BEARING HOUSINGS - CBC Bearings

BEARING HOUSINGS - CBC Bearings

BEARING HOUSINGS - CBC Bearings

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

9<br />

INTERNAL SELF-ALIGNING BALL & ROLLER <strong>BEARING</strong> UNITS<br />

5. Handling of bearings<br />

“C” spanners should be used where possible<br />

progressively tighten locknut whilst feeler gauge<br />

readings are taken (similar to Step 2) to achieve<br />

desired “residual clearance” (Step 3). Suggested<br />

method is to select mid range feeler, in case of<br />

example use . 140mm blade and tighten until slight<br />

interference is felt. When approaching this condition<br />

watch for locknut slot nearing alignment with a<br />

lockwasher tab.<br />

ÒCÓ spanner<br />

Insert<br />

spacer<br />

rings<br />

After double checking that<br />

desired residual clearance<br />

has been reached, tab should<br />

be bent into slot.<br />

8. The floating bearing should now be positioned<br />

slightly off housing centre toward locknut side of sleeve<br />

so that as nut is tightened, bearing will be displaced<br />

approximately back to centre line. Tighten as per Step 7.<br />

No spacer rings are used of course, and bearing<br />

does not have to be on centre as long as adequate<br />

float is available each side of bearing between<br />

housing seat shoulders. Rotate assembly by hand and<br />

ensure that there is no resistance.<br />

Float<br />

Float<br />

9. Lubrication is normally a No. 2 penetration mineral oil/<br />

lithium soap grease Shell Alvania No. 2 or equivalent.<br />

Grease should be “worked” into bearing for as much<br />

of circumference as possible rotating occasionally.<br />

Basic grease capacity rule is that 1 /2— 1 /3 of housing<br />

volumetric capacity be filled, this can be done by<br />

hand prior to fitting cap which in many cases can<br />

be “plugged” and only the taconite seals lubricated<br />

via nipples on a regular basis. High temperature or<br />

unusual applications may require a special grease<br />

selection and should be referred to <strong>CBC</strong> Technical<br />

Department.<br />

SUITABLE LUBRICANTS:<br />

Shell-Alvania R2, EP2<br />

BP - Energrease LS2, LSEP2.<br />

Mobil - Grease 77, Mobilux EP2<br />

Ampol - RRs, EP Grease C2.<br />

Caltex - Regal, Starfak, Premium 2.<br />

10. Housing cap, after cleaning, can be assembled to<br />

bodies (they are not interchangeable). Taconite seals<br />

should be fitted and it may be necessary to adjust<br />

housing base alignment to allow constant clearance<br />

around circumference of rotating labyrinth and<br />

193<br />

during these procedures that rotation is free and not<br />

impaired. Taconite seals should be lubricated until<br />

grease extrudes fully around labyrinth circumference.<br />

Do not “over grease” bearing housing as damage and<br />

overheating can occur during initial running period. It<br />

should be lubriucated and plugged as Step 9, or<br />

lubricated with a known quantity of grease.<br />

Note: These Steps show Mounting Procedures when fitting<br />

Spherical Roller Bearing and Adapter Sleeve into <strong>CBC</strong><br />

Split Bearing Housing.<br />

GENERAL NOTES<br />

a) Check that the shaft diameter conforms to ISO Tolerance<br />

h9, and IT5 for ovality.<br />

b) Table values are for normal loads, solid shafts and bearing<br />

internal clearance groups of ‘Normal’ and C3. For heavy<br />

loads (Pr>0.15 Cr) Please Consult <strong>CBC</strong>.<br />

c) After determining residual clearance in Step 3. Consult<br />

column D in table as a double check that figure obtained<br />

does not fall below min. permissable residual clearance.<br />

d) In some applications it may not be possible to use feeler<br />

gauges to serve as tightening guide, in these cases it is<br />

often possible to measure “Axial Displacement” between<br />

adapter sleeve and inner race of bearing during tightening<br />

(See chart Column ‘C’). These values are for relative<br />

movement between sleeve and bearing faces and can be<br />

measured with tail end of standard vernier gauge or other<br />

methods.<br />

e) All joint faces are machined. Grease applied between faces<br />

should be sufficient to act as a sealant. However, in<br />

exposed locations we recommend jointing compound be<br />

used, especially with ’A’ type (closed) covers.<br />

f) As with all bearing assemblies, tools and work area should<br />

be as clean as practicable.<br />

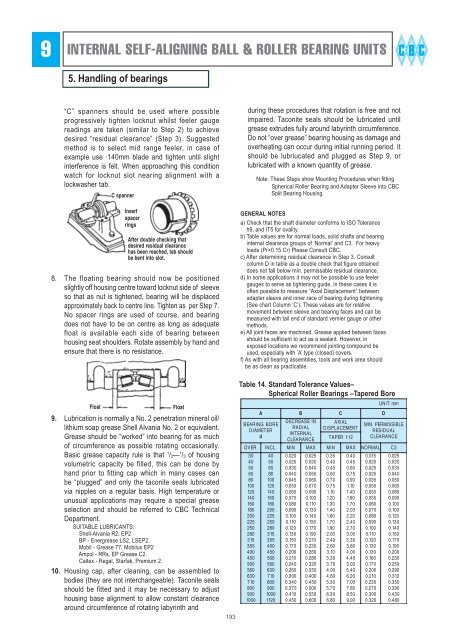

Table 14. Standard Tolerance Values–<br />

Spherical Roller <strong>Bearings</strong> –Tapered Bore<br />

A B C D<br />

<strong>BEARING</strong> BORE<br />

DIAMETER<br />

d<br />

O VER. INCL.<br />

30<br />

40<br />

50<br />

65<br />

80<br />

100<br />

120<br />

140<br />

160<br />

180<br />

200<br />

225<br />

250<br />

280<br />

315<br />

355<br />

400<br />

450<br />

500<br />

560<br />

630<br />

710<br />

800<br />

900<br />

1000<br />

40<br />

50<br />

65<br />

80<br />

100<br />

120<br />

140<br />

160<br />

180<br />

200<br />

225<br />

250<br />

280<br />

315<br />

355<br />

400<br />

450<br />

500<br />

560<br />

630<br />

710<br />

800<br />

900<br />

1000<br />

1120<br />

DECREASE IN<br />

RADIAL<br />

INTERNAL<br />

CLEARANCE<br />

MIN<br />

0.020<br />

0.025<br />

0.030<br />

0.040<br />

0.045<br />

0.050<br />

0.065<br />

0.075<br />

0.080<br />

0.090<br />

0.100<br />

0.110<br />

0.120<br />

0.130<br />

0.150<br />

0.170<br />

0.200<br />

0.210<br />

0.240<br />

0.260<br />

0.300<br />

0.340<br />

0.370<br />

0.410<br />

0.450<br />

MAX<br />

0.025<br />

0.030<br />

0.040<br />

0.050<br />

0.060<br />

0.070<br />

0.090<br />

0.100<br />

0.110<br />

0.130<br />

0.140<br />

0.150<br />

0.170<br />

0.190<br />

0.210<br />

0.230<br />

0.260<br />

0.280<br />

0.320<br />

0.350<br />

0.400<br />

0.450<br />

0.500<br />

0.550<br />

0.600<br />

AXIAL<br />

DISPLACEMENT<br />

TAPER 1:12<br />

MIN<br />

0.35<br />

0.40<br />

0.45<br />

0.60<br />

0.70<br />

0.75<br />

1.10<br />

1.20<br />

1.30<br />

1.40<br />

1.60<br />

1.70<br />

1.90<br />

2.00<br />

2.40<br />

2.60<br />

3.10<br />

3.30<br />

3.70<br />

4.00<br />

4.60<br />

5.30<br />

5.70<br />

6.30<br />

6.80<br />

MAX<br />

0.40<br />

0.45<br />

0.60<br />

0.75<br />

0.90<br />

1.10<br />

1.40<br />

1.60<br />

1.70<br />

2.00<br />

2.20<br />

2.40<br />

2.70<br />

3.00<br />

3.30<br />

3.60<br />

4.00<br />

4.40<br />

5.00<br />

5.40<br />

6.20<br />

7.00<br />

7.80<br />

8.50<br />

9.00<br />

UNIT mm<br />

MIN. PERMISSIBLE<br />

RESIDUAL<br />

CLEARANCE<br />

NORMAL<br />

C3<br />

0.015<br />

0.020<br />

0.025<br />

0.025<br />

0.035<br />

0.050<br />

0.055<br />

0.055<br />

0.060<br />

0.070<br />

0.080<br />

0.090<br />

0.100<br />

0.110<br />

0.120<br />

0.130<br />

0.130<br />

0.160<br />

0.170<br />

0.200<br />

0.210<br />

0.230<br />

0.270<br />

0.300<br />

0.320<br />

0.025<br />

0.030<br />

0.035<br />

0.040<br />

0.050<br />

0.065<br />

0.080<br />

0.090<br />

0.100<br />

0.100<br />

0.120<br />

0.130<br />

0.140<br />

0.150<br />

0.170<br />

0.190<br />

0.200<br />

0.230<br />

0.250<br />

0.290<br />

0.310<br />

0.350<br />

0.390<br />

0.430<br />

0.480