BEARING HOUSINGS - CBC Bearings

BEARING HOUSINGS - CBC Bearings

BEARING HOUSINGS - CBC Bearings

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

9<br />

INTERNAL SELF-ALIGNING BALL & ROLLER <strong>BEARING</strong> UNITS<br />

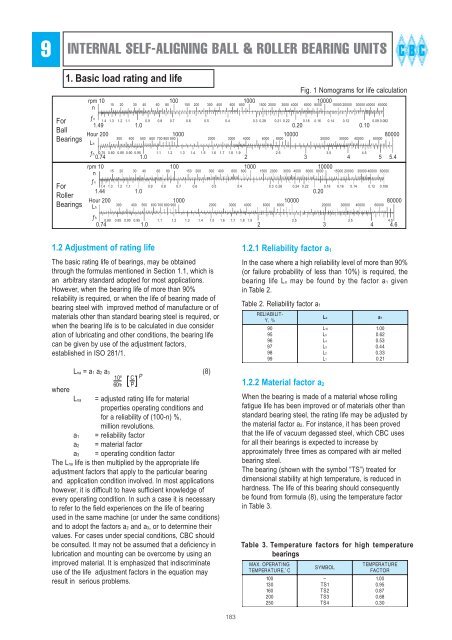

1. Basic load rating and life<br />

For<br />

Ball<br />

<strong>Bearings</strong><br />

Fig. 1 Nomograms for life calculation<br />

rpm 10 100 1000 10000<br />

15 20 30 40 60 80 150 200 300 400 600 800 1500 2000 3000 4000 6000 8000 15000 20000 30000 40000 60000<br />

n<br />

ƒn<br />

1.4 1.3 1.2 1.1 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.28 0.21 0.22 0.18 0.16 0.14 0.12 0.09 0.082<br />

1.49 1.0 0.20 0.10<br />

Hour 200 1000 10000 80000<br />

Lh<br />

300 400 500 600 700 800 900 2000 3000 4000 6000 8000 20000 30000 40000 60000<br />

For<br />

Roller<br />

<strong>Bearings</strong><br />

ƒh<br />

0.74 1.0 2 3 4 5 5.4<br />

rpm 10 100 1000 10000<br />

n<br />

ƒn<br />

0.75 0.80 0.85 0.90 0.95 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.5 3.5 4.5<br />

15 20 30 40 60 80 150 200 300 400 600 800 1500 2000 3000 4000 6000 8000 15000 20000 30000 40000 60000<br />

1.4 1.3 1.2 1.1 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.28 0.24 0.22 0.18 0.16 0.14 0.12 0.106<br />

1.44 1.0 0.20<br />

Hour 200 1000 10000 80000<br />

Lh<br />

300 400 500 600 700 800 900 2000 3000 4000 6000 8000 20000 30000 40000 60000<br />

ƒh<br />

0.80 0.85 0.90 0.95 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.5 3.5 4.5<br />

0.74 1.0 2 3 4 4.6<br />

1.2 Adjustment of rating life<br />

The basic rating life of bearings, may be obtained<br />

through the formulas mentioned in Section 1.1, which is<br />

an arbitrary standard adopted for most applications.<br />

However, when the bearing life of more than 90%<br />

reliability is required, or when the life of bearing made of<br />

bearing steel with improved method of manufacture or of<br />

materials other than standard bearing steel is required, or<br />

when the bearing life is to be calculated in due consider<br />

ation of lubricating and other conditions, the bearing life<br />

can be given by use of the adjustment factors,<br />

established in ISO 281/1.<br />

Lna = a1 a2 a3 (8)<br />

10 6 C P<br />

[ ] 60n1 P<br />

where<br />

Lna = adjusted rating life for material<br />

properties operating conditions and<br />

for a reliability of (100-n) %,<br />

million revolutions.<br />

a1 = reliability factor<br />

a2 = material factor<br />

a3 = operating condition factor<br />

The Lna life is then multiplied by the appropriate life<br />

adjustment factors that apply to the particular bearing<br />

and application condition involved. In most applications<br />

however, it is difficult to have sufficient knowledge of<br />

every operating condition. In such a case it is necessary<br />

to refer to the field experiences on the life of bearing<br />

used in the same machine (or under the same conditions)<br />

and to adopt the factors a2 and a3, or to determine their<br />

values. For cases under special conditions, <strong>CBC</strong> should<br />

be consulted. It may not be assumed that a deficiency in<br />

lubrication and mounting can be overcome by using an<br />

improved material. It is emphasized that indiscriminate<br />

use of the life adjustment factors in the equation may<br />

result in serious problems.<br />

1.2.1 Reliability factor a 1<br />

In the case where a high reliability level of more than 90%<br />

(or failure probability of less than 10%) is required, the<br />

bearing life Ln may be found by the factor a1 given<br />

in Table 2.<br />

Table 2. Reliability factor a1<br />

RELIABILIT-<br />

Y, %<br />

90<br />

95<br />

96<br />

97<br />

98<br />

99<br />

1.2.2 Material factor a 2<br />

Ln a 1<br />

L10<br />

L5<br />

L4<br />

L3<br />

L2<br />

L1<br />

1.00<br />

0.62<br />

0.53<br />

0.44<br />

0.33<br />

0.21<br />

When the bearing is made of a material whose rolling<br />

fatigue life has been improved or of materials other than<br />

standard bearing steel, the rating life may be adjusted by<br />

the material factor a2. For instance, it has been proved<br />

that the life of vacuum degassed steel, which <strong>CBC</strong> uses<br />

for all their bearings is expected to increase by<br />

approximately three times as compared with air melted<br />

bearing steel.<br />

The bearing (shown with the symbol “TS”) treated for<br />

dimensional stability at high temperature, is reduced in<br />

hardness. The life of this bearing should consequently<br />

be found from formula (8), using the temperature factor<br />

in Table 3.<br />

Table 3. Temperature factors for high temperature<br />

bearings<br />

MAX. OPERATING<br />

TEMPERATURE,˚ C<br />

100<br />

130<br />

160<br />

200<br />

250<br />

SYMBOL<br />

–<br />

TS1<br />

TS2<br />

TS3<br />

TS4<br />

TEMPERATURE<br />

FACTOR<br />

1.00<br />

0.95<br />

0.87<br />

0.68<br />

0.30<br />

183