Multi-component boron coatings on low carbon steel AISI 1018

Multi-component boron coatings on low carbon steel AISI 1018

Multi-component boron coatings on low carbon steel AISI 1018

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

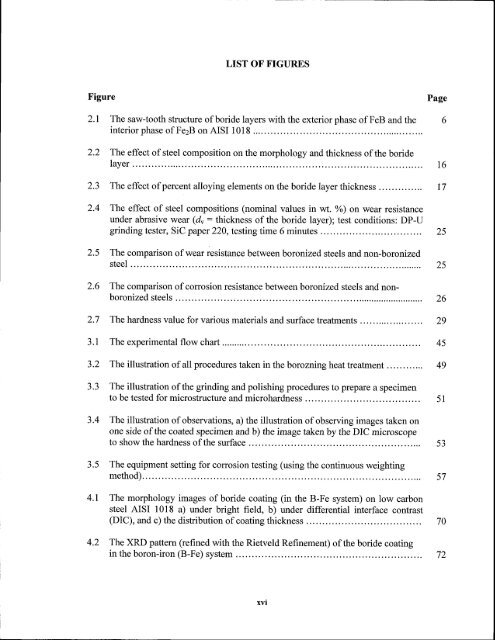

LIST OF FIGURES<br />

Figure<br />

Page<br />

2.1 The saw-tooth structure of boride layers with the exterior phase of FeB and the 6<br />

interior phase of Fe2B <strong>on</strong> <strong>AISI</strong> <strong>1018</strong><br />

2.2 The effect of <strong>steel</strong> compositi<strong>on</strong> <strong>on</strong> the morphology and thickness of the boride<br />

layer 16<br />

2.3 The effect of percent alloying elements <strong>on</strong> the boride layer thickness 17<br />

2.4 The effect of <strong>steel</strong> compositi<strong>on</strong>s (nominal values in wt. %) <strong>on</strong> wear resistance<br />

under abrasive wear (dv = thickness of the boride layer); test c<strong>on</strong>diti<strong>on</strong>s: DP-U<br />

grinding tester, SiC paper 220, testing time 6 minutes 25<br />

2.5 The comparis<strong>on</strong> of wear resistance between <str<strong>on</strong>g>bor<strong>on</strong></str<strong>on</strong>g>ized <strong>steel</strong>s and n<strong>on</strong>-<str<strong>on</strong>g>bor<strong>on</strong></str<strong>on</strong>g>ized<br />

<strong>steel</strong> 25<br />

2.6 The comparis<strong>on</strong> of corrosi<strong>on</strong> resistance between <str<strong>on</strong>g>bor<strong>on</strong></str<strong>on</strong>g>ized <strong>steel</strong>s and n<strong>on</strong><str<strong>on</strong>g>bor<strong>on</strong></str<strong>on</strong>g>ized<br />

<strong>steel</strong>s 26<br />

2.7 The hardness value for various materials and surface treatments 29<br />

3.1 The experimental f<strong>low</strong> chart 45<br />

3.2 The illustrati<strong>on</strong> of all procedures taken in the borozning heat treatment 49<br />

3.3 The illustrati<strong>on</strong> of the grinding and polishing procedures to prepare a specimen<br />

to be tested for microstructure and microhardness 51<br />

3.4 The illustrati<strong>on</strong> of observati<strong>on</strong>s, a) the illustrati<strong>on</strong> of observing images taken <strong>on</strong><br />

<strong>on</strong>e side of the coated specimen and b) the image taken by the DIC microscope<br />

to show the hardness of the surface 53<br />

3.5 The equipment setting for corrosi<strong>on</strong> testing (using the c<strong>on</strong>tinuous weighting<br />

method) 57<br />

4.1 The morphology images of boride coating (in the B-Fe system) <strong>on</strong> <strong>low</strong> carb<strong>on</strong><br />

<strong>steel</strong> <strong>AISI</strong> <strong>1018</strong> a) under bright field, b) under differential interface c<strong>on</strong>trast<br />

(DIC), and c) the distributi<strong>on</strong> of coating thickness 70<br />

4.2 The XRD pattern (refined with the Rietveld Refinement) of the boride coating<br />

in the <str<strong>on</strong>g>bor<strong>on</strong></str<strong>on</strong>g>-ir<strong>on</strong> (B-Fe) system 72<br />

xvi