Production of BHD (Bio Hydrofined Diesel) with Improved Cold Flow ...

Production of BHD (Bio Hydrofined Diesel) with Improved Cold Flow ...

Production of BHD (Bio Hydrofined Diesel) with Improved Cold Flow ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

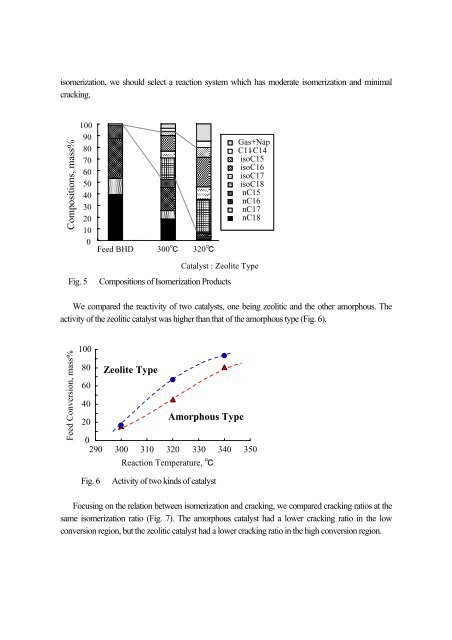

isomerization, we should select a reaction system which has moderate isomerization and minimal<br />

cracking.<br />

Compositions, mass%<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

Feed <strong>BHD</strong> 300℃ 320℃<br />

Gas+Nap<br />

C11-C14<br />

isoC15<br />

isoC16<br />

isoC17<br />

isoC18<br />

nC15<br />

nC16<br />

nC17<br />

nC18<br />

Fig. 5<br />

Catalyst : Zeolite Type<br />

Compositions <strong>of</strong> Isomerization Products<br />

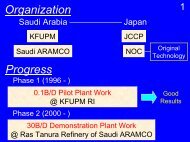

We compared the reactivity <strong>of</strong> two catalysts, one being zeolitic and the other amorphous. The<br />

activity <strong>of</strong> the zeolitic catalyst was higher than that <strong>of</strong> the amorphous type (Fig. 6).<br />

Feed Conversion, mass%<br />

100<br />

80 Zeolite Type<br />

60<br />

40<br />

20<br />

Amorphous Type<br />

0<br />

290 300 310 320 330 340 350<br />

Reaction Temperature, ℃<br />

Fig. 6<br />

Activity <strong>of</strong> two kinds <strong>of</strong> catalyst<br />

Focusing on the relation between isomerization and cracking, we compared cracking ratios at the<br />

same isomerization ratio (Fig. 7). The amorphous catalyst had a lower cracking ratio in the low<br />

conversion region, but the zeolitic catalyst had a lower cracking ratio in the high conversion region.