Enhancing Efficiency and Economics in Process ... - ForteBio

Enhancing Efficiency and Economics in Process ... - ForteBio

Enhancing Efficiency and Economics in Process ... - ForteBio

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

11<br />

APPLICATION NOTE<br />

<strong>Enhanc<strong>in</strong>g</strong> <strong>Efficiency</strong> <strong>and</strong> <strong>Economics</strong> <strong>in</strong> <strong>Process</strong><br />

Development <strong>and</strong> Manufactur<strong>in</strong>g of Biotherapeutics<br />

Rashi Takkar, Applications Scientist; Sriram Kumaraswamy, Director, Market<strong>in</strong>g Field Applications.<br />

INTRODUCTION<br />

Analytical techniques that measure prote<strong>in</strong> quantity <strong>and</strong> quality<br />

are used <strong>in</strong> nearly all stages of research, process development <strong>and</strong><br />

manufactur<strong>in</strong>g of biotherapeutics. UV spectroscopy, ELISA <strong>and</strong> HPLC<br />

have been <strong>in</strong> use for decades for prote<strong>in</strong> quantitation <strong>in</strong> physiological<br />

<strong>and</strong> process samples, <strong>and</strong> cont<strong>in</strong>ue to be the workhorses despite<br />

their many limitations. To characterize the functional activity of<br />

prote<strong>in</strong>s dur<strong>in</strong>g biotherapeutic development, label-free biosensorbased<br />

b<strong>in</strong>d<strong>in</strong>g assays are <strong>in</strong>creas<strong>in</strong>gly be<strong>in</strong>g utilized. The high cost<br />

<strong>and</strong> lengthy times associated with drug discovery <strong>and</strong> development<br />

have forced biopharm companies to improve the efficiency <strong>and</strong><br />

economics <strong>in</strong> all stages of development. These key drivers have<br />

fueled the search for <strong>in</strong>novative analytical techniques that provide<br />

improved performance <strong>and</strong> speed without <strong>in</strong>creas<strong>in</strong>g costs. Biopharmaceutical<br />

companies have enthusiastically adopted Pall <strong>ForteBio</strong>’s<br />

Octet systems due to their broad utility <strong>in</strong> prote<strong>in</strong> quantitation <strong>and</strong><br />

functional characterization comb<strong>in</strong>ed with enhanced throughput,<br />

decreased sample preparation requirements, <strong>and</strong> low cost of operation.<br />

This white paper describes the use of Octet <strong>in</strong>struments for<br />

prote<strong>in</strong> quantitation, particularly <strong>in</strong> the areas of process development<br />

<strong>and</strong> quality control.<br />

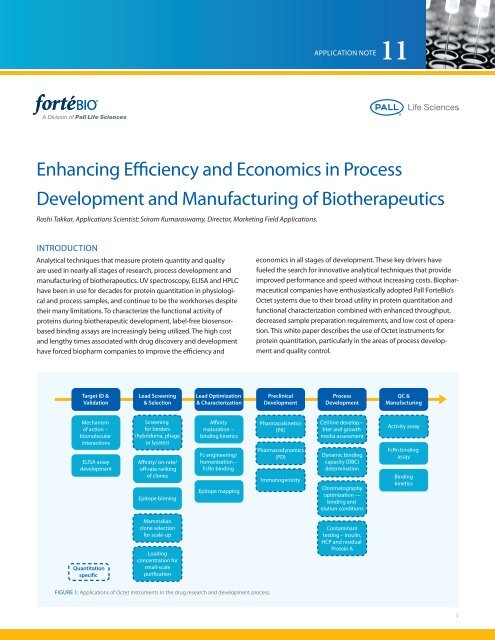

Target ID &<br />

Validation<br />

Lead Screen<strong>in</strong>g<br />

& Selection<br />

Lead Optimization<br />

& Characterization<br />

Precl<strong>in</strong>ical<br />

Development<br />

<strong>Process</strong><br />

Development<br />

QC &<br />

Manufactur<strong>in</strong>g<br />

Mechanism<br />

of action –<br />

biomolecular<br />

<strong>in</strong>teractions<br />

ELISA assay<br />

development<br />

Screen<strong>in</strong>g<br />

for b<strong>in</strong>ders<br />

(hybridoma, phage<br />

or lysates)<br />

Aff<strong>in</strong>ity/ on-rate/<br />

off-rate rank<strong>in</strong>g<br />

of clones<br />

Epitope b<strong>in</strong>n<strong>in</strong>g<br />

Aff<strong>in</strong>ity<br />

maturation –<br />

b<strong>in</strong>d<strong>in</strong>g k<strong>in</strong>etics<br />

Fc eng<strong>in</strong>eer<strong>in</strong>g/<br />

humanization –<br />

FcRn b<strong>in</strong>d<strong>in</strong>g<br />

Epitope mapp<strong>in</strong>g<br />

Pharmacok<strong>in</strong>etics<br />

(PK)<br />

Pharmacodynamics<br />

(PD)<br />

Immunogenicity<br />

Cell l<strong>in</strong>e develop.–<br />

titer <strong>and</strong> growth<br />

media assessment<br />

Dynamic b<strong>in</strong>d<strong>in</strong>g<br />

capacity (DBC)<br />

determ<strong>in</strong>ation<br />

Chromatography<br />

optimization —<br />

b<strong>in</strong>d<strong>in</strong>g <strong>and</strong><br />

elution conditions<br />

Activity assay<br />

FcRn b<strong>in</strong>d<strong>in</strong>g<br />

assay<br />

B<strong>in</strong>d<strong>in</strong>g<br />

k<strong>in</strong>etics<br />

Quantitation<br />

specific<br />

Mammalian<br />

clone selection<br />

for scale-up<br />

Load<strong>in</strong>g<br />

concentration for<br />

small-scale<br />

purification<br />

Contam<strong>in</strong>ant<br />

test<strong>in</strong>g – <strong>in</strong>sul<strong>in</strong>,<br />

HCP <strong>and</strong> residual<br />

Prote<strong>in</strong> A<br />

Figure 1: Applications of Octet <strong>in</strong>struments <strong>in</strong> the drug research <strong>and</strong> development process.<br />

1

<strong>Enhanc<strong>in</strong>g</strong> <strong>Efficiency</strong> <strong>and</strong> <strong>Economics</strong> <strong>in</strong> <strong>Process</strong> Development <strong>and</strong> Manufactur<strong>in</strong>g of Biotherapeutics<br />

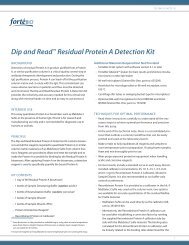

Prote<strong>in</strong> Quantitation of 70 Complex Samples<br />

Octet Systems<br />

Sample <strong>and</strong><br />

<strong>in</strong>strument prep<br />

30 m<strong>in</strong><br />

Data analysis<br />

10 m<strong>in</strong><br />

60 m<strong>in</strong> total assay time<br />

40 m<strong>in</strong> operator h<strong>and</strong>s-on time<br />

Sample run time<br />

20 m<strong>in</strong><br />

HPLC<br />

Sample <strong>and</strong><br />

<strong>in</strong>strument prep<br />

4 hr<br />

Sample <strong>in</strong>jection <strong>and</strong> run time<br />

18 hr<br />

Data analysis<br />

50 m<strong>in</strong><br />

23 hr total assay time<br />

5 hr operator h<strong>and</strong>s-on time<br />

ELISA<br />

B<strong>in</strong>d capture<br />

antigen to plate<br />

Overnight (16 hr)<br />

Sample <strong>and</strong><br />

<strong>in</strong>strument prep<br />

1 hr<br />

Sample run time<br />

4 hr<br />

Data analysis<br />

30 m<strong>in</strong><br />

21.5 hr total assay time<br />

5.5 hr operator h<strong>and</strong>s-on time<br />

Figure 2: Comparison of prote<strong>in</strong> quantitation <strong>in</strong> complex matrices us<strong>in</strong>g Octet systems <strong>and</strong> alternative methods.<br />

ADVANTAGES OVER ELISA AND HPLC<br />

The pr<strong>in</strong>ciples of concentration measurement with an Octet system<br />

are similar to established immunoassays such as ELISA <strong>and</strong><br />

HPLC. However, prote<strong>in</strong> quantitation protocols on the Octet platform<br />

provide several advantages. The Octet platform monitors<br />

b<strong>in</strong>d<strong>in</strong>g of prote<strong>in</strong>s from solution to a biosensor surface <strong>in</strong> real<br />

time, without need for labels or other detection reagents. This<br />

real-time monitor<strong>in</strong>g of b<strong>in</strong>d<strong>in</strong>g <strong>in</strong>teractions enables clear<br />

discrim<strong>in</strong>ation between specific <strong>and</strong> non-specific b<strong>in</strong>d<strong>in</strong>g<br />

signals, which can shorten assay development times dramatically.<br />

Octet assays are also much faster: quantitation of a 96-well<br />

plate requires 15 – 30 m<strong>in</strong>utes, or 60 m<strong>in</strong>utes for a 384-well<br />

plate, depend<strong>in</strong>g on the <strong>in</strong>strument model. Figure 2 provides a<br />

comparison of analysis times. Analysis of 70 samples on an Octet<br />

RED96 system requires as little as 55 m<strong>in</strong>utes <strong>in</strong>clud<strong>in</strong>g operator<br />

h<strong>and</strong>s-on time, whereas ELISA or HPLC assays require at least 22<br />

hours <strong>in</strong>clud<strong>in</strong>g several hours of analyst <strong>in</strong>volvement. Samples<br />

run on Octet systems are also recoverable, so that researchers<br />

may save <strong>and</strong> reuse precious samples for other experiments. In<br />

addition, Octet assays are not affected by absorption <strong>in</strong>terferences<br />

<strong>in</strong> colored samples or by light scatter<strong>in</strong>g with turbid samples,<br />

enabl<strong>in</strong>g measurement of analyte concentration <strong>in</strong> crude matrices<br />

such as cell culture supernatant, cell lysate <strong>and</strong> serum. Octet<br />

concentration assays are complemented by the platform’s ability<br />

to measure functional activity. For example, titer for a monoclonal<br />

antibody (mAb) can be determ<strong>in</strong>ed us<strong>in</strong>g biosensors coated<br />

with Prote<strong>in</strong> A, while the functional activity of the mAb can be<br />

assessed <strong>in</strong> a second assay step <strong>in</strong>volv<strong>in</strong>g b<strong>in</strong>d<strong>in</strong>g to its specific<br />

antigen. In contrast, HPLC <strong>and</strong> A280 spectroscopy can determ<strong>in</strong>e<br />

only the total prote<strong>in</strong> concentration of a sample, <strong>and</strong> separate<br />

assays must be used to measure biological activity.<br />

BIO-LAYER INTERFEROMETRY TECHNOLOGY (BLI)<br />

BLI technology monitors <strong>and</strong> analyzes the <strong>in</strong>terference pattern<br />

generated from the reflection of white light from two different<br />

surfaces: a layer of immobilized prote<strong>in</strong> on the biosensor tip <strong>and</strong> an<br />

<strong>in</strong>ternal reference layer (Figure 3). Any <strong>in</strong>crease or decrease <strong>in</strong> the<br />

number of b<strong>in</strong>d<strong>in</strong>g molecules on the biosensor surface produces<br />

a change <strong>in</strong> optical thickness that causes a shift <strong>in</strong> the <strong>in</strong>terference<br />

2

Application Note 11<br />

Incident<br />

white<br />

light<br />

BLI signal<br />

process<strong>in</strong>g<br />

Biocompatible<br />

surface<br />

Relative Intensity<br />

1.0<br />

0.8<br />

0.6<br />

0.4<br />

Δ λ<br />

Bound<br />

molecule<br />

0.2<br />

Unbound molecules<br />

have no effect<br />

Wavelength (nm)<br />

Figure 3: Bio-Layer Interferometry is an optical analytical technique that analyzes the <strong>in</strong>terference pattern of white<br />

light reflected from two surfaces. Changes <strong>in</strong> the number of molecules bound to the biosensor causes a shift <strong>in</strong> the<br />

<strong>in</strong>terference pattern that is measured <strong>in</strong> real time.<br />

Biosensors<br />

St<strong>and</strong>ard<br />

Reference<br />

Unknown<br />

B<strong>in</strong>d<strong>in</strong>g (nm)<br />

0<br />

T ime (sec)<br />

120<br />

B<strong>in</strong>d<strong>in</strong>g Rate<br />

Concentration<br />

Figure 4: A typical quantitation assay setup. Biosensors dip <strong>in</strong>to st<strong>and</strong>ards run <strong>in</strong> duplicate to obta<strong>in</strong> b<strong>in</strong>d<strong>in</strong>g (nm shift) vs. time (sec)<br />

curves. The <strong>in</strong>itial slope of the <strong>in</strong>teraction is used to create the st<strong>and</strong>ard curve of the b<strong>in</strong>d<strong>in</strong>g rate vs. concentration. The concentration<br />

of an unknown sample is then <strong>in</strong>terpolated from the st<strong>and</strong>ard curve.<br />

pattern. Unbound molecules <strong>in</strong> complex matrices <strong>and</strong> changes<br />

<strong>in</strong> the refractive <strong>in</strong>dex of the surround<strong>in</strong>g medium have m<strong>in</strong>imal<br />

effect on the <strong>in</strong>terference pattern. BLI technology simplifies prote<strong>in</strong><br />

quantitation by enabl<strong>in</strong>g specific measurement <strong>in</strong> complex samples.<br />

The one-step Dip <strong>and</strong> Read assay format uses native prote<strong>in</strong>s,<br />

without need for labels or secondary reagents.<br />

CONCENTRATION MEASUREMENT<br />

Accurate determ<strong>in</strong>ation of biologically relevant prote<strong>in</strong> concentrations<br />

is essential to several areas <strong>in</strong> the biopharmaceutical <strong>in</strong>dustry<br />

<strong>in</strong>clud<strong>in</strong>g research, bioprocess<strong>in</strong>g, quality control <strong>and</strong> manufactur<strong>in</strong>g.<br />

The Octet platform uses a simple Dip <strong>and</strong> Read approach for<br />

rapid analysis of samples <strong>in</strong> 96 <strong>and</strong> 384-well microplate formats.<br />

The concentration of the target prote<strong>in</strong> or antibody <strong>in</strong> a sample<br />

is determ<strong>in</strong>ed via a direct b<strong>in</strong>d<strong>in</strong>g or s<strong>and</strong>wich assay. Biosensors<br />

coated with a capture molecule, called the lig<strong>and</strong>, are dipped <strong>in</strong>to<br />

solutions conta<strong>in</strong><strong>in</strong>g the analyte <strong>in</strong> a highly parallel, automated<br />

method to measure b<strong>in</strong>d<strong>in</strong>g <strong>in</strong>teractions. In a typical quantitation<br />

assay, a st<strong>and</strong>ard curve is generated us<strong>in</strong>g known amounts of the<br />

prote<strong>in</strong> analyte, <strong>and</strong> unknown sample concentrations are <strong>in</strong>terpolated<br />

from the st<strong>and</strong>ard curve (Figure 4). Concentration can be<br />

3

<strong>Enhanc<strong>in</strong>g</strong> <strong>Efficiency</strong> <strong>and</strong> <strong>Economics</strong> <strong>in</strong> <strong>Process</strong> Development <strong>and</strong> Manufactur<strong>in</strong>g of Biotherapeutics<br />

calculated from the <strong>in</strong>itial b<strong>in</strong>d<strong>in</strong>g rate of the <strong>in</strong>teraction which is<br />

based on the <strong>in</strong>itial slope or from the b<strong>in</strong>d<strong>in</strong>g rate at equilibrium.<br />

QUANTITATION APPLICATIONS FOR DRUG<br />

DEVELOPMENT<br />

Titer Assessment <strong>and</strong> Growth Media Optimization<br />

Us<strong>in</strong>g the Octet Platform<br />

Research <strong>and</strong> Early Bioprocess Development<br />

The Octet platform is a useful tool for cost-effective prote<strong>in</strong> expression<br />

screen<strong>in</strong>g <strong>in</strong> research <strong>and</strong> early bioprocess development with<br />

several significant benefits.<br />

Octet Platform Advantages<br />

• Antibody <strong>and</strong> prote<strong>in</strong> concentrations can be determ<strong>in</strong>ed <strong>in</strong> crude<br />

matrices, such as cell lysates or hybridoma supernatants, sav<strong>in</strong>g<br />

time <strong>and</strong> resources when process<strong>in</strong>g a large number of samples.<br />

• Octet assays have a dynamic range of greater than two orders of<br />

magnitude, enabl<strong>in</strong>g a s<strong>in</strong>gle quantitation assay to be utilized<br />

across all development stages – from early cell culture to production<br />

bioreactors.<br />

• Octet systems perform rapid quantitation with m<strong>in</strong>imal user<br />

<strong>in</strong>volvement. 96 samples are analyzed <strong>in</strong> as little as 20 m<strong>in</strong>utes,<br />

<strong>and</strong> 384 samples <strong>in</strong> 70 m<strong>in</strong>utes. With additional plate h<strong>and</strong>l<strong>in</strong>g<br />

automation, Octet 384 systems can process more than 1200<br />

samples per day.<br />

• Samples are analyzed <strong>in</strong> a non-destructive method <strong>and</strong> are fully<br />

recoverable, which is advantageous when work<strong>in</strong>g with low<br />

sample volumes <strong>and</strong> precious samples.<br />

• Octet systems are easy to learn <strong>and</strong> operate. Multiple analysts<br />

can operate the <strong>in</strong>strument with m<strong>in</strong>imal tra<strong>in</strong><strong>in</strong>g, allow<strong>in</strong>g rapid<br />

<strong>in</strong>tegration of these systems <strong>in</strong>to laboratory workflows.<br />

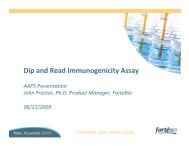

96-well Plates<br />

Pre-adapted<br />

Host Cells<br />

Range: 1–300 µg/mL<br />

Throughput: 1000s clones<br />

24-, 12- <strong>and</strong> 6-well Plates<br />

Range: 1–500 µg/mL<br />

Throughput: 200–500 clones<br />

T-flasks<br />

Range: 1–500 µg/mL<br />

Throughput: 100–150 clones<br />

Shake Flasks<br />

Range: 1–700 µg/mL<br />

Throughput: 50–100 clones<br />

Transfections<br />

Vector<br />

Octet<br />

Octet<br />

Octet<br />

Early Clone Selection<br />

In clone selection, thous<strong>and</strong>s of hybridoma or phage clones are<br />

screened to determ<strong>in</strong>e positive b<strong>in</strong>d<strong>in</strong>g clones <strong>and</strong> their prote<strong>in</strong> secretion<br />

levels. Titer measurements are used to select high-produc<strong>in</strong>g<br />

clones <strong>and</strong> to normalize the functional activity of these clones<br />

<strong>in</strong> crude matrices. Integration of an Octet system <strong>in</strong>to the antibody<br />

discovery workflow affords <strong>in</strong>creased screen<strong>in</strong>g throughput. With<br />

Octet RED384 <strong>and</strong> Octet QK384 <strong>in</strong>struments, automated plate<br />

h<strong>and</strong>l<strong>in</strong>g can also be added to achieve even higher throughput.<br />

Octet quantitation assays are also used to determ<strong>in</strong>e load<strong>in</strong>g levels<br />

of chromatography columns for small-scale purification.<br />

Fed-batch Shake Flasks<br />

Range: 1–700 µg/mL<br />

Throughput: 12–20 clones<br />

Octet<br />

Octet<br />

Cell L<strong>in</strong>e Development<br />

Harvest samples are screened on Octet systems to select highexpress<strong>in</strong>g<br />

clones dur<strong>in</strong>g various scale-up procedures <strong>in</strong>volv<strong>in</strong>g<br />

96-, 48-, 24- <strong>and</strong> 6-well plates, fed-batch shake flasks, <strong>and</strong> bioreactors<br />

(Figure 5). Octet assays also are used to determ<strong>in</strong>e prote<strong>in</strong><br />

levels dur<strong>in</strong>g media development for fed-batch <strong>and</strong> bioreactor<br />

processes (Figure 5). Follow<strong>in</strong>g modification of feed<strong>in</strong>g regimes,<br />

strategies <strong>and</strong> concentrations, Octet assays compare prote<strong>in</strong><br />

secretion levels. Data acquisition <strong>and</strong> subsequent data analysis<br />

1–3 L Seed Bioreactors<br />

Range: 1–4 mg/mL<br />

Throughput: 2–5 clones<br />

Figure 5: Prote<strong>in</strong> titer assessment <strong>and</strong> growth media optimization us<strong>in</strong>g the<br />

Octet system at different stages of cell l<strong>in</strong>e development.<br />

4

Application Note 11<br />

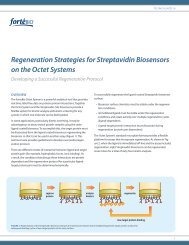

Cell Culture<br />

Harvest<br />

Aff<strong>in</strong>ity<br />

Chromatography<br />

Polish<strong>in</strong>g<br />

Chromatography<br />

(at least 2 steps)<br />

Viral<br />

Filtration<br />

Ultrafiltration<br />

Diafiltration<br />

Optimiz<strong>in</strong>g dynamic b<strong>in</strong>d<strong>in</strong>g<br />

capacity of column res<strong>in</strong>s<br />

• Detect prote<strong>in</strong> breakthrough<br />

<strong>in</strong> column flowthrough<br />

fractions<br />

Optimiz<strong>in</strong>g b<strong>in</strong>d<strong>in</strong>g, wash <strong>and</strong><br />

elution conditions<br />

• Prote<strong>in</strong> b<strong>in</strong>d<strong>in</strong>g/activity<br />

• Residual Prote<strong>in</strong> A<br />

• HCP (generic & specific)<br />

• Prote<strong>in</strong> recovery<br />

Optimiz<strong>in</strong>g dynamic b<strong>in</strong>d<strong>in</strong>g<br />

capacity of column res<strong>in</strong>s<br />

• B<strong>in</strong>d <strong>and</strong> elute mode:<br />

determ<strong>in</strong>e prote<strong>in</strong> breakthrough<br />

po<strong>in</strong>t<br />

• Flow-through mode:<br />

determ<strong>in</strong>e f<strong>in</strong>al fraction<br />

when target prote<strong>in</strong><br />

detectable<br />

Optimiz<strong>in</strong>g b<strong>in</strong>d<strong>in</strong>g, elution,<br />

<strong>and</strong> wash conditions<br />

• Prote<strong>in</strong> recovery<br />

• Prote<strong>in</strong> b<strong>in</strong>d<strong>in</strong>g/activity<br />

• Residual Prote<strong>in</strong> A<br />

• HCP (generic & specific)<br />

Optimize different formulations<br />

based on:<br />

• Prote<strong>in</strong> stability<br />

(concentration measurements<br />

needed)<br />

• Prote<strong>in</strong> activity/b<strong>in</strong>d<strong>in</strong>g<br />

Figure 6: Use of Octet systems <strong>in</strong> the downstream purification process of prote<strong>in</strong>s <strong>and</strong> antibodies.<br />

can be performed rapidly for hundreds of samples, bypass<strong>in</strong>g traditional<br />

process<strong>in</strong>g bottlenecks. Please see <strong>ForteBio</strong> Application<br />

Note 13, Fc-Fusion Prote<strong>in</strong> Quantitation <strong>in</strong> Cell Culture Supernatants,<br />

for more <strong>in</strong>formation.<br />

Downstream <strong>Process</strong> Development<br />

Efficient development of manufactur<strong>in</strong>g processes for antibodies<br />

<strong>and</strong> recomb<strong>in</strong>ant prote<strong>in</strong>s is a critical need for biopharmaceutical<br />

companies. Increas<strong>in</strong>gly str<strong>in</strong>gent regulatory requirements target<strong>in</strong>g<br />

better underst<strong>and</strong><strong>in</strong>g <strong>and</strong> control of manufactur<strong>in</strong>g processes<br />

are expected to impact product quality <strong>and</strong> performance. The Octet<br />

platform can quickly determ<strong>in</strong>e the impact of multiple process<br />

variables at different stages of the purification process, <strong>and</strong> help<br />

identify optimal conditions that provide prote<strong>in</strong> product with the<br />

desired yield, b<strong>in</strong>d<strong>in</strong>g specificity <strong>and</strong> potency (Figure 6). Pre-configured<br />

reagents <strong>and</strong> protocols are available for rapid quantitation<br />

of prote<strong>in</strong> products, host cell prote<strong>in</strong>s (HCP), <strong>and</strong> residual Prote<strong>in</strong> A<br />

levels dur<strong>in</strong>g purification processes.<br />

Octet Platform Advantages<br />

• One Octet <strong>in</strong>strument can be used to measure prote<strong>in</strong> titer, host<br />

cell prote<strong>in</strong>s <strong>and</strong> residual Prote<strong>in</strong> A contam<strong>in</strong>ant levels.<br />

• Octet assays are faster to develop <strong>and</strong> run than ELISA <strong>and</strong> HPLC<br />

assays.<br />

• Octet assays can be automated with robotic <strong>and</strong> liquid h<strong>and</strong>l<strong>in</strong>g<br />

systems for complete, walk-away screen<strong>in</strong>g.<br />

Dynamic B<strong>in</strong>d<strong>in</strong>g Capacity of Chromatography Columns<br />

Aff<strong>in</strong>ity chromatography often is the first major purification procedure<br />

performed on harvested cell culture samples <strong>in</strong> downstream<br />

bioprocess<strong>in</strong>g. The dynamic b<strong>in</strong>d<strong>in</strong>g capacity (DBC) of an aff<strong>in</strong>ity<br />

chromatography column is def<strong>in</strong>ed as the amount of prote<strong>in</strong> that<br />

will b<strong>in</strong>d to the column res<strong>in</strong> under a def<strong>in</strong>ed condition. DBC is<br />

determ<strong>in</strong>ed by cont<strong>in</strong>uously load<strong>in</strong>g a sample conta<strong>in</strong><strong>in</strong>g a known<br />

concentration of target prote<strong>in</strong> <strong>and</strong> monitor<strong>in</strong>g this prote<strong>in</strong> <strong>in</strong> the<br />

flow-through fractions. Quick determ<strong>in</strong>ation of DBC us<strong>in</strong>g HPLC or<br />

A280 spectroscopy is hampered by the presence of large amounts<br />

of host cell prote<strong>in</strong>s <strong>in</strong> the flow-through fractions. Specific detection<br />

of the prote<strong>in</strong> of <strong>in</strong>terest among contam<strong>in</strong>ants is straightforward<br />

with Octet systems, reduc<strong>in</strong>g the time required to optimize<br />

purification conditions (Figure 6).<br />

B<strong>in</strong>d<strong>in</strong>g, Wash <strong>and</strong> Elution Conditions<br />

Numerous chromatography b<strong>in</strong>d<strong>in</strong>g <strong>and</strong> elution conditions are<br />

tested dur<strong>in</strong>g optimization studies, <strong>in</strong>clud<strong>in</strong>g different buffer compositions,<br />

salt, pH, operat<strong>in</strong>g temperature <strong>and</strong> sample <strong>in</strong>jection<br />

volume. High-throughput tools, such as m<strong>in</strong>i columns <strong>and</strong> 96-well<br />

filter plates, often are used to screen these process variables. The<br />

impact of different conditions on product titer <strong>and</strong> quality can be<br />

analyzed rapidly <strong>and</strong> effectively on Octet systems, speed<strong>in</strong>g identification<br />

of optimal chromatography conditions (Figure 6).<br />

Contam<strong>in</strong>ant Test<strong>in</strong>g<br />

Downstream purification processes must remove host cell prote<strong>in</strong>s,<br />

residual Prote<strong>in</strong> A <strong>and</strong> residual DNA impurities. Accord<strong>in</strong>g to guidance<br />

from regulatory authorities, host cell prote<strong>in</strong>s <strong>in</strong> a drug substance<br />

should be “below detectable levels us<strong>in</strong>g a highly sensitive<br />

analytical method”, <strong>and</strong> as a rule this level should not exceed 100<br />

ppm. The type of assay required for HCP determ<strong>in</strong>ations depends<br />

on the phase of cl<strong>in</strong>ical studies for which the material is produced.<br />

For earlier cl<strong>in</strong>ical phases, a generic assay may be sufficient. However,<br />

a process-specific HCP assay generally is required for phase<br />

3 <strong>and</strong> later studies. Leached Prote<strong>in</strong> A is another contam<strong>in</strong>ant of<br />

concern <strong>in</strong> process development. The elution of antibodies dur<strong>in</strong>g<br />

Prote<strong>in</strong> A chromatography requires acidic conditions, which <strong>in</strong> turn<br />

can accelerate leach<strong>in</strong>g of Prote<strong>in</strong> A from the column. Residual Prote<strong>in</strong><br />

A levels should not exceed 10 ppm <strong>in</strong> the f<strong>in</strong>al drug product.<br />

5

<strong>Enhanc<strong>in</strong>g</strong> <strong>Efficiency</strong> <strong>and</strong> <strong>Economics</strong> <strong>in</strong> <strong>Process</strong> Development <strong>and</strong> Manufactur<strong>in</strong>g of Biotherapeutics<br />

CUSTOMER HIGHLIGHT: GLAXOSMITHKLINE<br />

The analytical lab at GlaxoSmithKl<strong>in</strong>e <strong>in</strong>corporated a generic<br />

HCP assay on the Octet QK384 system to streaml<strong>in</strong>e their<br />

workflow <strong>in</strong> process development. The automated Octet HCP<br />

assay required m<strong>in</strong>imal analyst <strong>in</strong>tervention <strong>and</strong> provided<br />

more accurate <strong>and</strong> precise results than their manual ELISA<br />

assay (Figure 7). H<strong>and</strong>s-on time for preparation <strong>and</strong> process<strong>in</strong>g<br />

of 1–3 assay plates was reduced to 30 m<strong>in</strong>utes from<br />

the previous 2.5 hours with manual ELISA, <strong>and</strong> antibody<br />

consumption decreased by 40%.<br />

More <strong>in</strong>formation on the development of the HCP assay on<br />

Octet systems can be found <strong>in</strong> Technical Note 24, Host Cell<br />

Prote<strong>in</strong> Dectection on the Pall <strong>ForteBio</strong> website.<br />

Benefits of Automated Octet CHO HCP Assay Compared to Manual ELISA<br />

Benefit<br />

Precision<br />

Reliability<br />

Streaml<strong>in</strong>ed<br />

<strong>Process</strong><br />

Walk Away<br />

Wash<strong>in</strong>g Steps<br />

Analysts<br />

Involvement<br />

Throughput<br />

Details<br />

Liquid h<strong>and</strong>l<strong>in</strong>g robot reduces pipett<strong>in</strong>g variation <strong>in</strong>herent <strong>in</strong><br />

manual pipett<strong>in</strong>g.<br />

Method performed exactly the same each time.<br />

Worklist drives robotic method <strong>and</strong> creates sample plate importation<br />

files. Robotic method automatically creates <strong>and</strong> executes<br />

Octet method file.<br />

No analyst <strong>in</strong>tervention needed to complete method after <strong>in</strong>strument<br />

loaded <strong>and</strong> diluent volumes are checked.<br />

No wash<strong>in</strong>g steps needed <strong>and</strong> plate washer <strong>in</strong>tegration not<br />

required.<br />

Automated Octet ~30 m<strong>in</strong>utes for 1–3 assay plates<br />

Manual ELISA ~2.5 hours per assay plate<br />

3 assay plates can be run <strong>in</strong> ~5 hours<br />

38 samples/plate <strong>in</strong> duplicate wells > 108 samples <strong>in</strong> 3 plates<br />

Antibody<br />

Consumed<br />

Re-use of coat<strong>in</strong>g antibody can significantly reduce consumption<br />

over multiple assay plates<br />

Figure 7: Benefits of automated Octet CHO HCP assay compared to manual ELISA.<br />

Presented by GSK researchers at several conferences.<br />

<strong>Process</strong> development assays for residual Prote<strong>in</strong> A <strong>and</strong> product<br />

titer can be fully automated on Octet 384 systems us<strong>in</strong>g external<br />

liquid h<strong>and</strong>l<strong>in</strong>g platforms. The Octet assay for leached Prote<strong>in</strong><br />

A is highly sensitive with a LLOQ of 0.20 ppm, has >2.5 logs of<br />

dynamic range, <strong>and</strong> is faster than compet<strong>in</strong>g methods. A residual<br />

Prote<strong>in</strong> A assay on the Octet RED384 system can be completed<br />

<strong>in</strong> 1 hour <strong>and</strong> 45 m<strong>in</strong>utes per plate with m<strong>in</strong>imal analyst <strong>in</strong>volvement,<br />

compared to a m<strong>in</strong>imum of 3.5 hours for ELISA (<strong>in</strong>clud<strong>in</strong>g<br />

significant analyst h<strong>and</strong>s-on time). For more <strong>in</strong>formation on the<br />

Octet residual Prote<strong>in</strong> A quantitation protocol, see Technical<br />

Note 18, Dip <strong>and</strong> Read Residual Prote<strong>in</strong> A Detection Kit on the Pall<br />

<strong>ForteBio</strong> website.<br />

Quality Control<br />

Octet systems provide robust <strong>and</strong> highly reproducible assays for<br />

prote<strong>in</strong> concentration <strong>and</strong> functional activity, <strong>and</strong> are suitable for<br />

operation <strong>in</strong> quality control <strong>and</strong> manufactur<strong>in</strong>g environments. Prote<strong>in</strong><br />

activity <strong>and</strong> various k<strong>in</strong>etic assays are used to support <strong>in</strong>-process<br />

test<strong>in</strong>g, drug potency, lot-to-lot variability <strong>and</strong> stability studies.<br />

Octet Platform Advantages<br />

• Octet systems are designed for GLP/GMP environments, <strong>and</strong><br />

provide 21 CFR Part 11 compliance tools.<br />

• Octet assays provide detailed <strong>in</strong>formation about the b<strong>in</strong>d<strong>in</strong>g<br />

behavior of prote<strong>in</strong> products, <strong>and</strong> reveal subtle differences <strong>in</strong><br />

b<strong>in</strong>d<strong>in</strong>g activity between production lots.<br />

Activity Assay<br />

Quantitation Assay<br />

Fab<br />

Streptavid<strong>in</strong> Biot<strong>in</strong>ylated Lig<strong>and</strong> — b<strong>in</strong>ds Fab Antibody<br />

Fc<br />

Prote<strong>in</strong> A — b<strong>in</strong>ds Fc<br />

Figure 8: An activity assay can be developed on the Octet platform by immobiliz<strong>in</strong>g a specific biot<strong>in</strong>ylated lig<strong>and</strong> on the biosensor <strong>and</strong> then detect<strong>in</strong>g b<strong>in</strong>d<strong>in</strong>g of an<br />

analyte, FAb or prote<strong>in</strong>. In the quantitation assay, mAb titer is determ<strong>in</strong>ed us<strong>in</strong>g Prote<strong>in</strong> A-loaded biosensors, which does not measure mAb activity towards its target.<br />

6

Application Note 11<br />

CUSTOMER HIGHLIGHT: ARAGEN BIOSCIENCE<br />

Aragen Bioscience created a stable <strong>and</strong> scalable CHO cell<br />

l<strong>in</strong>e, purification platform <strong>and</strong> manufactur<strong>in</strong>g process for a<br />

particular product <strong>in</strong> a GMP environment. They developed<br />

an Octet assay to compare the activity <strong>and</strong> quality of a new<br />

product lot (Lot 2) with a reference lot (Lot 1) throughout<br />

their bioprocess <strong>and</strong> manufactur<strong>in</strong>g processes. The assay<br />

<strong>in</strong>volved load<strong>in</strong>g a biot<strong>in</strong>ylated lig<strong>and</strong> on Streptavid<strong>in</strong><br />

biosensors, <strong>and</strong> measur<strong>in</strong>g b<strong>in</strong>d<strong>in</strong>g <strong>in</strong>teraction of the lig<strong>and</strong><br />

with the prote<strong>in</strong> analyte. As seen <strong>in</strong> Figure 9, Lot 2 conta<strong>in</strong>ed<br />

a large second peak that was absent <strong>in</strong> the Lot 1 reference<br />

material. The second peak <strong>in</strong> Lot 2 exhibited a slower<br />

on-rate <strong>and</strong> much faster off-rate, <strong>in</strong>dicative of a less-active<br />

fraction (Figure 10). Octet system activity data results were<br />

confirmed with a cell-based assay, <strong>and</strong> Aragen was able to<br />

modify their production conditions to significantly reduce<br />

this second peak fraction.<br />

Lot 1<br />

High Specific<br />

B<strong>in</strong>d<strong>in</strong>g Activity<br />

Peak 1<br />

Peak 2<br />

Lot 2<br />

Low Specific<br />

B<strong>in</strong>d<strong>in</strong>g Activity<br />

Peak 1<br />

Peak 2<br />

Presence of large<br />

second peak<br />

correlated with<br />

reduced specific<br />

b<strong>in</strong>d<strong>in</strong>g activity<br />

30 35<br />

30 35<br />

Figure 9: HPLC spectra of Lot 1 <strong>and</strong> Lot 2 of a drug molecule. Lot 2 was made by Aragen Bioscience <strong>and</strong> had an additional<br />

peak (Peak 2) compared to the reference lot (Lot 1) provided by their customer. Data provided courtesy of Aragen<br />

Bioscience.<br />

Peak 2<br />

Peak 1<br />

30 35<br />

The lower on-rate <strong>and</strong><br />

higher off-rate clearly<br />

<strong>in</strong>dicated a less active<br />

fraction.<br />

Figure 10: Octet b<strong>in</strong>d<strong>in</strong>g data demonstrated that Peak 1 was the active fraction <strong>and</strong> Peak 2 was the less-active fraction, with a slower on-rate <strong>and</strong> faster offrate.<br />

Data courtesy of Aragen Bioscience.<br />

7

<strong>Enhanc<strong>in</strong>g</strong> <strong>Efficiency</strong> <strong>and</strong> <strong>Economics</strong> <strong>in</strong> <strong>Process</strong> Development <strong>and</strong> Manufactur<strong>in</strong>g of Biotherapeutics<br />

• Octet quantitation assays provide a direct measure of the biological<br />

activity of the analyte(s) (Figure 8).<br />

• Octet assays can be easily transferred to manufactur<strong>in</strong>g operations.<br />

Activity Assays<br />

An activity assay is generally utilized dur<strong>in</strong>g process development,<br />

QC <strong>and</strong> manufactur<strong>in</strong>g to compare various prepared lots of the<br />

drug molecule, as well as its stability. Activity assays are critical<br />

because they differentiate active prote<strong>in</strong> from <strong>in</strong>active or clipped<br />

variants, as those species will not b<strong>in</strong>d the lig<strong>and</strong>. Active prote<strong>in</strong><br />

concentration can be determ<strong>in</strong>ed us<strong>in</strong>g a b<strong>in</strong>d<strong>in</strong>g assay on the<br />

Octet platform by immobiliz<strong>in</strong>g a specific lig<strong>and</strong> aga<strong>in</strong>st the target<br />

analyte onto the biosensor, <strong>and</strong> then measur<strong>in</strong>g its b<strong>in</strong>d<strong>in</strong>g <strong>in</strong>teraction<br />

with the analyte as shown <strong>in</strong> Figure 8.<br />

CONCLUSION<br />

Octet systems deliver comprehensive characterization of biotherapeutics,<br />

as well as rapid <strong>and</strong> reproducible determ<strong>in</strong>ation of prote<strong>in</strong><br />

concentrations dur<strong>in</strong>g different stages of the development process.<br />

Titer <strong>and</strong> functional activity assays on Octet systems are useful for<br />

a broad array of applications <strong>in</strong> target identification, lead selection,<br />

process development, formulation development, quality control,<br />

<strong>and</strong> manufactur<strong>in</strong>g. In early stages of drug development, Octet<br />

systems provide the high throughput needed to screen through<br />

large libraries of c<strong>and</strong>idate drug molecules. In later stages of<br />

process development <strong>and</strong> manufactur<strong>in</strong>g, Octet systems provide<br />

the required reliability, robustness <strong>and</strong> measurement accuracy. The<br />

broad utility of this s<strong>in</strong>gle platform makes the Octet <strong>in</strong>strument<br />

unique <strong>in</strong> its ability to deliver high value across a wide range of application<br />

needs <strong>in</strong> biopharmaceutical discovery, development <strong>and</strong><br />

manufactur<strong>in</strong>g processes.<br />

Acknowledgements<br />

The authors wish to thank Dan Schuessler, Scientist at GlaxoSmith-<br />

Kl<strong>in</strong>e <strong>and</strong> Oren Beske, VP Laboratory Services at Aragen Bioscience<br />

for their contributions.<br />

8<br />

Pall <strong>ForteBio</strong> Corp.<br />

1360 Willow Road, Suite 201<br />

Menlo Park, CA 94025<br />

t: 888.OCTET-75<br />

or 650.322.1360<br />

Pall <strong>ForteBio</strong> Europe<br />

5 Harbourgate Bus<strong>in</strong>ess Park<br />

Southampton Road<br />

Portsmouth, PO6 4BQ, UK<br />

t: +44-(0)203 318 2840<br />

www.fortebio.com<br />

Pall <strong>ForteBio</strong> Analytics (Shanghai) Co., Ltd.<br />

917 Halley Road, Bldg 4<br />

Zhangjiang High Tech Park<br />

Shanghai, Ch<strong>in</strong>a 201203<br />

t: +86-21-51320387<br />

© 2013, Pall Corporation. Pall, , <strong>ForteBio</strong>,<br />

Octet, BLItz <strong>and</strong> Dip <strong>and</strong> Read are trademarks<br />

of Pall Corporation. ® <strong>in</strong>dicates a trademark<br />

registered <strong>in</strong> the USA <strong>and</strong> <strong>in</strong>dicates a<br />

common law trademark.<br />

AN-4011 Rev A