DAZ-TA Pro

DAZ-TA Pro

DAZ-TA Pro

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

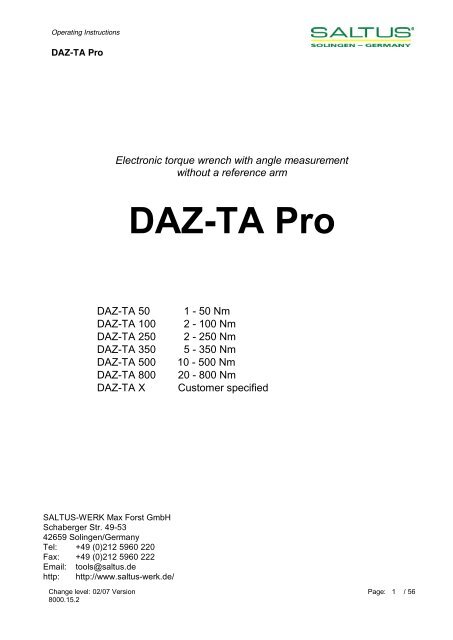

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

Electronic torque wrench with angle measurement<br />

without a reference arm<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

Measuring range<br />

1% in accordance<br />

with DIN 6789<br />

<strong>DAZ</strong>-<strong>TA</strong> 50 1 - 50 Nm 5 - 50 Nm<br />

<strong>DAZ</strong>-<strong>TA</strong> 100 2 - 100 Nm 10 - 100 Nm<br />

<strong>DAZ</strong>-<strong>TA</strong> 250 2 - 250 Nm 25 - 250 Nm<br />

<strong>DAZ</strong>-<strong>TA</strong> 350 5 - 350 Nm 35 - 350 Nm<br />

<strong>DAZ</strong>-<strong>TA</strong> 500 10 - 500 Nm 50 - 500 Nm<br />

<strong>DAZ</strong>-<strong>TA</strong> 800 20 - 800 Nm 80 - 800 Nm<br />

<strong>DAZ</strong>-<strong>TA</strong> X Customer specified<br />

SALTUS-WERK Max Forst GmbH<br />

Schaberger Str. 49-53<br />

42659 Solingen/Germany<br />

Tel: +49 (0)212 5960 220<br />

Fax: +49 (0)212 5960 222<br />

Email: tools@saltus.de<br />

http: http://www.saltus-werk.de/<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 1 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

I. Contents<br />

1. Layout<br />

1.1 Safety instructions<br />

1.2 Technical specifications<br />

1.3 Display<br />

1.4 Functions of the LEDs<br />

1.5 Display messages<br />

1.6 Keypad<br />

1.7 Menu structure/overview<br />

2. Operation<br />

2.1.0 Switching on<br />

2.2.0 Standard display<br />

2.3.0 Reading display<br />

2.4.0 Navigating between various joints<br />

3.0.0.0 Main menu: Start/password protection/navigating through the menu<br />

3.1.0.0 Main menu: Entering presets: Adding a new joint with its presets<br />

3.2.0.0 Main menu: Joint<br />

3.2.1.0 Main menu: Joint: Edit<br />

3.2.1.1 Main menu: Joint: Edit: Joint data<br />

3.2.2.0 Main menu: Joint: Explanation of the measuring methods<br />

3.2.2.1 Main menu: Joint: Measuring method: Torque/angle-controlled measurement<br />

3.2.2.2 Main menu: Joint: Measuring method: Torque measurement<br />

3.2.2.3 Main menu: Joint: Measuring method: Track<br />

3.2.2.4 Main menu: Joint: Measuring method: Prevail torque measurement<br />

3.2.2.5 Main menu: Joint: Measuring method: Loosening<br />

3.2.2.6 Main menu: Joint: Measuring method: Torque and/or angle measurement<br />

3.2.2.7 Main menu: Joint: Measuring method: Yield strength detection<br />

3.2.3.0 Main menu: Joint: Delete<br />

3.2.4.0 Main menu: Joint: Print all<br />

3.3.0.0 Main menu: Tightening sequence<br />

3.3.1.0 Main menu: Tightening sequence: Create<br />

3.3.1.1 Main menu: Tightening sequence: Create: Sequence name<br />

3.3.1.2 Main menu: Tightening sequence: Create: Sequence programming step<br />

3.3.2.0 Main menu: Tightening sequence: Select<br />

3.4.0.0 Main menu: Memory<br />

3.4.1.1 Main menu: Memory: Clearing the memory<br />

3.4.1.2 Main menu: Memory: Print memory<br />

3.5.0.0 Main menu: Angle zeroing<br />

3.6.0.0 Main menu: Angle stability control<br />

3.7.0.0 Main menu: Settings<br />

3.7.1.0 Main menu: Settings: Tool data<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 2 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.7.1.1 Main menu: Settings: Tool data: Extension<br />

3.7.1.2 Main menu: Settings: Tool data: Bending<br />

3.7.1.3 Main menu: Settings: Tool data: Dynamic snug<br />

3.7.1.4 Main menu: Settings: Tool data: Max. angle rate<br />

3.7.1.5 Main menu: Settings: Tool data: Tightening time<br />

3.7.1.6 Main menu: Settings: Tool data: Tool ID<br />

3.7.2.0 Main menu: Settings: ID code/product name<br />

3.7.3.0 Main menu: Settings: Autoprint/auto-zero balance<br />

3.7.4.0 Main menu: Settings: Advance warning point<br />

3.7.5.0 Main menu: Settings: Measuring graph/pitch behaviour at yield point<br />

3.7.6.0 Main menu: Settings: Time<br />

3.7.7.0 Main menu: Settings: Date<br />

3.7.8.0 Main menu: Settings: Tool detection (optional)<br />

3.7.9.0 Main menu: Settings: Advanced settings<br />

3.7.9.1 Main menu: Settings: Advanced settings: Wrench number<br />

3.7.9.2 Main menu: Settings: Advanced settings: Unit<br />

3.7.9.3 Main menu: Settings: Advanced settings: Language<br />

3.7.9.4 Main menu: Settings: Advanced settings: Turn-off time<br />

3.7.9.5 Main menu: Settings: Advanced settings: RS232/V.24<br />

3.7.9.6 Main menu: Settings: Advanced settings: Reset<br />

3.7.10.0 Main menu: Settings: Calibration settings<br />

3.7.10.1 Main menu: Settings: Calibration settings: Torque calibration<br />

3.7.10.2 Main menu: Settings: Calibration settings: Angle calibration<br />

3.7.10.3 Main menu: Settings: Calibration settings: Calibrating an extension<br />

3.7.10.4 Main menu: Settings: Calibration settings: Calibration date<br />

3.7.10.5 Main menu: Settings: Calibration settings: Calibration counter<br />

3.7.10.6 Main menu: Settings: Calibration settings: Mechanical overload<br />

3.7.10.7 Main menu: Settings: Calibration settings: Flash update<br />

3.8.0.0 Main menu: Information<br />

3.9.0.0 Main menu: Statistics<br />

4. Power supply<br />

4.1 Charging the battery<br />

4.2 Changing the battery<br />

5. Data transfer<br />

5.1 Transferring data to the printer<br />

5.2 Transferring data to and from a PC<br />

6. Service<br />

7. Important notes<br />

7.1 Disclaimer<br />

7.2 Trade marks<br />

7.3 Restrictions on use<br />

7.4 Warranty notes<br />

7.5 Service notes<br />

7.6 Form for service notes<br />

APENDIX: Enquiry form for customer-specific tool development<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 3 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

1. Layout<br />

1.1 Safety instructions<br />

torque wrench, please observe the following points:<br />

To ensure safe working with your SALTUS®<br />

- This torque wrench is a tightening tool which allows a defined torque to be applied to<br />

fasteners and may only be used by authorised staff after the appropriate training.<br />

- To guarantee accurate readings and to prevent accidents, the torque wrench must be<br />

gripped firmly by the handle - and only the handle - at all times while it is being used.<br />

- Before using the tool, check that it shows no signs of damage and only use perfect tools.<br />

Never use damaged tools!<br />

- The electronic components used in conjunction with this tool must be operated extremely<br />

carefully and in compliance with legal provisions for accident prevention.<br />

- Only apply force to the wrench up to the maximum rated value. Overloading the wrench<br />

can cause it to rupture (danger of personal injury).<br />

- Do not use a torque wrench to loosen seized bolts and rusty screws because there is<br />

considerable risk of damage to the wrench.<br />

- Make sure the torque wrench is never exposed to fluids and do not allow foreign bodies to<br />

penetrate the tool. Otherwise, the torque wrench may be damaged.<br />

- Observe the maximum tightening torques recommended by the manufacturers of the<br />

fasteners.<br />

- Do not apply pressure to the display because this might damage it.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 4 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

1.2 Technical specifications<br />

The SALTUS® <strong>TA</strong> Series torque wrenches conform with EU Directive 2002/95/EC (RoHS Directive).<br />

Measuring range: <strong>DAZ</strong>-<strong>TA</strong> 50 1 - 50 Nm 9 x 12 ± 1% for 5 – 50 Nm<br />

<strong>DAZ</strong>-<strong>TA</strong> 100 2 - 100 Nm 9 x 12 ± 1% for 10 – 100 Nm<br />

<strong>DAZ</strong>-<strong>TA</strong> 250 2 - 250 Nm 14 x 18 ± 1% for 25 – 250 Nm<br />

<strong>DAZ</strong>-<strong>TA</strong> 350 5 - 350 Nm 14 x 18 ± 1% for 35 – 350 Nm<br />

<strong>DAZ</strong>-<strong>TA</strong> 500 10 - 500 Nm 14 x 18 ± 1% for 50 – 500 Nm<br />

<strong>DAZ</strong>-<strong>TA</strong> 800 20 - 800 Nm 14 x 18 ± 1% for 80 – 800 Nm<br />

Zero balance:<br />

Automatic<br />

Measuring accuracy: Torque (Nm): max. deviation ±1% in accordance with DIN 6789<br />

angle (DEG) : max. deviation ±1% at 6°/s over 360° = 1 r.p.m.<br />

by analogy with VDI/VDE 2648<br />

Resolution:<br />

0,01 Nm<br />

0.01° (DEG)<br />

Angle rate:<br />

Measuring methods:<br />

Torque display:<br />

LED display:<br />

Status messages:<br />

Memory:<br />

from 1 °/s to 150 °/s (adjustable)<br />

M0 = Torque / angle (N)<br />

M1 = torque (D)<br />

M2 = Analogue/track mode (25 readings /s via RS232) (tightening curve storage)<br />

(A)<br />

M3 = prevail torque (tightening curve storage) (B;PT;FT)<br />

M4 = loosening (U)<br />

M5 = Either/or mode (torque - and/or angle measurement) (O)<br />

M6 = Yield strength detection (tightening curve storage) (S)<br />

LCD graphics display<br />

2 RGB LEDs (upper LED = torque, lower LED = angle)<br />

Min. and max. values displayed by 2 RGB LEDs (red, green & blue)<br />

and display message, with acoustic signal & vibration alarm as an<br />

option<br />

4000 readings,<br />

Tightening curve storage with 100 readings /s<br />

(from the last 5 tightening curves with 1200 pairs of readings each)<br />

Tool detection:<br />

Optional for 14x18 as automatic (5) or interactive method<br />

Tool management: Five with separate extension, bending compensation, dynamic snug<br />

point, tightening speed and tightening time details.<br />

Joints: 50<br />

Sequences:<br />

50 with a max. total of 50 joints each<br />

User levels: 3<br />

Power supply:<br />

3 x 1.2V rechargeable cells (NiMH AA 2450 mAh) for 8 hours'<br />

operation, interchangeable<br />

Mains adaptor/charging cradle: 12 V / 700 mAh<br />

Operating temperature: +10 to +40 °C<br />

Storage temperature: -10 to +50 °C<br />

Dimensions: <strong>DAZ</strong>-<strong>TA</strong> 50 53 x 36 x 396 mm (approx. 890 g)<br />

<strong>DAZ</strong>-<strong>TA</strong> 100 53 x 36 x 396 mm (approx. 890 g)<br />

<strong>DAZ</strong>-<strong>TA</strong> 250 53 x 36 x 420 mm (approx. 1000 g)<br />

<strong>DAZ</strong>-<strong>TA</strong> 350 53 x 36 x 580 mm (approx. 1600 g)<br />

<strong>DAZ</strong>-<strong>TA</strong> 500 53 x 36 x 736 mm (approx. 3080 g)<br />

<strong>DAZ</strong>-<strong>TA</strong> 800 53 x 36 x 1237 mm (approx. 5810 g)<br />

Interface: RS 232<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 5 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

1.3 Display<br />

Standard display<br />

1.4 Functions of the LEDs<br />

Snug point reached in torque/angle (N) measuring mode<br />

Torque: (blue) snug point reached<br />

Angle: (off) not yet reached<br />

Preset reached (OK) in torque/angle (N) measuring mode<br />

Torque: (green) OK<br />

Angle: (green) OK<br />

Torque exceeded (not OK) in torque/angle (N) measuring mode<br />

Torque: (red) Not OK<br />

Angle: (green) OK<br />

Torque and angle exceeded (not OK) in torque/angle (N) measuring mode<br />

Torque: (red) Not OK<br />

Angle: (red) Not OK<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 6 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

NOK<br />

Nm<br />

Max Nm<br />

Deviation<br />

Target Nm = (Max Nm +Min Nm)/2<br />

OK<br />

Min Nm<br />

advance warning Nm = 80% Set Nm<br />

LED Nm<br />

snug point<br />

0°<br />

snug point<br />

advance warning Nm = 80% Set Nm<br />

Min °<br />

Target ° = (Max ° +Min °)/2<br />

Max °<br />

LED °<br />

OK<br />

NOK<br />

TORQUE LED Nm:<br />

Upper LED flashes blue:<br />

Upper LED shows steady blue:<br />

Upper LED flashes green:<br />

Upper LED shows steady green:<br />

Upper LED shows steady red:<br />

TIGHTENING ANGLE LED°:<br />

Lower LED flashes blue:<br />

Lower LED shows steady blue:<br />

Lower LED flashes green:<br />

Lower LED shows steady green:<br />

Lower LED shows steady red:<br />

Snug point reached<br />

Advance warning point attained<br />

Min. torque attained (OK)<br />

Preset torque attained (OK)<br />

Max. torque attained (Not OK)<br />

Snug point attained (start angle measurement)<br />

Advance angle warning point attained<br />

Min. angle attained (OK)<br />

Preset angle attained (OK)<br />

Max. angle attained (Not OK)<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 7 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

1.5 Display messages<br />

DISPLAY MESSAGES:<br />

Check Calibr.! CC1 Wrench overloaded. Check calibration before reusing.<br />

Check Calibr.! CC2 Calibration counter/date has been exceeded. Check<br />

calibration before reusing.<br />

Tare angle!<br />

The angle sensor's zero balance is working.<br />

<strong>TA</strong>RA<br />

The angle sensor's zero balance is working. (charging cradle)<br />

Hold still!<br />

The wrench was moved during the angle zeroing process.<br />

Release!<br />

Force is being applied - please do not apply force to the<br />

wrench.<br />

Memory full!<br />

The corresponding memory is full.<br />

Memory empty!<br />

The corresponding memory is empty.<br />

Blocked!<br />

The wrench is blocked if the link to the computer, for<br />

example, is active.<br />

Printing!<br />

The wrench is currently transferring data to a peripheral<br />

device.<br />

Power off!<br />

The wrench is switching off.<br />

No stats!<br />

The system could not calculate any statistics.<br />

No PT!<br />

The system could not calculate prevail torque.<br />

No YP!<br />

The system could not calculate the yield point.<br />

ERROR MESSAGES - upper and lower LEDs flash red:<br />

Existing screw!<br />

An existing joint (DDT) has been detected (Not OK)<br />

Max. angle rate!<br />

Max. angle rate (MVA) exceeded (Not OK)<br />

ERROR MESSAGES:<br />

EEprom init<br />

Default values were reset after a flash update.<br />

EEP failed<br />

The setting data are corrupt.<br />

ADC system<br />

AD converter is faulty.<br />

Code memory<br />

<strong>Pro</strong>gram memory and wrench software are corrupt.<br />

RAM memory CPU memory faulty<br />

Oscillator<br />

The oscillator is operating outside the permissible<br />

specifications.<br />

Sensor<br />

Automatic zero balance has failed.<br />

Power-up RESET! The wrench has been reset (data have been lost) and default<br />

values have been reinstated (refer to RESET).<br />

1.6 Keypad<br />

1.7 Menu structure/overview<br />

ON<br />

OFF<br />

ON OFF-Key<br />

PRINT<br />

Print-Key<br />

-0-<br />

Zero - Key<br />

SET<br />

SET-Key<br />

Up<br />

Down<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 8 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.0.0.0<br />

Enter Setpoint<br />

3.1.0.0<br />

Target Force<br />

Target Angle<br />

Deviation<br />

Denotation<br />

default:<br />

tool= t1<br />

mode = M0<br />

Angle/Torque<br />

Bolts presettings<br />

3.2.0.0<br />

Selection<br />

bolts settings<br />

0-50<br />

Print all<br />

Edit<br />

copy<br />

delete<br />

add<br />

change<br />

3.2.4.0<br />

3.2.1.0<br />

3.2.3.0<br />

MIN Force<br />

MAX Force<br />

snug point<br />

MIN Angle<br />

MAX Angle<br />

rotation<br />

priority<br />

measure mode<br />

rehit detection<br />

tool<br />

<strong>Pro</strong>cess<br />

sequence<br />

3.3.0.0<br />

Print<br />

Select<br />

delete<br />

create<br />

3.3.2.0<br />

3.3.1.0<br />

select of<br />

batchsequence 1-50<br />

Denotation<br />

enter of batchsequence 1-<br />

50<br />

select<br />

steps<br />

1-50<br />

swap<br />

add<br />

delete<br />

MAINMENUE<br />

Memory 3.4.0.0<br />

Angle Tare<br />

3.5.0.0<br />

Statistics<br />

Angle stability<br />

3.6.0.0<br />

Setup<br />

3.7.0.0<br />

Information<br />

3.8.0.0<br />

visual data<br />

manual compensation<br />

Number<br />

Filter: Joint<br />

Filter: ID<br />

X = 3 or 4<br />

visual stability<br />

tool set<br />

ID Code<br />

Autom.Print<br />

time<br />

date<br />

calibration settings<br />

delete<br />

print<br />

adjustment<br />

select<br />

tool t1-t5<br />

Edit<br />

time for Autoprint<br />

advance warn. 3.7.4.0 value in %<br />

gradient 3.7.5.0 value in %<br />

tool recognition<br />

3.7.8.0<br />

Extra Setup<br />

3.7.1.0<br />

3.7.2.0<br />

3.7.3.0<br />

3.7.6.0<br />

3.7.7.0<br />

3.7.9.0<br />

3.7.10.0<br />

Calculation:<br />

Standard deviation<br />

Cm value<br />

Cmk value<br />

time<br />

date<br />

disable/off<br />

usermode<br />

automatic<br />

wrench No.<br />

unit<br />

time / date<br />

no. of bolts / tool iD<br />

batterystatus / no. of stored values<br />

language 3.7.9.3 english,french,german<br />

turn off time 3.7.9.4<br />

RS232/V.24 3.7.9.5<br />

Reset<br />

3.4.1.1<br />

3.4.1.2<br />

3.7.9.1<br />

3.7.9.2<br />

3.7.9.6<br />

Flashupdate<br />

torque calib. 3.7.10.1<br />

angle calib. 3.7.10.2<br />

Extension 3.7.10.3<br />

calib. Date 3.7.10.4<br />

calib. counter 3.7.10.5<br />

Extension 3.7.1.1<br />

Bending<br />

Dynamic FGP<br />

max. rate of angle<br />

working time<br />

Denotation 3.7.1.6<br />

automatic control<br />

from tool t1-t5 based on<br />

bolt setting 1-5<br />

wrench no.<br />

unit<br />

shut down time<br />

baudrate<br />

restore default<br />

userlevel low<br />

userlevel middle<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 9 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

2. Operation<br />

2.1.0 Switching on<br />

Turn on the wrench by pressing the ON/OFF switch for 1 sec. The wrench will perform a<br />

self-test including a zero balance and angle zeroing and is ready for use after the zeroing<br />

message has been displayed. Angle zeroing should be performed while the wrench is still<br />

in its cradle or, if it is not, the wrench must not be moved at all. When the wrench is in its<br />

cradle, zeroing is performed automatically every 60 s (Tara), during which the keypad is<br />

blocked. After zeroing has completed, the display will show the current reading 0.00 Nm,<br />

the unit of measure (e.g. Nm), the current joint, the direction of rotation (R or L), the<br />

current measuring mode (M0 = torque/angle, M1 = torque, M2 = track , M3 = prevail<br />

torque, M4 = loosen, M5 = torque and/or angle, M6 = yield strength detection) and the<br />

current sequence.<br />

Display after switching on:<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

Fw. Rel. 8000.15.1<br />

SN: 127796<br />

5s<br />

Version and serial number (for 5 s)<br />

Message:<br />

Tare angle<br />

Zero balance/angle zeroing (on start-up approx. 60 s)<br />

During this procedure the wrench must not be moved at all and must be left in its<br />

charging cradle.<br />

2.2.0 Standard display<br />

Joint<br />

Direction of rotation<br />

Measuring mode<br />

Sequence name<br />

INTERN<br />

21:58<br />

R<br />

M0<br />

0.00 Nm<br />

Wrench is now ready for use.<br />

Time<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 10 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

2.3.0 Reading display<br />

Joint<br />

Direction of rotation<br />

INTERN<br />

21:58<br />

R<br />

18.32 o<br />

Time<br />

Angle bracket<br />

Torque<br />

Sequence name 20.10<br />

Bending compensation /<br />

Tightening time<br />

The wrench is currently measuring, use the Print button to stop the measurement and<br />

store the data. To do so, the wrench must be released.<br />

2.4.0 Navigating between various joints<br />

Press the UP/DOWN selector keys while in the standard display and select the required<br />

joint option. Up to 50 different joints can be preset and pressing the SET button briefly<br />

displays the data for the currently selected joint:<br />

Joint name<br />

Min. tque. Max. tque.<br />

Min. angle Max. angle<br />

# 0 INTERN<br />

15.0 25.0 15.0<br />

25° 35° 0°<br />

clockwise W1 *<br />

Snug point<br />

Preangle<br />

Direction of rotation Tools (W1 – W5)<br />

Priority<br />

3.0.0.0 Main menu: Start/password protection/navigating through the menu<br />

Access the main menu as described below to make or modify appropriate settings,<br />

depending on your user access level.<br />

Press the SET button for approx. 2 s to access the setup menu<br />

You will be prompted to enter a security code once after start-up:<br />

Enter CODE:<br />

x<br />

SET : Clockw<br />

ESC : Ok -0-: Clr<br />

Use the UP/DOWN selector keys to enter the appropriate code/PIN (user levels: Operator<br />

= 123 (read only) or Foreman = 456 (read/write))<br />

User level: Setter/QA = XXXX (calibration menu/write/read))<br />

SET button to move on to next value or zero button to clear the display.<br />

Note: The selected user level is not deactivated until the torque wrench is switched<br />

off.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 11 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

Enter CODE:<br />

123X<br />

SET : Clockw<br />

ESC : Ok -0-: Clr<br />

After entering the next number, press the SET button again, and return to the main menu<br />

by pressing the ON/OFF button:<br />

Main menu:<br />

Information<br />

Enter preset<br />

Joint<br />

To select menu options<br />

To confirm your selection<br />

To leave the menu option<br />

To leave the setup menu<br />

use the UP / DOWN keys to select an option<br />

press the SET button<br />

press the ON/OFF button<br />

press the ON/OFF button<br />

Of course, you may use our software to make and adjust settings and to programme the<br />

wrench quickly and easily. Contact us or download a demo version from our website:<br />

http://www.saltus-werk.de/.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 12 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.1.0.0 Main menu: Entering presets: Adding a new joint with its presets<br />

Activate the main menu as described at Point 3.0.0.0 (menu option Enter presets) and<br />

press the SET button, then use the UP/DOWN selector keys to adjust the parameter as<br />

required and then press the SET button to move on to the next number.<br />

Main menu:<br />

Information<br />

Enter preset<br />

Joint<br />

If the message: "Memory full!" appears, the maximum number of joints has been<br />

reached and you will have to delete one or more joints before you can proceed.<br />

Tightening torque preset:<br />

TORQUE PRESET:<br />

20.0 Nm<br />

Min: 2.0 Max: 250.0<br />

Tightening angle preset:<br />

PRESET ANGLE:<br />

30°<br />

Min: 1 Max: 1200<br />

Tolerance:<br />

DEVIATION:<br />

10 %<br />

Min: 1 Max: 100<br />

Name:<br />

Name:<br />

NEWX<br />

SET : Clockw<br />

ESC : Ok -0-: Clr<br />

Joint:<br />

# 14 NEW<br />

22.0 220.0 20.0<br />

27° 33° 0°<br />

clockwise W1 *<br />

Press the UP/DOWN selector keys while in<br />

this display to adjust the name (max. 15<br />

characters) and use the ON/OFF button to<br />

leave the display.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Measuring mode: Torque/angle-controlled<br />

measurement<br />

Tools: W1<br />

Snug point = torque preset<br />

Minimum torque: preset + tolerance<br />

Maximum torque: Limit of torque range<br />

Minimum angle: preset - tolerance<br />

Maximum angle: preset + tolerance<br />

Direction of rotation: clockwise<br />

Page: 13 / 56<br />

Priority: High (*)<br />

Preangle: 0° no detection of an existing joint

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

Press the ON/OFF button twice to return the wrench to the current joint where it will be<br />

ready to make readings using the above measuring mode and direction of rotation.<br />

If you need to modify any of the displayed parameters again, select the "joint" menu<br />

option. Select a joint and press the SET button, then , under Edit, you will be able to edit<br />

this joint again, see Point 2.2.1.0.<br />

3.2.0.0 Main menu: Joint<br />

Activate the main menu as described at Point 3.0.0.0 and select the Joint menu option,<br />

press the SET button.<br />

Main menu:<br />

Enter preset<br />

Joint<br />

Tightening sequence<br />

Joint name<br />

Min. tque. Max. tque.<br />

Min. angle Max. angle<br />

# 0 INTERN<br />

15.0 25.0 15.0<br />

25° 35° 0°<br />

Snug point<br />

Preangle<br />

Direction of rotation Tools (W1 – W5)<br />

clockwise W1 *<br />

Priority<br />

Press the UP/DOWN selector keys while in this display to select the required settings. Up<br />

to 50 different joints can be preset and pressing the SET button briefly displays the data<br />

for the currently selected joint.<br />

3.2.1.0 Main menu: Joint: Edit<br />

Activate the main menu as described at Point 3.2.0.0 and select a joint, press the SET<br />

button.<br />

SCREW (N) MENU:<br />

Print all<br />

Edit<br />

Add<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 14 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.2.1.1 Main menu: Joint: Edit: Joint data<br />

Activate the settings menu as described at Point 3.2.1.0 and press the SET button, then<br />

use the UP/DOWN selector keys (within the displayed min. and max. limits) to adjust the<br />

parameter as required and then press the SET button to move on to the next number.<br />

Minimum torque:<br />

TORQUE MIN:<br />

15.0 Nm<br />

Min: 2.0 Max: 25.0<br />

Maximum torque:<br />

TORQUE MAX:<br />

25.0 Nm<br />

Min: 15.0 Max: 220.0<br />

Snug point:<br />

SNUG POINT DFF:<br />

15.0 Nm<br />

Min: 2.0 Max: 25.0<br />

Minimum angle:<br />

MIN ANGLE:<br />

25°<br />

Min: 2.0 Max: 35<br />

Maximum angle:<br />

MAX ANGLE:<br />

35°<br />

Min: 25 Max: 1200<br />

Direction of rotation/direction of tightening:<br />

sequences)<br />

Direction of rotation:<br />

Anticlockwise<br />

clockwise<br />

Measuring mode:<br />

Priority: (for processing<br />

Priority:<br />

Low ’ # ’<br />

High ’ * ’<br />

Detection of existing joint:<br />

Measuring mode:<br />

yield point (YP)<br />

Angle/torque<br />

Torque<br />

PREANGLE MEAS.<br />

5°<br />

Min: 1 Max: 15<br />

See Point 3.2.2.0<br />

M0 Angle/torque: Torque/angle-controlled measurement<br />

M1 Torque:<br />

Torque measurement<br />

M2 Track: Free measurement, 25 values /s<br />

M3 Prevail torque: Measuring prevail torque<br />

M4 Loosen:<br />

Torque measurement at lowest value<br />

M5 Either Or:<br />

Torque and/or angle measurement<br />

M6 Yield point:<br />

Yield strength detection<br />

Change level: 02/07 Version<br />

8000.15.2<br />

.<br />

Refer to lower figure: If the snug point is reached within<br />

the preangle (e.g. 5°), the wrench will show "Existing<br />

joint" (DDT)<br />

(Joint Not OK).<br />

Page: 15 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

Nm<br />

30<br />

40<br />

38.14<br />

25<br />

35<br />

32.44<br />

30<br />

20<br />

Maximum<br />

angle for<br />

rehit detection<br />

Minimum<br />

27<br />

rehit detection<br />

N<br />

28<br />

25<br />

15<br />

20<br />

15<br />

10<br />

snug point<br />

10<br />

5<br />

5<br />

snug point<br />

00<br />

5°<br />

0° 3.8°<br />

0°<br />

Min °<br />

15.2°<br />

0,00 4,94 8,73 11,59 13,94 16,25 19,09 22,28 24,87 27,91<br />

configuration:<br />

angle for rehit detection: 5°<br />

0,53,79<br />

stored values :<br />

27 0 0 10 N 38.14 Nm 3.8° 30.0 40.0 10° 20° 15.0 15.08.2006 15:15:13 Nok 1 SALTUS<br />

28 0 0 10 N 32.22 Nm 15.2° 30.0 40.0 10° 20° 15.0 15.08.2006 15:15:33 Ok 1 SALTUS<br />

Max °<br />

Tools:<br />

Tools:<br />

W5<br />

W1<br />

W2<br />

See Point: 3.7.1.0 Creating tool data<br />

Press the UP/DOWN selector keys while in this display to adjust the settings as required<br />

and press the SET button briefly to confirm the entry.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 16 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.2.2.0 Main menu: Joint: Explanation of the measuring methods<br />

3.2.2.1 Main menu: Joint: Measuring method: Torque/angle-controlled measurement<br />

M0 Measuring method: Torque/angle-controlled measurement (N) default<br />

This measuring method measures the peak torque and angle values in the prescribed<br />

torquing direction. Once the snug point has been reached, angle measurement begins.<br />

The stored data record contains the following code: N.<br />

3.2.2.2 Main menu: Joint: Measuring method: Torque measurement<br />

M1 Measuring method: Torque measurement (D)<br />

This measuring method measures the peak torque value in the prescribed torquing<br />

direction. The stored data record contains the following code: D.<br />

3.2.2.3 Main menu: Joint: Measuring method: Track<br />

M2 Measuring method: Track measurement (A)<br />

This measuring method displays the current torque and angle values in the prescribed<br />

torquing direction. Once the snug point has been reached, angle measurement begins.<br />

From the beginning of the wrench's measuring range, it will poll 25 readings (angle/force)<br />

per second via the RS232 interface. Press the Print button to stop this mode. The<br />

stored data record (peak values) contains the following code: A.<br />

In this measuring method, a tightening curve memory is filled with 100 measured pairs of<br />

readings per second (maximum duration is 12 s per curve), this is then used as a ring<br />

storage system (max. 5 curves). Each new reading deletes the oldest stored reading.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 17 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.2.2.4 Main menu: Joint: Measuring method: Prevail torque measurement<br />

M3 Measuring method: Prevail torque (B,P,F)<br />

300<br />

295<br />

Nm<br />

pre-set 270.0 Nm<br />

290<br />

287.35<br />

L<br />

285<br />

Maximum<br />

283.61<br />

E<br />

280<br />

275<br />

276.03<br />

Minimum<br />

W<br />

270<br />

265<br />

260<br />

snug point<br />

0°<br />

Min °<br />

4.65°<br />

Max °<br />

0,02<br />

0,23<br />

0,48<br />

0,68<br />

1,01<br />

1,38<br />

1,71<br />

2,12<br />

2,44<br />

2,73<br />

3,02<br />

3,36<br />

3,74<br />

4,16<br />

4,55<br />

4,94<br />

5,02<br />

store values of dynamic torque audit method:<br />

66 0 0 1 L 287.35 Nm 1.19° 275.0 285.0 1° 6° 240.0 29.01.2007 09:14:15 Nok 1 SALTUS<br />

67 0 0 1 W 276.03 Nm 2.96° 275.0 285.0 1° 6° 240.0 29.01.2007 09:14:15 Ok 1 SALTUS<br />

68 0 0 1 E 283.61 Nm 4.65° 275.0 285.0 1° 6° 240.0 29.01.2007 09:14:15 Ok 1 SALTUS<br />

This measuring method determines the breakaway torque (B) , prevail torque (P) and the<br />

end torque (E). Autoprint must be activated for this function and preangle/bending<br />

compensation should both be 0°. From the snug point on (240 Nm), the graph is recorded<br />

and the minimum torque value (275 Nm) must be exceeded. On the basis of the preset<br />

parameters, an existing joint is deliberately exceeded by e.g. 5° and the upper tolerance<br />

level at the final torque achieved is monitored. Each value (L, PT, FT) is separately<br />

evaluated: in this example, torque (breakaway torque) shows RED initially and then goes<br />

GREEN at the end of the measurement because the final torque is OK. Three data<br />

records are stored under the following codes: B, P and F. In this measuring method, a<br />

tightening curve memory is filled with 100 measured pairs of readings per second<br />

(maximum duration is 12 s per curve), this is then used as a ring storage system (max. 5<br />

curves). Each new reading deletes the oldest stored reading.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 18 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

Example:<br />

PT: 276.03 Nm<br />

4.65° BAT: 287.35<br />

FT: 283.61<br />

PT = prevail torque<br />

BAT = breakaway torque<br />

FT = final torque<br />

3.2.2.5 Main menu: Joint: Measuring method: Loosening<br />

M4 Measuring method: Loosening (U)<br />

This measuring method measures the smallest torque reading and the largest angle in the<br />

prescribed torquing direction. Once the snug point has been reached, angle measurement<br />

begins. Here, the joint is loosened by a defined tightening angle and the loosening torque<br />

recorded. The stored data record contains the following code: U.<br />

3.2.2.6 Main menu: Joint: Measuring method: Torque and/or angle measurement<br />

M5 Measuring method: Torque/angle-controlled measurement (O)<br />

This measuring method measures the peak torque and angle values in the prescribed<br />

torquing direction. Once the snug point has been reached, angle measurement begins.<br />

The stored data record contains the following code: O. The measurement is OK if at least<br />

one condition (Min. < torque or tightening angle < Max.) is met during the measurement.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 19 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.2.2.7 Main menu: Joint: Measuring method: Yield strength detection<br />

M6 Measuring method is yield strength detection (S)<br />

50<br />

Nm<br />

40<br />

Maximum<br />

40.25<br />

37.24<br />

M8 8.8<br />

S<br />

gradient<br />

E<br />

30<br />

Minimum<br />

20<br />

snug point<br />

10<br />

snug point<br />

0°<br />

18.2°<br />

35.0°<br />

0<br />

0,00 10,26 16,25 23,49 30,98 41,82 52,94 63,02<br />

stored values for the yield point S:<br />

23 0 0 15 S 37.24 Nm 18.2° 30.0 45.0 15° 40° 15.0 14.08.2006 14:19:16 Ok 1 SALTUS<br />

24 0 0 15 E 40.25 Nm 35.0° 30.0 45.0 15° 40° 15.0 14.08.2006 14:19:17 Ok 1 SALTUS<br />

In this mode, the torque existing at the point where the yield point (S) is exceeded and the<br />

final torque (FT) are calculated. Autoprint must be activated for this function and<br />

preangle/bending compensation should both be 0°. From the snug point on, the graph is<br />

recorded and the minimum torque value must be exceeded. If the pitch as defined at Point<br />

3.7.5.0 drops (e.g. to 50%), 2 data records are stored with these codes: S and E.<br />

In this measuring method, a tightening curve memory is filled with 100 measured pairs of<br />

readings per second (maximum duration is 12 s per curve), this is then used as a ring storage<br />

system (max. 5 curves). Each new reading deletes the oldest stored reading.<br />

Min °<br />

Max °<br />

Change level: 02/07 Version<br />

8000.15.2<br />

YP: 37.24 Nm<br />

35.0° FT: 40.25<br />

Page: 20 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.2.3.0 Main menu: Joint: Delete<br />

Activate the main menu as described at Point 3.2.0.0 and select a joint, press the SET<br />

button.<br />

SCREW (N) MENU:<br />

Replace<br />

Delete<br />

Print all<br />

The selected joint is deleted.<br />

Note: The internal joint 0 cannot be deleted.<br />

3.2.4.0 Main menu: Joint: Print all<br />

Activate the main menu as described at Point 3.2.0.0 and select the Joint menu option.<br />

SCREW (N) MENU:<br />

Delete<br />

Print all<br />

Edit<br />

This outputs all the joints via the RS232 interface.<br />

Output:<br />

0 15.0 25.0 25 35 6.0 R * 0 0 1 INTERN<br />

1 25.0 40.0 3 10 20.0 R * 3 0 2 PREVAIL TORQUE<br />

2 20.0 40.0 10 20 18.0 R * 0 3 1 BOLT1/MITVO<br />

3 20.0 40.0 10 20 18.0 R * 0 0 2 BOLT2/MITVO<br />

4 20.0 30.0 0 0 20.0 R * 1 3 1 PRETIGHT/NM<br />

5 20.0 40.0 10 20 20.0 R * 0 0 2 FINAL TQ/ANGLE<br />

6 4.0 110.0 1 360 2.0 R * 2 0 5 ANALOG/TRACK<br />

3.3.0.0 Main menu: Tightening sequence<br />

Activate the main menu as described at Point 3.2.0.0 and select the Tightening<br />

sequences menu option.<br />

Main menu:<br />

Joint<br />

Tightening sequence<br />

Memory<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 21 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.3.1.0 Main menu: Tightening sequence: Create<br />

Activate the main menu as described at Point 3.3.0.0 and select the Create menu option,<br />

press the SET button.<br />

SEQUENCE MENU:<br />

Select<br />

Create<br />

Delete<br />

3.3.1.1 Main menu: Tightening sequence: Create: Sequence name<br />

Activate the settings menu as described at Point 3.3.1.0.<br />

Name:<br />

NEWSEQ X<br />

SET : Clockw<br />

ESC : Ok -0-: Clr<br />

Press the UP/DOWN selector keys while in this<br />

display to adjust the settings as required and<br />

press the ON/OFF button to confirm the entry.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 22 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.3.1.2 Main menu: Tightening sequence: Create: Sequence programming step<br />

Activate the settings menu as described at Point 3.3.1.1.<br />

ENTER MACROSEQ.:<br />

Step: # 1/50<br />

BOLT1/MITVO X<br />

Press the UP/DOWN selector keys while in<br />

this display to make the required selection<br />

and press the SET button to add the joint.<br />

ENTER MACROSEQ.:<br />

Step: # 2/50<br />

LOOSEN<br />

Complete the data entry by pressing the<br />

ON/OFF button.<br />

BOLT1/MI# 1 17:39<br />

R<br />

M0 0.00 Nm<br />

NEWSEQ<br />

The wrench is in Joint 1 (Bolt 1) and in the<br />

new sequence (NEWSEQ).<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 23 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.3.2.0 Main menu: Tightening sequence: Select<br />

Activate the main menu as described at Point 3.3.0.0 and select the Select menu option,<br />

press the SET button.<br />

SEQUENCE MENU:<br />

Print sequ.<br />

Select<br />

Create<br />

SELECT MACROSEQ.:<br />

# 1 SEQUENCE1<br />

Press the UP/DOWN selector keys while in<br />

this display to make the required selection<br />

and press the SET button to activate the<br />

corresponding tightening sequence.<br />

# 1 SEQUENCE1<br />

Step: # 4/50<br />

LOOSEN<br />

Press the UP/DOWN selector keys while in<br />

this display to view all the steps making up<br />

this sequence, press the ON/OFF button to<br />

activate the corresponding tightening<br />

sequence.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 24 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.4.0.0 Main menu: Memory<br />

Activate the main menu as described at Point 3.0.0.0 and select the Memory menu<br />

option.<br />

Main menu:<br />

Tightening sequence<br />

Memory<br />

Tare angle<br />

# 2 0/13 n Not OK<br />

388.93 Nm 29.91°<br />

< 18.00 27.00<br />

> 22.00 33.00<br />

Press the UP/DOWN selector keys while in this display to select the required data record.<br />

The wrench can store up to 4000 readings. Once the memory is full, the oldest reading in<br />

the memory is deleted and the display shows this message: "Memory full!" (ring storage).<br />

3.4.1.1 Main menu: Memory: Clearing the memory<br />

Activate the main menu as described at Point 3.0.0.0 and select the Memory menu<br />

option.<br />

Main menu:<br />

Tightening sequence<br />

Memory<br />

Tare angle<br />

# 2 0/13 n Not OK<br />

388.93 Nm 29.91°<br />

< 18.00 27.00<br />

> 22.00 33.00<br />

Press the Zero button while in this display to<br />

delete the entire contents of the memory.<br />

DELETE<br />

No<br />

Yes<br />

A<br />

Press the SET button and opt for "Yes" to complete the delete process.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 25 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.4.1.2 Main menu: Memory: Print memory<br />

Activate the main menu as described at Point 3.0.0.0 and select the Memory menu<br />

option.<br />

Main menu:<br />

Tightening sequence<br />

Memory<br />

Tare angle<br />

# 2 0/13 n Not OK<br />

388.93 Nm 29.91°<br />

< 18.00 27.00<br />

> 22.00 33.00<br />

Message:<br />

Printing!<br />

Press the Print button while in this display to<br />

print the entire contents of the memory.<br />

3.5.0.0 Main menu: Angle zeroing<br />

Activate the main menu as described at Point 3.0.0.0 and select the Angle tare option,<br />

press the SET button to activate the angle zeroing function.<br />

Main menu:<br />

Memory<br />

Tare angle<br />

Angle stability<br />

Message:<br />

Tare angle<br />

If the wrench is not in the charging cradle, this option initiates a manual angle zeroing<br />

process.<br />

The wrench must not be moved at all during this zeroing action.<br />

The process takes approx. 60 s.<br />

Note: When the wrench is in place in the charging cradle, angle zeroing (<strong>TA</strong>RA) is automatically<br />

performed.<br />

INTERN 13:32<br />

R<br />

<strong>TA</strong>RA 0.00 Nm<br />

If the wrench is in its charging cradle, the<br />

angle zeroing process takes place<br />

automatically as a background process.<br />

The wrench is ready for use at any time.<br />

During this process, the setup menu is<br />

blocked.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 26 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.6.0.0 Main menu: Angle stability control<br />

Activate the main menu as described at Point 3.0.0.0 and select the Angle stability menu<br />

option.<br />

Main menu:<br />

Tare angle<br />

Angle stability<br />

Settings<br />

The integrated sensor is sensitive to<br />

temperature fluctuations. These<br />

fluctuations can be checked and adjusted<br />

here e.g. in laboratory or continuous<br />

operation without a charging cradle.<br />

Angle stability<br />

± 0 0.1°<br />

Press the UP/DOWN selector keys while<br />

in this display to adjust the sensitivity of<br />

the sensor. This action requires the<br />

highest level of access rights (setter/QA).<br />

3.7.0.0 Main menu: Settings<br />

Activate the main menu as described at Point 3.0.0.0 and select the Settings menu<br />

option.<br />

Main menu:<br />

Tare angle<br />

Settings<br />

Information<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 27 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.7.1.0 Main menu: Settings: Tool data<br />

Activate the settings menu as described at Point 3.7.0.0 and select the Tools menu<br />

option.<br />

SETTING MENU:<br />

Calibr.settings<br />

Tools<br />

ID Code<br />

Press the UP/DOWN selector keys to select the required tool presettings. Up to five<br />

different tools can be preset and press the SET button briefly to move from one<br />

parameter to the next: extension, bending, preangle, dynamic snug and angle rate.<br />

Tool ID(1)1<br />

Dynamic<br />

snug (FGP)<br />

Extension (25)<br />

Tightening time<br />

#1 FBD8258<br />

75% > 90°/s<br />

25.0 mm 0.011°/Nm<br />

30s<br />

Angle rate<br />

Bending<br />

3.7.1.1 Main menu: Settings: Tool data: Extension<br />

EXTENSION:<br />

25.0 mm<br />

Min: .0 Max: 200.0<br />

Here, the corresponding extension = tool length (L) is entered.<br />

With the <strong>DAZ</strong>-<strong>TA</strong> 9 x 12, the default length is 17.5 mm,<br />

With the <strong>DAZ</strong>-<strong>TA</strong> 14 x 18 and higher, the default length is 25.0 mm,<br />

L<br />

L [mm]<br />

<strong>DAZ</strong>-T(A) 50 17,5<br />

<strong>DAZ</strong>-T(A) 100 17,5<br />

<strong>DAZ</strong>-T(A) 250<br />

<strong>DAZ</strong>-T(A) 350<br />

<strong>DAZ</strong>-T(A) 500<br />

<strong>DAZ</strong>-T(A) 800<br />

25<br />

25<br />

25<br />

25<br />

Note: If the extension deviates, the calibration should be checked.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 28 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.7.1.2 Main menu: Settings: Tool data: Bending<br />

BENDING:<br />

0.011° /Nm<br />

Min: .000 Max: .500<br />

Here, it is important to enter the corresponding inherent bending of the wrench and tool<br />

(e.g.: 1.1° at 100 Nm = 0.011 °/Nm). This value is used in the joint data later for dynamic<br />

bending compensation.<br />

3.7.1.3 Main menu: Settings: Tool data: Dynamic snug<br />

DYNAM.SNUG POINT:<br />

0.95<br />

Min: .01 Max: 1.00<br />

Here, we enter the corresponding dynamic snug as a percentage. When retorquing, 95%<br />

of the last torque must be attained so that angle measurement can restart.<br />

3.7.1.4 Main menu: Settings: Tool data: Max. angle rate<br />

Max. Angle rate:<br />

120 °/s<br />

Min: 1 Max: 150<br />

Here, the corresponding value is stored as degrees per second.<br />

If this tightening speed is exceeded, both LED’s will flash red and the joint is classed as<br />

Not OK (Nok).<br />

3.7.1.5 Main menu: Settings: Tool data: Tightening time<br />

TIGHTENING TIME:<br />

30 S<br />

Min: 0 Max: 99<br />

The corresponding tightening time per second is stored here.<br />

If this time limit is exceeded, the data is auto-printed.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 29 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.7.1.6 Main menu: Settings: Tool data: Tool ID<br />

TOOL ID<br />

FBD8258<br />

SET : Clockw<br />

ESC : Ok -0-: Clr<br />

Enter any required name - however if tool detection is activated, this should be the code<br />

for the tool to be detected.<br />

#1 FBD8258<br />

75% > 90°/s<br />

25.0 mm 0.011°/Nm<br />

30s<br />

Use the UP/DOWN selector keys to select a different tool and pressing the SET button<br />

briefly enables it to be edited.<br />

3.7.2.0 Main menu: Settings: ID code/product name<br />

Activate the settings menu as described at Point 3.7.0.0 and select the ID Code menu<br />

option.<br />

Enter a suitable, meaningful name (max. 20 characters), and this will appear at the end of<br />

each data record.<br />

SETTING MENU:<br />

Tools<br />

ID Code<br />

Autom.Print<br />

ID Code:<br />

Station232<br />

SET : Clockw<br />

ESC : Ok -0-: Clr<br />

e.g.: Worker's name, product number,<br />

operation, production location etc.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 30 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.7.3.0 Main menu: Settings: Autoprint/auto-zero balance<br />

Activate the settings menu as described at Point 3.7.0.0 and select the Autom.Print menu<br />

option.<br />

The <strong>DAZ</strong>-<strong>TA</strong> provides the choice of automatic printing and storage functions. After<br />

successful reading or torquing, there will automatically be a zero balance. To this end, the<br />

operator only has to release the wrench. When releasing the wrench, ensure the<br />

corresponding minimum conditions are met (e.g. reading < 2.0 Nm).<br />

After that, the <strong>DAZ</strong>-<strong>TA</strong> automatically transmits the current reading to the PC or printer via<br />

the RS 232 interface and stores the reading in the wrench's memory. After transmission<br />

and storage, the wrench automatically resets itself to 0.0 and it is then ready for the next<br />

job.<br />

SETTING MENU:<br />

ID Code<br />

Autom.Print<br />

Advance warning point<br />

AUTOPRINT (s):<br />

OFF<br />

0.5 _<br />

1<br />

Select using the UP/DOWN selector keys and press the SET button to confirm the<br />

selection.<br />

e.g.: 0.5 = approx. 0.5 s = (OFF – 0.5 – 1 – 1.5)<br />

3.7.4.0 Main menu: Settings: Advance warning point<br />

Activate the settings menu as described at Point 3.7.0.0 and select the advance warning<br />

point menu option.<br />

SETTING MENU:<br />

Autom.Print<br />

Advance warning point<br />

Measuring curve<br />

ADVANCE WARNING<br />

POINT:<br />

80 %<br />

Min: 50 Max: 95<br />

The advance warning point is stored as a percentage. For example: 80%, advance<br />

warning will occur at 80% of the preset (Nm and angle) and the corresponding LED will<br />

light up a steady blue.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 31 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.7.5.0 Main menu: Settings: Measuring graph/pitch behaviour at yield point<br />

Activate the settings menu as described at Point 3.7.0.0 and select the Measuring curve<br />

menu option.<br />

SETTING MENU:<br />

Advance warning point<br />

Measuring curve<br />

Time<br />

GRADIENT:<br />

0.50<br />

Min: .10 Max: 1.00<br />

Here, the percentage for the gradient dip is stored (gradient resulting from torque/angle).<br />

For example: 50%, this means that when the gradient (NM/angle) dips by 50% (=0.50), the<br />

yield strength detection is initiated.<br />

3.7.6.0 Main menu: Settings: Time<br />

Activate the settings menu as described at Point 3.7.0.0 and select the Time menu<br />

option.<br />

SETTING MENU:<br />

Measuring curve<br />

Time<br />

Date<br />

MINUTES:<br />

30<br />

Min: 0 Max: 59<br />

HOURS:<br />

14<br />

Min: 0 Max: 23<br />

e.g.: 14:30:00<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 32 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.7.7.0 Main menu: Settings: Date<br />

Activate the settings menu as described at Point 3.7.0.0 and select the Date menu option.<br />

DAY:<br />

8<br />

Min: 1 Max: 31<br />

SETTING MENU:<br />

Time<br />

Date<br />

Tool detection<br />

MONTH:<br />

7<br />

Min: 1 Max: 12<br />

3.7.8.0 Main menu: Settings: Tool detection (optional)<br />

YEAR:<br />

6<br />

Min: 0 Max: 99<br />

e.g.: 08.07.2006<br />

Activate the settings menu as described at Point 3.7.0.0 and select the Tool detection<br />

menu option.<br />

Caution! The tool detection function can only work if your torque wrench is equipped<br />

with that option.<br />

SETTING MENU:<br />

Date<br />

Tool detection<br />

Adv. settings<br />

TOOL MODE:<br />

OFF<br />

User mode<br />

Automatic<br />

Select using the UP/DOWN selector keys and press the SET button to confirm the<br />

selection. Select the OFF option to deactivate the function. The User mode option<br />

activates the interactive tool detection system - all joints are available in this mode. Select<br />

the Automatic option to activate automatic tool detection. This causes tools to be<br />

allocated automatically: tool W1 to joint 1 through to tool W5 to joint 5.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 33 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

Example of tool detection in user mode without tool:<br />

Required tool (GET)<br />

Currently detected<br />

tool (ACT)<br />

new<br />

Tools:<br />

GET: W1 FBD8258<br />

ACT: <br />

The NEW joint is included in the selection and this joint requires Tool W1, designation<br />

FBD8258. The wrench will not be ready for use again until the correct tool (W1) has been<br />

attached.<br />

3.7.9.0 Main menu: Settings: Advanced settings<br />

Activate the settings menu as described at Point 3.7.0.0 and select the Extra setup menu<br />

option.<br />

SETTING MENU:<br />

Tool detection<br />

Adv. settings<br />

Calibration settings<br />

3.7.9.1 Main menu: Settings: Advanced settings: Wrench number<br />

Activate the advanced settings menu as described at Point 3.7.9.0 and select the Wrench<br />

no. menu option.<br />

Here, you can enter any number (max. 12 characters) which will then appear in the data<br />

record.<br />

ADVANCE MENU:<br />

Reset<br />

Wrench no.<br />

Unit<br />

WRENCH NO:<br />

5018<br />

SET : Clockw<br />

ESC : Ok -0-: Clr<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 34 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.7.9.2 Main menu: Settings: Advanced settings: Unit<br />

Activate the advanced settings menu as described at Point 3.7.9.0 and select the Unit<br />

menu option.<br />

ADVANCE MENU:<br />

Wrench no.<br />

Unit<br />

Language<br />

Unit:<br />

kgcm<br />

Nm<br />

cNm<br />

Select using the UP/DOWN selector keys and press the SET button to confirm the<br />

selection.<br />

e.g.: Nm (Nm, cNm, lbft, , lbfi, ozf, kgf cm, kgf m)<br />

Note: If the unit is changed on the wrench, the data for the joint will not be<br />

converted.<br />

3.7.9.3 Main menu: Settings: Advanced settings: Language<br />

Activate the advanced settings menu as described at Point 3.7.9.0 and select the<br />

Language menu option.<br />

ADVANCE MENU:<br />

Unit<br />

Language<br />

Turn-off time<br />

Language:<br />

Français<br />

Deutsch<br />

English<br />

Select using the UP/DOWN selector keys and press the SET button to confirm the<br />

selection.<br />

e.g.: German (German, French, English)<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 35 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.7.9.4 Main menu: Settings: Advanced settings: Turn-off time<br />

Activate the advanced settings menu as described at Point 3.7.9.0 and select the Turnoff<br />

time menu option.<br />

ADVANCE MENU:<br />

Language<br />

Turn-off time<br />

RS232/V.24<br />

TURN-OFF TIME:<br />

0 min<br />

Min: 0 Max: 60<br />

Use the UP/DOWN selector keys to set the required turn-off time and press the SET<br />

button to confirm the setting.<br />

e.g.: Default setting = 0 min (production operation)<br />

Note: If the wrench is used in conjunction with the cradle, automatic turn-off is not<br />

required.<br />

3.7.9.5 Main menu: Settings: Advanced settings: RS232/V.24<br />

Activate the advanced settings menu as described at Point 3.7.9.0 and select the<br />

RS232/V.24 menu option.<br />

ADVANCE MENU:<br />

Turn-off time<br />

RS232/V.24<br />

Reset<br />

BAUDRATE:<br />

9600<br />

19200<br />

300<br />

Select using the UP/DOWN selector keys and press the SET button to confirm<br />

the selection. The modified settings will not take effect until the wrench is switched<br />

off and on again.<br />

e.g.: Default = 19200 baud (300 – 19200 baud)<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 36 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.7.9.6 Main menu: Settings: Advanced settings: Reset<br />

Activate the advanced settings menu as described at Point 3.7.9.0 and select the Reset<br />

menu option.<br />

ADVANCE MENU:<br />

RS232/V.24<br />

Reset<br />

Wrench no.<br />

DELETE:<br />

Yes<br />

No<br />

Select using the UP/DOWN selector keys and press the SET button to confirm the<br />

selection. If you select the Yes option, the default values will be restored. (This<br />

deactivates autoprint, keypad lock, turn-off time; S<strong>TA</strong>TUS OUTPUT and sequence mode)<br />

Default setting:<br />

Extension<br />

= depends on type of wrench<br />

Start measuring<br />

= depends on type of wrench<br />

Advance warning point = 80%<br />

Default setting for internal joint:<br />

TORQUE MIN: = 30.0<br />

TORQUE MAX: = 40.0<br />

Minimum angle = 25%<br />

Maximum angle = 35%<br />

Snug point = 25.0<br />

Direction of rotation = Clockwise<br />

Priority = *<br />

Measuring mode<br />

= M0 (torque / angle)<br />

Tool = W1<br />

3.7.10.0 Main menu: Settings: Calibration settings<br />

Activate the settings menu as described at Point 3.7.0.0 and select the Calibr. Settings<br />

menu option.<br />

Note: The calibration menu is only accessible if you entered the appropriate code<br />

under Point 3.0.0.0.<br />

SETTING MENU:<br />

Adv. settings<br />

Calibration settings<br />

Tools<br />

CALIBRATION MENU:<br />

Flash update<br />

Calib. torque<br />

Calib.angle<br />

Select by using the UP/DOWN selector keys.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 37 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.7.10.1 Main menu: Settings: Calibration settings: Torque calibration<br />

Activate the settings menu as described at Point 3.7.10.0 and select the Torque calibrate<br />

menu option.<br />

Before attempting to calibrate the wrench, ensure that the correct extension has<br />

been entered under 3.7.10.3 and use the Saltus software to back up the original<br />

calibration settings (factory settings) first.<br />

Caution! Press the SET button to activate the calibration mode.<br />

CALIBRATION MENU:<br />

Flash update<br />

Calib. torque<br />

Calib.angle<br />

Calib. torque:<br />

CP 5 1<br />

Use the UP/DOWN selector keys to select the calibration point.<br />

The wrench should be inspected at regular intervals. If the actual values no longer tally<br />

with the presets within the required tolerances, the wrench will need calibrating and<br />

adjusting .<br />

The <strong>DAZ</strong>-<strong>TA</strong> allows you to adjust the wrench up to 5 points in a negative or positive<br />

direction.<br />

IMPOR<strong>TA</strong>NT: At the minimum, calibration points CP 5 and CP -5 must be set.<br />

The display will then show:<br />

Calib. torque:<br />

CP 5 1<br />

Calib. torque:<br />

CP 5 0<br />

After you have activated the calibration mode, use the UP/DOWN selector keys to select<br />

the calibration point you wish to calibrate (CP 5, CP 4 etc.)<br />

Note that the highest calibration values must be set for points CP5 and CP -5.<br />

Example: <strong>DAZ</strong>-<strong>TA</strong> 100<br />

CP 5 100 Nm<br />

CP 4<br />

60 Nm<br />

CP 3<br />

CP 2<br />

CP 1<br />

CP -1<br />

CP -2<br />

CP -3<br />

CP -4<br />

20 Nm<br />

15 Nm<br />

10 Nm<br />

10 Nm<br />

15 Nm<br />

20 Nm<br />

60 Nm<br />

CP -5 100 Nm<br />

Note: Calibration in accordance with DIN EN ISO 6789 only requires you to set<br />

calibration points C5P and C5N.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 38 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

Next, apply a known torque e.g. 200 Nm (<strong>DAZ</strong>-<strong>TA</strong>2) to the wrench. When you have<br />

reached your known value of 200 Nm, confirm by pressing the SET button. The wrench<br />

will save this load automatically and the display will show the preset:<br />

Calib. torque:<br />

CP 5 9587<br />

TORQUE PRESET:<br />

194.2 Nm<br />

Min: 2.0 Max: 220.0<br />

Use the UP/DOWN selector keys to set the current known value /preset (e.g. 194.2 Nm)<br />

for the load in Nm in the wrench.<br />

Preset<br />

(Current reading on the tester) :<br />

After setting, confirm the value by pressing the SET button.<br />

The wrench can now be released.<br />

If you wish to continue by calibrating additional points, you can select the next point using<br />

the UP/DOWN selector keys. Otherwise, press the ON/OFF button to return to the<br />

measuring mode where you can begin the next measurement with the calibrated wrench.<br />

When running the tests, check to see if:<br />

ACT= PRESET within a tolerance of 1% (196.3 – 204.3)<br />

Display <strong>DAZ</strong>-<strong>TA</strong>:<br />

Tester display:<br />

TEST 250 17:07<br />

R<br />

M1 200.77 Nm<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 39 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.7.10.2 Main menu: Settings: Calibration settings: Angle calibration<br />

Activate the settings menu as described at Point 3.7.10.0 and select the Calibr. angle<br />

menu option.<br />

Caution! The M0 measuring mode (torque/angle) must be activated. Press the SET<br />

button to activate the angle calibration mode, and ensure this process is correctly<br />

completed.<br />

CALIBRATION MENU:<br />

Calib. torque<br />

Calib.angle<br />

Extension<br />

Calibr. angle<br />

360.1°<br />

Next, rotate the wrench through one full circle (360°). When you have reached 360°,<br />

confirm this fact by pressing the SET button. The wrench will save this value automatically<br />

and the display will show: approx. 360 ° +/- 0.5°.<br />

Use the ON/OFF button to leave this menu option.<br />

3.7.10.3 Main menu: Settings: Calibration settings: Calibrating an extension<br />

Activate the settings menu as described at Point 3.7.10.0 and select the Extension menu<br />

option.<br />

CALIBRATION MENU:<br />

Calib.angle<br />

Extension<br />

Calib. date<br />

EXTENSION:<br />

25.0 mm<br />

Min: .0 Max: 200.0<br />

Enter here the corresponding calibration extension = tool length.<br />

9 x 12, the default is 17.5 mm.<br />

With the <strong>DAZ</strong>-<strong>TA</strong> 14 x 18, the default is 25.0 mm.<br />

With the <strong>DAZ</strong>-<strong>TA</strong><br />

See illustration under 3.7.1.1<br />

Note: If the calibration extension is to be changed, it is essential to perform a<br />

complete recalibration: see Point 3.7.10.1<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 40 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.7.10.4 Main menu: Settings: Calibration settings: Calibration date<br />

Activate the settings menu as described at Point 3.7.10.0 and select the Calibr. Date<br />

menu option.<br />

CALIBRATION MENU:<br />

Extension<br />

Calib. date<br />

Calib. counter<br />

YEAR:<br />

7<br />

Min: 0 Max: 99<br />

MONTH:<br />

6<br />

Min: 1 Max: 12<br />

Enter here the date for the next scheduled test. In this example, if the wrench is switched<br />

on after 1 June 2007, the user will see this message: "Check calibration"<br />

Message:<br />

Check Calibr.!<br />

CC: 2<br />

Press the ON/OFF button to override the message and continue working.<br />

The message is deactivated when the calibration date is changed.<br />

3.7.10.5 Main menu: Settings: Calibration settings: Calibration counter<br />

Besides Point 3.7.10.4 (Calibration date), it is possible to set a counter for all the joints<br />

tightened.<br />

Activate the settings menu as described at Point 3.7.10.0 and select the Calibr. Counter<br />

menu option.<br />

CALIBRATION MENU:<br />

Calib. date<br />

Calib. counter<br />

Flash update<br />

COUNTER:<br />

30<br />

Min: 1 Max: 5000<br />

Set the point at which you wish to be reminded of the next check. The preset<br />

counter/cycle counts down every 100th reading (30 * 100 = 3000 readings) until zero is<br />

reached. In this example, if the wrench is switched on after that, the user will see this<br />

message: Check Calibr.!<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 41 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

Message:<br />

Check Calibr.!<br />

CC: 2<br />

Press the ON/OFF button to override the message and continue working. The message is<br />

deactivated when the calibration counter is reset.<br />

3.7.10.6 Main menu: Settings: Calibration settings: Mechanical overload<br />

If a joint measurement takes place outside the measuring range (actual torque ≥ max. limit<br />

of measuring range + 10% e.g. 275 Nm with the <strong>DAZ</strong>-<strong>TA</strong> 250 2-250 Nm), then this<br />

message appears on the display and the counter is reset.<br />

Message 'CC' appears after the direction of rotation on the display and remains visible<br />

until the wrench is switched off.<br />

CC = overload<br />

INTERN 14:39<br />

R CC<br />

M0 0.00 Nm<br />

Important note:<br />

After an overload, the wrench should be subjected to a thorough<br />

inspection and, if necessary, recalibrated.<br />

Message:<br />

Check Calibr.!<br />

CC: 1<br />

Press the ON/OFF button to override the message and continue working.<br />

The message is deactivated when the calibration counter is reset.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 42 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.7.10.7 Main menu: Settings: Calibration settings: Flash update<br />

Activate the settings menu as described at Point 3.7.10.0 and select the Flash update<br />

menu option.<br />

Caution! Firmware updates can only be performed by SALTUS.<br />

CALIBRATION MENU:<br />

Calib. counter<br />

Flash update<br />

Calib. torque<br />

Load programme<br />

Yes<br />

No<br />

Only possible with additional flash software<br />

from SALTUS. Press the SET button and<br />

select the "No" option to abort the process<br />

without updating.<br />

3.8.0.0 Main menu: Information<br />

Activate the main menu as described at Point 3.0.0.0 and select the Information menu<br />

option.<br />

Main menu:<br />

Settings<br />

Information<br />

Enter preset<br />

14:35 08/06/2006<br />

Joint: 14<br />

Battery: 10 MEM: 12<br />

TID : FBD8258<br />

Joint:<br />

Total number of joints (max. 50)<br />

Battery:<br />

Battery status (1 = empty, 10= full)<br />

MEM/memory:<br />

Number of stored readings<br />

TID/tool ID:<br />

Tool detected<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 43 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

3.9.0.0 Main menu: Statistics<br />

Use the Statistics option to call up a subsequent statistical analysis of joints processed.<br />

Activate the main menu as described at Point 3.0.0.0 and select the Statistics menu<br />

option.<br />

Main menu:<br />

Memory<br />

Statistics<br />

Tare angle<br />

The following parameters can be entered here for calculating statistics.<br />

Number of readings to be used for the calculation.<br />

NUMBER:<br />

Min:10<br />

25<br />

max:4000<br />

Joint to be evaluated:<br />

S<strong>TA</strong>T. JOINT:<br />

60.0 Nm ± 1%<br />

ON/OFF: Esc<br />

SET: OK<br />

Tightening mode:<br />

S<strong>TA</strong>T. IDENTIFIER:<br />

D<br />

ON/OFF: Esc<br />

SET: OK<br />

0-: n Normal (torque and angle)<br />

1: D Torque<br />

2: a Analogue/track<br />

3: PT Prevail torque<br />

4: U Loosen/unfix<br />

5: O Either/or<br />

6-: S yield point (YP)<br />

7-: L Breakaway torque<br />

8-: FT final torque<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 44 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

X value:<br />

X value:<br />

3<br />

Min:1<br />

max:10<br />

X value determines whether the process or<br />

machine capability is to be calculated<br />

(range is 1 to 10, default: 3)<br />

Setting determines whether only "good" joints or also "bad" joints are to be included.<br />

ONLY OK’s<br />

No<br />

Yes<br />

No = Evaluate OK and NOT OK data records<br />

Yes = Evaluate only OK data records<br />

After all the entries have been made, the wrench will automatically display the results of<br />

the calculation:<br />

0,4%<br />

# 25 torque<br />

std.dv 0.050 0.000<br />

cm/p 4.021 0.000<br />

cmk/pk 3.147 0.000<br />

Standard deviation = 0.050<br />

Cm value = 4.021<br />

Cmk value = 3.147<br />

Deviation in %<br />

Abweichung %<br />

0,3%<br />

0,2%<br />

0,1%<br />

0,0%<br />

-0,1%<br />

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25<br />

-0,2%<br />

-0,3%<br />

-0,4%<br />

2424-9909005<br />

Press the ON/OFF button to return to the main menu.<br />

Change level: 02/07 Version<br />

8000.15.2<br />

Page: 45 / 56

Operating Instructions<br />

<strong>DAZ</strong>-<strong>TA</strong> <strong>Pro</strong><br />

4. Power supply<br />

The torque wrench will run for 8 hours on 3 x 1.2V NiMH AA 2450 mAh rechargeable<br />