equipment sourcebook - Loctite.ph

equipment sourcebook - Loctite.ph

equipment sourcebook - Loctite.ph

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Dispense Systems<br />

DISPENSING<br />

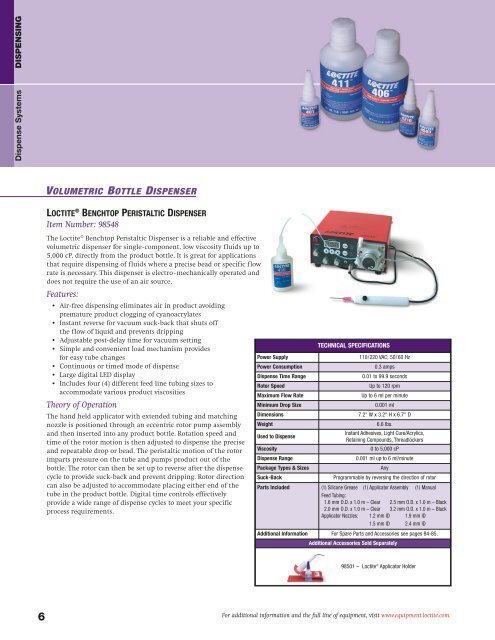

VOLUMETRIC BOTTLE DISPENSER<br />

LOCTITE ® BENCHTOP PERISTALTIC DISPENSER<br />

Item Number: 98548<br />

The <strong>Loctite</strong>® Benchtop Peristaltic Dispenser is a reliable and effective<br />

volumetric dispenser for single-component, low viscosity fluids up to<br />

5,000 cP, directly from the product bottle. It is great for applications<br />

that require dispensing of fluids where a precise bead or specific flow<br />

rate is necessary. This dispenser is electro - mechanically operated and<br />

does not require the use of an air source.<br />

Features:<br />

• Air-free dispensing eliminates air in product avoiding<br />

premature product clogging of cyanoacrylates<br />

• Instant reverse for vacuum suck-back that shuts off<br />

the flow of liquid and prevents dripping<br />

• Adjustable post-delay time for vacuum setting<br />

• Simple and convenient load mechanism provides<br />

for easy tube changes<br />

• Continuous or timed mode of dispense<br />

• Large digital LED display<br />

• Includes four (4) different feed line tubing sizes to<br />

accommodate various product viscosities<br />

Theory of Operation<br />

The hand held applicator with extended tubing and matching<br />

nozzle is positioned through an eccentric rotor pump assembly<br />

and then inserted into any product bottle. Rotation speed and<br />

time of the rotor motion is then adjusted to dispense the precise<br />

and repeatable drop or bead. The peristaltic motion of the rotor<br />

imparts pressure on the tube and pumps product out of the<br />

bottle. The rotor can then be set up to reverse after the dispense<br />

cycle to provide suck-back and prevent dripping. Rotor direction<br />

can also be adjusted to accommodate placing either end of the<br />

tube in the product bottle. Digital time controls effectively<br />

provide a wide range of dispense cycles to meet your specific<br />

process requirements.<br />

Power Supply<br />

Power Consumption<br />

Dispense Time Range<br />

Rotor Speed<br />

Maximum Flow Rate<br />

Minimum Drop Size<br />

Dimensions<br />

Weight<br />

Used to Dispense<br />

Viscosity<br />

Dispense Range<br />

Package Types & Sizes<br />

Suck-Back<br />

TECHNICAL SPECIFICATIONS<br />

110/220 VAC; 50/60 Hz<br />

0.3 amps<br />

0.01 to 99.9 seconds<br />

Up to 120 rpm<br />

Up to 6 ml per minute<br />

0.001 ml<br />

7.2" W x 3.2" H x 6.7" D<br />

6.6 lbs.<br />

Instant Adhesives, Light Cure/Acrylics,<br />

Retaining Compounds, Threadlockers<br />

0 to 5,000 cP<br />

0.001 ml up to 6 ml/minute<br />

Any<br />

Programmable by reversing the direction of rotor<br />

Parts Included (1) Silicone Grease (1) Applicator Assembly (1) Manual<br />

Feed Tubing:<br />

1.6 mm O.D. x 1.0 m – Clear 2.5 mm O.D. x 1.0 m – Black<br />

2.0 mm O.D. x 1.0 m – Clear 3.2 mm O.D. x 1.0 m – Black<br />

Applicator Nozzles: 1.2 mm ID 1.9 mm ID<br />

1.5 mm ID 2.4 mm ID<br />

Additional Information For Spare Parts and Accessories see pages 84-85.<br />

Additional Accessories Sold Separately<br />

98501 – <strong>Loctite</strong> ® Applicator Holder<br />

6<br />

For additional information and the full line of <strong>equipment</strong>, visit www.<strong>equipment</strong>.loctite.com.