HR01 Appliance-Loft Mechanical Ventilation with Heat Recovery ...

HR01 Appliance-Loft Mechanical Ventilation with Heat Recovery ...

HR01 Appliance-Loft Mechanical Ventilation with Heat Recovery ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The EMC Directive 2004/108/EC<br />

The Low Voltage directive 2006/95/EC<br />

<strong>HR01</strong> <strong>Appliance</strong>-<strong>Loft</strong><br />

<strong>Mechanical</strong> <strong>Ventilation</strong> <strong>with</strong> <strong>Heat</strong> <strong>Recovery</strong><br />

Installation and Maintenance<br />

1.0 Introduction<br />

IMPORTANT: Unit must not be switched off during normal<br />

operation, the product is designed to run continuously.<br />

<strong>HR01</strong>-<strong>Loft</strong> is designed to provide mechanical supply and<br />

extract ventilation <strong>with</strong> heat recovery. (Code: <strong>HR01</strong>L).<br />

The units are fitted <strong>with</strong> two independent fans. Each fan has<br />

full speed control for background and boost ventilation rates<br />

as well as a run-on timer facility. To recover heat from the<br />

extract air the heat exchanger block is utilised. This heat<br />

exchanger can recover up to 95% of the normally wasted heat.<br />

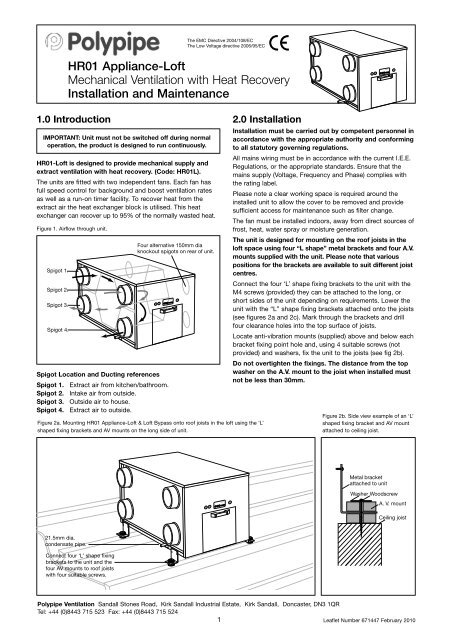

Figure 1. Airflow through unit.<br />

Spigot 1.<br />

Spigot 2.<br />

Spigot 3.<br />

Spigot 4.<br />

Spigot Location and Ducting references<br />

Spigot 1. Extract air from kitchen/bathroom.<br />

Spigot 2. Intake air from outside.<br />

Spigot 3. Outside air to house.<br />

Spigot 4. Extract air to outside.<br />

Four alternative 150mm dia<br />

knockout spigots on rear of unit.<br />

Figure 2a. Mounting <strong>HR01</strong> <strong>Appliance</strong>-<strong>Loft</strong> & <strong>Loft</strong> Bypass onto roof joists in the loft using the ‘L’<br />

shaped fixing brackets and AV mounts on the long side of unit.<br />

2.0 Installation<br />

Installation must be carried out by competent personnel in<br />

accordance <strong>with</strong> the appropriate authority and conforming<br />

to all statutory governing regulations.<br />

All mains wiring must be in accordance <strong>with</strong> the current I.E.E.<br />

Regulations, or the appropriate standards. Ensure that the<br />

mains supply (Voltage, Frequency and Phase) complies <strong>with</strong><br />

the rating label.<br />

Please note a clear working space is required around the<br />

installed unit to allow the cover to be removed and provide<br />

sufficient access for maintenance such as filter change.<br />

The fan must be installed indoors, away from direct sources of<br />

frost, heat, water spray or moisture generation.<br />

The unit is designed for mounting on the roof joists in the<br />

loft space using four “L shape” metal brackets and four A.V.<br />

mounts supplied <strong>with</strong> the unit. Please note that various<br />

positions for the brackets are available to suit different joist<br />

centres.<br />

Connect the four ‘L’ shape fixing brackets to the unit <strong>with</strong> the<br />

M4 screws (provided) they can be attached to the long, or<br />

short sides of the unit depending on requirements. Lower the<br />

unit <strong>with</strong> the “L” shape fixing brackets attached onto the joists<br />

(see figures 2a and 2c). Mark through the brackets and drill<br />

four clearance holes into the top surface of joists.<br />

Locate anti-vibration mounts (supplied) above and below each<br />

bracket fixing point hole and, using 4 suitable screws (not<br />

provided) and washers, fix the unit to the joists (see fig 2b).<br />

Do not overtighten the fixings. The distance from the top<br />

washer on the A.V. mount to the joist when installed must<br />

not be less than 30mm.<br />

Figure 2b. Side view example of an ‘L’<br />

shaped fixing bracket and AV mount<br />

attached to ceiling joist.<br />

Metal bracket<br />

attached to unit<br />

Washer Woodscrew<br />

A. V. mount<br />

Ceiling joist<br />

21.5mm dia.<br />

condensate pipe.<br />

Connect four ‘L’ shape fixing<br />

brackets to the unit and the<br />

four AV mounts to roof joists<br />

<strong>with</strong> four suitable screws.<br />

Polypipe <strong>Ventilation</strong> Sandall Stones Road, Kirk Sandall Industrial Estate, Kirk Sandall, Doncaster, DN3 1QR<br />

Tel: +44 (0)8443 715 523 Fax: +44 (0)8443 715 524<br />

1<br />

Leaflet Number 671447 February 2010

Installation and Maintenance<br />

<strong>HR01</strong> <strong>Appliance</strong>-<strong>Loft</strong><br />

Installation cont.<br />

Figure 2c. Mounting <strong>HR01</strong> <strong>Appliance</strong>-<strong>Loft</strong> & <strong>Loft</strong> Bypass onto roof joists using the ‘L’ shaped fixing brackets and AV mounts on the short side of the unit.<br />

Connect four ‘L’ shape fixing<br />

brackets to the unit and the four<br />

AV mounts to roof joists <strong>with</strong><br />

four suitable screws.<br />

21.5mm dia.<br />

condensate pipe.<br />

2.1 Condensate Drain<br />

1. Remove top cover and remove heat exchanger.<br />

The condensate outlet can then be seen at the base of<br />

the unit. Using a 90 Deg bend and suitable length of<br />

¾” / 21.5mm diameter overflow pipe (not supplied) take<br />

the condensate to the outside of the unit (can be taken<br />

to either side of the unit as required).<br />

Suitable adhesive should be used for all connections.<br />

2. The drain should run through a secondary trap before<br />

being discharged through the eaves or into the waste<br />

water system.<br />

3. Pour a little water into the drip tray to create an air trap.<br />

Figure 3. Plan view of unit showing drip tray and condensate drain.<br />

Drain Tray<br />

21.5mm dia. condensate<br />

drain alternative position<br />

2.2 Extract/input areas<br />

The unit is designed to extract air from all wet rooms<br />

e.g. bathroom, kitchen, en-suite, utility room (<strong>with</strong> sink).<br />

WC’s do not need to be ventilated if openable windows are<br />

fitted. Supply air should be to all habitable rooms e.g. bedrooms<br />

and lounge. Extract / input grilles should be adjustable<br />

valve types (not supplied).<br />

2.3 Ducting<br />

1. If the unit has been specified as SAP appendix Q installation<br />

the use of flexible is prohibited. If flexible ducting is to be<br />

used it should be kept to a minimum and should always be<br />

pulled taught.<br />

2. The unit is supplied <strong>with</strong> 150mm and 125mm outlets. It is<br />

recommended that 150mm ducting be used from outside<br />

to the unit and 125mm used from the unit to the dwelling<br />

rooms. To prevent condensation on the ducting they should<br />

be insulated externally vapour-proof as far as the unit.<br />

3. Ducting layout plans should be adhered to if available.<br />

4. It is recommended the 204 x 60mm ducting be used and<br />

the number of 90 Deg bends be kept to a minimum.<br />

5. Ducting joints must be sealed <strong>with</strong> duct tape and/or silicone<br />

sealant.<br />

For further information refer to Building Regulations Part F and<br />

BRE appendix Q website.<br />

21.5mm dia.<br />

condensate drain<br />

IMPORTANT: Any air intake terminal MUST be installed<br />

in accordance <strong>with</strong> the appropriate regulation.<br />

As a guide, the BS5440 series of British Standards<br />

deals <strong>with</strong> this issue and currently states that an air<br />

intake must be at a minimum distance of 300mm from<br />

a gas boiler balanced flue. Installers are advised to be<br />

aware of the requirements of this standard when<br />

installing ‘through the wall’ supply air ducting.<br />

Similarly, supply and extract air grilles should be at<br />

least 300mm apart.<br />

2<br />

Leaflet Number 671447 February 2010

Installation and Maintenance<br />

<strong>HR01</strong> <strong>Appliance</strong>-<strong>Loft</strong><br />

Installation cont.<br />

Figure 4. Main unit components shown <strong>with</strong> front and lid removed.<br />

Figure 5.<br />

G4 removable filter.<br />

(Code: <strong>HR01</strong>FG4).<br />

<strong>Heat</strong> exchanger.<br />

Four optional 150mm dia.<br />

knockout spigot locations on<br />

rear of unit.<br />

If required for use cut through<br />

the acoustic foam round the<br />

circumference of the knockout.<br />

(see figure 5)<br />

G4 removable filter.<br />

(Code: <strong>HR01</strong>FG4).<br />

Adjustment potentiometers and<br />

indication lights.<br />

3.0 Dimensions (mm)<br />

View from front (4 X 125mm spigots)<br />

Side view<br />

430<br />

840<br />

Condensate<br />

Drain<br />

450<br />

21.5mm dia.<br />

condensate<br />

drain alternative<br />

position<br />

View from top<br />

3<br />

Leaflet Number 671447 February 2010

Installation and Maintenance<br />

<strong>HR01</strong> <strong>Appliance</strong>-<strong>Loft</strong><br />

4.0 Electrical Connection<br />

Please note: the electrical connection of the unit must be be carried<br />

out by a qualified electrician.<br />

IMPORTANT: For good EMC engineering practice, any<br />

sensor cables or switched live cables should not be<br />

placed <strong>with</strong>in 50mm of other cables or on the same<br />

metal cable tray as other cables.<br />

The unit is supplied <strong>with</strong> a flexible cord for connection to the<br />

mains supply.<br />

Electrical details:-<br />

Voltage: 240V 1ph 50Hz<br />

Consumption: 75W (max) 0.6 amps<br />

Fuse rating: 3 Amp<br />

NOTE: This unit must be earthed<br />

The three core cable from the mains power supply should be<br />

connected to a fixed wiring installation, via a fused isolator, in<br />

accordance <strong>with</strong> current IEE wiring regulations.<br />

Figure 5a. Power supply PCB.<br />

230V in, 24V dc out.<br />

Internal wiring<br />

Figure 5b.<br />

Control PCB. 24V<br />

Connections for<br />

optional controls<br />

Volt free relay<br />

contacts.<br />

Fault<br />

Run<br />

Switch to deactivate<br />

continuous trickle<br />

Fan connections<br />

230V IN<br />

50Hz<br />

Mains<br />

SWL N L<br />

Connection to supply cord<br />

Earth point<br />

Unit serving kitchen and bathroom<br />

Figure 6.<br />

MAINS<br />

230V<br />

50Hz<br />

N<br />

L<br />

Fuse 2A<br />

Light<br />

switch<br />

(Double<br />

Pole)<br />

Room<br />

light<br />

3 Pole<br />

isolator<br />

Green/yellow<br />

Blue<br />

Brown<br />

Black<br />

Supply cord<br />

from unit<br />

Kitchen switch<br />

Summer<br />

bypass<br />

switch<br />

Grey (only used<br />

on bypass unit)<br />

Unit serving kitchen and two bathrooms<br />

Figure 7.<br />

MAINS<br />

230V<br />

50Hz<br />

N<br />

L<br />

Fuse 2A<br />

Light<br />

switches<br />

(Double<br />

Pole)<br />

Kitchen switch<br />

Room<br />

lights<br />

3 Pole<br />

isolator<br />

Green/yellow<br />

Blue<br />

Brown<br />

Black<br />

Summer<br />

bypass<br />

switch<br />

Grey (only used<br />

on bypass unit)<br />

Supply cord<br />

from unit<br />

4<br />

Leaflet Number 671447 February 2010

Installation and Maintenance<br />

<strong>HR01</strong> <strong>Appliance</strong>-<strong>Loft</strong><br />

Electrical connection cont.<br />

Optional Connections<br />

Ecosmart control (see figure 5a)<br />

(a) J11/12/13<br />

The IDC plug-in connectors are provided for the connection of<br />

compatible sensors.<br />

NOTE: Do not run the data cable in the same conduit as the<br />

mains cable and leave a 50mm separation <strong>with</strong> any power<br />

cables.<br />

LED Indication<br />

PWR GREEN: Power on and OK,<br />

RED:<br />

Standby LED on when fan is not running.<br />

As the unit runs continuously this LED<br />

should be off. If it is illuminated locate the<br />

trickle switch and change its position.<br />

Fan 1 GREEN: Fan 1 is running, RED: Fan 1 faulty.<br />

Fan 2 GREEN: Fan 2 is running, RED: Fan 2 faulty.<br />

(b) Volt Free Relay Contacts<br />

Note that the volt free contacts are not fused. If these are used<br />

to power any external equipment, the installer must provide<br />

adequate fusing or other protections. These contacts are rated<br />

at 5A resistive, 0.5A inductive.<br />

Run connections (J5) - These contacts are closed when the<br />

fan is running.<br />

Fault connections (J7) - No fault = the contacts are closed.<br />

Fault = the contacts are opened (this includes no power<br />

supply at the unit).<br />

5.0 Ancillaries<br />

<strong>HR01</strong>-PIR Sensor<br />

<strong>HR01</strong>-Humidistat Sensor<br />

<strong>HR01</strong>-System Monitor<br />

(Code: <strong>HR01</strong>P)<br />

(Code: <strong>HR01</strong>H)<br />

(Code: <strong>HR01</strong>M)<br />

(c) Data Cable installation<br />

A 4-core data cable is used to connect devices such as<br />

sensors to the fan and for interconnecting multiple fan units.<br />

Do not run data cable in the same conduit as the mains cables<br />

and ensure there is a 50mm separation between the data<br />

cable and other cables. The maximum cable run between any<br />

two devices is 300m when it is installed in accordance <strong>with</strong><br />

the instructions.<br />

Please note that the total data cable length used in any<br />

system must be less than 1000m. Keep the number of cable<br />

joints to a minimum to ensure the best data transmission<br />

efficiency between devices.<br />

5<br />

Leaflet Number 671447 February 2010

Installation and Maintenance<br />

6.0 Commissioning<br />

1. For the required airflow rates refer to the design<br />

specification for the property or refer to Building<br />

Regulations Part F.<br />

2. The unit is supplied <strong>with</strong> control of both the normal<br />

airflow and boost airflow. (see figure below).<br />

3. Commissioning should be carried out using a moving<br />

vane anemometer in conjunction <strong>with</strong> a hood.<br />

4. Once commissioned the house owner / tenant should<br />

be informed that the unit should not be adjusted as it<br />

will have a detrimental effect on the indoor air quality<br />

and could result in condensation and mould growth.<br />

Figure 8. Detail of unit control on side panel.<br />

8.0 Replacement of Parts<br />

Should any component need replacing Polypipe keep extensive<br />

stocks for quick delivery. Ensure that the unit is electrically<br />

isolated, before carrying out any work.<br />

When ordering spare parts, please quote the serial number<br />

of the unit and the ARC number of the purchase if possible.<br />

(This information will be available on the fan label).<br />

9.0 Warranty<br />

<strong>HR01</strong> <strong>Appliance</strong>-<strong>Loft</strong><br />

Standard warranty starts from the day of purchase or delivery.<br />

Polypipe extend the warranty from one to three years on<br />

receipt of the warranty card attached and proof of delivery/<br />

purchase, providing this is returned <strong>with</strong>in the first year.<br />

The warranty covers all parts proven to be faulty at point of<br />

manufacture but excludes problems arising from incorrect<br />

installation. In this instance, if a Polypipe engineer is required<br />

to attend site the call out will be chargeable.<br />

This warranty is conditional upon evidence of planned<br />

maintenance and does not extend to consumable items.<br />

Damaged appliances must not be installed but returned to<br />

point of purchase.<br />

10.0 Service Enquiries<br />

Polypipe can assist you in all aspects of service. Our service<br />

department will be happy to provide any assistance required,<br />

initially by telephone and If necessary arrange for an<br />

engineer to call.<br />

7.0 Maintenance/Cleaning<br />

IMPORTANT: Isolation - Before commencing work make<br />

sure that the unit, switched live and control are electrically<br />

isolated from the mains supply and switched live supply.<br />

1. Replace filters every 5 years. Remove the top cover and<br />

slide out the two G4 filters fitted either side of the heat<br />

exchanger. Replace <strong>with</strong> new filters.<br />

2. Inspect heat exchanger every 5 years. Generally check<br />

for damage and security of components. Refit top cover.<br />

3. Inspecting motors. Motors can be accessed through<br />

removal side panels.<br />

Figure 9. Removing filters.<br />

6<br />

Leaflet Number 671447 February 2010

Notes<br />

7<br />

Leaflet Number 671447 February 2010

Installation and Maintenance<br />

<strong>HR01</strong> <strong>Appliance</strong>-<strong>Loft</strong><br />

11.0 Warranty Card <strong>HR01</strong> <strong>Appliance</strong>-<strong>Loft</strong><br />

*Name:<br />

*Address:<br />

*Postcode:<br />

*Telephone:<br />

Email:<br />

*Model:<br />

*Serial No:<br />

Installer:<br />

Installer Address:<br />

*Date Installed:<br />

*Date Purchased:<br />

Retailer:<br />

Retailer Location:<br />

May we send you relevant product information and remind you when service is due<br />

Your details will not be disclosed to any third party.<br />

*Data required<br />

Return <strong>with</strong> proof of delivery/purchase to:<br />

Polypipe <strong>Ventilation</strong><br />

Sandall Stones Road,<br />

Kirk Sandall Industrial Estate,<br />

Kirk Sandall,<br />

Doncaster, DN3 1QR<br />

Tel: +44 (0)8443 715 523<br />

Fax: +44 (0)8443 715 524<br />

Technical or commercial considerations may, from time to time, make it necessary to alter the design, performance and<br />

dimensions of equipment and the right is reserved to make such changes <strong>with</strong>out prior notice.<br />

8<br />

Leaflet Number 671447 February 2010

The EMC Directive 2004/108/EC<br />

The Low Voltage directive 2006/95/EC<br />

<strong>HR01</strong> <strong>Appliance</strong>-Wall<br />

<strong>Mechanical</strong> <strong>Ventilation</strong> <strong>with</strong> <strong>Heat</strong> <strong>Recovery</strong><br />

Installation and Maintenance<br />

1.0 Introduction<br />

Figure 2. Fixing the mounting bracket to the wall.<br />

IMPORTANT: Unit must not be switched off during normal<br />

operation, the product is designed to run continuously.<br />

<strong>HR01</strong>-Wall is designed to provide mechanical supply and<br />

extract ventilation <strong>with</strong> heat recovery. (Code: <strong>HR01</strong>W).<br />

The unit is fitted <strong>with</strong> two independent fans. Each fan has full<br />

speed control for background and boost ventilation rates as<br />

well as a run-on timer facility. To recover heat from the extract<br />

air the heat exchanger block is utilised. This heat exchanger<br />

can recover up to 95% of the normally wasted heat.<br />

Figure 1. Airflow through unit.<br />

Figure 3. Fixing the mounting<br />

bracket to the rear of unit.<br />

Figure 4. Mounting the unit on<br />

the wall mounted bracket.<br />

Exhaust air<br />

from house<br />

to outside<br />

Intake air<br />

from outside<br />

Supply air<br />

to house<br />

Extract air<br />

from house<br />

2.0 Installation<br />

Installation must be carried out by competent personnel in<br />

accordance <strong>with</strong> the appropriate authority and conforming<br />

to all statutory governing regulations.<br />

All mains wiring must be in accordance <strong>with</strong> the current I.E.E.<br />

Regulations, or the appropriate standards. Ensure that the<br />

mains supply (Voltage, Frequency and Phase) complies <strong>with</strong><br />

the rating label.<br />

Please note a clear working space is required around the<br />

installed unit to allow the cover to be removed and provide<br />

sufficient access for maintenance such as filter change.<br />

The fan must be installed indoors, on a wall away from direct<br />

sources of frost, heat, water spray or moisture generation. For<br />

a vibration-free result the unit must be mounted to a solid wall.<br />

The unit is designed for wall mounting only.<br />

1. One part of the mounting bracket should be offered up to<br />

the wall, ensuring it’s located horizontally. Mark the fixing<br />

points through the pre drilled holes in the bracket and<br />

install <strong>with</strong> screws (by others), ensuring the interlock side<br />

is at the top (fig. 2).<br />

2. Fix the remaining part of the bracket to the unit using the<br />

M6 screws ensuring the interlock side is at the bottom (fig. 3).<br />

3. Install the unit on the wall by ensuring the bracket on the<br />

unit interlocks over the wall mounted bracket (fig. 4).<br />

2.1 Condensate Drain<br />

1. Remove the front cover from the unit.<br />

2. Insert the drain connector through the base of the unit from<br />

outside. The condensate must be discharged under a water<br />

level in a U-trap drainpipe or an alternative drain method<br />

which acts as an airlock.<br />

3. Ensure the drain connector forms a seal <strong>with</strong> the drain tray<br />

applying sealant if necessary. This condensate discharge<br />

connection is suitable for 21.5mm dia. overflow pipe.<br />

Solvent cement should be used to make the joint.<br />

4. Pour water into the drip tray to create an air trap.<br />

Figure 5. Condensate pipe connection to unit and a typical<br />

example of a “U” trap drainpipe.<br />

Collar<br />

21.5mm dia. condensate pipe.<br />

See point 3 above for sealing.<br />

5 o Drop<br />

Polypipe <strong>Ventilation</strong> Sandall Stones Road, Kirk Sandall Industrial Estate, Kirk Sandall, Doncaster, DN3 1QR<br />

Tel: +44 (0)8443 715 523 Fax: +44 (0)8443 715 524<br />

1<br />

Leaflet Number 671446 February 2010

Installation and Maintenance<br />

<strong>HR01</strong> <strong>Appliance</strong>-Wall<br />

2.2 Extract/input areas<br />

The unit is designed to extract air from<br />

all wet rooms e.g. bathroom, kitchen,<br />

en-suite, utility room (<strong>with</strong> sink).<br />

WC’s do not need to be ventilated<br />

if openable windows are fitted.<br />

Supply air should be to all habitable<br />

rooms e.g. bedrooms and lounge.<br />

Extract / input grilles should be<br />

adjustable valve types (not supplied).<br />

2<br />

3<br />

Figure 6. Main unit components and spigot location.<br />

1<br />

4<br />

Mounting bracket<br />

on wall and rear of<br />

unit.<br />

2.3 Ducting<br />

The use of flexible ducting must be kept<br />

to a minimum and should always be<br />

pulled taut.<br />

To prevent condensation on the outside<br />

of the outside air inlet duct and the air<br />

outlet duct from the <strong>HR01</strong> <strong>Appliance</strong>-Wall<br />

& Wall Bypass, these ducts should be<br />

insulated.<br />

Ducting must be installed in such a way<br />

that resistance to airflow is minimised.<br />

A minimum distance of 200mm between<br />

the appliance and any bends in ductwork<br />

is recommended.<br />

Ducting joints must be sealed <strong>with</strong><br />

ducting tape and or silicone type sealant.<br />

Unit heat<br />

exchanger pod.<br />

Condensate<br />

tray.<br />

Two removable<br />

G2 filters.<br />

(Code: <strong>HR01</strong>FG2<br />

Removable access cover.<br />

Spigot Location and Ducting references (see figure 6)<br />

Spigot 1. 125mm dia. = extract air from dwelling.<br />

Spigot 2. 125mm dia. = exhaust air to outside.<br />

Spigot 3. 125mm dia. = intake air from outside.<br />

Spigot 4. 125mm dia. = supply air to house.<br />

3.0 Dimensions<br />

View from front <strong>with</strong> cover removed<br />

IMPORTANT: Any air intake<br />

terminal MUST be installed in<br />

accordance <strong>with</strong> the appropriate<br />

regulation.<br />

As a guide, the BS5440 series of<br />

British Standards deals <strong>with</strong> this<br />

issue and currently states that an<br />

air intake must be at a minimum<br />

distance of 300mm from a gas<br />

boiler balanced flue. Installers<br />

are advised to be aware of the<br />

requirements of this standard<br />

when installing ‘through the wall’<br />

supply air ducting. Similarly,<br />

supply and extract air grilles<br />

should be at least 300mm apart.<br />

435<br />

21.5mm dia. condensate drain<br />

598<br />

View from top<br />

Mounting bracket<br />

SIDE VIEW<br />

Mounting<br />

bracket<br />

285<br />

2<br />

Leaflet Number 671446 February 2010

Installation and Maintenance<br />

<strong>HR01</strong> <strong>Appliance</strong>-Wall<br />

4.0 Electrical Connection<br />

Please note: the electrical connection of the unit must be be carried<br />

out by a qualified electrician.<br />

For good EMC engineering practice, any sensor cables<br />

or switched live cables should not be<br />

placed <strong>with</strong>in 50mm of other cables or on the same<br />

metal cable tray as other cables.<br />

Electrical details:-<br />

Voltage: 240V 1ph 50Hz<br />

Consumption: 75W (max) 0.6 amps<br />

Fuse rating: 3 Amp<br />

NOTE This unit must be earthed.<br />

Figure 7a. Power supply<br />

PCB. 230V in, 24V dc out.<br />

Earth point<br />

230V IN<br />

50Hz<br />

Mains<br />

SL N L<br />

Figure 8.<br />

Unit serving Kitchen and Bathroom<br />

MAINS<br />

230V<br />

50Hz<br />

N<br />

L<br />

Fuse 2A<br />

Light<br />

switch<br />

(Double<br />

Pole)<br />

Kitchen switch<br />

Room<br />

light<br />

3 Pole<br />

isolator<br />

Fan<br />

Unit<br />

N<br />

L<br />

SL<br />

Figure 9.<br />

Unit serving Kitchen and two Bathrooms<br />

Fan<br />

Unit<br />

Figure 7b.<br />

Control PCB. 24V<br />

Internal wiring<br />

MAINS<br />

230V<br />

50Hz<br />

N<br />

L<br />

Fuse 2A<br />

Light<br />

switches<br />

(Double<br />

Pole)<br />

Kitchen switch<br />

Room<br />

lights<br />

N<br />

L<br />

SL<br />

3 Pole<br />

isolator<br />

Connections for<br />

optional controls<br />

Volt free relay<br />

contacts I<br />

Fault<br />

Run<br />

Switch to deactivate<br />

continuous trickle<br />

Fan connections<br />

3<br />

Leaflet Number 671446 February 2010

Installation and Maintenance<br />

Electrical connection cont.<br />

Optional Connections<br />

Ecosmart control (see figure 7b)<br />

(a) J11/12/13<br />

The IDC plug-in connectors are provided for the connection of<br />

compatible sensors.<br />

NOTE: Do not run the data cable in the same conduit as the<br />

mains cable and leave a 50mm separation <strong>with</strong> any power<br />

cables.<br />

(b) Volt Free Relay Contacts<br />

Note that the volt free contacts are not fused. If these are used<br />

to power any external equipment, the installer must provide<br />

adequate fusing or other protections. These contacts are rated<br />

at 5A resistive, 0.5A inductive.<br />

6.0 Commissioning<br />

1. For the required airflow rates refer to the design<br />

specification for the property or refer to Building<br />

Regulations Part F.<br />

2. The unit is supplied <strong>with</strong> control of both the normal<br />

airflow and boost airflow. (see figure below).<br />

3. Commissioning should be carried out using a moving<br />

vane anemometer in conjunction <strong>with</strong> a hood.<br />

4. Once commissioned the house owner / tenant should<br />

be informed that the unit should not be adjusted as it<br />

will have a detrimental effect on the indoor air quality<br />

and could result in condensation and mould growth.<br />

Figure 10. Detail of unit control on front panel.<br />

<strong>HR01</strong> <strong>Appliance</strong>-Wall<br />

Run connections (J5) - These contacts are closed when the<br />

fan is running.<br />

Fault connections (J7) -No fault = the contacts are closed.<br />

Fault = The contacts are opened (this includes no power<br />

supply at the unit).<br />

(c) Data Cable installation<br />

A 4-core data cable is used to connect devices such as<br />

sensors to the fan and for interconnecting multiple fan units.<br />

Do not run data cable in the same conduit as the mains cables<br />

and ensure there is a 50mm separation between the data<br />

cable and other cables. The maximum cable run between any<br />

two devices is 300m when it is installed in accordance <strong>with</strong><br />

the instructions.<br />

Please note that the total data cable length used in any<br />

system must be less than 1000m. Keep the number of cable<br />

joints to a minimum to ensure the best data transmission<br />

efficiency between devices.<br />

LED Indication<br />

PWR GREEN: Power on and OK,<br />

RED:<br />

Standby LED on when fan is not running.<br />

As the unit runs continuously this LED<br />

should be off. If it is illuminated locate the<br />

trickle switch and change its position.<br />

Fan 1 GREEN: Fan 1 is running, RED: Fan 1 faulty.<br />

Fan 2 GREEN: Fan 2 is running, RED: Fan 2 faulty.<br />

5.0 Ancillaries<br />

<strong>HR01</strong>-PIR Sensor<br />

<strong>HR01</strong>-Humidistat Sensor<br />

<strong>HR01</strong>-System Monitor<br />

(Code: <strong>HR01</strong>P)<br />

(Code: <strong>HR01</strong>H)<br />

(Code: <strong>HR01</strong>M)<br />

4<br />

Leaflet Number 671446 February 2010

Installation and Maintenance<br />

<strong>HR01</strong> <strong>Appliance</strong>-Wall<br />

7.0 Maintenance/Cleaning<br />

Isolation - Before commencing work make sure that<br />

the unit, switched live and control are electrically<br />

isolated from the mains supply and switched live supply.<br />

1. We recommend that the two G2 fiters are inspected after<br />

6 months, and replaced every 12 to 18 months.<br />

2. Remove the front cover and slide out the filters which<br />

are fitted either side of the heat exchanger, return or<br />

replace them as necessary.<br />

3. Inspect the heat exchanger every 5 years.<br />

Generally check for damage and security of components.<br />

Refit cover.<br />

4. Inspecting motors. Motors can be accessed through<br />

removal side panels.<br />

8.0 Replacement of Parts<br />

Should any component need replacing Polypipe keep extensive<br />

stocks for quick delivery. Ensure that the unit is electrically<br />

isolated, before carrying out any work.<br />

When ordering spare parts, please quote the serial number<br />

of the unit and the ARC number of the purchase if possible.<br />

(This information will be available on the fan label).<br />

9.0 Warranty<br />

Standard warranty starts from the day of purchase or delivery.<br />

Polypipe extend the warranty from one to three years on<br />

receipt of the warranty card attached and proof of delivery/<br />

purchase, providing this is returned <strong>with</strong>in the first year.<br />

The warranty covers all parts proven to be faulty at point of<br />

manufacture but excludes problems arising from incorrect<br />

installation. In this instance, if a Polypipe engineer is required<br />

to attend site the call out will be chargeable.<br />

This warranty is conditional upon evidence of planned<br />

maintenance and does not extend to consumable items.<br />

Damaged appliances must not be installed but returned to<br />

point of purchase.<br />

10.0 Service Enquiries<br />

Polypipe can assist you in all aspects of service. Our service<br />

department will be happy to provide any assistance required,<br />

initially by telephone and If necessary arrange for an<br />

engineer to call.<br />

5<br />

Leaflet Number 671446 February 2010

Notes<br />

6<br />

Leaflet Number 671446 February 2010

Notes<br />

7<br />

Leaflet Number 671446 February 2010

Installation and Maintenance<br />

<strong>HR01</strong> <strong>Appliance</strong>-Wall<br />

11.0 Warranty Card <strong>HR01</strong> <strong>Appliance</strong>-Wall<br />

*Name:<br />

*Address:<br />

*Postcode:<br />

*Telephone:<br />

Email:<br />

*Model:<br />

*Serial No:<br />

Installer:<br />

Installer Address:<br />

*Date Installed:<br />

*Date Purchased:<br />

Retailer:<br />

Retailer Location:<br />

May we send you relevant product information and remind you when service is due<br />

Your details will not be disclosed to any third party.<br />

*Data required<br />

Return <strong>with</strong> proof of delivery/purchase to:<br />

Polypipe <strong>Ventilation</strong><br />

Sandall Stones Road,<br />

Kirk Sandall Industrial Estate,<br />

Kirk Sandall,<br />

Doncaster, DN3 1QR<br />

Tel: +44 (0)8443 715 523<br />

Fax: +44 (0)8443 715 524<br />

Technical or commercial considerations may, from time to time, make it necessary to alter the design, performance and<br />

dimensions of equipment and the right is reserved to make such changes <strong>with</strong>out prior notice.<br />

8<br />

Leaflet Number 671446 February 2010

The EMC Directive 89/336/EEC<br />

With modification 92/31/EEC<br />

The Low Voltage directive 73/23/EEC<br />

<strong>HR01</strong>-PIR Sensor<br />

(Low Voltage Passive Infra Red)<br />

Installation and Maintenance<br />

IMPORTANT: Please refer to the installation instructions<br />

of the fan to check the compatibility of this sensor.<br />

Code: <strong>HR01</strong>P<br />

Parts check list:<br />

● <strong>HR01</strong>-PIR Passive Infra Red Occupancy Sensor<br />

● 1 off 10 metre length of plugged cable<br />

1.0 <strong>HR01</strong>-PIR Sensor<br />

Designed to be compatible <strong>with</strong> the Ecosmart system, this<br />

PIR sensor is supplied <strong>with</strong> a pre-plugged, 10 metre length of<br />

communications cable. Note: longer lengths are available if<br />

required.<br />

The PIR sensor operates <strong>with</strong> low voltage <strong>with</strong> power supplied<br />

from the fan unit via the communications cable.<br />

The PIR sensor will activate the system when movement is<br />

detected. An adjustable 1-60 minute timer is incorporated to<br />

provide a run on facility.<br />

2.0 Fault indication<br />

The LED will change from green to red if any fan connected in<br />

that zone has failed.<br />

3.0 Multiple Sensors<br />

Multiple sensors can be connected to the network.<br />

Please refer to the actual fan installation instructions for exact<br />

quantities.<br />

4.0 Installing <strong>HR01</strong>-PIR Sensor<br />

The PIR sensor should be installed away from any direct<br />

source of heat (e.g. radiators) and areas where it would be<br />

subjected to waterspray.<br />

The sensor is supplied complete <strong>with</strong> 10 metres of connecting<br />

cable <strong>with</strong> plugs attached. Sensors are also supplied <strong>with</strong> all<br />

fixings and are clipped into a backplate wall mounting bracket.<br />

a) Fix one end of the 10m cable to the fans customer<br />

connection box (connection sockets marked NET).<br />

b) Select a suitable location for the sensor and arrange the<br />

cable in position. Leave approx. 75mm of the cable free at<br />

the mounting point to ease the connection of the plug (fig.1).<br />

c) Carefully separate the sensor from the backplate using a<br />

small screwdriver (see Fig 2) Note: the sensor will remain<br />

connected by its internal cable.<br />

d) Release this cable from the bracket by simply pulling the<br />

plug off the socket pins in the backplate.<br />

e) Before fixing the backplate to the wall, connect the wall<br />

fixed cable end plug to the upper set of pins on the bracket<br />

(fig 3) Note: check the colour code matching on when<br />

fitting the plug onto the pins.<br />

Arrange the cable to lay in the cable slot at the top of the<br />

backplate moulding and fix the bracket to the wall surface<br />

using the screws supplied.<br />

f) The sensor plug can now be connected into the backplate<br />

Note: check the colour code matching when fitting the<br />

plug onto the pins.<br />

Clip the sensor body in the backplate arms and adjust the<br />

sensor body to the desired position.<br />

Figure 1.<br />

Figure 3.<br />

Figure 5.<br />

10m sensor connection<br />

wire (supplied).<br />

Clearance aperture for wire<br />

should be approx 20mm dia<br />

to allow passage of plug end.<br />

Allow approx 75mm of wire<br />

through for fitting to the<br />

backplate.<br />

To fan connector<br />

box terminal<br />

marked NET.<br />

Backplate<br />

(rear view).<br />

Plug end.<br />

Note colour<br />

code guide<br />

label when<br />

fitting.<br />

Set point<br />

adjuster screw.<br />

Wire can be located behind<br />

a wall panel or fixed to wall<br />

surface.<br />

Wall<br />

Figure 4.<br />

Fixing screws supplied.<br />

Figure 2.<br />

Small screwdriver<br />

Before fixing the backplate<br />

to the wall, fit the plug end<br />

from sensor body into the<br />

backplate.<br />

Note that colour coded<br />

connections are matching<br />

Sensor can now clip onto<br />

backplate.<br />

Polypipe <strong>Ventilation</strong> Sandall Stones Road, Kirk Sandall Industrial Estate, Kirk Sandall, Doncaster, DN3 1QR<br />

Tel: +44 (0)8443 715 523 Fax: +44 (0)8443 715 524<br />

Leaflet Number 671450 February 2010

Installation and Maintenance<br />

5.0 Data cable installation<br />

A 4-core data cable is used to connect devices. Do not run<br />

data cable in the same conduit as the mains cables and<br />

ensure there is a 50mm separation between the data cable<br />

and other cables. The maximum cable run between any two<br />

devices is 300m when it is installed in accordance <strong>with</strong> the<br />

instructions. Please note that the total data cable length used<br />

in any system must be less than 1000m. Keep the number of<br />

cable joints to a minimum to ensure the best data transmission<br />

efficiency between devices.<br />

6.0 Adjusting the <strong>HR01</strong>-PIR run on<br />

timer (1-60 minutes)<br />

Assuming the sensor(s) are installed, adjustment of the set<br />

points achieved by tilting the sensor forwards which exposes<br />

the adjustment aperture (see fig 5). Using a small screwdriver,<br />

gently turn the dial either clockwise or anti-clockwise to<br />

increase or decrease the set point. When adjustments are<br />

made to the sensor, the LED light on the sensor front will flash<br />

on and off to show the set point. First, green flashes will<br />

indicate the set point in TENS, then red flashes will indicate<br />

UNITS. For example one green flash and five red flashes show<br />

you that the PIR timer is set to fifteen minutes.<br />

7.0 Detection range<br />

Up to 10m directly in front of lens and up to 2m at 40 o to the<br />

lens axis.<br />

<strong>HR01</strong>-PIR Sensor<br />

8.0 Maintenance<br />

The unit does not require any maintenance. However, for<br />

optimum performance, it is advisable to remove any<br />

accumulated dust <strong>with</strong> a low power vacuum cleaner.<br />

NOTE: Installation and Maintenance of the equipment must<br />

be as directed in the instructions provided <strong>with</strong> the unit.<br />

9.0 Warranty<br />

Standard warranty starts from the day of purchase or delivery.<br />

Polypipe extend the warranty from one to three years on<br />

receipt of the warranty card attached and proof of delivery/<br />

purchase, providing this is returned <strong>with</strong>in the first year.<br />

The warranty covers all parts proven to be faulty at point of<br />

manufacture but excludes problems arising from incorrect<br />

installation. In this instance, if a Polypipe engineer is required<br />

to attend site the call out will be chargeable.<br />

This warranty is conditional upon evidence of planned<br />

maintenance and does not extend to consumable items.<br />

Damaged appliances must not be installed but returned to<br />

point of purchase.<br />

10.0 Service Enquiries<br />

Polypipe can assist you in all aspects of service. Our service<br />

department will be happy to provide any assistance required,<br />

initially by telephone and If necessary arrange for an engineer<br />

to call.<br />

11.0 Warranty Card <strong>HR01</strong>-PIR Sensor<br />

*Name:<br />

*Address:<br />

*Postcode:<br />

*Telephone:<br />

Email:<br />

*Model:<br />

*Serial No:<br />

Installer:<br />

Installer Address:<br />

*Date Installed:<br />

*Date Purchased:<br />

Retailer:<br />

Retailer Location:<br />

May we send you relevant product information and remind you when service is due<br />

Your details will not be disclosed to any third party.<br />

*Data required:<br />

Return <strong>with</strong> proof of delivery/purchase to:<br />

Polypipe <strong>Ventilation</strong><br />

Sandall Stones Road, Kirk Sandall Industrial Estate,<br />

Kirk Sandall, Doncaster, DN3 1QR<br />

Tel: +44 (0)8443 715 523 Fax: +44 (0)8443 715 524<br />

Technical or commercial considerations may, from time to time,<br />

make it necessary to alter the design, performance<br />

and dimensions of equipment and the right is reserved to make<br />

such changes <strong>with</strong>out prior notice.<br />

Leaflet Number 671450 February 2010

The EMC Directive 89/336/EEC<br />

With modification 92/31/EEC<br />

The Low Voltage directive 73/23/EEC<br />

<strong>HR01</strong>-Humidistat Sensor<br />

(Low Voltage)<br />

Installation and Maintenance<br />

IMPORTANT: Please refer to the installation instructions<br />

of the fan to check the compatibility of this sensor.<br />

Code: <strong>HR01</strong>H<br />

Parts check list:<br />

● <strong>HR01</strong>-Humidistat Sensor<br />

● 1 off 10 metre length of plugged cable<br />

1.0 <strong>HR01</strong>-Humidistat Sensor<br />

Designed to be compatible <strong>with</strong> the Ecosmart system, this<br />

Humidistat sensor is supplied <strong>with</strong> a pre-plugged, 10 metre<br />

length of communications cable. Note: longer lengths are<br />

available if required.<br />

The Humidistat sensor operates <strong>with</strong> low voltage <strong>with</strong> power<br />

supplied from the fan unit via the communications cable.<br />

The Humidistat sensor will enable the fan when the measured<br />

humidity level is 2% above the set point and will stop the fan<br />

when the humidity is at or below set point.<br />

2.0 Fault indication<br />

The LED will change from green to red if any fan connected in<br />

that zone has failed.<br />

3.0 Multiple Sensors<br />

Multiple sensors can be connected to the network. Please refer<br />

to the actual fan installation instructions for exact quantities.<br />

4.0 Installing <strong>HR01</strong>-Humidistat Sensor<br />

The sensor unit should be installed away from any direct<br />

source of heat (e.g. radiators) and areas where it would be<br />

subjected to waterspray.<br />

The sensor is supplied complete <strong>with</strong> 10 metres of connecting<br />

cable <strong>with</strong> plugs attached. Sensors are also supplied <strong>with</strong> all<br />

fixings and are clipped into a backplate wall mounting bracket.<br />

a) Fix one end of the 10m cable to the fans customer<br />

connection box (connection sockets marked NET).<br />

b) Select a suitable location for the sensor and arrange the<br />

cable in position. Leave approx. 75mm of the cable free at<br />

the mounting point to ease the connection of the plug (fig.1).<br />

c) Carefully separate the sensor from the backplate using a<br />

small screwdriver (see Fig 2) Note: the sensor will remain<br />

connected by its internal cable.<br />

d) Release this cable from the bracket by simply pulling the<br />

plug off the socket pins in the backplate.<br />

e) Before fixing the backplate to the wall, connect the wall<br />

fixed cable end plug to the upper set of pins on the bracket<br />

(fig 3) Note: check the colour code matching on when<br />

fitting the plug onto the pins.<br />

Arrange the cable to lay in the cable slot at the top of the<br />

backplate moulding and fix the bracket to the wall surface<br />

using the screws supplied.<br />

f) The sensor plug can now be connected into the backplate<br />

Note: check the colour code matching when fitting the<br />

plug onto the pins.<br />

Clip the sensor body in the backplate arms and adjust the<br />

sensor body to the desired position.<br />

Figure 1.<br />

Figure 3.<br />

Figure 5.<br />

10m sensor connection<br />

wire (supplied).<br />

Clearance aperture for wire<br />

should be approx 20mm dia<br />

to allow passage of plug end.<br />

Allow approx 75mm of wire<br />

through for fitting to the<br />

backplate.<br />

To fan connector<br />

box terminal<br />

marked NET.<br />

Backplate<br />

(rear view).<br />

Plug end.<br />

Note colour<br />

code guide<br />

label when<br />

fitting.<br />

Set point<br />

adjuster screw.<br />

Wire can be located behind<br />

a wall panel or fixed to wall<br />

surface.<br />

Wall<br />

Figure 4.<br />

Fixing screws supplied.<br />

Figure 2.<br />

Small screwdriver<br />

Before fixing the backplate<br />

to the wall, fit the plug end<br />

from sensor body into the<br />

backplate.<br />

Note that colour coded<br />

connections are matching<br />

Sensor can now clip onto<br />

backplate.<br />

Polypipe <strong>Ventilation</strong> Sandall Stones Road, Kirk Sandall Industrial Estate, Kirk Sandall, Doncaster, DN3 1QR<br />

Tel: +44 (0)8443 715 523 Fax: +44 (0)8443 715 524<br />

Leaflet Number 671451 February 2010

Installation and Maintenance<br />

5.0 Data cable installation<br />

A 4-core data cable is used to connect devices. Do not run<br />

data cable in the same conduit as the mains cables and<br />

ensure there is a 50mm separation between the data cable<br />

and other cables. The maximum cable run between any two<br />

devices is 300m when it is installed in accordance <strong>with</strong> the<br />

instructions.<br />

Please note that the total data cable length used in any<br />

system must be less than 1000m. Keep the number of cable<br />

joints to a minimum to ensure the best data transmission<br />

efficiency between devices.<br />

6.0 Adjusting the <strong>HR01</strong>-Humidistat<br />

set points<br />

(Adjustable RH settings 65 - 85%)<br />

Assuming the sensor(s) are installed, adjustment of the set<br />

points achieved by tilting the sensor forwards which exposes<br />

the adjustment aperture (see fig 5).<br />

Using a small screwdriver, gently turn the dial either clockwise<br />

or anti-clockwise to increase or decrease the set point.<br />

When adjustments are made to the sensor, the LED light on<br />

the sensor front will flash on and off to show the set point.<br />

First, green flashes will indicate the set point in TENS, then red<br />

flashes will indicate UNITS. For example seven green flashes<br />

and three red flashes show a RH set point of 73%.<br />

7.0 Maintenance<br />

Standard warranty starts from the day of purchase or delivery.<br />

Polypipe extend the warranty from one to three years on<br />

receipt of the warranty card attached and proof of delivery/<br />

purchase, providing this is returned <strong>with</strong>in the first year.<br />

The warranty covers all parts proven to be faulty at point of<br />

manufacture but excludes problems arising from incorrect<br />

installation. In this instance, if a Polypipe engineer is required<br />

to attend site the call out will be chargeable.<br />

This warranty is conditional upon evidence of planned<br />

maintenance and does not extend to consumable items.<br />

Damaged appliances must not be installed but returned to<br />

point of purchase.<br />

8.0 Warranty<br />

<strong>HR01</strong>-Humidistat Sensor<br />

The 3 year warranty starts from the day of delivery and<br />

includes parts and labour for the first year.<br />

The remaining 2 years covers replacement parts only.<br />

This warranty is conditional on planned maintenance being<br />

undertaken.<br />

9.0 Service Enquiries<br />

Polypipe can assist you in all aspects of service. Our service<br />

department will be happy to provide any assistance required,<br />

initially by telephone and If necessary arrange for an engineer<br />

to call.<br />

10.0 Warranty Card <strong>HR01</strong>-Humidistat Sensor<br />

*Name:<br />

*Address:<br />

*Postcode:<br />

*Telephone:<br />

Email:<br />

*Model:<br />

*Serial No:<br />

Installer:<br />

Installer Address:<br />

*Date Installed:<br />

*Date Purchased:<br />

Retailer:<br />

Retailer Location:<br />

May we send you relevant product information and remind you when service is due<br />

Your details will not be disclosed to any third party.<br />

*Data required:<br />

Return <strong>with</strong> proof of delivery/purchase to:<br />

Polypipe <strong>Ventilation</strong><br />

Sandall Stones Road, Kirk Sandall Industrial Estate,<br />

Kirk Sandall, Doncaster, DN3 1QR<br />

Tel: +44 (0)8443 715 523 Fax: +44 (0)8443 715 524<br />

Technical or commercial considerations may, from time to time,<br />

make it necessary to alter the design, performance<br />

and dimensions of equipment and the right is reserved to make<br />

such changes <strong>with</strong>out prior notice.<br />

Leaflet Number 671451 February 2010

The EMC Directive 89/336/EEC<br />

With modification 92/31/EEC<br />

The Low Voltage directive 73/23/EEC<br />

<strong>HR01</strong>-System Monitor<br />

(Low Voltage Remote Fail Indicator)<br />

Installation and Maintenance<br />

IMPORTANT: Please refer to the installation instructions<br />

of the fan to check the compatibility of this sensor.<br />

Code: <strong>HR01</strong>M<br />

Parts check list:<br />

● <strong>HR01</strong>-System Monitor<br />

● 1 off 10 metre length of plugged cable<br />

1.0 <strong>HR01</strong>-System Monitor<br />

Designed to be compatible <strong>with</strong> the Ecosmart system, this<br />

system monitor sensor is supplied <strong>with</strong> a preplugged 10m<br />

length of communication cable. Longer lengths are available<br />

if required.<br />

The sensor operates <strong>with</strong> low voltage <strong>with</strong> power supplied by<br />

the fan unit via the communication cable.<br />

When a fan failure occurs the sensor will flash a warning on<br />

the large RED ‘LED’.<br />

A warning sounder will be heard for at least 10 seconds.<br />

Then one second every minute until the fault is cleared.<br />

The smaller ‘LED’ on the front panel shows the status of the<br />

monitor, showing GREEN when correctly connected and RED<br />

if there is a problem.<br />

2.0 Installing <strong>HR01</strong>-System Monitor<br />

The sensor unit should be installed away from any direct<br />

source of heat (e.g. radiators) and areas where it would be<br />

subjected to waterspray.<br />

The sensor is supplied complete <strong>with</strong> 10 metres of connecting<br />

cable <strong>with</strong> plugs attached. Units are also supplied <strong>with</strong> all<br />

fixings and are clipped into a backplate wall mounting bracket.<br />

a) Fix one end of the 10m cable to the fans customer<br />

connection box (connection sockets marked NET).<br />

b) Select a suitable location for the sensor and arrange the<br />

cable in position. Leave approx. 75mm of the cable free at<br />

the mounting point to ease the connection of the plug (fig.1).<br />

c) Carefully separate the sensor from the backplate using a<br />

small screwdriver (see Fig 2) Note: the sensor will remain<br />

connected by its internal cable.<br />

d) Release this cable from the bracket by simply pulling the<br />

plug off the socket pins in the backplate.<br />

e) Before fixing the backplate to the wall, connect the wall<br />

fixed cable end plug to the upper set of pins on the bracket<br />

(fig 3) Note: check the colour code matching on when<br />

fitting the plug onto the pins.<br />

Arrange the cable to lay in the cable slot at the top of the<br />

backplate moulding and fix the bracket to the wall surface<br />

using the screws supplied.<br />

f) The sensor plug can now be connected into the backplate<br />

Note: check the colour code matching when fitting the<br />

plug onto the pins.<br />

Clip the sensor body in the backplate arms and adjust the<br />

sensor body to the desired position.<br />

Figure 1.<br />

Figure 3.<br />

Figure 5.<br />

10m sensor connection<br />

wire (supplied).<br />

Clearance aperture for wire<br />

should be approx 20mm dia<br />

to allow passage of plug end.<br />

Allow approx 75mm of wire<br />

through for fitting to the<br />

backplate.<br />

To fan connector<br />

box terminal<br />

marked NET.<br />

Backplate<br />

(rear view).<br />

Plug end.<br />

Note colour<br />

code guide<br />

label when<br />

fitting.<br />

Set point<br />

adjuster screw.<br />

Wire can be located behind<br />

a wall panel or fixed to wall<br />

surface.<br />

Wall<br />

Figure 4.<br />

Fixing screws supplied.<br />

Figure 2.<br />

Small screwdriver<br />

Before fixing the backplate<br />

to the wall, fit the plug end<br />

from sensor body into the<br />

backplate.<br />

Note that colour coded<br />

connections are matching<br />

Sensor can now clip onto<br />

backplate.<br />

Polypipe <strong>Ventilation</strong> Sandall Stones Road, Kirk Sandall Industrial Estate, Kirk Sandall, Doncaster, DN3 1QR<br />

Tel: +44 (0)8443 715 523 Fax: +44 (0)8443 715 524<br />

Leaflet Number 671452 February 2010

Installation and Maintenance<br />

3.0 Data cable installation<br />

Do not run data cable in the same conduit as the mains cables<br />

and ensure there is a 50mm separation between the data<br />

cable and other cables. The maximum cable run between any<br />

two devices is 300m when it is installed in accordance <strong>with</strong><br />

the instructions.<br />

Please note that the total data cable length used in any system<br />

must be less than 1000m. Keep the number of cable joints to<br />

a minimum to ensure the best data transmission<br />

efficiency between devices.<br />

4.0 Maintenance<br />

The unit does not require any maintenance. However, for<br />

optimum performance, it is advisable to remove any<br />

accumulated dust <strong>with</strong> a low power vacuum cleaner.<br />

NOTE: Installation and Maintenance of the equipment must<br />

be as directed in the instructions provided <strong>with</strong> the unit.<br />

5.0 Warranty<br />

Standard warranty starts from the day of purchase or delivery.<br />

Polypipe extend the warranty from one to three years on<br />

receipt of the warranty card attached and proof of delivery/<br />

purchase, providing this is returned <strong>with</strong>in the first year.<br />

The warranty covers all parts proven to be faulty at point of<br />

manufacture but excludes problems arising from incorrect<br />

installation. In this instance, if a Polypipe engineer is required<br />

to attend site the call out will be chargeable.<br />

This warranty is conditional upon evidence of planned<br />

maintenance and does not extend to consumable items.<br />

Damaged appliances must not be installed but returned to<br />

point of purchase.<br />

6.0 Service Enquiries<br />

<strong>HR01</strong>-System Monitor<br />

Polypipe can assist you in all aspects of service. Our service<br />

department will be happy to provide any assistance required,<br />

initially by telephone and If necessary arrange for an engineer<br />

to call.<br />

7.0 Warranty Card <strong>HR01</strong>-System Monitor<br />

*Name:<br />

*Address:<br />

*Postcode:<br />

*Telephone:<br />

Email:<br />

*Model:<br />

*Serial No:<br />

Installer:<br />

Installer Address:<br />

*Date Installed:<br />

*Date Purchased:<br />

Retailer:<br />

Retailer Location:<br />

May we send you relevant product information and remind you when service is due<br />

Your details will not be disclosed to any third party.<br />

*Data required:<br />

Return <strong>with</strong> proof of delivery/purchase to:<br />

Polypipe <strong>Ventilation</strong><br />

Sandall Stones Road, Kirk Sandall Industrial Estate,<br />

Kirk Sandall, Doncaster, DN3 1QR<br />

Tel: +44 (0)8443 715 523 Fax: +44 (0)8443 715 524<br />

Technical or commercial considerations may, from time to time,<br />

make it necessary to alter the design, performance<br />

and dimensions of equipment and the right is reserved to make<br />

such changes <strong>with</strong>out prior notice.<br />

Leaflet Number 671452 February 2010