low-voltage

low-voltage

low-voltage

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Squirrel-cage motors<br />

Technical information<br />

Mechanical design<br />

■ Bearings<br />

Bearing life (nominal rated<br />

life)<br />

The nominal bearing life is<br />

specified by standard calculation<br />

methods (DIN ISO 281) and<br />

is achieved or exceeded by<br />

90 % of bearings when operated<br />

in accordance with catalog<br />

specifications.<br />

If the operating conditions are<br />

be<strong>low</strong> average, a bearing life of<br />

100,000 (L h10 ) hours can be<br />

achieved.<br />

The bearing life essentially depends<br />

on the size of the bearing,<br />

the load, the operating conditions,<br />

the speed, and the relubrication<br />

interval.<br />

Bearing system<br />

The nominal bearing life of motors<br />

with horizontal type of construction<br />

is at least 40,000 hours<br />

if there is no additional axial<br />

loading at the output coupling;<br />

with the maximum permitted<br />

loads it is at least 20,000 hours.<br />

This is provided that the motor is<br />

operated at 50 Hz. The nominal<br />

bearing life is reduced for converter-fed<br />

operation with higher<br />

frequencies.<br />

In the basic design of the bearings<br />

system, the floating bearing<br />

is at the drive end (DE) and<br />

the located bearing (axially<br />

fixed from frame size 160) at the<br />

non-drive end (NDE). The located<br />

bearings can also be fitted to<br />

the drive end (DE) on request,<br />

(Fig. 3 Page 2/34).<br />

Order Code K94<br />

The bearings system is axially<br />

pre-loaded with a spring which<br />

ensures that the motor runs<br />

smoothly and free of clearance.<br />

This does not apply to designs<br />

with parallel roller bearings. The<br />

bearings of these motors must<br />

always be operated with sufficient<br />

radial force (do not operate<br />

motor in test bay without additional<br />

axial loading).<br />

The motors of the 1LA6, 1LA7,<br />

1LA9, and 1MA7 series up to<br />

and including frame size 132<br />

are fitted with a floating bearings<br />

system (Fig. 1 Page 2/34).<br />

An additional axially secured<br />

bearing at the non-drive end<br />

(NDE) with a retaining ring can<br />

be delivered up to frame size<br />

132 on request (Fig. 2<br />

Page 2/34).<br />

Order Code L04<br />

From frame size 160, all bearings<br />

are axially fixed (Fig. 2, 4,<br />

and 5, Page 2/34).<br />

If high cantilever forces are exerted<br />

at the drive end, e.g. owing<br />

to a belt transmission, the<br />

motors can be fitted with<br />

strengthened bearings on request.<br />

Order Code K20<br />

The 1LG4/6 motors with frame<br />

sizes 180 to 250 and with frame<br />

size 315, 2-pole, are available<br />

with strengthened deep groove<br />

ball bearings on both sides<br />

(dimension series 03).<br />

Order Code K36<br />

See pages 2/32 and 2/33 for a<br />

selection of bearings for high<br />

cantilever forces; maximum<br />

loadings on Page 2/37.<br />

Prelubricated<br />

For prelubricated bearings, the<br />

grease life is tailored to the<br />

bearing life. However, the motor<br />

must be operated according to<br />

catalogue specifications.<br />

Standard motors with a frame<br />

size of up to and including 250<br />

are prelubricated.<br />

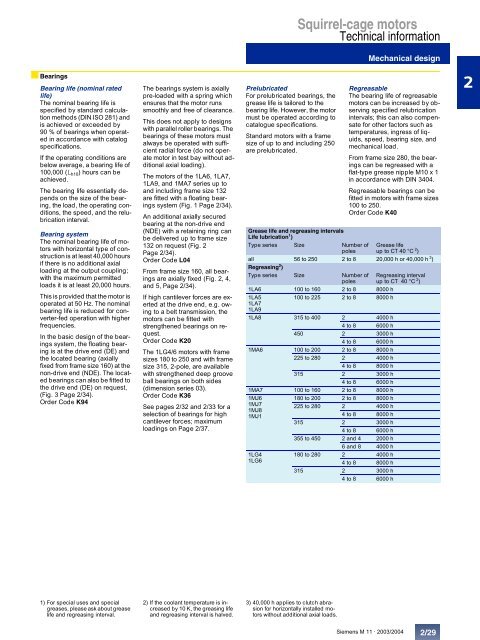

Grease life and regreasing intervals<br />

Life lubrication 1 )<br />

Type series Size Number of<br />

poles<br />

Regreasable<br />

The bearing life of regreasable<br />

motors can be increased by observing<br />

specified relubrication<br />

intervals; this can also compensate<br />

for other factors such as<br />

temperatures, ingress of liquids,<br />

speed, bearing size, and<br />

mechanical load.<br />

From frame size 280, the bearings<br />

can be regreased with a<br />

flat-type grease nipple M10 x 1<br />

in accordance with DIN 3404.<br />

Regreasable bearings can be<br />

fitted in motors with frame sizes<br />

100 to 250.<br />

Order Code K40<br />

Grease life<br />

up to CT 40 °C 2 )<br />

all 56 to 250 2 to 8 20,000 h or 40,000 h 3 )<br />

Regreasing 2 )<br />

Type series Size Number of<br />

poles<br />

1LA6 100 to 160 2 to 8 8000 h<br />

1LA5<br />

100 to 225 2 to 8 8000 h<br />

1LA7<br />

1LA9<br />

1LA8 315 to 400 2 4000 h<br />

4 to 8 6000 h<br />

450 2 3000 h<br />

4 to 8 6000 h<br />

1MA6 100 to 200 2 to 8 8000 h<br />

225 to 280 2 4000 h<br />

4 to 8 8000 h<br />

315 2 3000 h<br />

4 to 8 6000 h<br />

1MA7 100 to 160 2 to 8 8000 h<br />

1MJ6<br />

1MJ7<br />

1MJ8<br />

1MJ1<br />

180 to 200 2 to 8 8000 h<br />

225 to 280 2 4000 h<br />

4 to 8 8000 h<br />

315 2 3000 h<br />

4 to 8 6000 h<br />

355 to 450 2 and 4 2000 h<br />

6 and 8 4000 h<br />

180 to 280 2 4000 h<br />

4 to 8 8000 h<br />

315 2 3000 h<br />

4 to 8 6000 h<br />

Regreasing interval<br />

up to CT 40 °C 2 )<br />

2<br />

1LG4<br />

1LG6<br />

1) For special uses and special<br />

greases, please ask about grease<br />

life and regreasing interval.<br />

2) If the coolant temperature is increased<br />

by 10 K, the greasing life<br />

and regreasing interval is halved.<br />

3) 40,000 h applies to clutch abrasion<br />

for horizontally installed motors<br />

without additional axial loads.<br />

Siemens M 11 · 2003/2004 2/29