Production of BHD (Bio Hydrofined Diesel) with Improved Cold Flow ...

Production of BHD (Bio Hydrofined Diesel) with Improved Cold Flow ...

Production of BHD (Bio Hydrofined Diesel) with Improved Cold Flow ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

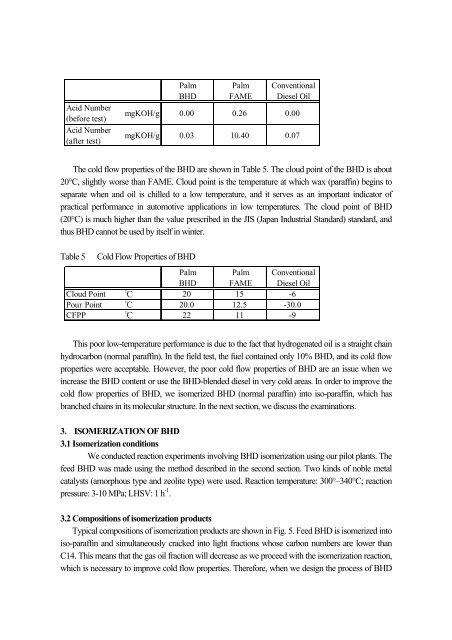

Acid Number<br />

(before test)<br />

Acid Number<br />

(after test)<br />

Palm<br />

<strong>BHD</strong><br />

Palm<br />

FAME<br />

Conventional<br />

<strong>Diesel</strong> Oil<br />

mgKOH/g 0.00 0.26 0.00<br />

mgKOH/g 0.03 10.40 0.07<br />

The cold flow properties <strong>of</strong> the <strong>BHD</strong> are shown in Table 5. The cloud point <strong>of</strong> the <strong>BHD</strong> is about<br />

20°C, slightly worse than FAME. Cloud point is the temperature at which wax (paraffin) begins to<br />

separate when and oil is chilled to a low temperature, and it serves as an important indicator <strong>of</strong><br />

practical performance in automotive applications in low temperatures. The cloud point <strong>of</strong> <strong>BHD</strong><br />

(20°C) is much higher than the value prescribed in the JIS (Japan Industrial Standard) standard, and<br />

thus <strong>BHD</strong> cannot be used by itself in winter.<br />

Table 5<br />

<strong>Cold</strong> <strong>Flow</strong> Properties <strong>of</strong> <strong>BHD</strong><br />

Palm<br />

<strong>BHD</strong><br />

Palm<br />

FAME<br />

Conventional<br />

<strong>Diesel</strong> Oil<br />

Cloud Point ℃ 20 15 -6<br />

Pour Point ℃ 20.0 12.5 -30.0<br />

CFPP ℃ 22 11 -9<br />

This poor low-temperature performance is due to the fact that hydrogenated oil is a straight chain<br />

hydrocarbon (normal paraffin). In the field test, the fuel contained only 10% <strong>BHD</strong>, and its cold flow<br />

properties were acceptable. However, the poor cold flow properties <strong>of</strong> <strong>BHD</strong> are an issue when we<br />

increase the <strong>BHD</strong> content or use the <strong>BHD</strong>-blended diesel in very cold areas. In order to improve the<br />

cold flow properties <strong>of</strong> <strong>BHD</strong>, we isomerized <strong>BHD</strong> (normal paraffin) into iso-paraffin, which has<br />

branched chains in its molecular structure. In the next section, we discuss the examinations.<br />

3. ISOMERIZATION OF <strong>BHD</strong><br />

3.1 Isomerization conditions<br />

We conducted reaction experiments involving <strong>BHD</strong> isomerization using our pilot plants. The<br />

feed <strong>BHD</strong> was made using the method described in the second section. Two kinds <strong>of</strong> noble metal<br />

catalysts (amorphous type and zeolite type) were used. Reaction temperature: 300°–340°C; reaction<br />

pressure: 3-10 MPa; LHSV: 1 h -1 .<br />

3.2 Compositions <strong>of</strong> isomerization products<br />

Typical compositions <strong>of</strong> isomerization products are shown in Fig. 5. Feed <strong>BHD</strong> is isomerized into<br />

iso-paraffin and simultaneously cracked into light fractions whose carbon numbers are lower than<br />

C14. This means that the gas oil fraction will decrease as we proceed <strong>with</strong> the isomerization reaction,<br />

which is necessary to improve cold flow properties. Therefore, when we design the process <strong>of</strong> <strong>BHD</strong>