Download pdf - International Potato Center

Download pdf - International Potato Center

Download pdf - International Potato Center

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CIP • SOCIAL SCIENCES WORKING PAPER 2010-1<br />

The most important source of potatoes for 71% of retail outlets in Burundi is imports from<br />

Rwanda, which is dominated by a popular variety for chips making called Ruhengeri. Other retail<br />

outlets source their potatoes from local retail markets.<br />

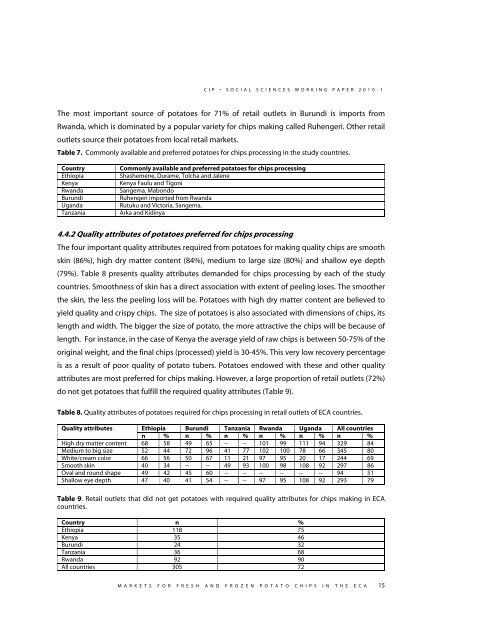

Table 7. Commonly available and preferred potatoes for chips processing in the study countries.<br />

Country<br />

Ethiopia<br />

Kenya<br />

Rwanda<br />

Burundi<br />

Uganda<br />

Tanzania<br />

Commonly available and preferred potatoes for chips processing<br />

Shashemene, Durame, Tolcha and Jalene<br />

Kenya Faulu and Tigoni<br />

Sangema, Mabondo<br />

Ruhengeri imported from Rwanda<br />

Rutuku and Victoria, Sangema,<br />

Arka and Kidinya<br />

4.4.2 Quality attributes of potatoes preferred for chips processing<br />

The four important quality attributes required from potatoes for making quality chips are smooth<br />

skin (86%), high dry matter content (84%), medium to large size (80%) and shallow eye depth<br />

(79%). Table 8 presents quality attributes demanded for chips processing by each of the study<br />

countries. Smoothness of skin has a direct association with extent of peeling loses. The smoother<br />

the skin, the less the peeling loss will be. <strong>Potato</strong>es with high dry matter content are believed to<br />

yield quality and crispy chips. The size of potatoes is also associated with dimensions of chips, its<br />

length and width. The bigger the size of potato, the more attractive the chips will be because of<br />

length. For instance, in the case of Kenya the average yield of raw chips is between 50-75% of the<br />

original weight, and the final chips (processed) yield is 30-45%. This very low recovery percentage<br />

is as a result of poor quality of potato tubers. <strong>Potato</strong>es endowed with these and other quality<br />

attributes are most preferred for chips making. However, a large proportion of retail outlets (72%)<br />

do not get potatoes that fulfill the required quality attributes (Table 9).<br />

Table 8. Quality attributes of potatoes required for chips processing in retail outlets of ECA countries.<br />

Quality attributes<br />

Ethiopia Burundi Tanzania Rwanda Uganda All countries<br />

n % n % n % n % n % n %<br />

High dry matter content 68 58 49 65 -- -- 101 99 111 94 329 84<br />

Medium to big size 52 44 72 96 41 77 102 100 78 66 345 80<br />

White/cream color 66 56 50 67 11 21 97 95 20 17 244 69<br />

Smooth skin 40 34 -- -- 49 93 100 98 108 92 297 86<br />

Oval and round shape 49 42 45 60 -- -- -- -- -- -- 94 51<br />

Shallow eye depth 47 40 41 54 -- -- 97 95 108 92 293 79<br />

Table 9. Retail outlets that did not get potatoes with required quality attributes for chips making in ECA<br />

countries.<br />

Country n %<br />

Ethiopia 118 75<br />

Kenya 35 46<br />

Burundi 24 32<br />

Tanzania 36 68<br />

Rwanda 92 90<br />

All countries 305 72<br />

M A R K E T S F O R F R E S H A N D F R O Z E N P O T A T O C H I P S I N T H E E C A 15