<br />

96-microreactor array is shown in Figure 4C. From these<br />

measurements, several chemical parameters in the combinatorial<br />

samples were identified. The spectral shape <strong>of</strong> the fluorescence<br />

emission with an excitation at 340 nm provided the information<br />

about the concentration <strong>of</strong> the branched product in the polycarbonate<br />

polymer <strong>and</strong> the selectivity <strong>of</strong> a catalyst used for the<br />

melt polymerization. 60,64,65 A representative fluorescence spectrum<br />

(along with an excitation line at 340 nm) from a single<br />

microreactor in the array is illustrated in Figure 4D.<br />

When measurements are done with a first-order instrument <strong>and</strong><br />

there is another independent variable involved, this constitutes a<br />

Figure 4. Typical examples <strong>of</strong> zero-, first, <strong>and</strong> second-order analytical<br />

measurements for high-throughput materials characterization: (A, B)<br />

Zero-order measurements <strong>of</strong> scattered light from each organic coating in<br />

a 48-element array at a single wavelength upon an abrasion resistance<br />

test. A, reflected-light image <strong>of</strong> the coatings array. B, representative<br />

reflected light intensity from a single coating in the array. (C, D) Firstorder<br />

measurements <strong>of</strong> fluorescence spectra from each polycarbonate<br />

material in a 96-element microreactor array at a single excitation<br />

wavelength. C, reflected-light image <strong>of</strong> the microreactor array. D,<br />

representative fluorescence spectrum from a single polymer material<br />

in the array. (E, F) Second-order measurements <strong>of</strong> color changes in<br />

colorimetric sensing materials in a 48-element array. E, general view <strong>of</strong><br />

the sensor materials array in a gas flow-through cell. F, representative<br />

absorption spectra from a single material in the array collected over a<br />

period <strong>of</strong> time <strong>of</strong> reaction <strong>of</strong> this sensor material with a vapor <strong>of</strong> interest.<br />

second-order measurement approach (see Figure 4E <strong>and</strong> F). This<br />

type <strong>of</strong> screening was used for the evaluation <strong>of</strong> sensing materials.<br />

584 dx.doi.org/10.1021/co200007w |ACS Comb. Sci. 2011, 13, 579–633