E1.10 2009 Product Catalog (pdf) - Lincoln Electric

E1.10 2009 Product Catalog (pdf) - Lincoln Electric

E1.10 2009 Product Catalog (pdf) - Lincoln Electric

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

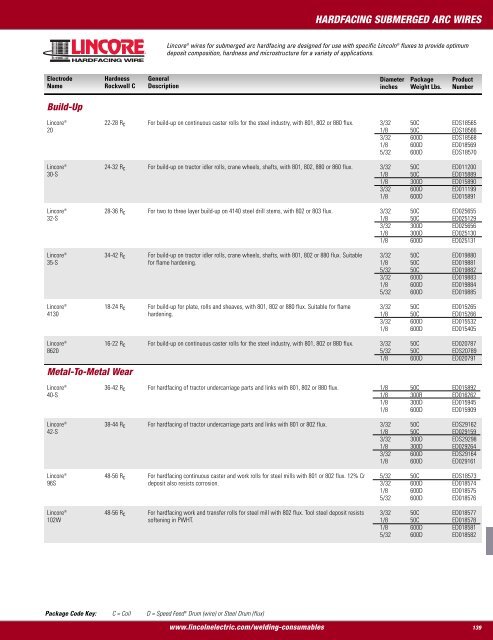

HARDFACING SUBMERGED ARC WIRES<br />

Lincore ® wires for submerged arc hardfacing are designed for use with specific <strong>Lincoln</strong> ® fluxes to provide optimum<br />

deposit composition, hardness and microstructure for a variety of applications.<br />

Electrode Hardness General<br />

Name Rockwell C Description<br />

Diameter Package <strong>Product</strong><br />

inches Weight Lbs. Number<br />

Build-Up<br />

Lincore ® 22-28 Rc For build-up on continuous caster rolls for the steel industry, with 801, 802 or 880 flux.<br />

20<br />

Lincore ® 24-32 Rc For build-up on tractor idler rolls, crane wheels, shafts, with 801, 802, 880 or 860 flux.<br />

30-S<br />

Lincore ® 28-36 Rc For two to three layer build-up on 4140 steel drill stems, with 802 or 803 flux.<br />

32-S<br />

Lincore ® 34-42 Rc For build-up on tractor idler rolls, crane wheels, shafts, with 801, 802 or 880 flux. Suitable<br />

35-S for flame hardening.<br />

Lincore ® 18-24 Rc For build-up for plate, rolls and sheaves, with 801, 802 or 880 flux. Suitable for flame<br />

4130 hardening.<br />

Lincore ® 16-22 Rc For build-up on continuous caster rolls for the steel industry, with 801, 802 or 880 flux.<br />

8620<br />

Metal-To-Metal Wear<br />

Lincore ® 36-42 Rc For hardfacing of tractor undercarriage parts and links with 801, 802 or 880 flux.<br />

40-S<br />

Lincore ® 38-44 Rc For hardfacing of tractor undercarriage parts and links with 801 or 802 flux.<br />

42-S<br />

Lincore ® 48-56 Rc For hardfacing continuous caster and work rolls for steel mills with 801 or 802 flux. 12% Cr<br />

96S<br />

deposit also resists corrosion.<br />

Lincore ® 48-56 Rc For hardfacing work and transfer rolls for steel mill with 802 flux. Tool steel deposit resists<br />

102W<br />

softening in PWHT.<br />

3/32 50C EDS18565<br />

1/8 50C EDS18566<br />

3/32 600D EDS18568<br />

1/8 600D ED018569<br />

5/32 600D EDS18570<br />

3/32 50C ED011200<br />

1/8 50C ED015889<br />

1/8 300D ED015890<br />

3/32 600D ED011199<br />

1/8 600D ED015891<br />

3/32 50C ED025655<br />

1/8 50C ED025129<br />

3/32 300D ED025656<br />

1/8 300D ED025130<br />

1/8 600D ED025131<br />

3/32 50C ED019880<br />

1/8 50C ED019881<br />

5/32 50C ED019882<br />

3/32 600D ED019883<br />

1/8 600D ED019884<br />

5/32 600D ED019885<br />

3/32 50C ED015265<br />

1/8 50C ED015266<br />

3/32 600D ED015532<br />

1/8 600D ED015405<br />

3/32 50C ED020787<br />

5/32 50C EDS20789<br />

1/8 600D ED020791<br />

1/8 50C ED015892<br />

1/8 300R ED016262<br />

1/8 300D ED015945<br />

1/8 600D ED015909<br />

3/32 50C EDS29162<br />

1/8 50C ED029159<br />

3/32 300D EDS29298<br />

1/8 300D ED029264<br />

3/32 600D EDS29164<br />

1/8 600D ED029161<br />

5/32 50C EDS18573<br />

3/32 600D ED018574<br />

1/8 600D ED018575<br />

5/32 600D ED018576<br />

3/32 50C ED018577<br />

1/8 50C ED018578<br />

1/8 600D ED018581<br />

5/32 600D ED018582<br />

Package Code Key: C = Coil D = Speed Feed ® Drum (wire) or Steel Drum (flux)<br />

www.lincolnelectric.com/welding-consumables<br />

139