Photonic crystals in biology

Photonic crystals in biology

Photonic crystals in biology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

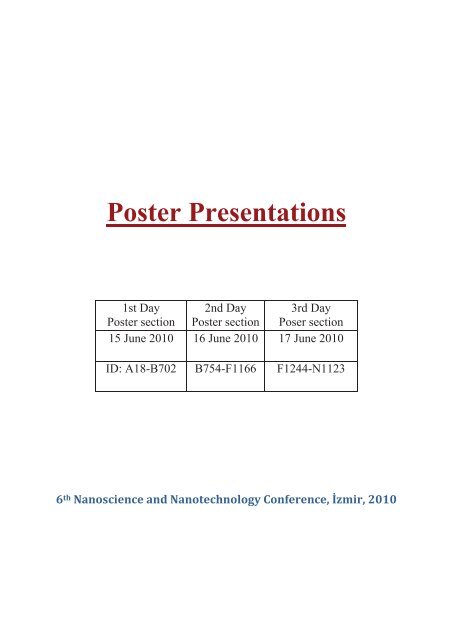

Poster Presentations<br />

1st Day 2nd Day 3rd Day<br />

Poster section Poster section Poser section<br />

15 June 2010 16 June 2010 17 June 2010<br />

ID: A18-B702 B754-F1166 F1244-N1123<br />

6 th Nanoscience and Nanotechnology Conference, İzmir, 2010

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Absorption Hypothesis: Attachment of Beetles to Nanoporous Substrates<br />

Elena Gorb 1 *, Solveig Kle<strong>in</strong>z 1 and Stanislav Gorb 1<br />

1 Department of Functional Morphology and Biomechanics, Zoological Institute, University of Kiel, 24098 Kiel, Germany<br />

Abstract-Traction experiments with ladybird beetles showed that forces on nanoporous substrates were significantly lower t hat those on solid<br />

surface samples. The comparison of the evolution <strong>in</strong> contact angles of the two fluids, polar water and non-polar m<strong>in</strong>eral oil, showed that porous<br />

substrates absorbed both polar and non-polar fluids, whereas solid surface samples did not. Thus, the reduction of <strong>in</strong>sect attachment on<br />

nanoporous surfaces may be expla<strong>in</strong>ed by (1) the absorption of the secretion fluid from <strong>in</strong>sect adhesive pads by porous media and/or (2) the<br />

effect of surface roughness.<br />

It has been repeatedly reported that micro- and<br />

nanostructured waxy surfaces of plants strongly reduce <strong>in</strong>sect<br />

attachment. To expla<strong>in</strong> anti-adhesive properties of such<br />

substrates, four hypotheses have been previously proposed: (a)<br />

roughness hypothesis; (b) contam<strong>in</strong>ation hypothesis; (c) fluid<br />

absorption hypothesis; and (d) wax dissolv<strong>in</strong>g hypothesis [1].<br />

Recently, only the two first hypotheses ([2 – 6] for (a) and [7 –<br />

9] fo r (b)) were proven. To date, the wax d issolv<strong>in</strong>g<br />

hypothesis and the fluid absorption hypothesis have not been<br />

experimentally tested. In the present study, we used<br />

nanoporous substrates with the same pore diameter (220 – 235<br />

nm), but different porosity (area of voids <strong>in</strong> a material surface,<br />

normalized over the total area), <strong>in</strong> order to test the fluid<br />

absorption hypothesis, claim<strong>in</strong>g that the structured wax<br />

coverage of plants may absorb the fluid from the setal surface<br />

of <strong>in</strong>sect adhesive pads and by this reduce the adhesion force.<br />

We performed traction force measurements with tethered<br />

seven-spotted ladybird beetles Cocc<strong>in</strong>ella septempunctata L.<br />

(Coleoptera, Cocc<strong>in</strong>ellidae), walk<strong>in</strong>g on five different<br />

substrates [10]: (1) smooth glass plate; (2) smooth solid Al 2 O 3<br />

(sapphire) disc; (3 – 5) three types of nanoporous Al 2 O 3 discs<br />

(back side of anodisc membranes Whatman, Schleicher and<br />

Schuell, Whatman International Ltd., Maidstone, UK) hav<strong>in</strong>g<br />

the porosity of 28, 42 and 51%. Forces were measured with a<br />

load cell force transducer (10g capacity, Biopac Systems Ltd.,<br />

Santa Barbara, CA, USA). Both males (n=10) and females<br />

(n=10) were used <strong>in</strong> the experiments.<br />

We found that the forces ranged from 0.16 to 16.59 mN <strong>in</strong><br />

males and from 0.32 to 8.99 mN <strong>in</strong> females. The highest force<br />

values were obta<strong>in</strong>ed on the smooth surfaces, where males<br />

generated considerably higher forces compared to females. On<br />

all three porous substrates, the forces were significantly<br />

reduced, and the only difference was obta<strong>in</strong>ed between<br />

nanoporous membranes hav<strong>in</strong>g the highest and lowest<br />

porosity. Males produced essentially lower forces than<br />

females on porous samples [10].<br />

The reduction of <strong>in</strong>sect attachment on nanoporous<br />

substrates may be expla<strong>in</strong>ed by (1) possible absorption of the<br />

secretory fluid from <strong>in</strong>sect pads by porous media and (2)<br />

surface roughness, reduc<strong>in</strong>g real contact area between tenent<br />

setae of <strong>in</strong>sect adhesive pads and substrate.<br />

To exam<strong>in</strong>e the ability of porous substrates to absorb fluids,<br />

we performed additional absorption experiments with solid<br />

and nanoporous surfaces samples us<strong>in</strong>g a high-speed optical<br />

contact angle measur<strong>in</strong>g device OCAH 200 (DataPhysics<br />

Instruments GmbH, Filderstadt, Germany). The comparison of<br />

the evolution <strong>in</strong> contact angles of the two fluids, polar water<br />

and non-polar m<strong>in</strong>eral oil (Mobil DTE Medium, viscosity 43.4<br />

mm 2 •s at 40°C [11]), showed that porous substrates absorbed<br />

both polar and non-polar fluids (figure), whereas solid surface<br />

samples did not. S<strong>in</strong>ce the beetle secretion or at least a part of<br />

it consists of oily substances, we can conclude that adhesion<br />

reduction <strong>in</strong> our traction experiments at least partially can be<br />

expla<strong>in</strong>ed by the ability of nanoporous substrates to adsorb<br />

non-polar lipid-like fluids.<br />

contact angle [ ° ]<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

0 10 20 30 40 50 60<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

absorption<br />

absorption<br />

0<br />

0 10 20 30 40 50 60<br />

time [s]<br />

(a)<br />

(b)<br />

Figure 1. The evolution <strong>in</strong> contact angles of water (a) and oil (b)<br />

on the nanoporous surface sample with the porosity of 42%.<br />

This work was partially supported by the SPP 1420 priority<br />

program of the German Science Foundation (DFG)<br />

“Biomimetic Materials Research: Functionality by<br />

Hierarchical Structur<strong>in</strong>g of Materials” (project GO 995/9-1).<br />

The first author thanks Naoe Hosoda (NIMS, Tsukuba, Japan)<br />

for fruitful discussions.<br />

*Correspond<strong>in</strong>g author: egorb@zoologie.uni-kiel.de<br />

[1] E.V. Gorb and S.N. Gorb, Entomol. Exp. Appl. 105, 13 (2002).<br />

[21] S. Gorb, Attachment devices of <strong>in</strong>sect cuticle (2001).<br />

[3] A. Peressadko and S. Gorb, Proc. 1st Int. Conf. Bionik, 257<br />

(2004).<br />

[41] D. Voi gt et al., J. Insect Physiol. 54, 765 (2008).<br />

[51] E. Gorb and S. Gorb, Entomol. Exp. Appl. 130, 222 (2009).<br />

[6] J. M. Bullock and W. Federle, J. Exp. Biol. 212, 1876 (2009).<br />

[7] L. Gaume et al., Arthropod Structure & Development 33, 103<br />

(2004).<br />

[8] E. Gorb et al., J. Exp. Biol. 208, 4651 (2005).<br />

[9] E. Gorb and S. Gorb, Ecology and biomechanics: A mechanical<br />

approach to the ecology of animals and plants, 147 (2006).<br />

[10] E. Gorb et al., Proc. 9th Biennial ASME Conf. on ESDA, 1<br />

(2008).<br />

[11] M. Varenberg and S. Gorb, Adv. Mater. 21, 483 (2009).<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 208

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Phosphorus Conta<strong>in</strong><strong>in</strong>g Novel Polyimide/Silica Nanocomposite Materials via Sol-Gel Technique<br />

Canan Kızılkaya *, Sevim Karataş , Nilhan Kayaman Apohan , Atilla Güngör<br />

Marmara University, Department of Chemistry 34722 Istanbul/Turkey<br />

Abstract- In this work, the high temperature capability and fire-resistance of phosphorus-conta<strong>in</strong><strong>in</strong>g polyimide/ silica<br />

(PI/SiO 2 ) nano hybrid films were synthesized by sol-gel reaction and thermal imidization.The silica content <strong>in</strong> the hybrid<br />

films was varied from 0 to 20 wt %. The thermal, mechanical, optic, electrical and surface properties of the hybrid films<br />

have been <strong>in</strong>vestigated and compared to pure PI.<br />

Organic-<strong>in</strong>organic nanocomposite materials prepared by<br />

the sol-gel technique are an important class of newgeneration<br />

materials, which comb<strong>in</strong>e the desirable<br />

properties of an <strong>in</strong>organic component (heat resistance,<br />

retention of mechanical properties at high temperatures<br />

and low thermal expansion) and those of organic polymer<br />

(toughness, ductility and processability) [1,2].<br />

Polyimides (PI) are promis<strong>in</strong>g materials used for a wide<br />

range of applications because of their high glass transition<br />

temperature, good heat resistance, low dielectric constant,<br />

and excellent mechanical properties. The sol–gel process is<br />

a unique and versatile approach among the various<br />

methods used to produce polyimide/SiO 2 hybrid materials<br />

.The nature of the <strong>in</strong>terfaces between SiO 2 particles and<br />

polyimides matrix, the content and size of SiO 2 particles,<br />

greatly affect the properties of the hybrid materials. Strong<br />

<strong>in</strong>terfaces <strong>in</strong> which covalent bond should be formed<br />

between SiO 2 particles and polyimides matrix, are needed<br />

for obta<strong>in</strong><strong>in</strong>g excellent properties [2,3] .<br />

Polymers conta<strong>in</strong><strong>in</strong>g the phenylphosph<strong>in</strong>e oxide<br />

(PPO)group have been studied extensively for a number of<br />

applications <strong>in</strong> recent years. These polymers are the most<br />

important ones both due to good their thermal and<br />

chemical stability, excellent mechanical properties, very<br />

good fire retardancy. Polyimides conta<strong>in</strong><strong>in</strong>g phosph<strong>in</strong>e<br />

oxide moieties display good flame resistance and excellent<br />

adhesion properties. It has been proven that the<br />

phenylphosph<strong>in</strong>e oxide moiety provides a strong<br />

<strong>in</strong>teract<strong>in</strong>g site for impart<strong>in</strong>g miscibility with several<br />

systems [2-5].<br />

In this work, a series of novel phosph<strong>in</strong>e oxide<br />

conta<strong>in</strong><strong>in</strong>g polyimide / silica nanocomposite materials<br />

were prepared via sol-gel technique and imidization. The<br />

silica content <strong>in</strong> the hybrid coat<strong>in</strong>g materials was varied<br />

from 0 to 20 wt%. The FTIR and 29 Si-NMR spectra<br />

showed that the fully condensed <strong>in</strong>organic network had<br />

formed dur<strong>in</strong>g the imidization. Tensile modulus and<br />

hardness of the polyimide/silica coat<strong>in</strong>g materials<br />

<strong>in</strong>creased gradually with <strong>in</strong>creas<strong>in</strong>g <strong>in</strong>organic content due<br />

to the enhanced <strong>in</strong>terfacial <strong>in</strong>teraction between PI matrix<br />

and silica particles. The thermal analysis of the coat<strong>in</strong>g<br />

materials showed that the degradation of PI was largely<br />

reduced with <strong>in</strong>corporation of silica and also the flame<br />

retardancy of the nanocomposite <strong>in</strong>creased. The<br />

morphology studies <strong>in</strong>dicated that, the silica particles <strong>in</strong><br />

the polyimide matrix are dispersed homogeneously and the<br />

particle size is <strong>in</strong> the range of 30-55 nm. Furthermore, it<br />

was observed that optical transparencies of the hybrid<br />

coat<strong>in</strong>g materials decreased due to the <strong>in</strong>troduction of<br />

higher silica content <strong>in</strong>to the polyimide matrix and the<br />

<strong>in</strong>creas<strong>in</strong>g contact angles demonstrated the formation of<br />

hydrophobic nanocomposite surface.<br />

(a)<br />

Figure 1: SEM micrographs of (a) PI/SiO2-15 (b) Si mapp<strong>in</strong>g of<br />

PI/SiO2-15.<br />

*Correspond<strong>in</strong>g author: ckizilkaya@gmail.com<br />

[1] S Karatas, N.K. Apohan, H. Demirer, A. Gungor Polym.<br />

Adv. Technol., 18,490–496 (2007)<br />

[2] C.Kızılkaya ,S. Karataş , N. K. Apohan , A. Güngör, Journal<br />

of Applied Polymer Science, 115, 3256-3264 (2010).<br />

[3] M. Çakır, S Karataş, Y.Menceloğlu, N.K.Apohan, A.<br />

Güngör, Macromol. Chem. and Phys., 209 , 919 , (2008).<br />

[4] C.J Cornelius, E. Marand, Polymer , 43, 2385( 2002)<br />

[5] Y.Delaviz, A. Güngör, J.E. McGrath, H.W Gibson, Polymer,<br />

34, 210 (1993).<br />

(b)<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 209

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Piezoelectric properties of 0.65Pb(Mg 1/3 ,Nb 2/3 )O 3 -0.35PbTiO 3 ceramics prepared from<br />

nanopowders<br />

M. Ghasemifard a , S. M. Hosse<strong>in</strong>i a , H. Ghasemifard b<br />

a Department of Physics (Materials and Electroceramics Laboratory), Ferdowsi University of Mashhad, Mashhad, Iran,<br />

b Department of Medical Eng<strong>in</strong>ear<strong>in</strong>g, Azad University of Mashhad, Mashhad, Iran<br />

Abstract- The piezoelectric properties of relaxor ferroelectric 0.65Pb(Mg 1/3 Nb 2/3 )O 3 –0.35PbTiO 3 (0.65PMN–0.35PT) ceramics<br />

prepared by a sol-gel combustion method have been <strong>in</strong>vestigated as a function of s<strong>in</strong>ter<strong>in</strong>g temperatures. The XRD results show<br />

that the phase structure is near the morphoteropic phase boundary (MPB). The highest piezoelectric coefficients were observed<br />

for the samples s<strong>in</strong>tered at temperature of 1200 o C. In comparison with pure PMN, the substitution of 35% PT results <strong>in</strong> the<br />

decrease of s<strong>in</strong>tered temperature and peculiar relaxation behavior.<br />

Relaxors ferroelectric based on the PMN-PT ceramics<br />

display excellent piezoelectric/electrostrictive properties along<br />

with a variety of compositional modification, because of the<br />

volatilization of PbO and the differences of the reactive<br />

temperature between Pb-Nb and Pb-Mg [1-3]. The major<br />

problem <strong>in</strong> synthesis pure PMN-PT ceramics with perovskite<br />

structure is the formation of pyrochlore phases such as PbO,<br />

Pb 3 Nb 4 O 13 , Pb 2 Nb 2 O 7 and Pb 5 Nb 4 O 15 . A successful method to<br />

overcome these problems is a sol-gel process<strong>in</strong>g [4] which leads<br />

to approximately pure perovskite phase at low temperature with<br />

an improvement <strong>in</strong> the properties of PMN-PT ceramics. An<br />

additional benefit of this process<strong>in</strong>g is that it leads to small<br />

particles which cause pretty high density of ceramics. We have<br />

already managed to prepare PMN-PT nanopowders by sol-gel<br />

combustion [5]. This method provided a very f<strong>in</strong>e particles and<br />

a higher piezoelectric constant compared to traditional mixed<br />

oxide process<strong>in</strong>g. The aim of this paper was to <strong>in</strong>vestigate the<br />

effect of s<strong>in</strong>ter<strong>in</strong>g temperature on the 0.65PMN-0.35PT<br />

ceramics prepared by a new sol-gel combustion process<strong>in</strong>g<br />

method. We also have discussed the results of piezoelectric<br />

properties for the samples made from PMN-PT as a function of<br />

s<strong>in</strong>ter<strong>in</strong>g temperature.<br />

Nanopowders of (1-x)Pb(Mg 1/3 Nb 2/3 )O 3 -(x)PbTiO 3 (PMN-<br />

PT) with x=0.35 were synthesis by sol-gel combustion method<br />

us<strong>in</strong>g metal organic and salts precursors as start<strong>in</strong>g materials [5,<br />

6]. X-ray diffraction patterns of PMN-PT powders are shows <strong>in</strong><br />

Fig.1. The presence of a monocl<strong>in</strong>ic phase at 850 o C can be<br />

identify<strong>in</strong>g from Fig. 1. The XRD results reveal the existence of<br />

a perovskite-type phase for gel-combustion method <strong>in</strong> all<br />

temperature.<br />

Fig. 1 XRD spectra of samples of the PMN-PT<br />

Fig. 2 shows the microstructure of the PMN-PT ceramics<br />

s<strong>in</strong>tered at different temperatures. With the <strong>in</strong>crease of s<strong>in</strong>ter<strong>in</strong>g<br />

temperature, the gra<strong>in</strong> size <strong>in</strong>creases.<br />

Fig. 2. SEM micrographs of surface of PMN-PT ceramics<br />

The gra<strong>in</strong> size has strong effects on dielectric properties and<br />

polarization of piezoelectric materials [7]. The electrical<br />

parameters are summarized <strong>in</strong> Table 1.<br />

Table 1. Various parameters on some electrical properties<br />

Temperature<br />

( o C)<br />

Gra<strong>in</strong> size<br />

(μm)<br />

Density<br />

(gr/cm 3 )<br />

d 33<br />

(pC/N)<br />

1100 - 7.26 149 4.98 0.33<br />

1150 - 43.7 375 5.01 0.48<br />

1200 1.5 7.86 484 5.86 0.54<br />

1250 2 8.02 552 6.03 0.57<br />

1300 3.5 7.76 515 5.13 0.56<br />

[8] 2.8** 7.86 - - -<br />

[9] * - - 2200 - 0.92<br />

*PMN-0.32PT s<strong>in</strong>gle crystal. **S.T.=1240 o C<br />

In general, the results of measurement <strong>in</strong>dicated most electrical<br />

and piezoelectric parameters are maximum for the samples s<strong>in</strong>tered at<br />

temperature of 1250 o C.<br />

*Correspond<strong>in</strong>g author: mahdi572@yahoo.com<br />

[1] D. S. Paik, S. Komarneni, V. 34, (1999), 2255-2491.<br />

[2] M. Lejeune, J . P . Bilot, Ceram. Int. 8(3) (1982) 99.<br />

[3] O. Bouqu<strong>in</strong>, M. Lejeune, J . P . Bilot, J. Amer. Ceram. Soc. 74(5), (1991),<br />

1152.<br />

[4] P . Ra<strong>in</strong>dranathan, S. Komarneni, A. S. Bhalla, R. Roy, J. Amer. Ceram.<br />

Soc. 74(12), (1991), 2996.<br />

[5] M. Ghasemifard, S.M. Hosse<strong>in</strong>i, Gh. Khorrami, Ceramic <strong>in</strong>ternational, 35,<br />

(2008), 2899-2905.<br />

[6] M. Ghasemifard, S.M. Hosse<strong>in</strong>i, M. M. Bagheri-Mohagheghi, N.<br />

Shahtahmasbi, J. Physica E, Article <strong>in</strong> press, (2009).<br />

[7] M. Alguero, A. Moure, L. Pardo, J. Holc, M. Kosec, Acta Mater. 54 (2006)<br />

501–511.<br />

[8] S. E. Park, T. R. Shrout, J. Appl. Phys., 82, (1997), 1804–1811.<br />

[9] T.R. Shrout, Z.P. Chang, N. Kim, S. Markgraf, Ferroelectrics Lett. Sect., 12,<br />

(1990), 63–69.<br />

Q m<br />

k p<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 210

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Electros pun Hybrid Scaffolds for Bone Tissue Repair<br />

1 *<br />

1 urkey.<br />

Abstract-The aim of this study is to develop novel hybrid (blend&layer by layer) tissue scaffolds for bone tissue repair by us<strong>in</strong>g electrosp<strong>in</strong>n<strong>in</strong>g<br />

method. PCL (poly--caprolactone), chitosan and hydroxyapatite (HA) nanoparticles were used as components for hybrid structures. 15 wt % of<br />

PCL and 8 wt % of chitosan concentrations and 90/10 vol % PCL/chitosan weight ratio were selected <strong>in</strong> order to obta<strong>in</strong> uniform and bead free<br />

fabrics. Detailed characterization studies performed <strong>in</strong> this study showed the desired properties of scaffolds for bioapplications. The control of<br />

suitability of the developed hybrid scaffolds for cell culture applications by us<strong>in</strong>g osteoblast cells is under process.<br />

Nanofibrous materials have been extensively studied as<br />

scaffold<strong>in</strong>g materials <strong>in</strong> tissue eng<strong>in</strong>eer<strong>in</strong>g and regenerative<br />

medic<strong>in</strong>e, due to the fact that the extracellular matrices (ECM)<br />

of native tissues are nanofeatured structures, and cells attach<br />

and proliferate better on nanofeatured structures than bulk<br />

materials [1,2]. Recently, researchers have <strong>in</strong>vestigated<br />

electrosp<strong>in</strong>n<strong>in</strong>g of blend polymers as candidate materials for<br />

biomedical applications because polymer blends have<br />

provided an efficient way to fulfill new requirements for<br />

material properties. Blends made of synthetic and natural<br />

polymers can present the wide range of physicochemical<br />

properties and process<strong>in</strong>g techniques of synthetic polymers as<br />

well as the biocompatibility and biological <strong>in</strong>teractions of<br />

natural polymers [3,4]. In addition, many researchers have<br />

reported that <strong>in</strong>corporation of calcium carbonate (CaCO 3 ) or a<br />

type of calcium phosphate such as hydroxyapatite (HA)<br />

helped to improve osteoblast proliferation and differentiation<br />

[5,6].<br />

In the present contribution, novel PCL (poly--caprolactone)<br />

and chitosan blend and layer by layer structures of hybrid<br />

scaffolds filled with hydroxyapapite (HA) nanoparticles were<br />

developed by us<strong>in</strong>g electrosp<strong>in</strong>n<strong>in</strong>g method. PCL, due to its<br />

slow degradation rate, is a good candidate to be used <strong>in</strong> bonescaffold<strong>in</strong>g<br />

applications. Chitosan is favorite for<br />

bioapplications because of its biocompatible property and low<br />

cost. HA nanoparticles (50-200 nm) prepared and<br />

characterized <strong>in</strong> our previous study [7] were used.<br />

In the first stage of the work, various solution/process<br />

parameters such as concentration, PCL/chitosan weight ratios,<br />

applied electric voltage, tip-collector distance were studied for<br />

optimization of scaffolds. After optimization studies, the<br />

concentrations for pure and hybrid (blend and layer by layer;<br />

PCL/Chitosan/PCL&Chitosan/PCL/Chitosan) PCL and<br />

chitosan scaffolds were chosen as 15 wt % of PCL and 8 wt %<br />

of chitosan <strong>in</strong> order to obta<strong>in</strong> desired nanofabric structures<br />

(uniform, bead free). The weight ratios of PCL and chitosan<br />

were determ<strong>in</strong>ed as 90/10 vol % for blend PCL/chitosan<br />

scaffolds. PCL/Chitosan/PCL layer by layer structure was<br />

selected for further studies. Applied electric voltages, tipcollector<br />

distances were determ<strong>in</strong>ed for each scaffolds. For the<br />

HA modification of the scaffolds different concentrations (1.5,<br />

5, 10, 20 wt%) of HA nanoparticles were added to<br />

PCL/chitosan solutions before electrosp<strong>in</strong>n<strong>in</strong>g process. In<br />

addition to naked eye observation SEM analysis was also used<br />

for the optimization of structures.<br />

In the characterization stage, the prepared scaffolds were<br />

first morphologically exam<strong>in</strong>ed by SEM analysis. By us<strong>in</strong>g<br />

computer software program (ImageJ, USA), average fiber<br />

diameters, HA and <strong>in</strong>ter fibers porosity sizes of scaffolds were<br />

calculated from obta<strong>in</strong>ed SEM photographs.<br />

Wettabilities of electrospun scaffolds were measured us<strong>in</strong>g<br />

sessile drop water contact angle measurement by a optical<br />

contact angle measurement (KSV, F<strong>in</strong>land) systems. The<br />

contact angle measurement study showed that hydrophobic<br />

characteristic of PCL scaffolds was decreased by add<strong>in</strong>g<br />

chitosan and HA components. The samples were cut <strong>in</strong><br />

rectangular strips with dimensions 40 mm × 5 mm, and tensile<br />

properties were characterized by tensile test<strong>in</strong>g mach<strong>in</strong>e<br />

(Llyod Instruments LK-5K, UK) equipped with a 500 N load<br />

cell. Elastic modulus, tensile strength and stra<strong>in</strong> at break (%)<br />

values of samples were determ<strong>in</strong>ed as a result of mechanical<br />

tests. FTIR-ATR analysis <strong>in</strong> the range of 500-4000 cm -1<br />

wavelength was used for the chemical structure confirmation<br />

of the prepared scaffolds. The obta<strong>in</strong>ed spectra showed that<br />

the hybrid scaffolds represent the characteristic peaks of PCL,<br />

chitosan and HA components. Swell<strong>in</strong>g properties of<br />

PCL/chitosan scaffolds were exam<strong>in</strong>ed by PBS absorption<br />

tests. In order to <strong>in</strong>vestigate the effect of chitosan on<br />

biodegradation of prepared scaffolds, biodegradation studies<br />

were carried out for the 7 th , 14 th , 21 st<br />

and 28 th<br />

days of<br />

<strong>in</strong>cubation <strong>in</strong> DMEM/F12 with chicken egg white lysozyme<br />

medium. Additionally, controlled release of BSA (Bov<strong>in</strong>e<br />

Serum Album<strong>in</strong>) studies was performed to have an idea about<br />

the effect of HA nanoparticles with different weight ratios on<br />

bone tissue repair.<br />

In summary, the characterization studies carried out <strong>in</strong> this<br />

work showed the desired properties of scaffolds for<br />

bioapplications. In the future part of this work, the control of<br />

suitability of prepared and well/detailed characterized hybrid<br />

PCL/chitosan scaffolds for cell culture applications will be<br />

performed by us<strong>in</strong>g osteoblast cells. This work was fully<br />

supported by TUBA/LOREAL under “Young Women <strong>in</strong><br />

Science” program. Dr. <br />

“Young Woman <strong>in</strong> Science” <strong>in</strong> Materials Science at 2009 with<br />

this project.<br />

*Correspond<strong>in</strong>g author: 1Thtsasmazel@atilim.edu.tr<br />

[1]J.A. Matthews, G.E. Wnek, D.G. Simpson, et al.<br />

Biomacromolecules 3, 232 (2002).<br />

[2] M. Pattison, S. Wurster, T. Webster, K. Haberstroh, Biomaterials<br />

26, 249 (2005).<br />

[3] Y. You, S.W. Lee, et al. Polymer Degradation and Stability 90,<br />

441 (2005).<br />

[4] S. Aparna, S.V. Madihally, Biomaterials 26, 5500 (2005).<br />

[5] A. G. A. Coombes, S. C. Rizzi, M.Williamson, J. E. Barralet,<br />

S. Downes, W. A. Wallace, Biomaterials 25, 315 (2004).<br />

[6] K. Fujihara, M. Kotaki, S. Ramakrishna, Biomaterials 26, 4139<br />

(2005).<br />

[7] A.P. Sommer, M. Çehreli, et al. Crystal Growth&Design 5, 21<br />

(2005).<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 211

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Fas t Track Preparat ion of ZnO nanorods <strong>in</strong> Water<br />

M. A. Shah 1 *, F.M.Al-Marzouki 1 and A.A. Al-Ghamdi 1<br />

1 Department of Physics, Faculty of Sciences, K<strong>in</strong>g Abdul Aziz University, Jeddah 21589, K<strong>in</strong>gdom of Saudi Arabia<br />

Abstract-We will present a fast, soft, economical and bio-safe synthesis of hexagonal-shaped z<strong>in</strong>c oxide (ZnO) nanorods at very low temperature<br />

of ~120 o C simply by us<strong>in</strong>g metallic z<strong>in</strong>c powder and de-ionized (DI) water without the use of any additives or am<strong>in</strong>es. The product is believed to<br />

be bio-safe and bio-compatible and can be readily used for medic<strong>in</strong>e besides other applications.<br />

Nanostructures of z<strong>in</strong>c oxide (ZnO), <strong>in</strong>clud<strong>in</strong>g particles,<br />

rods, wires, belts, tubes, cages, walls, flowers and r<strong>in</strong>gs have<br />

scattered a great deal of attention <strong>in</strong> recent years because of<br />

their useful electronic and optoelectronic properties and<br />

novel application <strong>in</strong> catalysis, pa<strong>in</strong>ts, wave filters, UV<br />

detectors, transparent conductive films, varistors, gas<br />

sens<strong>in</strong>g, solar cells, sun screens and other cosmetic products.<br />

Moreover, the wide range of morphological diversity <strong>in</strong> the<br />

nano-regime has made this material a promis<strong>in</strong>g candidate <strong>in</strong><br />

the field of nanotechnology and opened up new possibilit ies<br />

for the fabrication of high performance devices based on<br />

these nanostructures. Among the various nanoforms, one<br />

dimensional (1D) nanostructures have received considerable<br />

attention due to their potential <strong>in</strong>terests for understand<strong>in</strong>g<br />

fundamental physical concepts and for efficient field<br />

emission that has enormous commercial applications such as<br />

field emission flat panel displays, x-ray sources, parallel<br />

beam electron microscopy and vacuum microwave<br />

amp lifiers [1].<br />

Synthesis of nanomaterials forms a vital aspect of the<br />

science of nanomaterials and chemical methods have proved<br />

to be more effective and versatile than physical methods and<br />

have, therefore, been employed widely. While nanomaterials<br />

have been generated by physical methods too such as laser<br />

ablation, arc discharge and evaporation, chemical methods<br />

have proved to be more attractive as they provide better<br />

control over the size and shape, which is one of the essential<br />

features <strong>in</strong> nanoscience. Chemical synthesis of nanomaterials<br />

has been reviewed by few authors but <strong>in</strong>numerable<br />

improvements and better methods are be<strong>in</strong>g reported<br />

cont<strong>in</strong>ually <strong>in</strong> the last few years [2,3].<br />

In this work we will explore the formation of ZnO<br />

nanostructures by the reaction of z<strong>in</strong>c metal with DI water at<br />

very low temperature of 120oC. The simple reaction is<br />

carried out <strong>in</strong> absence of any additives and/or am<strong>in</strong>es. The<br />

synthesized ZnO products were characterized <strong>in</strong> terms of<br />

their structural and optical properties. By the morphological<br />

<strong>in</strong>vestigations us<strong>in</strong>g FESEM, it was observed that the grown<br />

products are hexagonal-shaped ZnO nanorods with the<br />

diameters and lengths <strong>in</strong> the range of 70-90 nm with several<br />

micrometers. The EDS and XRD pattern confirmed the<br />

composition and crystall<strong>in</strong> ity of the grown nanorods and<br />

revealed that the grown products are pure ZnO with the<br />

wurtzite hexagonal phase. The optical properties of grown<br />

products were characterized by room-temperature<br />

photolum<strong>in</strong>escence spectroscopy which confirmed the good<br />

optical properties for the grown products.<br />

[2] H. Wie, Y. Wu, N. Lun, and C. Hu, Mater. Sci. Eng. A Vol.<br />

393, 80 (2005).<br />

[3] Z.W. Pan, Z.R. Dia and Z.L. Wang, Science Vol. 291, 1947<br />

(2001).<br />

*Correspond<strong>in</strong>g author: 0Tmashahnit@yahoo.com<br />

[1] C. X. Xu, Y. Liu, and G. Wang, Solid State Communication<br />

Vol. 122, 175 (2002).<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 212

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Additive Free Synthesis of Alum<strong>in</strong>um Oxide Nanostructures<br />

F.M.Al-Marzouki 1 and M. A. Shah 1 *<br />

Department of Physics, Faculty of Sciences, K<strong>in</strong>g Abdu l Aziz University,<br />

Jeddah 21589, K<strong>in</strong>gdom of Saudi Arabia<br />

1<br />

Abstract- Water which is well known <strong>in</strong>expensive and an environmentally benign solvent have been used for the synthesis of alum<strong>in</strong>um oxide<br />

(Al 2 O 3 ) nanostructures. We will present an economical and bio-compatible synthesis of alum<strong>in</strong>um oxide nanorods at very low temperature of<br />

~180 o C without us<strong>in</strong>g any additives or surfactants. This is the first report where nanostructures of Al2O3 have been prepared at such a low<br />

temperature and by such a simple technique. The formation of Al 2 O 3 structures by the reaction of metals with DI water is suggested to occur due<br />

to the oxidation of alum<strong>in</strong>um <strong>in</strong> presence of water. The reported method besides be<strong>in</strong>g organics free is economical, fast and free of<br />

pollution, which will make it suitable for large scale production.<br />

Innovations at the <strong>in</strong>tersection of medic<strong>in</strong>e, biotechnology,<br />

eng<strong>in</strong>eer<strong>in</strong>g, physical sciences and <strong>in</strong>formation technology<br />

are spurr<strong>in</strong>g new directions <strong>in</strong> R&D, commercialization and<br />

technology transfer. The future of nanotechnology is likely<br />

to cont<strong>in</strong>ue <strong>in</strong> this <strong>in</strong>terdiscipl<strong>in</strong>ary manner.<br />

Nanotechnology is the next <strong>in</strong>dustrial revolution, and all<br />

most all <strong>in</strong>dustries will be radically transformed by it <strong>in</strong> a<br />

few years. Ceramics are regarded as versatile materials and<br />

alum<strong>in</strong>um oxide (Al2O 3 ), one of the ceramic materials<br />

commonly known as sapphire is known to exist <strong>in</strong> a number<br />

of metastable polymorphs <strong>in</strong> addition to the<br />

-Al 2 O 3 or corundum form.<br />

-Al 2 O 3<br />

is an important form of alum<strong>in</strong>a<br />

because of its porous structure and high catalytic surface<br />

activity. This material has been widely used as catalysts, an<br />

adsorbent and as a support for <strong>in</strong>dustrial catalysis <strong>in</strong><br />

hydrocarbon conversion. Ow<strong>in</strong>g to their brittleness, ceramics<br />

have been regarded as materials of modest performance<br />

especially under tension or bend<strong>in</strong>g conditions [1].<br />

A number of synthetic routes <strong>in</strong>clud<strong>in</strong>g, the sol-gel<br />

chemistry, spray pyrolysis, precipitation, solovothermal and<br />

physical methods are be<strong>in</strong>g extensively used for the<br />

synthesis of Al2O 3 nanostructures [2,3]. The other<br />

techniques are technically complex, requires high<br />

temperature, harsh growth conditions, expensive<br />

experimental setup, complicated control processes and use of<br />

excessive organics/am<strong>in</strong>es. Seek<strong>in</strong>g a simple approach for<br />

low cost, lower temperature, larger scale production and<br />

controlled growth without additives is desired [4].<br />

To this end, we present a novel and simple method for<br />

-A l 2 O 3 nanorods without catalysts or any<br />

other additive. The route is based on a simple reaction of<br />

alum<strong>in</strong>um powder and double distilled water at 180 o C<br />

without us<strong>in</strong>g any catalyst or any other additive. Moreover,<br />

the synthesis time is very short and the morphology could be<br />

controlled by vary<strong>in</strong>g reaction time. The aim of the study is<br />

to provide the feasibility of the simple route for the<br />

preparation of alum<strong>in</strong>um oxide nanostructures. Systematic<br />

studies are underway and will be presented dur<strong>in</strong>g<br />

conference.<br />

Correspond<strong>in</strong>g author: 0Tmashahnit@yahoo.com<br />

[1] Fang X, Zhang L. J. Mater. Sci. Tech.22, 1 (2006).<br />

[2] Y.Z J<strong>in</strong>, Y.Q Zhu, K Brigatt, H. Kroto, D.R.M Waltan, Appl.<br />

Phys. A 89, 1008 (2003).<br />

[3] X.S.Fang, C.H.Ye, L.D.Zhang, T. Xie Adv. Mater 17 (2005)<br />

1661<br />

[4] M.A.Shah and A.M. Asiri, Int. J. Modern Phy. B, Vol. 23, 2323<br />

(2009).<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 213

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Preparation and characterization of silver nanoparticles by an eco-friendly approach<br />

Reda El-Sh ishtawy 1 * Abdullah Asiri 1 and Maha Al-Otaibi 1<br />

Department of Chemistry, Faculty of Science, K<strong>in</strong>g Abdul-Aziz University, Jeddah 21589, PO Box 80203, Saudi Arabia<br />

1<br />

Abstract-This work reports on an environmentally benign method for the preparation of AgNPs <strong>in</strong> aqueous solution us<strong>in</strong>g glucose as the<br />

reduc<strong>in</strong>g agent <strong>in</strong> water/ micelles system, <strong>in</strong> which cetyltrimethylammonium bromide (CTAB) was used as capp<strong>in</strong>g agent (stabilizer).<br />

Spectrophotometric method was used to monitor the formation of AgNPs under different conditions such as a) concentration of sodium<br />

hydroxide, b) concentration of glucose, c) concentration of silver nitrate d) concentration of CTAB, and e) reaction time were used so as to f<strong>in</strong>d<br />

out the optimum conditions for the preparation of AgNPs.<br />

Silver nanoparticles (AgNPs) have received much more<br />

attention <strong>in</strong> recent years due to their unique physical, optical,<br />

electrical, magnetic, and chemical properties and their<br />

potential application <strong>in</strong> molecular electronic field [1].<br />

Therefore, extensive research has gone <strong>in</strong>to develop<strong>in</strong>g<br />

suitable preparation techniques to form AgNPs. These <strong>in</strong>clude<br />

chemical reduction, microorganisms <strong>in</strong>duced reduction as well<br />

as photochemical and high energy radiation <strong>in</strong>duced reduction<br />

of silver salt solution. Among these methods, chemical<br />

reduction is the most extensively <strong>in</strong>vestigated method [2-6].<br />

Figure 1 shows the UV-vis absorption spectrum of a diluted<br />

solution of AgNPs <strong>in</strong> which we can see a narrow absorption at<br />

403 nm (plasmon band) <strong>in</strong>dicat<strong>in</strong>g the presence AgNPs. The<br />

size of the AgNPs were determ<strong>in</strong>ed with the help of<br />

transmission electron microscope (Fig. 2). Also, a comparative<br />

k<strong>in</strong>etic formation of AgNPs us<strong>in</strong>g ultrasonic and conventional<br />

heat<strong>in</strong>g conditions were made and the result obta<strong>in</strong>ed <strong>in</strong>dicates<br />

(Figure 3) that the rate of formation of AgNPs us<strong>in</strong>g ultrasonic<br />

condition was about 1.5 times better than that obta<strong>in</strong>ed us<strong>in</strong>g<br />

conventional heat<strong>in</strong>g. The result <strong>in</strong>dicates the necessity of<br />

us<strong>in</strong>g CTAB as capp<strong>in</strong>g and stabiliz<strong>in</strong>g agent for AgNPs.<br />

nanoparticles. A future work is be<strong>in</strong>g under <strong>in</strong>vestigation to<br />

explore the viability of us<strong>in</strong>g AgNPs <strong>in</strong> different biomedical<br />

and photonic applications.<br />

Figure 2. TEM image of the as-prepared silver nanoparticles.<br />

ln(At-Af)<br />

1<br />

0<br />

-1 0 2 4 6 8 10 12 14<br />

-2<br />

-3<br />

-4<br />

-5<br />

-6<br />

-7<br />

-8<br />

yUS = -0.5891x + 0.2431<br />

R2 = 0.9943<br />

yCH = -0.3864x - 0.0064<br />

R2 = 0.9693<br />

Time (m<strong>in</strong>)<br />

25 Times diluted sample Concentrated sample<br />

Figure 3. Plots of ln(A t -A f ) versus time of AgNPs formation under<br />

ultrasonic and conventional conditions. Prepartion condition:[Ag<br />

NO 3 ] = 2.5 mM; [glucose] = 2.5 mM; [CTAB] = 0.5 mM; [NaOH] =<br />

25 mM at 50 o C.<br />

*Correspond<strong>in</strong>g author: elshishtawy@hotmail.com<br />

Figure 1. UV–vis spectrum of the as-prepared silver nanoparticles (25<br />

times diluted sample). Prepartion condition: [Ag NO 3 ] = 2.5 mM;<br />

[glucose] = 2.5 mM; [CTAB] = 0.5 mM; [NaOH] = 25 mM and<br />

reaction time was 20 m<strong>in</strong> at 50 o C.<br />

In conclusion, uniform AgNPs have been successfully<br />

prepared <strong>in</strong> glucose/CTAB micelles. CTAB displays excellent<br />

properties <strong>in</strong> the preparation and stabilization of silver<br />

[1] N.G.Khlebtsov, L. A. Dykman, J. Quant. Spectrosc. Radiat.<br />

Transfer, 111, 1–35 (2010) and references cited there<strong>in</strong>.<br />

[2] R. Janardhanan, M. Karuppaiah, N. Hebalkar, T. N. Rao,<br />

Polyhedron, 28, 2522–2530 (2009) and references cited there<strong>in</strong>.<br />

[3] K.K. Ghosh, S. Kolay, J. Dispersion Sci. Technol., 29, 676–681<br />

(2008).<br />

[4] V. K. Sharma, R. A. Yngard, Y. L<strong>in</strong>, Adv. Colloid Interface Sci.,<br />

145, 83–96 (2009) and references cited there<strong>in</strong>.<br />

[5] Y. Y<strong>in</strong>, Z-Y. Li, Z. Zhong, B. Gates, Y. Xia,S. Venkateswaran, J.<br />

Mater. Chem., 12, 522–527 (2002).<br />

[6] N. R. Jana, L. Gearheart,C. J. Murphy, Chem. Commun., 2001,<br />

617–618.<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 214

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Structure of unsupported s mall Al nanoparticles; Molecular dynamics study<br />

Amir Chamaani 1 * Reza Darvishi Kamachali 2 Ehsan Marzbanrad 3 Alireza Aghaei 3 Yashar Behnamian 4<br />

1 New materials Department, Materials and Energy Research Center (MERC), P.O. Box 14155-4777, Tehran, Iran<br />

2 ICAMS, Ruhr-University Bochum, Bochum 44801, Germany<br />

3 Ceramic Department, Materials and Energy Research Center (MERC), P.O. Box 14155-4777, Tehran, Iran<br />

4 Chemical and Materials Eng<strong>in</strong>eer<strong>in</strong>g Department, University of Alberta Edmonton AB, T6G 2V4, Canada<br />

Abstract-A classical molecular dynamics simulation has been used to study the structure of unsupported small Al nanoparticles. Our results<br />

support the existence of a core-shell structure for the common truncated octahedron shape of Al nanoparticles, <strong>in</strong> terms of cohesive energy.<br />

However, there is a critical size below which the core-shell model cannot be applied, because the entire structure of Al nanoparticles below this<br />

size consists of merely a surface zone.<br />

The cohesive energy of nanoparticles determ<strong>in</strong>es their<br />

physical and thermodynamic properties, such as melt<strong>in</strong>g po<strong>in</strong>t,<br />

thermal stability and structure. Different models have been<br />

developed to account for cohesive energy, <strong>in</strong>clud<strong>in</strong>g the BE<br />

model [1], SAD model [2], Xie’s model [3] and so on. Most<br />

recently, the core-shell model [4-5] has been used to describe<br />

the structure of nanoparticles, <strong>in</strong> which the core of the particle<br />

is the same as the bulk material, and the surface shell is not<br />

caused by large dangl<strong>in</strong>g bonds. This concept has already been<br />

used <strong>in</strong> particular models to calculate the cohesive energy of<br />

metallic nanoparticles. In these models [1, 3], the entire<br />

structure of the nanoparticle is divided <strong>in</strong>to two sections: a<br />

bulk and a surface zone. In other words, the cohesive energy<br />

of a nanoparticle is considered to consist of the cohesive<br />

energies of the bulk zone and of the surface zone. This study is<br />

a qualitative <strong>in</strong>vestigation of the structure of a common shape<br />

(truncated octahedron) for Al nanoparticles.<br />

In this study, the simulation was performed <strong>in</strong> NVT<br />

ensemble, us<strong>in</strong>g a semi-emp irical potential (glue) [6]. The<br />

expressions for and details of the potential used can be found<br />

<strong>in</strong> aforementioned paper. The primary structure of our<br />

nanoparticles was the truncated octahedron structure from an<br />

ideal Al crystal. The number of atoms <strong>in</strong> each nanoparticle<br />

was either 79, 201, 586, 1289, 2406 or 4033, with a particle<br />

size rang<strong>in</strong>g from 1–5 nm. A bulk simulation of 864 Al atoms<br />

us<strong>in</strong>g periodic boundary conditions (pbc) was carried out to<br />

serve as a comparative case. The Verlet velocity algorithm<br />

was employed for motion equations, and a simple redial<br />

distribution counter function was used to calculate energy<br />

distributions. The systems were divided <strong>in</strong>to the maximum<br />

possible redial layers for which every layer <strong>in</strong>cluded at least<br />

one atom.<br />

The cohesive energy versus the distance to center of Al<br />

nanoparticles and the correspond<strong>in</strong>g bulk value is shown <strong>in</strong><br />

Figure (1). Unlike Al bulk (864 atoms with pbc), the cohesive<br />

energy of Al nanoparticles at a specific temperature is not<br />

constant: reced<strong>in</strong>g from center to surface, cohesive energy<br />

deviates from the bulk value. Indeed, <strong>in</strong>ternal atoms of large<br />

nanoparticles (nanoparticles which consist of more than 201<br />

atoms) have the bulk cohesive energy (-3.34 eV/atom), but<br />

surface atoms have a lower cohesive energy. Because of this<br />

separation between surface and <strong>in</strong>terior atoms of large Al<br />

nanoparticles, the whole structure of large nanoparticles can<br />

be consider as hav<strong>in</strong>g two parts: the core of the nanoparticle<br />

(the bulk zone), and the shell of the nanoparticle (the surface<br />

zone). The bulk zone <strong>in</strong> large nanoparticles consists of atoms<br />

which have the bulk cohesive energy, whereas surface zone<br />

atoms have a lower cohesive energy. Furthermore, as shown<br />

<strong>in</strong> Figure (1), with decreas<strong>in</strong>g nanoparticle size, the bulk zone<br />

gradually decreases, and below a crit ical size it co mpletely<br />

disappears. Under our conditions, the critical size is about 1.6<br />

nm (201 atoms). Therefore, the entire structure of<br />

nanoparticles below the critical size consists of only a surface<br />

zone. These nanoparticles cannot be considered to have a<br />

core-shell structure and it is better to def<strong>in</strong>e them simply as<br />

surface materials. Recently, Qi [4-5], us<strong>in</strong>g mo lecular<br />

dynamics simulation, suggested that nanoparticles of all sizes<br />

can be regarded as hav<strong>in</strong>g a core-shell structure, even small<br />

ones. However, accord<strong>in</strong>g to our results, the structure of very<br />

small nanoparticles consists of only a surface zone; the<br />

cohesive energies of the two smaller nanoparticles (201 and 79<br />

atoms) are composed of only the cohesive energy of their<br />

surface zones. Consequently, the validity of the BE and Xie<br />

models, which are based on the core-shell model, is called <strong>in</strong>to<br />

question for small nanoparticles.<br />

Figure 1. Cohesive energy of Al nanoparticles and bulk counterpart versus<br />

distance to center<br />

In summary, we <strong>in</strong>vestigated the structure of unsupported Al<br />

nanoparticles <strong>in</strong> terms of the radial distribution of cohesive<br />

energy. Our results show that the structure of nanoparticles<br />

can be described by the core-shell model. However, there is a<br />

critical size below which there is no bulk zone; the whole<br />

structure of nanoparticles of this size consists of the surface<br />

zone. Therefore, the validity of some cohesive energy models<br />

based on the core-shell model, such as the BE and Xie models,<br />

may not hold true for very small nanoparticles.<br />

*Correspond<strong>in</strong>g author: amir_chamani@merc.ac.ir<br />

[1] W.H. Qi, B.Y. Huang, M.P. Wang et al., Phys. Lett. A 370, 494<br />

(2007).<br />

[2] W.H.Qi, M.P.Wang, J.Mater.Sci.letter. 21, 1743 (2002).<br />

[3] D Xie, M.P.Wang and W.H.Qi, j.phys.condens.matter.16, L401<br />

(2004).<br />

[4] W.H.Qi, B.Huang, M.P.Wang, J. comput.theor. nanoscience. 6,<br />

1546 (2009).<br />

[5] W.H. Qi, S.T. Lee, chem.phys.lett. 483, 247–249 (2009).<br />

[6] F. Ercolessi, J. B. Adams, Europhys. Lett. 26, 584 (1994).<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 215

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

New stationary phase based on stabilized by o rga nic liga nds gold nanoparticles on silica surface for<br />

HPLC<br />

Ir<strong>in</strong>a Ananieva 1 *, Yana Elfimova 1 , Aleksandr Majouga 1 , Nikolay Zyk 1 and Oleg Shpigun 1<br />

1 Department of Chemistry, Lomonosov Moscow State University, Moscow, Russia<br />

Abstract-New nanohybrid materials for HPLC based on gold nanoparticles supported on silica gel and stabilized by<br />

L-cyste<strong>in</strong>, pyrid<strong>in</strong>e, citrate and ascorbic acid are synthesized. The possibility of separation of different model compounds <strong>in</strong> normal-phase<br />

mode of chromatography is studied.<br />

Nowadays gold nanoparticles attract a great deal of<br />

attention <strong>in</strong> a wide variety of scientific fields and technology<br />

due to their unique chemical and physical properties, which<br />

are directly related to chemical composition, size and<br />

surface structural characteristics of nanoparticles [1].<br />

Materials based on gold nanoparticles have already found<br />

widespread application <strong>in</strong> medic<strong>in</strong>e, optoelectronics,<br />

catalysis, biochemical sensors development [2]. It seems to<br />

be very perspective to use gold nanoparticles supported on<br />

oxide surface and stabilized by sulfur-bear<strong>in</strong>g organic<br />

ligands for creation of new class of separation materials for<br />

liquid chromatography. Due to the specific structures and<br />

additional <strong>in</strong>teraction between gold nanoparticles on the<br />

stationary phase surface and separat<strong>in</strong>g compounds a good<br />

resolution of different organic compounds may be achieved.<br />

The ma<strong>in</strong> advantage of these selectors is covalent attach<strong>in</strong>g<br />

of organic ligands on the surface of nanoparticles that allows<br />

to synthesize a stable sorbent and obta<strong>in</strong> reproducible data.<br />

Nanohybrid materials have been synthesized by follow<br />

method. In the first one gold nanoparticles with the 10 nm<br />

size have been prepared by reduction H[AuCl 4 ] <strong>in</strong> an aqua<br />

solution by sodium citrate, and then they have been<br />

adsorbed on silica gel. In the last stage citrate-ions have<br />

been substituted for such organic ligands as L-cyste<strong>in</strong><br />

(column 1), pyrid<strong>in</strong>e, ascorbic acid. The scheme of the<br />

synthesized stationary phase with organic ligand is<br />

presented on Figure 1.<br />

am<strong>in</strong>opyrid<strong>in</strong>es had the greatest capacity coefficients on all<br />

stationary phases, and the retention rose with the growth of<br />

<strong>in</strong>vestigat<strong>in</strong>g compounds polarity because of the <strong>in</strong>creas<strong>in</strong>g<br />

of dipole-dipole <strong>in</strong>teractions. The <strong>in</strong>crease of capacity<br />

coefficients well correlates with the <strong>in</strong>crease of of<br />

am<strong>in</strong>opyrid<strong>in</strong>es. The smaller capacity coefficient of 2-<br />

am<strong>in</strong>opyrid<strong>in</strong>e (pKa 6.67) <strong>in</strong> comparison with 3-<br />

am<strong>in</strong>opyrid<strong>in</strong>e (pKa 6.16) can be expla<strong>in</strong>ed by steric<br />

h<strong>in</strong>drance of NH 2 -group. The greatest retention time of all<br />

model compounds was observed for the stationary phase<br />

conta<strong>in</strong><strong>in</strong>g pyrid<strong>in</strong>e as the modificator because of strong -<br />

Chromatogram of am<strong>in</strong>opyrid<strong>in</strong>e separation<br />

is presented on Figure 2.<br />

Figure 2. Chromatogram of separation of am<strong>in</strong>opyrid<strong>in</strong>es. Column<br />

1 (1004,0 mm) . Mobile phase: hexane/i-propanol<br />

(90/10). Injection volume 20 l. 1 - 2-am<strong>in</strong>o-5-chlor<strong>in</strong>epyrid<strong>in</strong>e; 2<br />

- 2-am<strong>in</strong>o-5-methylpyrid<strong>in</strong>e; 3 - 2-am<strong>in</strong>o-4-methylpyrid<strong>in</strong>e; 4 – 2-<br />

am<strong>in</strong>opyrid<strong>in</strong>e.<br />

Figure 1. Layout view of the adsorption of modified gold<br />

nanoparticles on the silicon oxide’s surface.<br />

In order to estimate the retentive ability of prepared<br />

nanohybrid sorbents such model compounds as anil<strong>in</strong>es,<br />

phenols, am<strong>in</strong>opyrid<strong>in</strong>es, some optically active compounds<br />

were used <strong>in</strong> normal-phase mode of HPLC. Previous<br />

research have shown that the optimum mobile phase was<br />

90% hexane/10% isopropanol. It was found that<br />

Obta<strong>in</strong>ed results show that new nanohybrid materials<br />

based on stabilized by L-cyste<strong>in</strong>, pyrid<strong>in</strong>e and citrate gold<br />

nanoparticles on silica surface are very perspective for<br />

further <strong>in</strong>vestigation.<br />

This work was supported by the Russian Foundation for<br />

Basic Research (09-03-00519-).<br />

*Correspond<strong>in</strong>g author: irishan@mail.ru<br />

[1] M. Brust, M. Walker, D. Bethell, D. Schiffr<strong>in</strong>, R. Whyman, J.<br />

Chem. Soc., Chem. Commun., 801-802 (1994).<br />

[2] Kiml<strong>in</strong>g J., Maier M., Okenve B., Kotaidis V., Ballot H., Plech<br />

A., J. Phys. Chem. B. 110 15700 (2006).<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 216

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

L-cyste<strong>in</strong> go ld nanoparticles on silica surface for HPLC separation<br />

Yana Elfimova 1 *, Ir<strong>in</strong>a Ananieva 1 , Aleksandr Majouga 1 , Nikolay Zyk 1 and Oleg Shpigun 1<br />

1 Department of Chemistry, Lomonosov Moscow State University, Moscow, Russia<br />

Abstract-New nanohybrid material for HPLC based on gold nanoparticles supported on silica gel and stabilized by<br />

L-cyste<strong>in</strong> is synthesized. The possibility of separation of -blockers and am<strong>in</strong>o acids <strong>in</strong> different modes of chromatography is<br />

studied.<br />

Gold nanoparticles play an important role <strong>in</strong> applied<br />

science and technology because they exhibit unique<br />

chemical and physical properties which depend on their<br />

shape, size, and local environment [1]. Materials based on<br />

gold nanoparticles are widely used <strong>in</strong> the field of chemistry,<br />

<strong>biology</strong>, material science and physics. The dimensions of<br />

gold nanoparticles allow us<strong>in</strong>g them for the creation of a<br />

new class of separation materials for liquid chromatography.<br />

We suggest new sorbent based on the gold nanoparticles<br />

supported on silica gel and stabilized by L-cyste<strong>in</strong> for the<br />

separation of different organic compounds <strong>in</strong>clud<strong>in</strong>g<br />

optically active compounds.<br />

Optically active compounds attract great attention because<br />

of their widespread application <strong>in</strong> many fields of science,<br />

particularly <strong>in</strong> pharmaceutics. Compounds that have optical<br />

isomers <strong>in</strong> many cases exhibit different pharmacological and<br />

toxicological properties. This fact has stimulated the<br />

application of enantiomerically pure products. -blockers<br />

play an important role among optically active compounds.<br />

-blockers are drugs that slow the heart rate, decrease<br />

cardiac output, lessen the force with which the heart muscle<br />

contracts and reduce blood vessel contraction. They do this<br />

by block<strong>in</strong>g beta-adrenergic receptors <strong>in</strong> various parts of the<br />

body. Another important class of optically active<br />

compounds is am<strong>in</strong>o acids. Am<strong>in</strong>o acids<br />

co-exist <strong>in</strong> biological liquids of liv<strong>in</strong>g organisms though<br />

D- and L-isomers play different roles. That is why the<br />

problem of enantioseparation of different am<strong>in</strong>o acids is<br />

very actual nowadays. HPLC has many applications <strong>in</strong> the<br />

fields of determ<strong>in</strong>ation of am<strong>in</strong>o acids. The commonly used<br />

method performance is the determ<strong>in</strong>ation of am<strong>in</strong>o acids as<br />

hydrophobic derivatives <strong>in</strong> reverse-phase mode on the<br />

hydrophobic stationary phase. In the present time much<br />

works <strong>in</strong> chiral separations have been directed to the<br />

development of new chiral selectors.<br />

Gold nanoparticles with average 10 nm size have been<br />

synthesized by reduction H[AuCl 4 ] <strong>in</strong> an aqua solution by<br />

sodium citrate, and then they have been modified by<br />

L-cyste<strong>in</strong>. Prepared nanoparticles have been adsorbed on<br />

silica gel. The scheme of the synthesized stationary phase<br />

with L-cyste<strong>in</strong> as organic lidand is presented on Fig.1.<br />

Obta<strong>in</strong>ed material has been tested for ability of<br />

-blockers<br />

and am<strong>in</strong>oacids. The best separation of am<strong>in</strong>opyrid<strong>in</strong>es was<br />

achieved <strong>in</strong> the normal-phase mode us<strong>in</strong>g 90% hexane/10%<br />

isopropanol as a mobile phase. The retention of<br />

am<strong>in</strong>opyrid<strong>in</strong>es rises with the growth of <strong>in</strong>vestigat<strong>in</strong>g<br />

compounds polarity because of the <strong>in</strong>creas<strong>in</strong>g of dipoledipole<br />

<strong>in</strong>teractions.<br />

We studied t-blockers enantioseparation<br />

<strong>in</strong> normal-phase and polar-organic modes of<br />

chromatography. The best results were observed for<br />

p<strong>in</strong>dolol at use of a mobile phase – acetonitrile / methanol /<br />

CH 3 COOH / triethylam<strong>in</strong>e (60/40/0.2/0.2).<br />

The separation of am<strong>in</strong>o acids was performed <strong>in</strong> the ion<br />

exchange variant of chromatography with<br />

spectrophotometric detection at 210 nm. We used 0.05M<br />

borate buffer (pH 7.7) as the mobile phase. Because a small<br />

molecule of L-cyste<strong>in</strong> was used as a chiral selector the best<br />

enantioseparation was achieved for such a small molecules<br />

of am<strong>in</strong>o acids as leuc<strong>in</strong>e and val<strong>in</strong>e. Chromatogram of<br />

enantioseparation is presented on Fig.2.<br />

Figure 2. Chromatogram enantioseparation of p<strong>in</strong>dolol. Column<br />

(100 . Mobile phase:<br />

acetonitrile/methanol/CH3COOH/threeethylam<strong>in</strong>e (60/40/0,2/0,2).<br />

Injection volume 20 l.<br />

This work was supported by the Russian Foundation for<br />

Basic Research (09-03-00519-).<br />

*Correspond<strong>in</strong>g author: elfimova_16@list.ru<br />

Figure 1. Layout view of the adsorption of modified gold<br />

nanoparticles on the silicon oxide’s surface.<br />

[1] A. Vasil’kov, S. Nikolaev, V. Smirnov, A. Naumk<strong>in</strong>, I. Volkov<br />

and V. Podshibikh<strong>in</strong>, Mendeleev Commun. 17, 268-270 (2007).<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 217

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Investigation of CdS Langmuir-Blodgett Th<strong>in</strong> Films by Us<strong>in</strong>g EFM Technique<br />

S.A. Klimova 1 , M. Yavuz 2 *, S.V. Stetsyura 1 ,M. Arslan 2 , E.G. Glukhovskoy 1 , S.B. Venig 1 , Y. Elerman 2<br />

1 University of Saratov State, Department of Nano- and Biomedical Technology, 410012, Saratov, Russia<br />

2University of Ankara, Department of Eng<strong>in</strong>eer<strong>in</strong>g Physics, Faculty of Eng<strong>in</strong>eer<strong>in</strong>g, 06100 Besevler, Ankara, Turkey<br />

Abstract- In this study, the CdS LB films with<br />

different pH values have been studied by EFM. The surface potentials of<br />

films were calculated from EFM phase-voltagee curves. It was found that surface potential and EFM phase decrease with<br />

<strong>in</strong>creas<strong>in</strong>g pH.<br />

Recently, structural <strong>in</strong>vestigations of Langmuir-<br />

Blodgett (LB) films are <strong>in</strong>creased rapidly for various<br />

device applications rang<strong>in</strong>g from biosensors to<br />

nanostructured electronic devices [1]. This is due to<br />

their precise thickness control and welll ordered<br />

structure.<br />

One extensively studied semiconduct<strong>in</strong>g<br />

material<br />

is CdS which is distributed <strong>in</strong> fatty acid. The<br />

electronic properties of LB films for different pH<br />

values (pH 3 and 8) were <strong>in</strong>vestigated by us<strong>in</strong>g<br />

Electrical Force Microscopy from NT-MDTT (Model:<br />

Solver Pro-M). Semi-contact imag<strong>in</strong>g was<br />

done <strong>in</strong><br />

height mode and some images are presented here<strong>in</strong>.<br />

For imag<strong>in</strong>g, the scann<strong>in</strong>g velocity 8.37 μm/s. A Pt<br />

coated cantilever was used and the cantilever’s free<strong>in</strong>terleave<br />

resonant frequency was about 76 kHz. The<br />

scan lift height was 50 nm. In EFM – phase<br />

measurement for small force gradient the phase shift<br />

is;<br />

QdF<br />

arcs<strong>in</strong><br />

<br />

kdz <br />

<br />

arcs<strong>in</strong><br />

<br />

kdz<br />

2<br />

QdC<br />

2<br />

<br />

U<br />

<br />

2<br />

<br />

<br />

<br />

(1)<br />

where k is the spr<strong>in</strong>g constant (2 N/m) and<br />

Q is the<br />

quality factor (260) of the cantilever.<br />

In this study, the CdS LB films were <strong>in</strong>vestigated<br />

with different bias voltage (±7 V) by EFM. For<br />

obta<strong>in</strong><strong>in</strong>g surface potential from EFM measurements,<br />

we selected a bright po<strong>in</strong>t <strong>in</strong> topography image. Fig. 1<br />

is a plot of phase shifts at different biases. The data<br />

were fitted <strong>in</strong> the range of -5 V to +5 V us<strong>in</strong>g a least<br />

squares method to give the solid curve.<br />

The fit function used was<br />

2<br />

arcs<strong>in</strong> A V V <br />

0<br />

B<br />

<br />

where A represents the constant parameter<br />

(Q/2k)d 2 C/dz 2 , and B represents an offset to<br />

0 o when<br />

V=V 0 [2].<br />

Table 1. Calculated A, B, and V 0 parameters for films<br />

pH 3 pH 8<br />

A (V -2 ) 3.42x10 -3 2.69x10 -3<br />

B ( o ) 0.0137 0.049<br />

V 0 (V) 0.579 -0.396<br />

For pH 3 and pH 8 samples, surface potentials (SP)<br />

and electrostatic force gradients (dF/dz) were<br />

calculated from the EFM phase data along a 0.45 μm<br />

length by us<strong>in</strong>g A, B, and V 0 parameters. Some am<strong>in</strong>e<br />

groups are transformed from a positive charged<br />

species to a neutral charge, reduc<strong>in</strong>g surfactant-<br />

than the<br />

polymer <strong>in</strong>teractions for pH values greater<br />

optimum [3]. Accord<strong>in</strong>g to EFM phase,<br />

surface<br />

potential and electrostatic force gradient curves, while<br />

the pH values were <strong>in</strong>creas<strong>in</strong>g, electrical properties<br />

decreased.<br />

*murat_yavuz59@yahoo.com<br />

[1]Swalen J. D., Allara D. L., Andrade J. D.,<br />

Chandross E. A., Langmuir, 3, 393 (1987).<br />

[2]Lei C. H., Das A., Elliott M. and Macdonald J. E.<br />

IOP Nanotechnology 15, 627-634 (2004).<br />

[3]Stroeve P. and Hwa M. J., Th<strong>in</strong> Solid Films 284-<br />

285, 561-563 (1996).<br />

(2)<br />

Figure 1. Topography and EFM Phase-Voltage curve for (a) pH:3, and (b) pH:8 CdS LB films<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 218

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Preparat ion of mag netic nanoparticles with surfactant-controlled size and shape<br />

Aysel Bayrak 1 ,Sema Vural 1 ,Yavuz Çelik 1 , Turgay Seçk<strong>in</strong> 1 *<br />

1 Department of Chemistry, University of Inonu, Malatya, TR Türkiye 44280<br />

Abstract-This manuscript describes a simple one-pot reaction that affords cobalt iron oxide nanoparticles with unprecedented dimensions as<br />

large as 30 nm <strong>in</strong> monodisperse form. Unique synthetic method, which requires no multiple growth steps typical of other methods, utilizes the<br />

thermal decomposition of metal precursor complexes <strong>in</strong> the presence of speci<br />

and shape of these unusually large magnetic nanoparticles (MNPs) can be manipulated at will simply by adjust<strong>in</strong>g the surfactant composition,<br />

lead<strong>in</strong>g to enhanced control over the dimensions of the nanoparticles because of the surface-differentiat<strong>in</strong>g <strong>in</strong><br />

the produced ferrites were <strong>in</strong>vestigated by X-ray diffraction analysis (XRD), scann<strong>in</strong>g electron microscope (SEM) and vibrat<strong>in</strong>g sample<br />

magnetome-ter (VSM).<br />

Monodisperse magnetic nanoparticles (MNPs) with<br />

controlled sizes and shapes are of great <strong>in</strong>terest for<br />

fundamental science and for both exist<strong>in</strong>g and develop<strong>in</strong>g<br />

technological applications. The morphology of MNPs strongly<br />

<strong>in</strong> <br />

especially their magnetic and electrical properties. More<br />

speci <br />

strongly depend on the size, shape, functionality, and<br />

magnetization of the MNPs.<br />

Cobalt ferrite (CoFe 2 O 4 ), with a partially <strong>in</strong>verse sp<strong>in</strong>el<br />

structure, is one of the most important and most abundant<br />

magnetic materials. As a conventional magnetic material, with<br />

a Curie temperature (TC) around 793 K, CoFe 2 O 4 is well<br />

known to have large magnetic anisotropy, moderate saturation<br />

magnetization, remarkable chemical stability and a mechanical<br />

hardness, which make it a good candidate for the record<strong>in</strong>g<br />

med ia[1,2]. CoFe 2 O 4 ultraf<strong>in</strong>e powders [3–4] and films have<br />

attracted considerable attention for their wide range of<br />

technological applications such as transformer cores,<br />

record<strong>in</strong>g heads, antenna rods, memory, ferro fluids,<br />

biomedical application and sensors, etc.. Over recent years,<br />

the chemical solution routes were successively emerg<strong>in</strong>g as<br />

effective, convenient, less energy demand<strong>in</strong>g and less<br />

materials consum<strong>in</strong>g synthetic techniques for material<br />

preparation. However, the hydrothermal route is one of the<br />

most used ones, ow<strong>in</strong>g to its economics and the high degree of<br />

compositional control. In addition, the hydrothermal synthesis<br />

requires neither extremely high process<strong>in</strong>g temperature nor<br />

sophisticated process<strong>in</strong>g. For example, ferrites can be prepared<br />

via the hydrothermal method at a temperature of about 150 C,<br />

whereas the solid-state method requires a temperature of 800<br />

C. Hydrothermal synthesis of several ferrites has been<br />

reported. However, there is little report on the synthesis of<br />

s<strong>in</strong>gle-crystall<strong>in</strong>e CoFe 2 O 4 nanorods. We present here a<br />

simple hydrothermal route without a preformed template for<br />

the preparation of CoFe 2 O 4 nanorods.<br />

The growth rate has been shown to be an important factor <strong>in</strong><br />

controll<strong>in</strong>g the shape of magnetic nanoparticles. Moreover, the<br />

wet chemical synthesis of monodisperse large nanoparticles<br />

typically <strong>in</strong>volves precise control over the growth rate by<br />

us<strong>in</strong>g a high concentration of metal cation and controll<strong>in</strong>g the<br />

strength of b<strong>in</strong>d<strong>in</strong>g between various ligands and the emerg<strong>in</strong>g<br />

metal surface.<br />

In a typical procedure for the preparation of CoFe2O 4 , 1 g of<br />

cationic surfactant cetyltrimethylammonium bromide (CTAB)<br />

was dissolved <strong>in</strong> 35 ml deionized water to form a transparent<br />

solution. Then ferric chloride hexahydrate (FeCl3.6H2O) of 1<br />

g was added to the solution. After 10 m<strong>in</strong> stirr<strong>in</strong>g,<br />

stoichiometric amount of CoCl 2 was <strong>in</strong>troduced <strong>in</strong>to the<br />

mixed solution under vigorous stirr<strong>in</strong>g. Deionized water was<br />

added to make the solution for a total volume of 40 ml, and<br />

pH of the solution was adjusted to 11.0. Before be<strong>in</strong>g<br />

transferred to a Teflon-l<strong>in</strong>ed auto-clave of 50.0 ml capacity,<br />

the solution mixture was pretreated under an ultrasonic water<br />

bath for 30– 40 m<strong>in</strong>. Hydrothermal synthesis was carried out<br />

at 130 ºC for 15 h <strong>in</strong> an electric oven without shak<strong>in</strong>g or<br />

stirr<strong>in</strong>g. Afterwards, the autoclave was allowed to cool to<br />

room temperature gradually. The black precipitate collected<br />

was washed with distilled water three times <strong>in</strong> an ultrasonic<br />

bath to remove any possible impurities. The solid was then<br />

heated at 80 ºC and dried under vacuum for 2 h.<br />

Figure 1. X-ray diffraction patterns of the prepared CoFe 2 O 4<br />

particles and nanorods via hydrothermal for 15 h without CTAB (a)<br />

andwith CTAB (b).<br />

The product morphology changes from tetrapods, nanorods,<br />

and nanoparticles as the reaction temperature <strong>in</strong>creases from<br />

40 to 70 C with various surfactants.<br />

We note that monodisperse particles of this size represent an<br />

ideal compromise for many applications, offer<strong>in</strong>g the potential<br />

for both a strong magnetic moment and electrical properties.<br />

We also evaluated the key magnetic characteristics of our<br />

iron-manganese oxide nanoparticles. In particular, magnetic<br />

hysteresis loops and magnetic relaxation were measured for<br />

these particles at room temperature. The superparamagnetic<br />

nature of these particles is characterized by M-H hysteresis<br />

loop behavior at 290 K and rapid relaxation.<br />

*Correspond<strong>in</strong>g author: 1Ttseck<strong>in</strong>@<strong>in</strong>onu.edu.tr<br />

[1] Mornet, S.; Vasseur, S.; Grasset, F.; Duguet, E.J. Mater.<br />

Chem.2004, 14, 2161.<br />

[2] Gleich, B.; Weizenecker, J.Nature2005,435, 1214.<br />

[3] Mannix, R. J.; Kumar, S.; Cassiola, F.; Montoya-Zavala, M .;<br />

Fe<strong>in</strong>ste<strong>in</strong>, E.; Prentiss, M.; Ingber, D. E.Nat. Nanotechnol.2008,3,<br />

36.<br />

[4] Weitschies, W.; Ko¨titz, R.; Bunte, T.; Trahms, L.Pharm.<br />

Pharmacol. Lett.1997,7,1.<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 219

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Preparat ion of mag netic nanoparticles with controlled morphology<br />

Aysel Bayrak 1 ,Sema Vural 1 , Turgay Seçk<strong>in</strong> 1 *<br />

1 Department of Chemistry, University of Inonu, Malatya, TR Türkiye 44280<br />

Abstract-Cobalt, Nickel and z<strong>in</strong>c ferrites nanoparticles have been synthesized us<strong>in</strong>g the hydrothermally technique. Effects of synthesis<br />

conditions on the crystal structure, crystallite size, lattice parameter, microstructure and magnetic properties of the produced sp<strong>in</strong>el ferrites were<br />

<strong>in</strong>vestigated by X-ray diffraction analysis (XRD), scann<strong>in</strong>g electron microscope (SEM) and vibrat<strong>in</strong>g sample magnetometer (VSM).<br />

S<strong>in</strong>ce the beg<strong>in</strong>n<strong>in</strong>g of this century, 2000, science and<br />

eng<strong>in</strong>eer<strong>in</strong>g has seen a rapid <strong>in</strong>crease <strong>in</strong> <strong>in</strong>terest for materials<br />

at the nano-scale. Nano-materials have attracted such a strong<br />

<strong>in</strong>terest because of the physical, electronic, and magnetic<br />

properties result<strong>in</strong>g from their quantum size [1]. The potential<br />

for nano-technology is immensely diverse with potential<br />

applications <strong>in</strong> the fields of electronics, biomedical devices,<br />

energy applications, military uses, and waste management [2].<br />

Nano-materials could be utilized to design nano-transistors, to<br />

develop and deliver medic<strong>in</strong>es for locally treat<strong>in</strong>g diseases and<br />

ailments with<strong>in</strong> the body, and for the creation new age<br />

weapons and armor for military applications [3]. With<strong>in</strong> the<br />

field of nano-materials under worldwide research is the subset<br />

of magnetic nanomaterials and magnetic nanoparticles.<br />

Magnetic nanoparticles are of great <strong>in</strong>terest for researchers<br />