State Study 111 - Polymer Modified Hot Mix Asphalt Field Trial.pdf

State Study 111 - Polymer Modified Hot Mix Asphalt Field Trial.pdf

State Study 111 - Polymer Modified Hot Mix Asphalt Field Trial.pdf

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SCOPE<br />

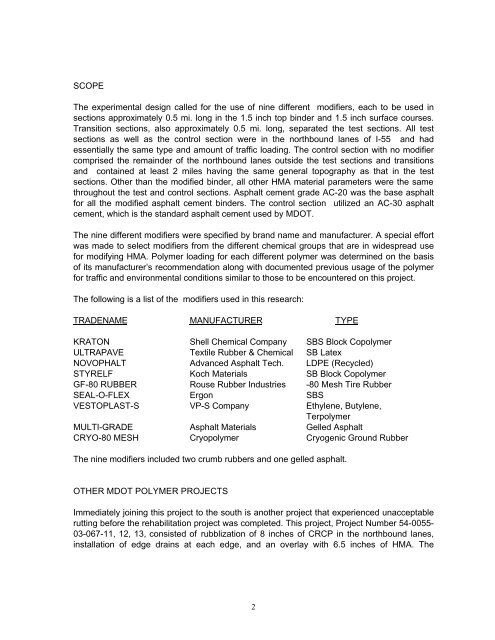

The experimental design called for the use of nine different modifiers, each to be used in<br />

sections approximately 0.5 mi. long in the 1.5 inch top binder and 1.5 inch surface courses.<br />

Transition sections, also approximately 0.5 mi. long, separated the test sections. All test<br />

sections as well as the control section were in the northbound lanes of I-55 and had<br />

essentially the same type and amount of traffic loading. The control section with no modifier<br />

comprised the remainder of the northbound lanes outside the test sections and transitions<br />

and contained at least 2 miles having the same general topography as that in the test<br />

sections. Other than the modified binder, all other HMA material parameters were the same<br />

throughout the test and control sections. <strong>Asphalt</strong> cement grade AC-20 was the base asphalt<br />

for all the modified asphalt cement binders. The control section utilized an AC-30 asphalt<br />

cement, which is the standard asphalt cement used by MDOT.<br />

The nine different modifiers were specified by brand name and manufacturer. A special effort<br />

was made to select modifiers from the different chemical groups that are in widespread use<br />

for modifying HMA. <strong>Polymer</strong> loading for each different polymer was determined on the basis<br />

of its manufacturer’s recommendation along with documented previous usage of the polymer<br />

for traffic and environmental conditions similar to those to be encountered on this project.<br />

The following is a list of the modifiers used in this research:<br />

TRADENAME MANUFACTURER TYPE<br />

KRATON Shell Chemical Company SBS Block Copolymer<br />

ULTRAPAVE Textile Rubber & Chemical SB Latex<br />

NOVOPHALT Advanced <strong>Asphalt</strong> Tech. LDPE (Recycled)<br />

STYRELF Koch Materials SB Block Copolymer<br />

GF-80 RUBBER Rouse Rubber Industries -80 Mesh Tire Rubber<br />

SEAL-O-FLEX Ergon SBS<br />

VESTOPLAST-S VP-S Company Ethylene, Butylene,<br />

Terpolymer<br />

MULTI-GRADE <strong>Asphalt</strong> Materials Gelled <strong>Asphalt</strong><br />

CRYO-80 MESH Cryopolymer Cryogenic Ground Rubber<br />

The nine modifiers included two crumb rubbers and one gelled asphalt.<br />

OTHER MDOT POLYMER PROJECTS<br />

Immediately joining this project to the south is another project that experienced unacceptable<br />

rutting before the rehabilitation project was completed. This project, Project Number 54-0055-<br />

03-067-11, 12, 13, consisted of rubblization of 8 inches of CRCP in the northbound lanes,<br />

installation of edge drains at each edge, and an overlay with 6.5 inches of HMA. The<br />

2