Photonic crystals in biology

Photonic crystals in biology

Photonic crystals in biology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

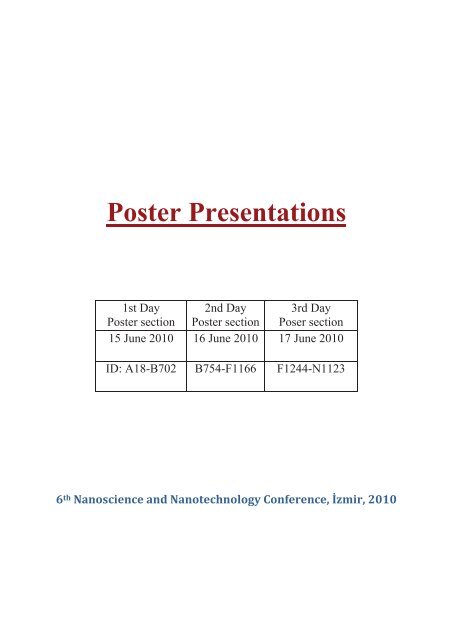

Poster Presentations<br />

1st Day 2nd Day 3rd Day<br />

Poster section Poster section Poser section<br />

15 June 2010 16 June 2010 17 June 2010<br />

ID: A18-B702 B754-F1166 F1244-N1123<br />

6 th Nanoscience and Nanotechnology Conference, İzmir, 2010

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Absorption Hypothesis: Attachment of Beetles to Nanoporous Substrates<br />

Elena Gorb 1 *, Solveig Kle<strong>in</strong>z 1 and Stanislav Gorb 1<br />

1 Department of Functional Morphology and Biomechanics, Zoological Institute, University of Kiel, 24098 Kiel, Germany<br />

Abstract-Traction experiments with ladybird beetles showed that forces on nanoporous substrates were significantly lower t hat those on solid<br />

surface samples. The comparison of the evolution <strong>in</strong> contact angles of the two fluids, polar water and non-polar m<strong>in</strong>eral oil, showed that porous<br />

substrates absorbed both polar and non-polar fluids, whereas solid surface samples did not. Thus, the reduction of <strong>in</strong>sect attachment on<br />

nanoporous surfaces may be expla<strong>in</strong>ed by (1) the absorption of the secretion fluid from <strong>in</strong>sect adhesive pads by porous media and/or (2) the<br />

effect of surface roughness.<br />

It has been repeatedly reported that micro- and<br />

nanostructured waxy surfaces of plants strongly reduce <strong>in</strong>sect<br />

attachment. To expla<strong>in</strong> anti-adhesive properties of such<br />

substrates, four hypotheses have been previously proposed: (a)<br />

roughness hypothesis; (b) contam<strong>in</strong>ation hypothesis; (c) fluid<br />

absorption hypothesis; and (d) wax dissolv<strong>in</strong>g hypothesis [1].<br />

Recently, only the two first hypotheses ([2 – 6] for (a) and [7 –<br />

9] fo r (b)) were proven. To date, the wax d issolv<strong>in</strong>g<br />

hypothesis and the fluid absorption hypothesis have not been<br />

experimentally tested. In the present study, we used<br />

nanoporous substrates with the same pore diameter (220 – 235<br />

nm), but different porosity (area of voids <strong>in</strong> a material surface,<br />

normalized over the total area), <strong>in</strong> order to test the fluid<br />

absorption hypothesis, claim<strong>in</strong>g that the structured wax<br />

coverage of plants may absorb the fluid from the setal surface<br />

of <strong>in</strong>sect adhesive pads and by this reduce the adhesion force.<br />

We performed traction force measurements with tethered<br />

seven-spotted ladybird beetles Cocc<strong>in</strong>ella septempunctata L.<br />

(Coleoptera, Cocc<strong>in</strong>ellidae), walk<strong>in</strong>g on five different<br />

substrates [10]: (1) smooth glass plate; (2) smooth solid Al 2 O 3<br />

(sapphire) disc; (3 – 5) three types of nanoporous Al 2 O 3 discs<br />

(back side of anodisc membranes Whatman, Schleicher and<br />

Schuell, Whatman International Ltd., Maidstone, UK) hav<strong>in</strong>g<br />

the porosity of 28, 42 and 51%. Forces were measured with a<br />

load cell force transducer (10g capacity, Biopac Systems Ltd.,<br />

Santa Barbara, CA, USA). Both males (n=10) and females<br />

(n=10) were used <strong>in</strong> the experiments.<br />

We found that the forces ranged from 0.16 to 16.59 mN <strong>in</strong><br />

males and from 0.32 to 8.99 mN <strong>in</strong> females. The highest force<br />

values were obta<strong>in</strong>ed on the smooth surfaces, where males<br />

generated considerably higher forces compared to females. On<br />

all three porous substrates, the forces were significantly<br />

reduced, and the only difference was obta<strong>in</strong>ed between<br />

nanoporous membranes hav<strong>in</strong>g the highest and lowest<br />

porosity. Males produced essentially lower forces than<br />

females on porous samples [10].<br />

The reduction of <strong>in</strong>sect attachment on nanoporous<br />

substrates may be expla<strong>in</strong>ed by (1) possible absorption of the<br />

secretory fluid from <strong>in</strong>sect pads by porous media and (2)<br />

surface roughness, reduc<strong>in</strong>g real contact area between tenent<br />

setae of <strong>in</strong>sect adhesive pads and substrate.<br />

To exam<strong>in</strong>e the ability of porous substrates to absorb fluids,<br />

we performed additional absorption experiments with solid<br />

and nanoporous surfaces samples us<strong>in</strong>g a high-speed optical<br />

contact angle measur<strong>in</strong>g device OCAH 200 (DataPhysics<br />

Instruments GmbH, Filderstadt, Germany). The comparison of<br />

the evolution <strong>in</strong> contact angles of the two fluids, polar water<br />

and non-polar m<strong>in</strong>eral oil (Mobil DTE Medium, viscosity 43.4<br />

mm 2 •s at 40°C [11]), showed that porous substrates absorbed<br />

both polar and non-polar fluids (figure), whereas solid surface<br />

samples did not. S<strong>in</strong>ce the beetle secretion or at least a part of<br />

it consists of oily substances, we can conclude that adhesion<br />

reduction <strong>in</strong> our traction experiments at least partially can be<br />

expla<strong>in</strong>ed by the ability of nanoporous substrates to adsorb<br />

non-polar lipid-like fluids.<br />

contact angle [ ° ]<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

0 10 20 30 40 50 60<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

absorption<br />

absorption<br />

0<br />

0 10 20 30 40 50 60<br />

time [s]<br />

(a)<br />

(b)<br />

Figure 1. The evolution <strong>in</strong> contact angles of water (a) and oil (b)<br />

on the nanoporous surface sample with the porosity of 42%.<br />

This work was partially supported by the SPP 1420 priority<br />

program of the German Science Foundation (DFG)<br />

“Biomimetic Materials Research: Functionality by<br />

Hierarchical Structur<strong>in</strong>g of Materials” (project GO 995/9-1).<br />

The first author thanks Naoe Hosoda (NIMS, Tsukuba, Japan)<br />

for fruitful discussions.<br />

*Correspond<strong>in</strong>g author: egorb@zoologie.uni-kiel.de<br />

[1] E.V. Gorb and S.N. Gorb, Entomol. Exp. Appl. 105, 13 (2002).<br />

[21] S. Gorb, Attachment devices of <strong>in</strong>sect cuticle (2001).<br />

[3] A. Peressadko and S. Gorb, Proc. 1st Int. Conf. Bionik, 257<br />

(2004).<br />

[41] D. Voi gt et al., J. Insect Physiol. 54, 765 (2008).<br />

[51] E. Gorb and S. Gorb, Entomol. Exp. Appl. 130, 222 (2009).<br />

[6] J. M. Bullock and W. Federle, J. Exp. Biol. 212, 1876 (2009).<br />

[7] L. Gaume et al., Arthropod Structure & Development 33, 103<br />

(2004).<br />

[8] E. Gorb et al., J. Exp. Biol. 208, 4651 (2005).<br />

[9] E. Gorb and S. Gorb, Ecology and biomechanics: A mechanical<br />

approach to the ecology of animals and plants, 147 (2006).<br />

[10] E. Gorb et al., Proc. 9th Biennial ASME Conf. on ESDA, 1<br />

(2008).<br />

[11] M. Varenberg and S. Gorb, Adv. Mater. 21, 483 (2009).<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 208

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Phosphorus Conta<strong>in</strong><strong>in</strong>g Novel Polyimide/Silica Nanocomposite Materials via Sol-Gel Technique<br />

Canan Kızılkaya *, Sevim Karataş , Nilhan Kayaman Apohan , Atilla Güngör<br />

Marmara University, Department of Chemistry 34722 Istanbul/Turkey<br />

Abstract- In this work, the high temperature capability and fire-resistance of phosphorus-conta<strong>in</strong><strong>in</strong>g polyimide/ silica<br />

(PI/SiO 2 ) nano hybrid films were synthesized by sol-gel reaction and thermal imidization.The silica content <strong>in</strong> the hybrid<br />

films was varied from 0 to 20 wt %. The thermal, mechanical, optic, electrical and surface properties of the hybrid films<br />

have been <strong>in</strong>vestigated and compared to pure PI.<br />

Organic-<strong>in</strong>organic nanocomposite materials prepared by<br />

the sol-gel technique are an important class of newgeneration<br />

materials, which comb<strong>in</strong>e the desirable<br />

properties of an <strong>in</strong>organic component (heat resistance,<br />

retention of mechanical properties at high temperatures<br />

and low thermal expansion) and those of organic polymer<br />

(toughness, ductility and processability) [1,2].<br />

Polyimides (PI) are promis<strong>in</strong>g materials used for a wide<br />

range of applications because of their high glass transition<br />

temperature, good heat resistance, low dielectric constant,<br />

and excellent mechanical properties. The sol–gel process is<br />

a unique and versatile approach among the various<br />

methods used to produce polyimide/SiO 2 hybrid materials<br />

.The nature of the <strong>in</strong>terfaces between SiO 2 particles and<br />

polyimides matrix, the content and size of SiO 2 particles,<br />

greatly affect the properties of the hybrid materials. Strong<br />

<strong>in</strong>terfaces <strong>in</strong> which covalent bond should be formed<br />

between SiO 2 particles and polyimides matrix, are needed<br />

for obta<strong>in</strong><strong>in</strong>g excellent properties [2,3] .<br />

Polymers conta<strong>in</strong><strong>in</strong>g the phenylphosph<strong>in</strong>e oxide<br />

(PPO)group have been studied extensively for a number of<br />

applications <strong>in</strong> recent years. These polymers are the most<br />

important ones both due to good their thermal and<br />

chemical stability, excellent mechanical properties, very<br />

good fire retardancy. Polyimides conta<strong>in</strong><strong>in</strong>g phosph<strong>in</strong>e<br />

oxide moieties display good flame resistance and excellent<br />

adhesion properties. It has been proven that the<br />

phenylphosph<strong>in</strong>e oxide moiety provides a strong<br />

<strong>in</strong>teract<strong>in</strong>g site for impart<strong>in</strong>g miscibility with several<br />

systems [2-5].<br />

In this work, a series of novel phosph<strong>in</strong>e oxide<br />

conta<strong>in</strong><strong>in</strong>g polyimide / silica nanocomposite materials<br />

were prepared via sol-gel technique and imidization. The<br />

silica content <strong>in</strong> the hybrid coat<strong>in</strong>g materials was varied<br />

from 0 to 20 wt%. The FTIR and 29 Si-NMR spectra<br />

showed that the fully condensed <strong>in</strong>organic network had<br />

formed dur<strong>in</strong>g the imidization. Tensile modulus and<br />

hardness of the polyimide/silica coat<strong>in</strong>g materials<br />

<strong>in</strong>creased gradually with <strong>in</strong>creas<strong>in</strong>g <strong>in</strong>organic content due<br />

to the enhanced <strong>in</strong>terfacial <strong>in</strong>teraction between PI matrix<br />

and silica particles. The thermal analysis of the coat<strong>in</strong>g<br />

materials showed that the degradation of PI was largely<br />

reduced with <strong>in</strong>corporation of silica and also the flame<br />

retardancy of the nanocomposite <strong>in</strong>creased. The<br />

morphology studies <strong>in</strong>dicated that, the silica particles <strong>in</strong><br />

the polyimide matrix are dispersed homogeneously and the<br />

particle size is <strong>in</strong> the range of 30-55 nm. Furthermore, it<br />

was observed that optical transparencies of the hybrid<br />

coat<strong>in</strong>g materials decreased due to the <strong>in</strong>troduction of<br />

higher silica content <strong>in</strong>to the polyimide matrix and the<br />

<strong>in</strong>creas<strong>in</strong>g contact angles demonstrated the formation of<br />

hydrophobic nanocomposite surface.<br />

(a)<br />

Figure 1: SEM micrographs of (a) PI/SiO2-15 (b) Si mapp<strong>in</strong>g of<br />

PI/SiO2-15.<br />

*Correspond<strong>in</strong>g author: ckizilkaya@gmail.com<br />

[1] S Karatas, N.K. Apohan, H. Demirer, A. Gungor Polym.<br />

Adv. Technol., 18,490–496 (2007)<br />

[2] C.Kızılkaya ,S. Karataş , N. K. Apohan , A. Güngör, Journal<br />

of Applied Polymer Science, 115, 3256-3264 (2010).<br />

[3] M. Çakır, S Karataş, Y.Menceloğlu, N.K.Apohan, A.<br />

Güngör, Macromol. Chem. and Phys., 209 , 919 , (2008).<br />

[4] C.J Cornelius, E. Marand, Polymer , 43, 2385( 2002)<br />

[5] Y.Delaviz, A. Güngör, J.E. McGrath, H.W Gibson, Polymer,<br />

34, 210 (1993).<br />

(b)<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 209

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Piezoelectric properties of 0.65Pb(Mg 1/3 ,Nb 2/3 )O 3 -0.35PbTiO 3 ceramics prepared from<br />

nanopowders<br />

M. Ghasemifard a , S. M. Hosse<strong>in</strong>i a , H. Ghasemifard b<br />

a Department of Physics (Materials and Electroceramics Laboratory), Ferdowsi University of Mashhad, Mashhad, Iran,<br />

b Department of Medical Eng<strong>in</strong>ear<strong>in</strong>g, Azad University of Mashhad, Mashhad, Iran<br />

Abstract- The piezoelectric properties of relaxor ferroelectric 0.65Pb(Mg 1/3 Nb 2/3 )O 3 –0.35PbTiO 3 (0.65PMN–0.35PT) ceramics<br />

prepared by a sol-gel combustion method have been <strong>in</strong>vestigated as a function of s<strong>in</strong>ter<strong>in</strong>g temperatures. The XRD results show<br />

that the phase structure is near the morphoteropic phase boundary (MPB). The highest piezoelectric coefficients were observed<br />

for the samples s<strong>in</strong>tered at temperature of 1200 o C. In comparison with pure PMN, the substitution of 35% PT results <strong>in</strong> the<br />

decrease of s<strong>in</strong>tered temperature and peculiar relaxation behavior.<br />

Relaxors ferroelectric based on the PMN-PT ceramics<br />

display excellent piezoelectric/electrostrictive properties along<br />

with a variety of compositional modification, because of the<br />

volatilization of PbO and the differences of the reactive<br />

temperature between Pb-Nb and Pb-Mg [1-3]. The major<br />

problem <strong>in</strong> synthesis pure PMN-PT ceramics with perovskite<br />

structure is the formation of pyrochlore phases such as PbO,<br />

Pb 3 Nb 4 O 13 , Pb 2 Nb 2 O 7 and Pb 5 Nb 4 O 15 . A successful method to<br />

overcome these problems is a sol-gel process<strong>in</strong>g [4] which leads<br />

to approximately pure perovskite phase at low temperature with<br />

an improvement <strong>in</strong> the properties of PMN-PT ceramics. An<br />

additional benefit of this process<strong>in</strong>g is that it leads to small<br />

particles which cause pretty high density of ceramics. We have<br />

already managed to prepare PMN-PT nanopowders by sol-gel<br />

combustion [5]. This method provided a very f<strong>in</strong>e particles and<br />

a higher piezoelectric constant compared to traditional mixed<br />

oxide process<strong>in</strong>g. The aim of this paper was to <strong>in</strong>vestigate the<br />

effect of s<strong>in</strong>ter<strong>in</strong>g temperature on the 0.65PMN-0.35PT<br />

ceramics prepared by a new sol-gel combustion process<strong>in</strong>g<br />

method. We also have discussed the results of piezoelectric<br />

properties for the samples made from PMN-PT as a function of<br />

s<strong>in</strong>ter<strong>in</strong>g temperature.<br />

Nanopowders of (1-x)Pb(Mg 1/3 Nb 2/3 )O 3 -(x)PbTiO 3 (PMN-<br />

PT) with x=0.35 were synthesis by sol-gel combustion method<br />

us<strong>in</strong>g metal organic and salts precursors as start<strong>in</strong>g materials [5,<br />

6]. X-ray diffraction patterns of PMN-PT powders are shows <strong>in</strong><br />

Fig.1. The presence of a monocl<strong>in</strong>ic phase at 850 o C can be<br />

identify<strong>in</strong>g from Fig. 1. The XRD results reveal the existence of<br />

a perovskite-type phase for gel-combustion method <strong>in</strong> all<br />

temperature.<br />

Fig. 1 XRD spectra of samples of the PMN-PT<br />

Fig. 2 shows the microstructure of the PMN-PT ceramics<br />

s<strong>in</strong>tered at different temperatures. With the <strong>in</strong>crease of s<strong>in</strong>ter<strong>in</strong>g<br />

temperature, the gra<strong>in</strong> size <strong>in</strong>creases.<br />

Fig. 2. SEM micrographs of surface of PMN-PT ceramics<br />

The gra<strong>in</strong> size has strong effects on dielectric properties and<br />

polarization of piezoelectric materials [7]. The electrical<br />

parameters are summarized <strong>in</strong> Table 1.<br />

Table 1. Various parameters on some electrical properties<br />

Temperature<br />

( o C)<br />

Gra<strong>in</strong> size<br />

(μm)<br />

Density<br />

(gr/cm 3 )<br />

d 33<br />

(pC/N)<br />

1100 - 7.26 149 4.98 0.33<br />

1150 - 43.7 375 5.01 0.48<br />

1200 1.5 7.86 484 5.86 0.54<br />

1250 2 8.02 552 6.03 0.57<br />

1300 3.5 7.76 515 5.13 0.56<br />

[8] 2.8** 7.86 - - -<br />

[9] * - - 2200 - 0.92<br />

*PMN-0.32PT s<strong>in</strong>gle crystal. **S.T.=1240 o C<br />

In general, the results of measurement <strong>in</strong>dicated most electrical<br />

and piezoelectric parameters are maximum for the samples s<strong>in</strong>tered at<br />

temperature of 1250 o C.<br />

*Correspond<strong>in</strong>g author: mahdi572@yahoo.com<br />

[1] D. S. Paik, S. Komarneni, V. 34, (1999), 2255-2491.<br />

[2] M. Lejeune, J . P . Bilot, Ceram. Int. 8(3) (1982) 99.<br />

[3] O. Bouqu<strong>in</strong>, M. Lejeune, J . P . Bilot, J. Amer. Ceram. Soc. 74(5), (1991),<br />

1152.<br />

[4] P . Ra<strong>in</strong>dranathan, S. Komarneni, A. S. Bhalla, R. Roy, J. Amer. Ceram.<br />

Soc. 74(12), (1991), 2996.<br />

[5] M. Ghasemifard, S.M. Hosse<strong>in</strong>i, Gh. Khorrami, Ceramic <strong>in</strong>ternational, 35,<br />

(2008), 2899-2905.<br />

[6] M. Ghasemifard, S.M. Hosse<strong>in</strong>i, M. M. Bagheri-Mohagheghi, N.<br />

Shahtahmasbi, J. Physica E, Article <strong>in</strong> press, (2009).<br />

[7] M. Alguero, A. Moure, L. Pardo, J. Holc, M. Kosec, Acta Mater. 54 (2006)<br />

501–511.<br />

[8] S. E. Park, T. R. Shrout, J. Appl. Phys., 82, (1997), 1804–1811.<br />

[9] T.R. Shrout, Z.P. Chang, N. Kim, S. Markgraf, Ferroelectrics Lett. Sect., 12,<br />

(1990), 63–69.<br />

Q m<br />

k p<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 210

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Electros pun Hybrid Scaffolds for Bone Tissue Repair<br />

1 *<br />

1 urkey.<br />

Abstract-The aim of this study is to develop novel hybrid (blend&layer by layer) tissue scaffolds for bone tissue repair by us<strong>in</strong>g electrosp<strong>in</strong>n<strong>in</strong>g<br />

method. PCL (poly--caprolactone), chitosan and hydroxyapatite (HA) nanoparticles were used as components for hybrid structures. 15 wt % of<br />

PCL and 8 wt % of chitosan concentrations and 90/10 vol % PCL/chitosan weight ratio were selected <strong>in</strong> order to obta<strong>in</strong> uniform and bead free<br />

fabrics. Detailed characterization studies performed <strong>in</strong> this study showed the desired properties of scaffolds for bioapplications. The control of<br />

suitability of the developed hybrid scaffolds for cell culture applications by us<strong>in</strong>g osteoblast cells is under process.<br />

Nanofibrous materials have been extensively studied as<br />

scaffold<strong>in</strong>g materials <strong>in</strong> tissue eng<strong>in</strong>eer<strong>in</strong>g and regenerative<br />

medic<strong>in</strong>e, due to the fact that the extracellular matrices (ECM)<br />

of native tissues are nanofeatured structures, and cells attach<br />

and proliferate better on nanofeatured structures than bulk<br />

materials [1,2]. Recently, researchers have <strong>in</strong>vestigated<br />

electrosp<strong>in</strong>n<strong>in</strong>g of blend polymers as candidate materials for<br />

biomedical applications because polymer blends have<br />

provided an efficient way to fulfill new requirements for<br />

material properties. Blends made of synthetic and natural<br />

polymers can present the wide range of physicochemical<br />

properties and process<strong>in</strong>g techniques of synthetic polymers as<br />

well as the biocompatibility and biological <strong>in</strong>teractions of<br />

natural polymers [3,4]. In addition, many researchers have<br />

reported that <strong>in</strong>corporation of calcium carbonate (CaCO 3 ) or a<br />

type of calcium phosphate such as hydroxyapatite (HA)<br />

helped to improve osteoblast proliferation and differentiation<br />

[5,6].<br />

In the present contribution, novel PCL (poly--caprolactone)<br />

and chitosan blend and layer by layer structures of hybrid<br />

scaffolds filled with hydroxyapapite (HA) nanoparticles were<br />

developed by us<strong>in</strong>g electrosp<strong>in</strong>n<strong>in</strong>g method. PCL, due to its<br />

slow degradation rate, is a good candidate to be used <strong>in</strong> bonescaffold<strong>in</strong>g<br />

applications. Chitosan is favorite for<br />

bioapplications because of its biocompatible property and low<br />

cost. HA nanoparticles (50-200 nm) prepared and<br />

characterized <strong>in</strong> our previous study [7] were used.<br />

In the first stage of the work, various solution/process<br />

parameters such as concentration, PCL/chitosan weight ratios,<br />

applied electric voltage, tip-collector distance were studied for<br />

optimization of scaffolds. After optimization studies, the<br />

concentrations for pure and hybrid (blend and layer by layer;<br />

PCL/Chitosan/PCL&Chitosan/PCL/Chitosan) PCL and<br />

chitosan scaffolds were chosen as 15 wt % of PCL and 8 wt %<br />

of chitosan <strong>in</strong> order to obta<strong>in</strong> desired nanofabric structures<br />

(uniform, bead free). The weight ratios of PCL and chitosan<br />

were determ<strong>in</strong>ed as 90/10 vol % for blend PCL/chitosan<br />

scaffolds. PCL/Chitosan/PCL layer by layer structure was<br />

selected for further studies. Applied electric voltages, tipcollector<br />

distances were determ<strong>in</strong>ed for each scaffolds. For the<br />

HA modification of the scaffolds different concentrations (1.5,<br />

5, 10, 20 wt%) of HA nanoparticles were added to<br />

PCL/chitosan solutions before electrosp<strong>in</strong>n<strong>in</strong>g process. In<br />

addition to naked eye observation SEM analysis was also used<br />

for the optimization of structures.<br />

In the characterization stage, the prepared scaffolds were<br />

first morphologically exam<strong>in</strong>ed by SEM analysis. By us<strong>in</strong>g<br />

computer software program (ImageJ, USA), average fiber<br />

diameters, HA and <strong>in</strong>ter fibers porosity sizes of scaffolds were<br />

calculated from obta<strong>in</strong>ed SEM photographs.<br />

Wettabilities of electrospun scaffolds were measured us<strong>in</strong>g<br />

sessile drop water contact angle measurement by a optical<br />

contact angle measurement (KSV, F<strong>in</strong>land) systems. The<br />

contact angle measurement study showed that hydrophobic<br />

characteristic of PCL scaffolds was decreased by add<strong>in</strong>g<br />

chitosan and HA components. The samples were cut <strong>in</strong><br />

rectangular strips with dimensions 40 mm × 5 mm, and tensile<br />

properties were characterized by tensile test<strong>in</strong>g mach<strong>in</strong>e<br />

(Llyod Instruments LK-5K, UK) equipped with a 500 N load<br />

cell. Elastic modulus, tensile strength and stra<strong>in</strong> at break (%)<br />

values of samples were determ<strong>in</strong>ed as a result of mechanical<br />

tests. FTIR-ATR analysis <strong>in</strong> the range of 500-4000 cm -1<br />

wavelength was used for the chemical structure confirmation<br />

of the prepared scaffolds. The obta<strong>in</strong>ed spectra showed that<br />

the hybrid scaffolds represent the characteristic peaks of PCL,<br />

chitosan and HA components. Swell<strong>in</strong>g properties of<br />

PCL/chitosan scaffolds were exam<strong>in</strong>ed by PBS absorption<br />

tests. In order to <strong>in</strong>vestigate the effect of chitosan on<br />

biodegradation of prepared scaffolds, biodegradation studies<br />

were carried out for the 7 th , 14 th , 21 st<br />

and 28 th<br />

days of<br />

<strong>in</strong>cubation <strong>in</strong> DMEM/F12 with chicken egg white lysozyme<br />

medium. Additionally, controlled release of BSA (Bov<strong>in</strong>e<br />

Serum Album<strong>in</strong>) studies was performed to have an idea about<br />

the effect of HA nanoparticles with different weight ratios on<br />

bone tissue repair.<br />

In summary, the characterization studies carried out <strong>in</strong> this<br />

work showed the desired properties of scaffolds for<br />

bioapplications. In the future part of this work, the control of<br />

suitability of prepared and well/detailed characterized hybrid<br />

PCL/chitosan scaffolds for cell culture applications will be<br />

performed by us<strong>in</strong>g osteoblast cells. This work was fully<br />

supported by TUBA/LOREAL under “Young Women <strong>in</strong><br />

Science” program. Dr. <br />

“Young Woman <strong>in</strong> Science” <strong>in</strong> Materials Science at 2009 with<br />

this project.<br />

*Correspond<strong>in</strong>g author: 1Thtsasmazel@atilim.edu.tr<br />

[1]J.A. Matthews, G.E. Wnek, D.G. Simpson, et al.<br />

Biomacromolecules 3, 232 (2002).<br />

[2] M. Pattison, S. Wurster, T. Webster, K. Haberstroh, Biomaterials<br />

26, 249 (2005).<br />

[3] Y. You, S.W. Lee, et al. Polymer Degradation and Stability 90,<br />

441 (2005).<br />

[4] S. Aparna, S.V. Madihally, Biomaterials 26, 5500 (2005).<br />

[5] A. G. A. Coombes, S. C. Rizzi, M.Williamson, J. E. Barralet,<br />

S. Downes, W. A. Wallace, Biomaterials 25, 315 (2004).<br />

[6] K. Fujihara, M. Kotaki, S. Ramakrishna, Biomaterials 26, 4139<br />

(2005).<br />

[7] A.P. Sommer, M. Çehreli, et al. Crystal Growth&Design 5, 21<br />

(2005).<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 211

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Fas t Track Preparat ion of ZnO nanorods <strong>in</strong> Water<br />

M. A. Shah 1 *, F.M.Al-Marzouki 1 and A.A. Al-Ghamdi 1<br />

1 Department of Physics, Faculty of Sciences, K<strong>in</strong>g Abdul Aziz University, Jeddah 21589, K<strong>in</strong>gdom of Saudi Arabia<br />

Abstract-We will present a fast, soft, economical and bio-safe synthesis of hexagonal-shaped z<strong>in</strong>c oxide (ZnO) nanorods at very low temperature<br />

of ~120 o C simply by us<strong>in</strong>g metallic z<strong>in</strong>c powder and de-ionized (DI) water without the use of any additives or am<strong>in</strong>es. The product is believed to<br />

be bio-safe and bio-compatible and can be readily used for medic<strong>in</strong>e besides other applications.<br />

Nanostructures of z<strong>in</strong>c oxide (ZnO), <strong>in</strong>clud<strong>in</strong>g particles,<br />

rods, wires, belts, tubes, cages, walls, flowers and r<strong>in</strong>gs have<br />

scattered a great deal of attention <strong>in</strong> recent years because of<br />

their useful electronic and optoelectronic properties and<br />

novel application <strong>in</strong> catalysis, pa<strong>in</strong>ts, wave filters, UV<br />

detectors, transparent conductive films, varistors, gas<br />

sens<strong>in</strong>g, solar cells, sun screens and other cosmetic products.<br />

Moreover, the wide range of morphological diversity <strong>in</strong> the<br />

nano-regime has made this material a promis<strong>in</strong>g candidate <strong>in</strong><br />

the field of nanotechnology and opened up new possibilit ies<br />

for the fabrication of high performance devices based on<br />

these nanostructures. Among the various nanoforms, one<br />

dimensional (1D) nanostructures have received considerable<br />

attention due to their potential <strong>in</strong>terests for understand<strong>in</strong>g<br />

fundamental physical concepts and for efficient field<br />

emission that has enormous commercial applications such as<br />

field emission flat panel displays, x-ray sources, parallel<br />

beam electron microscopy and vacuum microwave<br />

amp lifiers [1].<br />

Synthesis of nanomaterials forms a vital aspect of the<br />

science of nanomaterials and chemical methods have proved<br />

to be more effective and versatile than physical methods and<br />

have, therefore, been employed widely. While nanomaterials<br />

have been generated by physical methods too such as laser<br />

ablation, arc discharge and evaporation, chemical methods<br />

have proved to be more attractive as they provide better<br />

control over the size and shape, which is one of the essential<br />

features <strong>in</strong> nanoscience. Chemical synthesis of nanomaterials<br />

has been reviewed by few authors but <strong>in</strong>numerable<br />

improvements and better methods are be<strong>in</strong>g reported<br />

cont<strong>in</strong>ually <strong>in</strong> the last few years [2,3].<br />

In this work we will explore the formation of ZnO<br />

nanostructures by the reaction of z<strong>in</strong>c metal with DI water at<br />

very low temperature of 120oC. The simple reaction is<br />

carried out <strong>in</strong> absence of any additives and/or am<strong>in</strong>es. The<br />

synthesized ZnO products were characterized <strong>in</strong> terms of<br />

their structural and optical properties. By the morphological<br />

<strong>in</strong>vestigations us<strong>in</strong>g FESEM, it was observed that the grown<br />

products are hexagonal-shaped ZnO nanorods with the<br />

diameters and lengths <strong>in</strong> the range of 70-90 nm with several<br />

micrometers. The EDS and XRD pattern confirmed the<br />

composition and crystall<strong>in</strong> ity of the grown nanorods and<br />

revealed that the grown products are pure ZnO with the<br />

wurtzite hexagonal phase. The optical properties of grown<br />

products were characterized by room-temperature<br />

photolum<strong>in</strong>escence spectroscopy which confirmed the good<br />

optical properties for the grown products.<br />

[2] H. Wie, Y. Wu, N. Lun, and C. Hu, Mater. Sci. Eng. A Vol.<br />

393, 80 (2005).<br />

[3] Z.W. Pan, Z.R. Dia and Z.L. Wang, Science Vol. 291, 1947<br />

(2001).<br />

*Correspond<strong>in</strong>g author: 0Tmashahnit@yahoo.com<br />

[1] C. X. Xu, Y. Liu, and G. Wang, Solid State Communication<br />

Vol. 122, 175 (2002).<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 212

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Additive Free Synthesis of Alum<strong>in</strong>um Oxide Nanostructures<br />

F.M.Al-Marzouki 1 and M. A. Shah 1 *<br />

Department of Physics, Faculty of Sciences, K<strong>in</strong>g Abdu l Aziz University,<br />

Jeddah 21589, K<strong>in</strong>gdom of Saudi Arabia<br />

1<br />

Abstract- Water which is well known <strong>in</strong>expensive and an environmentally benign solvent have been used for the synthesis of alum<strong>in</strong>um oxide<br />

(Al 2 O 3 ) nanostructures. We will present an economical and bio-compatible synthesis of alum<strong>in</strong>um oxide nanorods at very low temperature of<br />

~180 o C without us<strong>in</strong>g any additives or surfactants. This is the first report where nanostructures of Al2O3 have been prepared at such a low<br />

temperature and by such a simple technique. The formation of Al 2 O 3 structures by the reaction of metals with DI water is suggested to occur due<br />

to the oxidation of alum<strong>in</strong>um <strong>in</strong> presence of water. The reported method besides be<strong>in</strong>g organics free is economical, fast and free of<br />

pollution, which will make it suitable for large scale production.<br />

Innovations at the <strong>in</strong>tersection of medic<strong>in</strong>e, biotechnology,<br />

eng<strong>in</strong>eer<strong>in</strong>g, physical sciences and <strong>in</strong>formation technology<br />

are spurr<strong>in</strong>g new directions <strong>in</strong> R&D, commercialization and<br />

technology transfer. The future of nanotechnology is likely<br />

to cont<strong>in</strong>ue <strong>in</strong> this <strong>in</strong>terdiscipl<strong>in</strong>ary manner.<br />

Nanotechnology is the next <strong>in</strong>dustrial revolution, and all<br />

most all <strong>in</strong>dustries will be radically transformed by it <strong>in</strong> a<br />

few years. Ceramics are regarded as versatile materials and<br />

alum<strong>in</strong>um oxide (Al2O 3 ), one of the ceramic materials<br />

commonly known as sapphire is known to exist <strong>in</strong> a number<br />

of metastable polymorphs <strong>in</strong> addition to the<br />

-Al 2 O 3 or corundum form.<br />

-Al 2 O 3<br />

is an important form of alum<strong>in</strong>a<br />

because of its porous structure and high catalytic surface<br />

activity. This material has been widely used as catalysts, an<br />

adsorbent and as a support for <strong>in</strong>dustrial catalysis <strong>in</strong><br />

hydrocarbon conversion. Ow<strong>in</strong>g to their brittleness, ceramics<br />

have been regarded as materials of modest performance<br />

especially under tension or bend<strong>in</strong>g conditions [1].<br />

A number of synthetic routes <strong>in</strong>clud<strong>in</strong>g, the sol-gel<br />

chemistry, spray pyrolysis, precipitation, solovothermal and<br />

physical methods are be<strong>in</strong>g extensively used for the<br />

synthesis of Al2O 3 nanostructures [2,3]. The other<br />

techniques are technically complex, requires high<br />

temperature, harsh growth conditions, expensive<br />

experimental setup, complicated control processes and use of<br />

excessive organics/am<strong>in</strong>es. Seek<strong>in</strong>g a simple approach for<br />

low cost, lower temperature, larger scale production and<br />

controlled growth without additives is desired [4].<br />

To this end, we present a novel and simple method for<br />

-A l 2 O 3 nanorods without catalysts or any<br />

other additive. The route is based on a simple reaction of<br />

alum<strong>in</strong>um powder and double distilled water at 180 o C<br />

without us<strong>in</strong>g any catalyst or any other additive. Moreover,<br />

the synthesis time is very short and the morphology could be<br />

controlled by vary<strong>in</strong>g reaction time. The aim of the study is<br />

to provide the feasibility of the simple route for the<br />

preparation of alum<strong>in</strong>um oxide nanostructures. Systematic<br />

studies are underway and will be presented dur<strong>in</strong>g<br />

conference.<br />

Correspond<strong>in</strong>g author: 0Tmashahnit@yahoo.com<br />

[1] Fang X, Zhang L. J. Mater. Sci. Tech.22, 1 (2006).<br />

[2] Y.Z J<strong>in</strong>, Y.Q Zhu, K Brigatt, H. Kroto, D.R.M Waltan, Appl.<br />

Phys. A 89, 1008 (2003).<br />

[3] X.S.Fang, C.H.Ye, L.D.Zhang, T. Xie Adv. Mater 17 (2005)<br />

1661<br />

[4] M.A.Shah and A.M. Asiri, Int. J. Modern Phy. B, Vol. 23, 2323<br />

(2009).<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 213

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Preparation and characterization of silver nanoparticles by an eco-friendly approach<br />

Reda El-Sh ishtawy 1 * Abdullah Asiri 1 and Maha Al-Otaibi 1<br />

Department of Chemistry, Faculty of Science, K<strong>in</strong>g Abdul-Aziz University, Jeddah 21589, PO Box 80203, Saudi Arabia<br />

1<br />

Abstract-This work reports on an environmentally benign method for the preparation of AgNPs <strong>in</strong> aqueous solution us<strong>in</strong>g glucose as the<br />

reduc<strong>in</strong>g agent <strong>in</strong> water/ micelles system, <strong>in</strong> which cetyltrimethylammonium bromide (CTAB) was used as capp<strong>in</strong>g agent (stabilizer).<br />

Spectrophotometric method was used to monitor the formation of AgNPs under different conditions such as a) concentration of sodium<br />

hydroxide, b) concentration of glucose, c) concentration of silver nitrate d) concentration of CTAB, and e) reaction time were used so as to f<strong>in</strong>d<br />

out the optimum conditions for the preparation of AgNPs.<br />

Silver nanoparticles (AgNPs) have received much more<br />

attention <strong>in</strong> recent years due to their unique physical, optical,<br />

electrical, magnetic, and chemical properties and their<br />

potential application <strong>in</strong> molecular electronic field [1].<br />

Therefore, extensive research has gone <strong>in</strong>to develop<strong>in</strong>g<br />

suitable preparation techniques to form AgNPs. These <strong>in</strong>clude<br />

chemical reduction, microorganisms <strong>in</strong>duced reduction as well<br />

as photochemical and high energy radiation <strong>in</strong>duced reduction<br />

of silver salt solution. Among these methods, chemical<br />

reduction is the most extensively <strong>in</strong>vestigated method [2-6].<br />

Figure 1 shows the UV-vis absorption spectrum of a diluted<br />

solution of AgNPs <strong>in</strong> which we can see a narrow absorption at<br />

403 nm (plasmon band) <strong>in</strong>dicat<strong>in</strong>g the presence AgNPs. The<br />

size of the AgNPs were determ<strong>in</strong>ed with the help of<br />

transmission electron microscope (Fig. 2). Also, a comparative<br />

k<strong>in</strong>etic formation of AgNPs us<strong>in</strong>g ultrasonic and conventional<br />

heat<strong>in</strong>g conditions were made and the result obta<strong>in</strong>ed <strong>in</strong>dicates<br />

(Figure 3) that the rate of formation of AgNPs us<strong>in</strong>g ultrasonic<br />

condition was about 1.5 times better than that obta<strong>in</strong>ed us<strong>in</strong>g<br />

conventional heat<strong>in</strong>g. The result <strong>in</strong>dicates the necessity of<br />

us<strong>in</strong>g CTAB as capp<strong>in</strong>g and stabiliz<strong>in</strong>g agent for AgNPs.<br />

nanoparticles. A future work is be<strong>in</strong>g under <strong>in</strong>vestigation to<br />

explore the viability of us<strong>in</strong>g AgNPs <strong>in</strong> different biomedical<br />

and photonic applications.<br />

Figure 2. TEM image of the as-prepared silver nanoparticles.<br />

ln(At-Af)<br />

1<br />

0<br />

-1 0 2 4 6 8 10 12 14<br />

-2<br />

-3<br />

-4<br />

-5<br />

-6<br />

-7<br />

-8<br />

yUS = -0.5891x + 0.2431<br />

R2 = 0.9943<br />

yCH = -0.3864x - 0.0064<br />

R2 = 0.9693<br />

Time (m<strong>in</strong>)<br />

25 Times diluted sample Concentrated sample<br />

Figure 3. Plots of ln(A t -A f ) versus time of AgNPs formation under<br />

ultrasonic and conventional conditions. Prepartion condition:[Ag<br />

NO 3 ] = 2.5 mM; [glucose] = 2.5 mM; [CTAB] = 0.5 mM; [NaOH] =<br />

25 mM at 50 o C.<br />

*Correspond<strong>in</strong>g author: elshishtawy@hotmail.com<br />

Figure 1. UV–vis spectrum of the as-prepared silver nanoparticles (25<br />

times diluted sample). Prepartion condition: [Ag NO 3 ] = 2.5 mM;<br />

[glucose] = 2.5 mM; [CTAB] = 0.5 mM; [NaOH] = 25 mM and<br />

reaction time was 20 m<strong>in</strong> at 50 o C.<br />

In conclusion, uniform AgNPs have been successfully<br />

prepared <strong>in</strong> glucose/CTAB micelles. CTAB displays excellent<br />

properties <strong>in</strong> the preparation and stabilization of silver<br />

[1] N.G.Khlebtsov, L. A. Dykman, J. Quant. Spectrosc. Radiat.<br />

Transfer, 111, 1–35 (2010) and references cited there<strong>in</strong>.<br />

[2] R. Janardhanan, M. Karuppaiah, N. Hebalkar, T. N. Rao,<br />

Polyhedron, 28, 2522–2530 (2009) and references cited there<strong>in</strong>.<br />

[3] K.K. Ghosh, S. Kolay, J. Dispersion Sci. Technol., 29, 676–681<br />

(2008).<br />

[4] V. K. Sharma, R. A. Yngard, Y. L<strong>in</strong>, Adv. Colloid Interface Sci.,<br />

145, 83–96 (2009) and references cited there<strong>in</strong>.<br />

[5] Y. Y<strong>in</strong>, Z-Y. Li, Z. Zhong, B. Gates, Y. Xia,S. Venkateswaran, J.<br />

Mater. Chem., 12, 522–527 (2002).<br />

[6] N. R. Jana, L. Gearheart,C. J. Murphy, Chem. Commun., 2001,<br />

617–618.<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 214

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Structure of unsupported s mall Al nanoparticles; Molecular dynamics study<br />

Amir Chamaani 1 * Reza Darvishi Kamachali 2 Ehsan Marzbanrad 3 Alireza Aghaei 3 Yashar Behnamian 4<br />

1 New materials Department, Materials and Energy Research Center (MERC), P.O. Box 14155-4777, Tehran, Iran<br />

2 ICAMS, Ruhr-University Bochum, Bochum 44801, Germany<br />

3 Ceramic Department, Materials and Energy Research Center (MERC), P.O. Box 14155-4777, Tehran, Iran<br />

4 Chemical and Materials Eng<strong>in</strong>eer<strong>in</strong>g Department, University of Alberta Edmonton AB, T6G 2V4, Canada<br />

Abstract-A classical molecular dynamics simulation has been used to study the structure of unsupported small Al nanoparticles. Our results<br />

support the existence of a core-shell structure for the common truncated octahedron shape of Al nanoparticles, <strong>in</strong> terms of cohesive energy.<br />

However, there is a critical size below which the core-shell model cannot be applied, because the entire structure of Al nanoparticles below this<br />

size consists of merely a surface zone.<br />

The cohesive energy of nanoparticles determ<strong>in</strong>es their<br />

physical and thermodynamic properties, such as melt<strong>in</strong>g po<strong>in</strong>t,<br />

thermal stability and structure. Different models have been<br />

developed to account for cohesive energy, <strong>in</strong>clud<strong>in</strong>g the BE<br />

model [1], SAD model [2], Xie’s model [3] and so on. Most<br />

recently, the core-shell model [4-5] has been used to describe<br />

the structure of nanoparticles, <strong>in</strong> which the core of the particle<br />

is the same as the bulk material, and the surface shell is not<br />

caused by large dangl<strong>in</strong>g bonds. This concept has already been<br />

used <strong>in</strong> particular models to calculate the cohesive energy of<br />

metallic nanoparticles. In these models [1, 3], the entire<br />

structure of the nanoparticle is divided <strong>in</strong>to two sections: a<br />

bulk and a surface zone. In other words, the cohesive energy<br />

of a nanoparticle is considered to consist of the cohesive<br />

energies of the bulk zone and of the surface zone. This study is<br />

a qualitative <strong>in</strong>vestigation of the structure of a common shape<br />

(truncated octahedron) for Al nanoparticles.<br />

In this study, the simulation was performed <strong>in</strong> NVT<br />

ensemble, us<strong>in</strong>g a semi-emp irical potential (glue) [6]. The<br />

expressions for and details of the potential used can be found<br />

<strong>in</strong> aforementioned paper. The primary structure of our<br />

nanoparticles was the truncated octahedron structure from an<br />

ideal Al crystal. The number of atoms <strong>in</strong> each nanoparticle<br />

was either 79, 201, 586, 1289, 2406 or 4033, with a particle<br />

size rang<strong>in</strong>g from 1–5 nm. A bulk simulation of 864 Al atoms<br />

us<strong>in</strong>g periodic boundary conditions (pbc) was carried out to<br />

serve as a comparative case. The Verlet velocity algorithm<br />

was employed for motion equations, and a simple redial<br />

distribution counter function was used to calculate energy<br />

distributions. The systems were divided <strong>in</strong>to the maximum<br />

possible redial layers for which every layer <strong>in</strong>cluded at least<br />

one atom.<br />

The cohesive energy versus the distance to center of Al<br />

nanoparticles and the correspond<strong>in</strong>g bulk value is shown <strong>in</strong><br />

Figure (1). Unlike Al bulk (864 atoms with pbc), the cohesive<br />

energy of Al nanoparticles at a specific temperature is not<br />

constant: reced<strong>in</strong>g from center to surface, cohesive energy<br />

deviates from the bulk value. Indeed, <strong>in</strong>ternal atoms of large<br />

nanoparticles (nanoparticles which consist of more than 201<br />

atoms) have the bulk cohesive energy (-3.34 eV/atom), but<br />

surface atoms have a lower cohesive energy. Because of this<br />

separation between surface and <strong>in</strong>terior atoms of large Al<br />

nanoparticles, the whole structure of large nanoparticles can<br />

be consider as hav<strong>in</strong>g two parts: the core of the nanoparticle<br />

(the bulk zone), and the shell of the nanoparticle (the surface<br />

zone). The bulk zone <strong>in</strong> large nanoparticles consists of atoms<br />

which have the bulk cohesive energy, whereas surface zone<br />

atoms have a lower cohesive energy. Furthermore, as shown<br />

<strong>in</strong> Figure (1), with decreas<strong>in</strong>g nanoparticle size, the bulk zone<br />

gradually decreases, and below a crit ical size it co mpletely<br />

disappears. Under our conditions, the critical size is about 1.6<br />

nm (201 atoms). Therefore, the entire structure of<br />

nanoparticles below the critical size consists of only a surface<br />

zone. These nanoparticles cannot be considered to have a<br />

core-shell structure and it is better to def<strong>in</strong>e them simply as<br />

surface materials. Recently, Qi [4-5], us<strong>in</strong>g mo lecular<br />

dynamics simulation, suggested that nanoparticles of all sizes<br />

can be regarded as hav<strong>in</strong>g a core-shell structure, even small<br />

ones. However, accord<strong>in</strong>g to our results, the structure of very<br />

small nanoparticles consists of only a surface zone; the<br />

cohesive energies of the two smaller nanoparticles (201 and 79<br />

atoms) are composed of only the cohesive energy of their<br />

surface zones. Consequently, the validity of the BE and Xie<br />

models, which are based on the core-shell model, is called <strong>in</strong>to<br />

question for small nanoparticles.<br />

Figure 1. Cohesive energy of Al nanoparticles and bulk counterpart versus<br />

distance to center<br />

In summary, we <strong>in</strong>vestigated the structure of unsupported Al<br />

nanoparticles <strong>in</strong> terms of the radial distribution of cohesive<br />

energy. Our results show that the structure of nanoparticles<br />

can be described by the core-shell model. However, there is a<br />

critical size below which there is no bulk zone; the whole<br />

structure of nanoparticles of this size consists of the surface<br />

zone. Therefore, the validity of some cohesive energy models<br />

based on the core-shell model, such as the BE and Xie models,<br />

may not hold true for very small nanoparticles.<br />

*Correspond<strong>in</strong>g author: amir_chamani@merc.ac.ir<br />

[1] W.H. Qi, B.Y. Huang, M.P. Wang et al., Phys. Lett. A 370, 494<br />

(2007).<br />

[2] W.H.Qi, M.P.Wang, J.Mater.Sci.letter. 21, 1743 (2002).<br />

[3] D Xie, M.P.Wang and W.H.Qi, j.phys.condens.matter.16, L401<br />

(2004).<br />

[4] W.H.Qi, B.Huang, M.P.Wang, J. comput.theor. nanoscience. 6,<br />

1546 (2009).<br />

[5] W.H. Qi, S.T. Lee, chem.phys.lett. 483, 247–249 (2009).<br />

[6] F. Ercolessi, J. B. Adams, Europhys. Lett. 26, 584 (1994).<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 215

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

New stationary phase based on stabilized by o rga nic liga nds gold nanoparticles on silica surface for<br />

HPLC<br />

Ir<strong>in</strong>a Ananieva 1 *, Yana Elfimova 1 , Aleksandr Majouga 1 , Nikolay Zyk 1 and Oleg Shpigun 1<br />

1 Department of Chemistry, Lomonosov Moscow State University, Moscow, Russia<br />

Abstract-New nanohybrid materials for HPLC based on gold nanoparticles supported on silica gel and stabilized by<br />

L-cyste<strong>in</strong>, pyrid<strong>in</strong>e, citrate and ascorbic acid are synthesized. The possibility of separation of different model compounds <strong>in</strong> normal-phase<br />

mode of chromatography is studied.<br />

Nowadays gold nanoparticles attract a great deal of<br />

attention <strong>in</strong> a wide variety of scientific fields and technology<br />

due to their unique chemical and physical properties, which<br />

are directly related to chemical composition, size and<br />

surface structural characteristics of nanoparticles [1].<br />

Materials based on gold nanoparticles have already found<br />

widespread application <strong>in</strong> medic<strong>in</strong>e, optoelectronics,<br />

catalysis, biochemical sensors development [2]. It seems to<br />

be very perspective to use gold nanoparticles supported on<br />

oxide surface and stabilized by sulfur-bear<strong>in</strong>g organic<br />

ligands for creation of new class of separation materials for<br />

liquid chromatography. Due to the specific structures and<br />

additional <strong>in</strong>teraction between gold nanoparticles on the<br />

stationary phase surface and separat<strong>in</strong>g compounds a good<br />

resolution of different organic compounds may be achieved.<br />

The ma<strong>in</strong> advantage of these selectors is covalent attach<strong>in</strong>g<br />

of organic ligands on the surface of nanoparticles that allows<br />

to synthesize a stable sorbent and obta<strong>in</strong> reproducible data.<br />

Nanohybrid materials have been synthesized by follow<br />

method. In the first one gold nanoparticles with the 10 nm<br />

size have been prepared by reduction H[AuCl 4 ] <strong>in</strong> an aqua<br />

solution by sodium citrate, and then they have been<br />

adsorbed on silica gel. In the last stage citrate-ions have<br />

been substituted for such organic ligands as L-cyste<strong>in</strong><br />

(column 1), pyrid<strong>in</strong>e, ascorbic acid. The scheme of the<br />

synthesized stationary phase with organic ligand is<br />

presented on Figure 1.<br />

am<strong>in</strong>opyrid<strong>in</strong>es had the greatest capacity coefficients on all<br />

stationary phases, and the retention rose with the growth of<br />

<strong>in</strong>vestigat<strong>in</strong>g compounds polarity because of the <strong>in</strong>creas<strong>in</strong>g<br />

of dipole-dipole <strong>in</strong>teractions. The <strong>in</strong>crease of capacity<br />

coefficients well correlates with the <strong>in</strong>crease of of<br />

am<strong>in</strong>opyrid<strong>in</strong>es. The smaller capacity coefficient of 2-<br />

am<strong>in</strong>opyrid<strong>in</strong>e (pKa 6.67) <strong>in</strong> comparison with 3-<br />

am<strong>in</strong>opyrid<strong>in</strong>e (pKa 6.16) can be expla<strong>in</strong>ed by steric<br />

h<strong>in</strong>drance of NH 2 -group. The greatest retention time of all<br />

model compounds was observed for the stationary phase<br />

conta<strong>in</strong><strong>in</strong>g pyrid<strong>in</strong>e as the modificator because of strong -<br />

Chromatogram of am<strong>in</strong>opyrid<strong>in</strong>e separation<br />

is presented on Figure 2.<br />

Figure 2. Chromatogram of separation of am<strong>in</strong>opyrid<strong>in</strong>es. Column<br />

1 (1004,0 mm) . Mobile phase: hexane/i-propanol<br />

(90/10). Injection volume 20 l. 1 - 2-am<strong>in</strong>o-5-chlor<strong>in</strong>epyrid<strong>in</strong>e; 2<br />

- 2-am<strong>in</strong>o-5-methylpyrid<strong>in</strong>e; 3 - 2-am<strong>in</strong>o-4-methylpyrid<strong>in</strong>e; 4 – 2-<br />

am<strong>in</strong>opyrid<strong>in</strong>e.<br />

Figure 1. Layout view of the adsorption of modified gold<br />

nanoparticles on the silicon oxide’s surface.<br />

In order to estimate the retentive ability of prepared<br />

nanohybrid sorbents such model compounds as anil<strong>in</strong>es,<br />

phenols, am<strong>in</strong>opyrid<strong>in</strong>es, some optically active compounds<br />

were used <strong>in</strong> normal-phase mode of HPLC. Previous<br />

research have shown that the optimum mobile phase was<br />

90% hexane/10% isopropanol. It was found that<br />

Obta<strong>in</strong>ed results show that new nanohybrid materials<br />

based on stabilized by L-cyste<strong>in</strong>, pyrid<strong>in</strong>e and citrate gold<br />

nanoparticles on silica surface are very perspective for<br />

further <strong>in</strong>vestigation.<br />

This work was supported by the Russian Foundation for<br />

Basic Research (09-03-00519-).<br />

*Correspond<strong>in</strong>g author: irishan@mail.ru<br />

[1] M. Brust, M. Walker, D. Bethell, D. Schiffr<strong>in</strong>, R. Whyman, J.<br />

Chem. Soc., Chem. Commun., 801-802 (1994).<br />

[2] Kiml<strong>in</strong>g J., Maier M., Okenve B., Kotaidis V., Ballot H., Plech<br />

A., J. Phys. Chem. B. 110 15700 (2006).<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 216

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

L-cyste<strong>in</strong> go ld nanoparticles on silica surface for HPLC separation<br />

Yana Elfimova 1 *, Ir<strong>in</strong>a Ananieva 1 , Aleksandr Majouga 1 , Nikolay Zyk 1 and Oleg Shpigun 1<br />

1 Department of Chemistry, Lomonosov Moscow State University, Moscow, Russia<br />

Abstract-New nanohybrid material for HPLC based on gold nanoparticles supported on silica gel and stabilized by<br />

L-cyste<strong>in</strong> is synthesized. The possibility of separation of -blockers and am<strong>in</strong>o acids <strong>in</strong> different modes of chromatography is<br />

studied.<br />

Gold nanoparticles play an important role <strong>in</strong> applied<br />

science and technology because they exhibit unique<br />

chemical and physical properties which depend on their<br />

shape, size, and local environment [1]. Materials based on<br />

gold nanoparticles are widely used <strong>in</strong> the field of chemistry,<br />

<strong>biology</strong>, material science and physics. The dimensions of<br />

gold nanoparticles allow us<strong>in</strong>g them for the creation of a<br />

new class of separation materials for liquid chromatography.<br />

We suggest new sorbent based on the gold nanoparticles<br />

supported on silica gel and stabilized by L-cyste<strong>in</strong> for the<br />

separation of different organic compounds <strong>in</strong>clud<strong>in</strong>g<br />

optically active compounds.<br />

Optically active compounds attract great attention because<br />

of their widespread application <strong>in</strong> many fields of science,<br />

particularly <strong>in</strong> pharmaceutics. Compounds that have optical<br />

isomers <strong>in</strong> many cases exhibit different pharmacological and<br />

toxicological properties. This fact has stimulated the<br />

application of enantiomerically pure products. -blockers<br />

play an important role among optically active compounds.<br />

-blockers are drugs that slow the heart rate, decrease<br />

cardiac output, lessen the force with which the heart muscle<br />

contracts and reduce blood vessel contraction. They do this<br />

by block<strong>in</strong>g beta-adrenergic receptors <strong>in</strong> various parts of the<br />

body. Another important class of optically active<br />

compounds is am<strong>in</strong>o acids. Am<strong>in</strong>o acids<br />

co-exist <strong>in</strong> biological liquids of liv<strong>in</strong>g organisms though<br />

D- and L-isomers play different roles. That is why the<br />

problem of enantioseparation of different am<strong>in</strong>o acids is<br />

very actual nowadays. HPLC has many applications <strong>in</strong> the<br />

fields of determ<strong>in</strong>ation of am<strong>in</strong>o acids. The commonly used<br />

method performance is the determ<strong>in</strong>ation of am<strong>in</strong>o acids as<br />

hydrophobic derivatives <strong>in</strong> reverse-phase mode on the<br />

hydrophobic stationary phase. In the present time much<br />

works <strong>in</strong> chiral separations have been directed to the<br />

development of new chiral selectors.<br />

Gold nanoparticles with average 10 nm size have been<br />

synthesized by reduction H[AuCl 4 ] <strong>in</strong> an aqua solution by<br />

sodium citrate, and then they have been modified by<br />

L-cyste<strong>in</strong>. Prepared nanoparticles have been adsorbed on<br />

silica gel. The scheme of the synthesized stationary phase<br />

with L-cyste<strong>in</strong> as organic lidand is presented on Fig.1.<br />

Obta<strong>in</strong>ed material has been tested for ability of<br />

-blockers<br />

and am<strong>in</strong>oacids. The best separation of am<strong>in</strong>opyrid<strong>in</strong>es was<br />

achieved <strong>in</strong> the normal-phase mode us<strong>in</strong>g 90% hexane/10%<br />

isopropanol as a mobile phase. The retention of<br />

am<strong>in</strong>opyrid<strong>in</strong>es rises with the growth of <strong>in</strong>vestigat<strong>in</strong>g<br />

compounds polarity because of the <strong>in</strong>creas<strong>in</strong>g of dipoledipole<br />

<strong>in</strong>teractions.<br />

We studied t-blockers enantioseparation<br />

<strong>in</strong> normal-phase and polar-organic modes of<br />

chromatography. The best results were observed for<br />

p<strong>in</strong>dolol at use of a mobile phase – acetonitrile / methanol /<br />

CH 3 COOH / triethylam<strong>in</strong>e (60/40/0.2/0.2).<br />

The separation of am<strong>in</strong>o acids was performed <strong>in</strong> the ion<br />

exchange variant of chromatography with<br />

spectrophotometric detection at 210 nm. We used 0.05M<br />

borate buffer (pH 7.7) as the mobile phase. Because a small<br />

molecule of L-cyste<strong>in</strong> was used as a chiral selector the best<br />

enantioseparation was achieved for such a small molecules<br />

of am<strong>in</strong>o acids as leuc<strong>in</strong>e and val<strong>in</strong>e. Chromatogram of<br />

enantioseparation is presented on Fig.2.<br />

Figure 2. Chromatogram enantioseparation of p<strong>in</strong>dolol. Column<br />

(100 . Mobile phase:<br />

acetonitrile/methanol/CH3COOH/threeethylam<strong>in</strong>e (60/40/0,2/0,2).<br />

Injection volume 20 l.<br />

This work was supported by the Russian Foundation for<br />

Basic Research (09-03-00519-).<br />

*Correspond<strong>in</strong>g author: elfimova_16@list.ru<br />

Figure 1. Layout view of the adsorption of modified gold<br />

nanoparticles on the silicon oxide’s surface.<br />

[1] A. Vasil’kov, S. Nikolaev, V. Smirnov, A. Naumk<strong>in</strong>, I. Volkov<br />

and V. Podshibikh<strong>in</strong>, Mendeleev Commun. 17, 268-270 (2007).<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 217

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Investigation of CdS Langmuir-Blodgett Th<strong>in</strong> Films by Us<strong>in</strong>g EFM Technique<br />

S.A. Klimova 1 , M. Yavuz 2 *, S.V. Stetsyura 1 ,M. Arslan 2 , E.G. Glukhovskoy 1 , S.B. Venig 1 , Y. Elerman 2<br />

1 University of Saratov State, Department of Nano- and Biomedical Technology, 410012, Saratov, Russia<br />

2University of Ankara, Department of Eng<strong>in</strong>eer<strong>in</strong>g Physics, Faculty of Eng<strong>in</strong>eer<strong>in</strong>g, 06100 Besevler, Ankara, Turkey<br />

Abstract- In this study, the CdS LB films with<br />

different pH values have been studied by EFM. The surface potentials of<br />

films were calculated from EFM phase-voltagee curves. It was found that surface potential and EFM phase decrease with<br />

<strong>in</strong>creas<strong>in</strong>g pH.<br />

Recently, structural <strong>in</strong>vestigations of Langmuir-<br />

Blodgett (LB) films are <strong>in</strong>creased rapidly for various<br />

device applications rang<strong>in</strong>g from biosensors to<br />

nanostructured electronic devices [1]. This is due to<br />

their precise thickness control and welll ordered<br />

structure.<br />

One extensively studied semiconduct<strong>in</strong>g<br />

material<br />

is CdS which is distributed <strong>in</strong> fatty acid. The<br />

electronic properties of LB films for different pH<br />

values (pH 3 and 8) were <strong>in</strong>vestigated by us<strong>in</strong>g<br />

Electrical Force Microscopy from NT-MDTT (Model:<br />

Solver Pro-M). Semi-contact imag<strong>in</strong>g was<br />

done <strong>in</strong><br />

height mode and some images are presented here<strong>in</strong>.<br />

For imag<strong>in</strong>g, the scann<strong>in</strong>g velocity 8.37 μm/s. A Pt<br />

coated cantilever was used and the cantilever’s free<strong>in</strong>terleave<br />

resonant frequency was about 76 kHz. The<br />

scan lift height was 50 nm. In EFM – phase<br />

measurement for small force gradient the phase shift<br />

is;<br />

QdF<br />

arcs<strong>in</strong><br />

<br />

kdz <br />

<br />

arcs<strong>in</strong><br />

<br />

kdz<br />

2<br />

QdC<br />

2<br />

<br />

U<br />

<br />

2<br />

<br />

<br />

<br />

(1)<br />

where k is the spr<strong>in</strong>g constant (2 N/m) and<br />

Q is the<br />

quality factor (260) of the cantilever.<br />

In this study, the CdS LB films were <strong>in</strong>vestigated<br />

with different bias voltage (±7 V) by EFM. For<br />

obta<strong>in</strong><strong>in</strong>g surface potential from EFM measurements,<br />

we selected a bright po<strong>in</strong>t <strong>in</strong> topography image. Fig. 1<br />

is a plot of phase shifts at different biases. The data<br />

were fitted <strong>in</strong> the range of -5 V to +5 V us<strong>in</strong>g a least<br />

squares method to give the solid curve.<br />

The fit function used was<br />

2<br />

arcs<strong>in</strong> A V V <br />

0<br />

B<br />

<br />

where A represents the constant parameter<br />

(Q/2k)d 2 C/dz 2 , and B represents an offset to<br />

0 o when<br />

V=V 0 [2].<br />

Table 1. Calculated A, B, and V 0 parameters for films<br />

pH 3 pH 8<br />

A (V -2 ) 3.42x10 -3 2.69x10 -3<br />

B ( o ) 0.0137 0.049<br />

V 0 (V) 0.579 -0.396<br />

For pH 3 and pH 8 samples, surface potentials (SP)<br />

and electrostatic force gradients (dF/dz) were<br />

calculated from the EFM phase data along a 0.45 μm<br />

length by us<strong>in</strong>g A, B, and V 0 parameters. Some am<strong>in</strong>e<br />

groups are transformed from a positive charged<br />

species to a neutral charge, reduc<strong>in</strong>g surfactant-<br />

than the<br />

polymer <strong>in</strong>teractions for pH values greater<br />

optimum [3]. Accord<strong>in</strong>g to EFM phase,<br />

surface<br />

potential and electrostatic force gradient curves, while<br />

the pH values were <strong>in</strong>creas<strong>in</strong>g, electrical properties<br />

decreased.<br />

*murat_yavuz59@yahoo.com<br />

[1]Swalen J. D., Allara D. L., Andrade J. D.,<br />

Chandross E. A., Langmuir, 3, 393 (1987).<br />

[2]Lei C. H., Das A., Elliott M. and Macdonald J. E.<br />

IOP Nanotechnology 15, 627-634 (2004).<br />

[3]Stroeve P. and Hwa M. J., Th<strong>in</strong> Solid Films 284-<br />

285, 561-563 (1996).<br />

(2)<br />

Figure 1. Topography and EFM Phase-Voltage curve for (a) pH:3, and (b) pH:8 CdS LB films<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 218

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Preparat ion of mag netic nanoparticles with surfactant-controlled size and shape<br />

Aysel Bayrak 1 ,Sema Vural 1 ,Yavuz Çelik 1 , Turgay Seçk<strong>in</strong> 1 *<br />

1 Department of Chemistry, University of Inonu, Malatya, TR Türkiye 44280<br />

Abstract-This manuscript describes a simple one-pot reaction that affords cobalt iron oxide nanoparticles with unprecedented dimensions as<br />

large as 30 nm <strong>in</strong> monodisperse form. Unique synthetic method, which requires no multiple growth steps typical of other methods, utilizes the<br />

thermal decomposition of metal precursor complexes <strong>in</strong> the presence of speci<br />

and shape of these unusually large magnetic nanoparticles (MNPs) can be manipulated at will simply by adjust<strong>in</strong>g the surfactant composition,<br />

lead<strong>in</strong>g to enhanced control over the dimensions of the nanoparticles because of the surface-differentiat<strong>in</strong>g <strong>in</strong><br />

the produced ferrites were <strong>in</strong>vestigated by X-ray diffraction analysis (XRD), scann<strong>in</strong>g electron microscope (SEM) and vibrat<strong>in</strong>g sample<br />

magnetome-ter (VSM).<br />

Monodisperse magnetic nanoparticles (MNPs) with<br />

controlled sizes and shapes are of great <strong>in</strong>terest for<br />

fundamental science and for both exist<strong>in</strong>g and develop<strong>in</strong>g<br />

technological applications. The morphology of MNPs strongly<br />

<strong>in</strong> <br />

especially their magnetic and electrical properties. More<br />

speci <br />

strongly depend on the size, shape, functionality, and<br />

magnetization of the MNPs.<br />

Cobalt ferrite (CoFe 2 O 4 ), with a partially <strong>in</strong>verse sp<strong>in</strong>el<br />

structure, is one of the most important and most abundant<br />

magnetic materials. As a conventional magnetic material, with<br />

a Curie temperature (TC) around 793 K, CoFe 2 O 4 is well<br />

known to have large magnetic anisotropy, moderate saturation<br />

magnetization, remarkable chemical stability and a mechanical<br />

hardness, which make it a good candidate for the record<strong>in</strong>g<br />

med ia[1,2]. CoFe 2 O 4 ultraf<strong>in</strong>e powders [3–4] and films have<br />

attracted considerable attention for their wide range of<br />

technological applications such as transformer cores,<br />

record<strong>in</strong>g heads, antenna rods, memory, ferro fluids,<br />

biomedical application and sensors, etc.. Over recent years,<br />

the chemical solution routes were successively emerg<strong>in</strong>g as<br />

effective, convenient, less energy demand<strong>in</strong>g and less<br />

materials consum<strong>in</strong>g synthetic techniques for material<br />

preparation. However, the hydrothermal route is one of the<br />

most used ones, ow<strong>in</strong>g to its economics and the high degree of<br />

compositional control. In addition, the hydrothermal synthesis<br />

requires neither extremely high process<strong>in</strong>g temperature nor<br />

sophisticated process<strong>in</strong>g. For example, ferrites can be prepared<br />

via the hydrothermal method at a temperature of about 150 C,<br />

whereas the solid-state method requires a temperature of 800<br />

C. Hydrothermal synthesis of several ferrites has been<br />

reported. However, there is little report on the synthesis of<br />

s<strong>in</strong>gle-crystall<strong>in</strong>e CoFe 2 O 4 nanorods. We present here a<br />

simple hydrothermal route without a preformed template for<br />

the preparation of CoFe 2 O 4 nanorods.<br />

The growth rate has been shown to be an important factor <strong>in</strong><br />

controll<strong>in</strong>g the shape of magnetic nanoparticles. Moreover, the<br />

wet chemical synthesis of monodisperse large nanoparticles<br />

typically <strong>in</strong>volves precise control over the growth rate by<br />

us<strong>in</strong>g a high concentration of metal cation and controll<strong>in</strong>g the<br />

strength of b<strong>in</strong>d<strong>in</strong>g between various ligands and the emerg<strong>in</strong>g<br />

metal surface.<br />

In a typical procedure for the preparation of CoFe2O 4 , 1 g of<br />

cationic surfactant cetyltrimethylammonium bromide (CTAB)<br />

was dissolved <strong>in</strong> 35 ml deionized water to form a transparent<br />

solution. Then ferric chloride hexahydrate (FeCl3.6H2O) of 1<br />

g was added to the solution. After 10 m<strong>in</strong> stirr<strong>in</strong>g,<br />

stoichiometric amount of CoCl 2 was <strong>in</strong>troduced <strong>in</strong>to the<br />

mixed solution under vigorous stirr<strong>in</strong>g. Deionized water was<br />

added to make the solution for a total volume of 40 ml, and<br />

pH of the solution was adjusted to 11.0. Before be<strong>in</strong>g<br />

transferred to a Teflon-l<strong>in</strong>ed auto-clave of 50.0 ml capacity,<br />

the solution mixture was pretreated under an ultrasonic water<br />

bath for 30– 40 m<strong>in</strong>. Hydrothermal synthesis was carried out<br />

at 130 ºC for 15 h <strong>in</strong> an electric oven without shak<strong>in</strong>g or<br />

stirr<strong>in</strong>g. Afterwards, the autoclave was allowed to cool to<br />

room temperature gradually. The black precipitate collected<br />

was washed with distilled water three times <strong>in</strong> an ultrasonic<br />

bath to remove any possible impurities. The solid was then<br />

heated at 80 ºC and dried under vacuum for 2 h.<br />

Figure 1. X-ray diffraction patterns of the prepared CoFe 2 O 4<br />

particles and nanorods via hydrothermal for 15 h without CTAB (a)<br />

andwith CTAB (b).<br />

The product morphology changes from tetrapods, nanorods,<br />

and nanoparticles as the reaction temperature <strong>in</strong>creases from<br />

40 to 70 C with various surfactants.<br />

We note that monodisperse particles of this size represent an<br />

ideal compromise for many applications, offer<strong>in</strong>g the potential<br />

for both a strong magnetic moment and electrical properties.<br />

We also evaluated the key magnetic characteristics of our<br />

iron-manganese oxide nanoparticles. In particular, magnetic<br />

hysteresis loops and magnetic relaxation were measured for<br />

these particles at room temperature. The superparamagnetic<br />

nature of these particles is characterized by M-H hysteresis<br />

loop behavior at 290 K and rapid relaxation.<br />

*Correspond<strong>in</strong>g author: 1Ttseck<strong>in</strong>@<strong>in</strong>onu.edu.tr<br />

[1] Mornet, S.; Vasseur, S.; Grasset, F.; Duguet, E.J. Mater.<br />

Chem.2004, 14, 2161.<br />

[2] Gleich, B.; Weizenecker, J.Nature2005,435, 1214.<br />

[3] Mannix, R. J.; Kumar, S.; Cassiola, F.; Montoya-Zavala, M .;<br />

Fe<strong>in</strong>ste<strong>in</strong>, E.; Prentiss, M.; Ingber, D. E.Nat. Nanotechnol.2008,3,<br />

36.<br />

[4] Weitschies, W.; Ko¨titz, R.; Bunte, T.; Trahms, L.Pharm.<br />

Pharmacol. Lett.1997,7,1.<br />

6th Nanoscience and Nanotechnology Conference, zmir, 2010 219

Poster Session, Tuesday, June 15<br />

Theme A1 - B702<br />

Preparat ion of mag netic nanoparticles with controlled morphology<br />

Aysel Bayrak 1 ,Sema Vural 1 , Turgay Seçk<strong>in</strong> 1 *<br />

1 Department of Chemistry, University of Inonu, Malatya, TR Türkiye 44280<br />

Abstract-Cobalt, Nickel and z<strong>in</strong>c ferrites nanoparticles have been synthesized us<strong>in</strong>g the hydrothermally technique. Effects of synthesis<br />

conditions on the crystal structure, crystallite size, lattice parameter, microstructure and magnetic properties of the produced sp<strong>in</strong>el ferrites were<br />

<strong>in</strong>vestigated by X-ray diffraction analysis (XRD), scann<strong>in</strong>g electron microscope (SEM) and vibrat<strong>in</strong>g sample magnetometer (VSM).<br />

S<strong>in</strong>ce the beg<strong>in</strong>n<strong>in</strong>g of this century, 2000, science and<br />

eng<strong>in</strong>eer<strong>in</strong>g has seen a rapid <strong>in</strong>crease <strong>in</strong> <strong>in</strong>terest for materials<br />

at the nano-scale. Nano-materials have attracted such a strong<br />

<strong>in</strong>terest because of the physical, electronic, and magnetic<br />

properties result<strong>in</strong>g from their quantum size [1]. The potential<br />

for nano-technology is immensely diverse with potential<br />

applications <strong>in</strong> the fields of electronics, biomedical devices,<br />

energy applications, military uses, and waste management [2].<br />

Nano-materials could be utilized to design nano-transistors, to<br />

develop and deliver medic<strong>in</strong>es for locally treat<strong>in</strong>g diseases and<br />

ailments with<strong>in</strong> the body, and for the creation new age<br />

weapons and armor for military applications [3]. With<strong>in</strong> the<br />

field of nano-materials under worldwide research is the subset<br />

of magnetic nanomaterials and magnetic nanoparticles.<br />

Magnetic nanoparticles are of great <strong>in</strong>terest for researchers<br />