download - prospect VitaSius - BrauKon GmbH

download - prospect VitaSius - BrauKon GmbH

download - prospect VitaSius - BrauKon GmbH

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Design and Implementation<br />

for Brewery and Beverage Industry

<strong>BrauKon</strong> <strong>VitaSius</strong><br />

Yeast degassing – Hygienic vitalization of the harvest yeast<br />

for a higher yeast vitality<br />

After the fermentation process is the harvest yeast highly stressed because<br />

of the adverse physiological alcohol and carbon dioxide content in the beer.<br />

These unfavorable conditions are mostly kept in the yeast storage tank,<br />

resulting in a slow recovery and a weak startup of the next fermentation.<br />

Even in former times brewers knew about this correlation regarding to the<br />

yeast vitality and its effect on flavor stability of beer.<br />

Due to this the harvest yeast was degassed before storage by the so-called<br />

“yeast washing” by using a yeast sieve.<br />

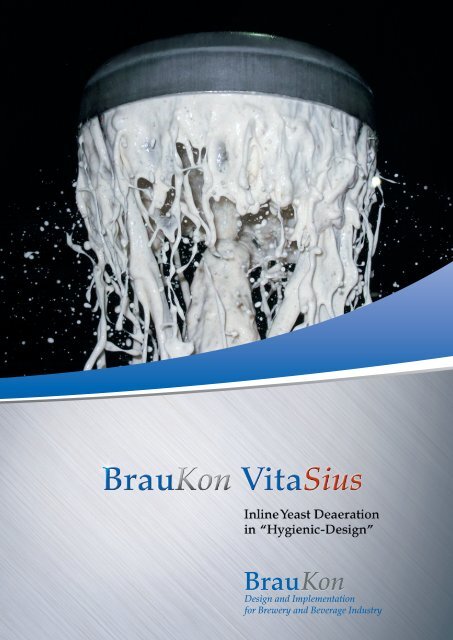

With the <strong>BrauKon</strong> <strong>VitaSius</strong> the yeast is hygienically and gently released from<br />

carbon dioxide “inline” during the harvest.<br />

This degassing is carried out in a hygienic, easy to clean in-line apparatus,<br />

which is fully integrated in the pipe cleaning process.<br />

Through the large sight glass the degassing process and harvest yeast<br />

is visible.<br />

Sterile air as carrier gas is gently added to the yeast before the degassing.<br />

The yeast is applied to the central pipe by an inlet distributor.<br />

On this occasion, the yeast is expanded by surface enlargement and carbon<br />

dioxide is emitted which is taken away from the surplus sterile air.<br />

The sterile air is consciously added without a mixing nozzle to avoid an<br />

excessive aeration of the yeast.<br />

The degassed yeast is transferred by a frequency-controlled pump to the<br />

yeast cellar.<br />

The <strong>VitaSius</strong> is fully integrated into the CIP of the yeast harvest pipe and<br />

requires no further cleaning steps.<br />

Advantages at a glance:<br />

•• Considerable higher yeast vitality<br />

•• Fresh and pleasant taste of beer<br />

•• Possibility to reduce the yeast cells for pitching<br />

•• Less dead cells in the harvest yeast<br />

•• Significant degassing of carbon dioxide<br />

•• Biological safety because of “Hygienic-Design”<br />

•• Simple and safe inline cleaning<br />

Design and Implementation<br />

for Brewery and Beverage Industry<br />

<strong>BrauKon</strong> <strong>GmbH</strong> · Mühlweg 2 · 83376 Truchtlaching, Germany<br />

phone: +49 (0) 8667 8 76 49-0 · fax: +49 (0) 8667 8 76 49-10<br />

www.braukon.com · E-mail: office@braukon.de