Production of BHD (Bio Hydrofined Diesel) with Improved Cold Flow ...

Production of BHD (Bio Hydrofined Diesel) with Improved Cold Flow ...

Production of BHD (Bio Hydrofined Diesel) with Improved Cold Flow ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Isomerized <strong>BHD</strong> <strong>BHD</strong><br />

Density 15℃ g/cm3 0.781 0.783<br />

Viscosity 30℃ mm2/s 3.9 4.1<br />

Pour Point ℃ +5.0 +20.0<br />

Cloud Point ℃ +4 +21<br />

Cetane Number 90.3 101<br />

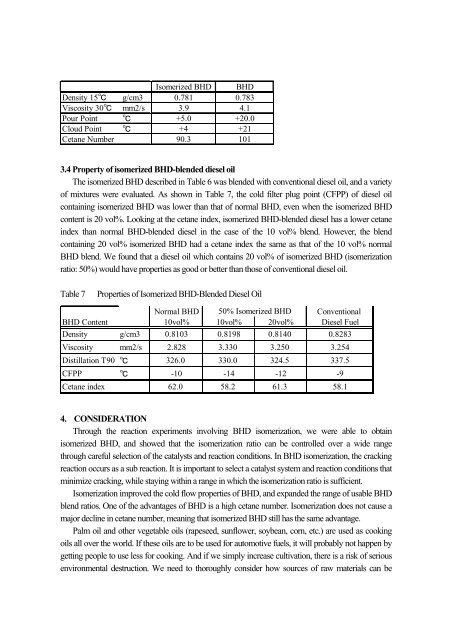

3.4 Property <strong>of</strong> isomerized <strong>BHD</strong>-blended diesel oil<br />

The isomerized <strong>BHD</strong> described in Table 6 was blended <strong>with</strong> conventional diesel oil, and a variety<br />

<strong>of</strong> mixtures were evaluated. As shown in Table 7, the cold filter plug point (CFPP) <strong>of</strong> diesel oil<br />

containing isomerized <strong>BHD</strong> was lower than that <strong>of</strong> normal <strong>BHD</strong>, even when the isomerized <strong>BHD</strong><br />

content is 20 vol%. Looking at the cetane index, isomerized <strong>BHD</strong>-blended diesel has a lower cetane<br />

index than normal <strong>BHD</strong>-blended diesel in the case <strong>of</strong> the 10 vol% blend. However, the blend<br />

containing 20 vol% isomerized <strong>BHD</strong> had a cetane index the same as that <strong>of</strong> the 10 vol% normal<br />

<strong>BHD</strong> blend. We found that a diesel oil which contains 20 vol% <strong>of</strong> isomerized <strong>BHD</strong> (isomerization<br />

ratio: 50%) would have properties as good or better than those <strong>of</strong> conventional diesel oil.<br />

Table 7<br />

Properties <strong>of</strong> Isomerized <strong>BHD</strong>-Blended <strong>Diesel</strong> Oil<br />

Normal <strong>BHD</strong> 50% Isomerized <strong>BHD</strong> Conventional<br />

<strong>BHD</strong> Content 10vol% 10vol% 20vol% <strong>Diesel</strong> Fuel<br />

Density g/cm3 0.8103 0.8198 0.8140 0.8283<br />

Viscosity mm2/s 2.828 3.330 3.250 3.254<br />

Distillation T90 ℃ 326.0 330.0 324.5 337.5<br />

CFPP ℃ -10 -14 -12 -9<br />

Cetane index 62.0 58.2 61.3 58.1<br />

4. CONSIDERATION<br />

Through the reaction experiments involving <strong>BHD</strong> isomerization, we were able to obtain<br />

isomerized <strong>BHD</strong>, and showed that the isomerization ratio can be controlled over a wide range<br />

through careful selection <strong>of</strong> the catalysts and reaction conditions. In <strong>BHD</strong> isomerization, the cracking<br />

reaction occurs as a sub reaction. It is important to select a catalyst system and reaction conditions that<br />

minimize cracking, while staying <strong>with</strong>in a range in which the isomerization ratio is sufficient.<br />

Isomerization improved the cold flow properties <strong>of</strong> <strong>BHD</strong>, and expanded the range <strong>of</strong> usable <strong>BHD</strong><br />

blend ratios. One <strong>of</strong> the advantages <strong>of</strong> <strong>BHD</strong> is a high cetane number. Isomerization does not cause a<br />

major decline in cetane number, meaning that isomerized <strong>BHD</strong> still has the same advantage.<br />

Palm oil and other vegetable oils (rapeseed, sunflower, soybean, corn, etc.) are used as cooking<br />

oils all over the world. If these oils are to be used for automotive fuels, it will probably not happen by<br />

getting people to use less for cooking. And if we simply increase cultivation, there is a risk <strong>of</strong> serious<br />

environmental destruction. We need to thoroughly consider how sources <strong>of</strong> raw materials can be