Gladiator Microwave Manual - Hawk Measurement

Gladiator Microwave Manual - Hawk Measurement

Gladiator Microwave Manual - Hawk Measurement

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

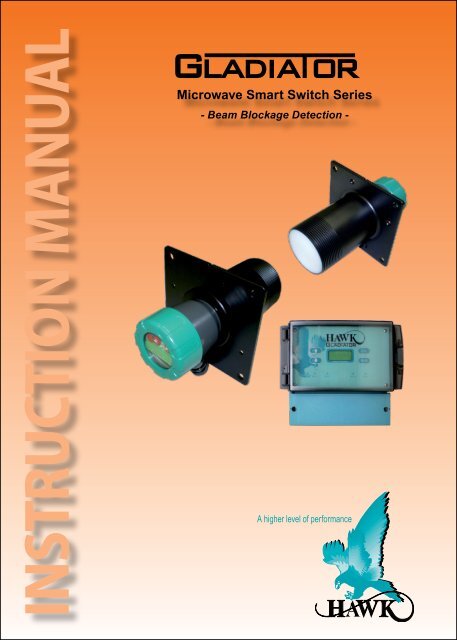

INSTRUCTION MANUAL<br />

<strong>Microwave</strong> Smart Switch Series<br />

- Beam Blockage Detection -<br />

A higher level of performance

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

INTRODUCTION<br />

CONTENTS<br />

PROPRIETARY NOTICE<br />

The information contained in this publication<br />

is derived in part from proprietary and patent<br />

data. This information has been prepared for<br />

the express purpose of assisting operating and<br />

maintenance personnel in the efficient use of the<br />

instrument described herein. Publication of this<br />

information does not convey any rights to use or<br />

reproduce it, or to use for any purpose other than<br />

in connection with the installation, operation and<br />

maintenance of the equipment described herein.<br />

WARNING<br />

This instrument contains electronic components<br />

that are susceptible to damage by static<br />

electricity. Proper handling procedures must<br />

be observed during the removal, installation, or<br />

handling of internal circuit boards or devices:<br />

Handling Procedure:<br />

1. Power to unit must be removed prior to<br />

commencement of any work.<br />

2. Personnel must be grounded, via wrist strap<br />

or other safe, suitable means, before any<br />

printed circuit board or other internal devices<br />

are installed, removed or adjusted.<br />

3. Printed circuit boards must be transported<br />

in a conductive bag or other conductive<br />

container. Boards must not be removed from<br />

protective container until the immediate time<br />

of installation. Removed boards must be<br />

placed immediately in a protective container<br />

for transport, storage, or return to factory.<br />

Comments:<br />

This instrument is not unique in its content<br />

of ESD (electrostatic discharge) sensitive<br />

components. Most modern electronic designs<br />

contain components that ut ilize metal oxide<br />

technology (NMOS, CMOS, etc.). Experience<br />

has proven that even small amounts of static<br />

electricity can damage or destroy these<br />

devices. Damaged components, even though<br />

they appear to function properly, exhibit early<br />

failure.<br />

General Description, Features 3<br />

Typical Applications 4-5<br />

Dimensions 6-12<br />

Mounting 13-17<br />

Wiring<br />

- Smart Integral Version 18<br />

- Remote - <strong>Hawk</strong> Cable 19<br />

- Remote - Customer Cable 20<br />

- Cable extensions 21<br />

- Relay Functions 22<br />

- Cross Talk Prevention<br />

• 2 Units 23<br />

• More than 2 Units 24<br />

- Multidrop Connections 25<br />

- <strong>Hawk</strong>Link GSM 26<br />

- Test Terminal 27<br />

Setup Procedure<br />

- Smart Integral Version 28<br />

- Remote Version 32<br />

Remote Software Menus<br />

- Software Tree 35<br />

- Diagnostic Displays 36<br />

- QuickSet Menu 37<br />

- App Types 38<br />

- Advanced Menu 39<br />

- Relay 2 Actions 41<br />

Troubleshooting / Error Codes 43<br />

Safety Information 44<br />

Part Numbering 45<br />

Specifications 48<br />

Contact Information (back cover)<br />

2

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

GENERAL DESCRIPTION<br />

FEATURES<br />

Principle of Operation<br />

Beam blockage<br />

A beam of microwave energy passes from<br />

a sender to a separate receiver in bursts<br />

approximately 200 times per second. If the<br />

path between the sender and receiver is<br />

blocked by any object or material which absorbs<br />

or reflects microwave energy, then the<br />

receiver will not be able to detect the signal.<br />

The presence or absence of the signal at<br />

the receiver is used to switch a relay for<br />

indication or control purposes.<br />

<strong>Microwave</strong>s are small (Micro) radio waves<br />

transmitted from point to point hence the<br />

system setup of ‘sender’ and ‘receiver’ units.<br />

Note:<br />

For wet, dusty environments where<br />

build up issues of wet high dielectric<br />

material is prevalent <strong>Microwave</strong><br />

technology will have performance<br />

problems. <strong>Hawk</strong> recommends the<br />

<strong>Gladiator</strong> Acoustic Switch for these<br />

applications.<br />

• Wide beam pattern for easy alignment<br />

• LCD setup/diagnostics on remote amplifier<br />

• Ranges up to 200 meters (656 ft)<br />

• Simple ‘1-minute’ setup<br />

• Remote sensor or Smart Integral ‘all in<br />

one’ types<br />

• Relay outputs: Smart Integral (1) Remote (2)<br />

• Remote test function<br />

• Adjustable ON and OFF delays (0-20 sec)<br />

• Smart communication options: Gos<strong>Hawk</strong>,<br />

Modbus, HART, Profibus DP, DeviceNet<br />

• Remote GSM Connection option<br />

• Remote amplifier to sensor separation up<br />

to 500 m (1640 ft)<br />

• Bright visual status indication on sensors<br />

• Independent housing alignment after<br />

mounting sensors<br />

3

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

TYPICAL APPLICATIONS<br />

Blocked Chute Detection / Machine Anti-Collision<br />

Shiploader Luffing<br />

Control/Boom Protection<br />

Boom Protection<br />

Shiploader Protection<br />

Blocked Chute Protection<br />

4

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

TYPICAL APPLICATIONS<br />

Bulk Material Handling<br />

High/low and blocked<br />

chute detection<br />

Receiving Unit<br />

Receiver<br />

<strong>Microwave</strong> Product Flow Blocked<br />

Chute Detection<br />

Customer<br />

Supplied<br />

Mounting<br />

Sender<br />

Flange Mounted to a<br />

Isolated Permanant S<br />

Structure i.e.<br />

I-Beam,and Rail, etc<br />

High Vibration Applic<br />

<strong>Microwave</strong> should be<br />

from normal material<br />

Brac<br />

Process Plants<br />

Solid Level - Cyclone Bin<br />

High/low Level<br />

<strong>Gladiator</strong><br />

Receiver<br />

Note: Distance between<br />

microwave face and window<br />

should not exceed 75mm (3")<br />

for all applications<br />

(UHMW/PTFE HighWindows,<br />

Sight Glass, Ceramic<br />

<strong>Gladiator</strong><br />

Brick<br />

and Firebrick assemblies).<br />

Sender<br />

Sending Unit<br />

“Blocked Chute”<br />

Mount <strong>Microwave</strong> under<br />

pulley or out of main<br />

Stable Support system flow<br />

Structure<br />

Receiver<br />

Sender<br />

Low<br />

<strong>Gladiator</strong><br />

Hopper/Feeder (Not to Scale)<br />

Ceramic or Firebrick<br />

W/Antenna Bracket<br />

High Temp Area<br />

High Temperature<br />

Non Intrusive Switch<br />

High/Low level<br />

Blocked Chute<br />

Wave Guides<br />

GLADIATOR<br />

Remote<br />

5

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

DIMENSIONS<br />

SMART INTEGRAL MICROWAVE SYSTEM<br />

Standard Sender or Receiver<br />

Ø85 mm (3.3”)<br />

High Power Sender,<br />

Receiver or SRS Receiver<br />

Ø85 mm (3.3”)<br />

50 mm (2”)<br />

129.5 mm (5.1”)<br />

135.5 mm (5.3”)<br />

90 mm (3.5”)<br />

2 mm (0.078”)<br />

10 mm (0.4”)<br />

50 mm (2”)<br />

90 mm (3.5”)<br />

12 mm (0.5”)<br />

Ø88 mm (3.5”)<br />

Ø160 mm (6.3”)<br />

250 mm (9.8”)<br />

Ø165 mm (6.5”)<br />

Ø277 mm (10.9”)<br />

Standard Sender or Receiver Flange<br />

High power Sender / Receiver or SRS Flange<br />

160 mm (6.3”)<br />

135 mm (5.3”)<br />

8xØ22 mm<br />

Holes THRU<br />

160 mm (6.3”)<br />

Alignment<br />

marks<br />

4x10 mm holes<br />

Ø238 mm(9.3”)<br />

Ø88.5 mm (3.5”)<br />

Ø165 mm (6.3”)<br />

Ø277 mm (10.9”)<br />

Note: Remote and Smart Integral types use the same flange dimensions<br />

6

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

DIMENSIONS<br />

REMOTE MICROWAVE SYSTEM<br />

Amplifier Enclosure<br />

192.5 mm (7.6”)<br />

174 mm (6.9”)<br />

111.5 mm (4.4”)<br />

78 mm (3.1”)<br />

14 mm (0.6”)<br />

30.7 mm (1.2”)<br />

7.5 mm (0.3”)<br />

192.5 mm (7.6”)<br />

147 mm (5.8”)<br />

108 mm (4.3”)<br />

190 mm (7.5”)<br />

107 mm (4.2”)<br />

190 mm (7.5”)<br />

167.5 mm (6.6”)<br />

141.5 mm (5.6”)<br />

131.5 mm (5.2”)<br />

182.5 mm (7.2”)<br />

50 mm (2”)<br />

74 mm (2.9”)<br />

4 mm (0.2”)<br />

147 mm (5.8”)<br />

158 mm (6.2”)<br />

182.5 mm (7.2”)<br />

Standard Sender or Receiver<br />

Ø85 mm (3.3”)<br />

High Power Sender,<br />

Receiver or SRS Receiver<br />

Ø85 mm (3.3”)<br />

50 mm (2”)<br />

90 mm (3.5”)<br />

2 mm (0.078”)<br />

10 mm (0.4”)<br />

129.5 mm (5.1”)<br />

135.5 mm (5.3”)<br />

50 mm (2”)<br />

90 mm (3.5”)<br />

12 mm (0.5”)<br />

Ø88 mm (3.5”)<br />

Ø160 mm (6.3”)<br />

250 mm (9.8”)<br />

Ø165 mm (6.5”)<br />

Note: For Flange dimensions see page 5<br />

Ø277 mm (10.9”)<br />

7

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

DIMENSIONS<br />

ACCESSORIES<br />

Weldments to suit UHMW/Teflon windows<br />

Size A B C D E F G<br />

G<br />

3” 100<br />

(3.94”)<br />

3”<br />

NPT 22<br />

(0.87”)<br />

5<br />

(0.2”)<br />

92.5<br />

(3.64”)<br />

118<br />

(4.65”)<br />

4<br />

(0.16”)<br />

A<br />

B<br />

E<br />

F<br />

4” 125<br />

(4.92”)<br />

6” 190.4<br />

(7.5”)<br />

4”<br />

NPT 24.4<br />

(0.96”)<br />

6”<br />

NPT 40<br />

(3.94”)<br />

5<br />

(0.2”)<br />

5<br />

(0.2”)<br />

120<br />

(4.72”)<br />

175<br />

(6.89”)<br />

148<br />

(5.83”)<br />

223<br />

(8.78”)<br />

4<br />

(0.16”)<br />

11.2<br />

(0.44”)<br />

UHMW/Teflon Windows<br />

75mm (2.95")<br />

Ø6.5mm(0.25”)<br />

2 Places<br />

I<br />

C<br />

H<br />

D<br />

15mm (0.59")<br />

3” steel weldment: MA-0 3” stainless steel weldment MA-19<br />

4” steel weldment: MA-18 4” stainless steel weldment MA-22<br />

Size H I<br />

3” 3”<br />

NPT<br />

4” 4”<br />

NPT<br />

6” 6”<br />

NPT<br />

28.7<br />

(1.13”)<br />

35<br />

(1.38”)<br />

40<br />

(1.57”)<br />

3” UHMW window only MA-21<br />

4” UHMW window only MA-20<br />

3” UHMW window & weldment MA-3<br />

4” UHMW window & weldment MA-4<br />

6” UHMW window & weldment MA-5<br />

3” teflon window & weldment MA-6<br />

4” teflon window & weldment MA-7<br />

6” teflon window & weldment MA-8<br />

Weldments to suit Ceramic windows R<br />

J<br />

K<br />

Retainer for Ceramic Windows<br />

(Bundled with matching Weldment)<br />

U<br />

Ø6.3mm(0.25”)<br />

2 Places<br />

L<br />

M<br />

N<br />

O P Q<br />

Size J K L M N O P Q R<br />

3” 100<br />

(3.94”)<br />

4” 125<br />

(4.92”)<br />

3”<br />

NPT<br />

4”<br />

NPT<br />

Ceramic Windows<br />

(Bundled with matching Weldment)<br />

22<br />

(0.87”)<br />

24.4<br />

(0.96”)<br />

5<br />

(0.2”)<br />

5<br />

(0.2”)<br />

65<br />

(2.56”)<br />

90<br />

(3.54”)<br />

75<br />

(2.95”)<br />

101<br />

(3.98”)<br />

92.5<br />

(3.64”)<br />

120<br />

(4.72”)<br />

118<br />

(4.65”)<br />

148<br />

(5.83”)<br />

Size S T U V<br />

3” 75<br />

(2.95”)<br />

65<br />

(2.56”)<br />

3”<br />

NPT<br />

74.5<br />

(2.93”)<br />

4<br />

(0.16”)<br />

4<br />

(0.16”)<br />

T<br />

V<br />

4” 100<br />

(3.94”)<br />

90<br />

(3.54”)<br />

4”<br />

NPT<br />

100.5<br />

(3.96”)<br />

S<br />

12.3mm (0.48”) 11-12.7mm (0.43-0.5”)<br />

3” ceramic window & weldment MA-16<br />

4” ceramic window & weldment MA-17<br />

Unlisted parts not available separately<br />

8

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

DIMENSIONS<br />

ACCESSORIES<br />

Ceramic Tile Window Assembly<br />

MA-10<br />

Ceramic Time Mounting Assembly<br />

152.4mm (6.0")<br />

101.6mm<br />

(4.0")<br />

317.5mm (12.5")<br />

Ceramic Tile (alumina)<br />

101.6mm (4.0")<br />

152.4mm (6.0")<br />

25.4mm (1")<br />

9

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

DIMENSIONS<br />

ACCESSORIES<br />

Firebrick Window Assembly<br />

MA-9<br />

Firebrick Mounting Assembly<br />

228.6mm (9.0")<br />

114.3mm<br />

(4.5")<br />

215.9mm<br />

(8.5")<br />

419.1mm (16.5")<br />

50.8mm<br />

(2.0")<br />

Firebrick<br />

114.3mm<br />

(4.5")<br />

228.6mm (9.0")<br />

76.2mm<br />

(3.0")<br />

10

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

DIMENSIONS<br />

ACCESSORIES<br />

Example High Temperature Waveguide Parts<br />

*All Waveguide Parts available on special order only<br />

Waveguide<br />

WR90 Cone<br />

41mm<br />

(1.625")<br />

33mm<br />

(1.283")<br />

41mm<br />

(1.625")<br />

32mm<br />

(1.275")<br />

10mm<br />

(0.90")<br />

23mm<br />

(0.890")<br />

Waveguide WR90 Straight<br />

FB<br />

GTAW<br />

4mm Ø.172) ( Thru<br />

Typ 4 Pics<br />

33mm<br />

(1.283")<br />

"A"<br />

Note: "A" = Per Application<br />

Finish Per Application<br />

33mm (1.283")<br />

Waveguide WR90 Bend<br />

4mm (Ø .172) Thru<br />

Type 8 Pics 33mm (1.283")<br />

FB<br />

33mm<br />

(1.283")<br />

"A"<br />

GTAW<br />

FB<br />

Note: "A" = Per Application<br />

Finish Per Application<br />

11

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

DIMENSIONS<br />

ACCESSORIES<br />

Adjustable <strong>Microwave</strong> Bracket<br />

MA-12 - With UHMW Window<br />

MA-13 - With PTFE Window<br />

135mm (5.3")<br />

4 x 10mm (3/8")<br />

Mounting holes<br />

Ø<br />

225mm<br />

(8.85")<br />

120mm (4.72")<br />

148mm (5.83")<br />

336mm (13.2")<br />

Glass Window MA-1<br />

Flanged Pipe Mount MA-15<br />

300mm (11.8")<br />

2" N.P.T.<br />

19.9mm (0.78")<br />

6.3mm (0.25")<br />

135mm (5.31") 140mm (5.51")<br />

94mm<br />

(3.7")<br />

4 mounting holes 10mm (3/8")<br />

101mm<br />

(3.97")<br />

End closed<br />

with UHMW<br />

window<br />

Flanged pipe mount<br />

recommended for<br />

collision detection<br />

applications<br />

12

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

MOUNTING<br />

GENERAL GUIDELINES<br />

1. The microwave beam is a polarized form<br />

of energy. As such, it is necessary to align<br />

the units in the same spatial plane. If the<br />

units do not have the same orientation, the<br />

amount of received energy is diminished. At<br />

90° to each other, the detector is blind and<br />

cannot detect the beam. The actual angle<br />

of mounting is not relevant, so long as both<br />

the Sender & Receiver have the same angle<br />

and elevation. Flanges are marked with an<br />

alignment notch cut into one edge of the<br />

flange to assist in mounting correctly.<br />

2. When looking for a mounting location it<br />

is important to locate and mount the interior<br />

of the window/sensor face for each unit<br />

flush with the vessel wall and where minimal<br />

build-up will occur. The system can penetrate<br />

through generous amounts of buildup<br />

of various products, however, the better the<br />

position, the more reliably it will operate. A<br />

cavity in the vessel mount position where<br />

build up is possible will result in a ‘plug’<br />

forming in front of the beam path resulting in<br />

unit performance issues.<br />

3. <strong>Microwave</strong> energy cannot penetrate<br />

through steel linings or other conductive<br />

linings. You must cut a viewing hole and use<br />

an appropriate windowed weldment.<br />

4. For high vibration applications, it is<br />

necessary to isolate the electronics to keep<br />

them from long term damage. This is most<br />

often accomplished using 4” UHMW or<br />

Teflon windowed weldments in the vessel<br />

walls, and mounting the <strong>Microwave</strong> Sender<br />

and Receiver to a separate stable structure<br />

(I-beam, handrail) to isolate them from vibration.<br />

Isolation shock mounts can also be<br />

provided to help protect the electronics.<br />

5. For high temperature applications which<br />

exceed 65°C/150°F (precipitators, cement<br />

cyclones, etc.), it is necessary to ensure<br />

that the sensors always remain below<br />

65°C/150°F. This is normally achieved by<br />

installation of temperature resistant windows<br />

of ceramic or firebrick, and positioning<br />

of the Sender and Receiver in line with the<br />

windows, and set back far enough that their<br />

temperature remains below the given limit.<br />

Where this is impossible, it will be necessary<br />

to use remote mounting microwaves<br />

with waveguide assemblies. This allows<br />

the electronics to be placed in an area<br />

where ambient temperatures do not exceed<br />

the maximum allowable for operation. It is<br />

necessary to contact the factory for this last<br />

type of waveguide application.<br />

13

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

MOUNTING<br />

SPECIFIC APPLICATIONS<br />

1. When mounting to monitor the level<br />

of a flowing product such as coal, ore or<br />

wood chips, position the microwave path<br />

out of the direct product flow stream. If at all<br />

possible, go behind the flow stream or well<br />

in front of it. This will minimise any possibility<br />

of unwanted trips due to abnormal<br />

product flow blocking the beam. Always use<br />

the recommended setup for blocked chute<br />

detection.<br />

2. When using the system as a proximity<br />

switch such as truck detection the mounting<br />

arrangement is application dependent<br />

and must ensure proper operation even<br />

under worst case conditions.<br />

4. Mounting of a <strong>Microwave</strong> system on<br />

sloped vessel walls can be accomplished<br />

using the <strong>Microwave</strong> Adjustable Mount (MA-<br />

12 or MA-13). This system allows the microwaves<br />

to be mounted to a sloped surface<br />

and then adjusted horizontally for optimum<br />

performance and operation. The adjustable<br />

mount has an integral 4” weldment with<br />

UHMW polyethylene or PTFE (Teflon) window<br />

options. An option with the bracket is a<br />

vibration isolation kit (shock mounts) to help<br />

protect the electronics from damage. Each<br />

side wall of the vessel must not exceed 30<br />

degrees from the vertical centerline. To<br />

mount the adjustable bracket, simply cut a<br />

hole and weld the 4” weldment directly to<br />

the vessel, install the window, mount the<br />

microwave and adjust horizontally.<br />

Similar performance can be obtained by<br />

fabrication of fixed brackets which mount<br />

the Sender and Receiver in direct line with<br />

one another and aimed through the centre<br />

of two MA-4 windowed weldments.<br />

6. For boom protection / anti collision<br />

mounting the MA15 flange pipe should be<br />

used to assist in the reduction of beam<br />

spread over long distances. The units<br />

should be mounted with a 2 meter exclusion<br />

zone in mind for the beam path between<br />

the sender and receiver. Do not use Integral<br />

units for boom protection.<br />

See the dedicated <strong>Hawk</strong> <strong>Microwave</strong> alignment<br />

& setup procedure guide for further<br />

information about anti collision / boom<br />

protection application information<br />

www.hawkmeasure.com<br />

14

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

MOUNTING<br />

CORRECT MOUNTING ANGLE<br />

Correct Elevation<br />

Maximum Signal Strength to Receiver is indicated by maximum brightness<br />

of Green LED on Receiver.<br />

Sending Unit<br />

<br />

<strong>Microwave</strong> Beam<br />

Receiving Unit<br />

Incorrect Elevation<br />

Sending Unit<br />

Receiving Unit<br />

<br />

ALIGN SENDER AND RECEIVER<br />

Rotate so that Visual Alignment Guide is in the<br />

same position on both sender and receiver.<br />

<br />

<br />

!<br />

Correct rotational alignment is<br />

critical for correct performance<br />

15

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

MOUNTING<br />

MOUNTING WITH WINDOWED WELDMENTS<br />

Metal Bin/Chute Walls<br />

4” UHMW Windowed Weldment<br />

Sender<br />

Receiver<br />

Fabricated Bracket<br />

Attach fabricated brackets to separate structure<br />

if bin/chute walls are subject to high vibration<br />

BLOCKED CHUTE MOUNTING<br />

MAIN PRODUCT FLOW<br />

Receiving Unit<br />

Sending Unit<br />

Housing can be rotated<br />

within 200º after the<br />

mounting thread is<br />

tightened, to allow cable<br />

entries to face downwards<br />

or allow optimal cable<br />

clearance.<br />

Position blocked<br />

chute detectors<br />

to one side of<br />

main product flow<br />

16

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

MOUNTING<br />

INSTALLATION WITH ADJUSTABLE MOUNTING<br />

Product Flow<br />

Hopper/Feeder<br />

X<br />

X<br />

X = 30° Maximum<br />

Sending Unit<br />

Receiving Unit<br />

Isolation Mount<br />

Adjustable microwave mounting bracket<br />

MA-12 or MA-13 welded to vessel wall.<br />

UHMW (MA-12) or Teflon (MA-13) Window.<br />

17

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

WIRING<br />

SMART INTEGRAL SYSTEM<br />

Receiver<br />

Green Power/Signal<br />

strength/alignment indicator LED<br />

Blue Calibration/Error LED<br />

Red Relay Status LED<br />

Sender<br />

Green Power ON LED<br />

Red Transmitter enabled LED<br />

SENSITIVITY<br />

HI FSH CAL TEST<br />

DELAY<br />

Remove Plug-In<br />

terminal block for<br />

easier wiring.<br />

MICROWAVE SENDER<br />

INT 1 2 3<br />

PRESS<br />

PWR TX TO TEST<br />

1 2 3 4 5 6 7 8 9 10<br />

1 2 3 4 5 6 7 8 9 10<br />

The AC earth/ground cable<br />

must be connected to the<br />

ground screw inside the<br />

housing when using AC<br />

power.<br />

Hole for securing of<br />

optional identification tag<br />

M4 grounding screw<br />

If only one cable is used for both<br />

power and output signal, then the<br />

second entry port must be<br />

plugged or blinded. Every Smart<br />

receiver is supplied with two M20<br />

glands (or 3/4”NPT adaptors)<br />

mounted on the unit and one<br />

blind plug loose.<br />

**Ground the housing to<br />

vessel, if vessel is metallic.<br />

Ground the housing to<br />

plant ground, if vessel is<br />

non-metallic.<br />

**<br />

RECEIVER TERMINAL LAYOUT<br />

RELAY COMMS DC-IN AC-IN<br />

SENDER TERMINAL LAYOUT<br />

DC-IN<br />

AC-IN<br />

1. NC<br />

2. COM<br />

3. NO<br />

4. Test<br />

5. A<br />

6. B<br />

7. +<br />

-<br />

N<br />

8.<br />

9.<br />

10. L1<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

7. +<br />

-<br />

N<br />

8.<br />

9.<br />

10. L1<br />

RS 485<br />

12-30VDC 80-260VAC<br />

12-30VDC 80-260VAC<br />

Terminals 1, 2, 3, 4, 5, 6 not used<br />

Note: AC power terminals may only be used when<br />

universal AC power supply option has been selected<br />

- see part numbers - AC terminals have no function in<br />

products without universal AC power option.<br />

18

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

WIRING<br />

REMOTE SYSTEM - HAWK SUPPLIED CABLE<br />

The black wire of <strong>Hawk</strong> supplied cable<br />

comes with one end GND and the other<br />

GND/SHLD together.<br />

The GND/SHLD end is a larger cable which<br />

has been heat shrunk. The GND only end is<br />

the same size as the other coloured cables.<br />

The GND/SHLD end must be connected<br />

to the amplifier and the GND end to the<br />

sender/receiver.<br />

Remote Receiver<br />

TERMINAL LAYOUT<br />

Remote Sender<br />

TERMINAL LAYOUT<br />

Green Power ON LED<br />

Red Transmitter<br />

enabled LED<br />

1.<br />

2.<br />

3.<br />

4. BROWN<br />

5. WHITE<br />

6. BLUE<br />

7. RED<br />

8. BLACK<br />

9.<br />

10.<br />

1.<br />

2.<br />

3.<br />

4. BROWN<br />

5.<br />

6.<br />

7. RED<br />

8. BLACK<br />

9.<br />

10.<br />

MICROWAVE SENDER<br />

INT 1 2 3<br />

PRESS<br />

PWR TX TO TEST<br />

Terminals 1, 2, 3, 9, 10 not used<br />

Terminals 1, 2, 3, 5, 6, 9, 10 not used<br />

Green Power/<br />

Signal strength/<br />

alignment indicator LED<br />

1 2 3 4 5 6 7 8 9 10<br />

Signal<br />

Status<br />

Remove Plug-In<br />

terminal block for<br />

easier wiring.<br />

Signal strength/<br />

alignment test<br />

point for volt<br />

meter connection<br />

1 2 3 4 5 6 7 8 9 10<br />

Hole for securing of<br />

optional identification tag<br />

Add wire<br />

between<br />

terminal 8<br />

and ground<br />

screw<br />

Add wire between<br />

terminal 8 and<br />

ground screw<br />

M4 grounding screw<br />

**Ground the housing to<br />

vessel, if vessel is metallic.<br />

Ground the housing to<br />

plant ground, if vessel is<br />

non-metallic.<br />

<strong>Gladiator</strong> Remote Amplifier<br />

Is<br />

+ –<br />

4-20mA (N/A)<br />

Note: AC power terminals may only be used when<br />

universal AC power supply option has been selected<br />

- see part numbers - AC terminals have no function in<br />

products without universal AC power option.<br />

RED<br />

BLACK<br />

BROWN<br />

SLAVE IN<br />

MASTER OUT<br />

TEST IN<br />

NC<br />

COM<br />

NO<br />

NC<br />

COM<br />

STRIP INSULATION<br />

NO<br />

9mm<br />

MIC-SENDER<br />

RED<br />

BLACK<br />

BLUE<br />

WHITE<br />

BROWN<br />

RELAY 1<br />

B<br />

A<br />

**<br />

– +<br />

RELAY 2<br />

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30<br />

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15<br />

N<br />

SENSOR COMMS DC-In AC-In*<br />

L1<br />

Relay 1 - Output Relay<br />

Relay 2 - FailSafe Relay<br />

AWG 22 -14<br />

(0.5 -1.5mm)<br />

User pliers to extract<br />

terminal blocks<br />

19

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

WIRING<br />

REMOTE SYSTEM - CUSTOMER SUPPLIED CABLE<br />

Remote Receiver<br />

TERMINAL LAYOUT<br />

Remote Sender<br />

TERMINAL LAYOUT<br />

Green Power ON LED<br />

Red Transmitter<br />

enabled LED<br />

1.<br />

2.<br />

3.<br />

4. BROWN<br />

5. WHITE<br />

6. BLUE<br />

7. RED<br />

8. BLACK<br />

9.<br />

10.<br />

1.<br />

2.<br />

3.<br />

4. BROWN<br />

5.<br />

6.<br />

7. RED<br />

8. BLACK<br />

9.<br />

10.<br />

MICROWAVE SENDER<br />

INT 1 2 3<br />

PRESS<br />

PWR TX TO TEST<br />

Terminals 1, 2, 3, 9, 10 not used<br />

Terminals 1, 2, 3, 5, 6, 9, 10 not used<br />

Green Power/<br />

Signal strength/<br />

alignment indicator LED<br />

1 2 3 4 5 6 7 8 9 10<br />

Signal<br />

Status<br />

1 2 3 4 5 6 7 8 9 10<br />

Remove Plug-In<br />

terminal block for<br />

easier wiring.<br />

Signal strength/<br />

alignment test<br />

point for volt<br />

meter connection<br />

SHIELD wire is<br />

NOT CONNECTED<br />

at terminal block -<br />

SHIELD is<br />

connected to<br />

grounding screw<br />

Hole for securing of<br />

optional identification tag<br />

M4 grounding screw<br />

<strong>Gladiator</strong> Remote Amplifier<br />

MIC-SENDER<br />

RELAY 1<br />

**<br />

RELAY 2<br />

RED<br />

BLACK<br />

BROWN<br />

SLAVE IN<br />

MASTER OUT<br />

TEST IN<br />

NC<br />

COM<br />

NO<br />

NC<br />

COM<br />

NO<br />

SHIELD wire is<br />

NOT CONNECTED<br />

at terminal block -<br />

SHIELD is<br />

connected to<br />

grounding screw<br />

**Ground the housing to<br />

vessel, if vessel is metallic.<br />

Ground the housing to<br />

plant ground, if vessel is<br />

non-metallic.<br />

Alternate cable type between Amplifier and Sensors<br />

6 or 8 conductor (5 used) shielded twisted pair instrument cable.<br />

Conductor size dependent on cable length.<br />

BELDEN 3120A, DEKORON or equivalent.<br />

Max: BELDEN 3120A = 500m (1640 ft). 3 pairs, 1 conductor not used.<br />

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30<br />

Is<br />

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15<br />

+ –<br />

4-20mA (N/A)<br />

RED<br />

BLACK<br />

BLUE<br />

WHITE<br />

BROWN<br />

Relay 1 - Output Relay<br />

Relay 2 - FailSafe Relay<br />

Connect BOTH GND<br />

AND SHIELD to ‘black’<br />

terminal at Amplifier<br />

end only<br />

B<br />

A<br />

– +<br />

N<br />

SENSOR COMMS DC-In AC-In*<br />

L1<br />

User pliers to extract<br />

terminal blocks<br />

Alternate Cable Colour Equivalents<br />

<strong>Hawk</strong> Belden 3120A Dekoron (Pair 4 not used )<br />

Pair 1<br />

Red<br />

Black<br />

Red<br />

Black<br />

White 1<br />

Black 1<br />

Note: AC power terminals may only be used when<br />

universal AC power supply option has been selected<br />

- see part numbers - AC terminals have no function in<br />

products without universal AC power option.<br />

Pair 2<br />

Pair 3<br />

White<br />

Blue<br />

Brown<br />

---<br />

Yellow<br />

Green<br />

Brown<br />

White (not used)<br />

White 2<br />

Black 2<br />

White 3<br />

Black 3 (not used)<br />

20

RED<br />

BROWN<br />

BLACK<br />

SHIELD<br />

RED<br />

BLACK<br />

RED<br />

BLACK<br />

BLUE<br />

BROWN<br />

WHITE<br />

BROWN<br />

BLUE<br />

BLACK<br />

RED<br />

WHITE<br />

BROWN<br />

SHIELD<br />

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

WIRING<br />

JUNCTION BOX / CABLE EXTENSION<br />

Cable shields<br />

connect to<br />

BLACK<br />

at AMPLIFIER end<br />

<strong>Gladiator</strong> <strong>Microwave</strong><br />

Amplifier<br />

MIC-SENDER<br />

Re-connect<br />

Cable Shield<br />

to Black<br />

SENSOR<br />

Cable<br />

Shield<br />

Seperate<br />

Black/Shield<br />

Re-connect<br />

Cable Shield<br />

to Black<br />

CUSTOMER<br />

JUNCTION BOX.<br />

DO NOT GROUND<br />

SHIELD CABLE AT<br />

JUNCTION BOX<br />

Cable<br />

Shield<br />

Seperate<br />

Black/Shield<br />

SENDER TERMINAL CONNECTIONS<br />

RECEIVER TERMINAL CONNECTIONS<br />

4. BROWN<br />

7. RED<br />

8. BLACK<br />

4. BROWN<br />

5. WHITE<br />

6. BLUE<br />

7. RED<br />

8. BLACK<br />

SHIELD CABLE<br />

NOT CONNECTED<br />

TO SENDER/RECEIVER<br />

SENDER<br />

RECEIVER<br />

Alternate cable type between Amplifier and Sensors<br />

6 or 8 conductor (5 used) shielded twisted pair instrument cable.<br />

Conductor size dependent on cable length.<br />

BELDEN 3120A, DEKORON or equivalent.<br />

Max: BELDEN 3120A = 500m (1640 ft). 3 pairs, 1 conductor not used.<br />

Max: DEKORON IED183AA004 = 350m (1150 ft). 4 pairs, 3 conductors not used.<br />

21

WIRING<br />

RELAY FUNCTIONS<br />

<strong>Microwave</strong> Smart Switch Series<br />

Level Switch Contact Action<br />

Relay - for Smart Integral Probe Version (Set Relay<br />

Action selection switch pages 27 and 28)<br />

Relay 1 - for Remote Version (Set ‘Relay Action’<br />

parameter pages 32 and 35)<br />

FailSafe Low<br />

FSL<br />

Relay Action<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

FailSafe High<br />

FSH (default)<br />

State 1<br />

1 2 3<br />

NC COM NO<br />

1 2 3<br />

NC COM NO<br />

Relay Status<br />

Smart Integral<br />

Receiver terminal<br />

numbers<br />

Remote Amplifier<br />

terminal function<br />

labels<br />

LED Status<br />

Material level rising<br />

State 2<br />

1 2 3<br />

NC COM NO<br />

1 2 3<br />

NC COM NO<br />

Material detected<br />

State 3<br />

1 2 3<br />

NC COM NO<br />

1 2 3<br />

NC COM NO<br />

Material level falling<br />

POWER FAILURE<br />

1 2 3<br />

NC COM NO<br />

1 2 3<br />

NC COM NO<br />

FailSafe Switch Contact Action<br />

Relay 2 - Remote version only. For<br />

Smart Integral units, the Test terminal<br />

can act as a solid state output with a<br />

similar function.<br />

(see page 25)<br />

POWER FAILURE<br />

OR<br />

INTERNAL FAILURE<br />

SYSTEM OPERATING<br />

NORMALLY<br />

NC COM NO NC COM NO<br />

NC COM NO<br />

NC COM NO<br />

22

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

WIRING<br />

CROSS-TALK PREVENTION - FOR 2 UNITS (REMOTE ONLY)<br />

Within the menu for each unit, select Master<br />

for one system and select Slave for the<br />

second system. These settings are located<br />

in the Advanced menu then under Operation<br />

Mode.<br />

Operation Mode has 3 selections:<br />

1. Remote<br />

2. Master<br />

3. Slave<br />

MASTER*<br />

Receiver 1<br />

Sender 1<br />

The wiring needs to be as indicated, with a<br />

shielded connection cable between the two<br />

units. The selected Master has a connection<br />

to Master Out and GND/DC- and the<br />

selected Slave has a connection to Slave In<br />

and GND/DC-.<br />

The shield is conncted to the Ground or<br />

24Vdc (-ve) terminal on each unit.<br />

Receiver 2<br />

SLAVE*<br />

Sender 2<br />

GLADIATOR MICROWAVE REMOTE AMPLIFIER - MASTER<br />

GLADIATOR MICROWAVE REMOTE AMPLIFIER - SLAVE<br />

MIC-SENDER<br />

RED<br />

BLACK<br />

BROWN<br />

SLAVE IN<br />

MASTER OUT<br />

TEST IN<br />

RELAY 1<br />

NC<br />

COM<br />

NO<br />

RELAY 2<br />

NC<br />

COM<br />

NO<br />

MIC-SENDER<br />

RED<br />

BLACK<br />

BROWN<br />

SLAVE IN<br />

MASTER OUT<br />

TEST IN<br />

RELAY 1<br />

NC<br />

COM<br />

NO<br />

RELAY 2<br />

NC<br />

COM<br />

NO<br />

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30<br />

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30<br />

Is<br />

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15<br />

+ –<br />

RED<br />

BLACK<br />

BLUE<br />

WHITE<br />

BROWN<br />

B<br />

A<br />

– +<br />

N<br />

L1<br />

4-20mA (N/A) SENSOR COMMS DC-In AC-In*<br />

Is<br />

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15<br />

+ –<br />

RED<br />

BLACK<br />

BLUE<br />

WHITE<br />

BROWN<br />

B<br />

A<br />

– +<br />

N<br />

L1<br />

4-20mA (N/A) SENSOR COMMS DC-In AC-In*<br />

Ground<br />

* Software selected<br />

MICROWAVE MASTER/SLAVE CALIBRATION<br />

Step 1: Place the Master unit into CAL mode by<br />

pressing the CAL button.<br />

Step 2: Ensure that the Slave system, which you<br />

intend to Calibrate, has been set to Slave mode.<br />

Step 3: To calibrate the Slave system select the<br />

CalMounting option, which can be found in the<br />

Quickset menu and select YES.<br />

Step 5: To calibrate the Master system select the<br />

CalMounting option, which can be found in the<br />

Quickset menu and select YES.<br />

Step 6: Press the RUN button to resume operation.<br />

The calibration process is now complete for<br />

a Master/Slave system.<br />

Step 4: Press the RUN button to resume operation.<br />

23

B<br />

A<br />

N<br />

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

B<br />

A<br />

N<br />

Is<br />

WIRING<br />

CROSS-TALK PREVENTION - FOR MORE THAN 2 UNITS<br />

(REMOTE ONLY)<br />

Operation is similar to cross-talk prevention<br />

for 2 units except that the GMSEQ <strong>Microwave</strong><br />

sequencer will operate as the Master and each<br />

individual <strong>Microwave</strong> unit will operate as a Slave.<br />

The sequencer will control and step from CH1 to<br />

CH2 to CH3 to CH4 then return to CH1.<br />

The maximum time between scans if 4 channels<br />

are connected is approx. 3ms. More than one<br />

unit can be connected to each channel, note that<br />

each unit connected to the same channel will be<br />

part of the same slave ‘sequence’ in the pulsing<br />

Within the menu of each individual <strong>Microwave</strong><br />

unit, select Slave mode in the Advanced Menu<br />

under Operating Mode.<br />

Receiver 1<br />

SLAVE 1<br />

Sender 1<br />

GLADIATOR MICROWAVE REMOTE AMPLIFIER - SLAVE<br />

GLADIATOR MICROWAVE REMOTE AMPLIFIER - SLAVE<br />

Is<br />

Receiver 2<br />

SLAVE 2<br />

Sender 2<br />

MIC-SENDER<br />

+ –<br />

Tx<br />

SLAVE IN<br />

MASTER OUT<br />

Test in<br />

RELAY 1<br />

NC<br />

COM<br />

NO<br />

NC<br />

RELAY 2<br />

COM<br />

NO<br />

MIC-SENDER<br />

+ –<br />

Tx<br />

SLAVE IN<br />

MASTER OUT<br />

Test in<br />

RELAY 1<br />

NC<br />

COM<br />

NO<br />

NC<br />

RELAY 2<br />

COM<br />

NO<br />

CURRENT<br />

SENSOR<br />

COMMS<br />

DC-IN<br />

AC-IN<br />

CURRENT<br />

SENSOR<br />

COMMS<br />

DC-IN<br />

AC-IN<br />

+ –<br />

RED<br />

BLACK<br />

BLUE<br />

WHITE<br />

BROWN<br />

– +<br />

L1<br />

24 VDC 80-265 VAC<br />

+ –<br />

RED<br />

BLACK<br />

BLUE<br />

WHITE<br />

BROWN<br />

– +<br />

L1<br />

24 VDC 80-265 VAC<br />

GMSEQ <strong>Microwave</strong> Sequencer Terminal<br />

CH1 CH2 CH3 CH4<br />

com<br />

Tx<br />

com<br />

Tx<br />

com<br />

Tx<br />

com<br />

Tx<br />

TO<br />

SLAVE 3<br />

MICROWAVE MASTER/SLAVE CALIBRATION<br />

TO<br />

SLAVE 4<br />

Step 1: Place the Sequencer unit into CAL unlock<br />

1 mode by pressing the CAL button on the sequencer<br />

unit.<br />

Step 2: Ensure that the systems that you intend<br />

to calibrate is set Operation Mode’ as ‘Slave’.<br />

The Sequencer unit will operate as the Master to<br />

control the pulsing sequence.<br />

Step 3: Remove the wire connection to the Slave<br />

In terminal, which connects between the slave<br />

system and the sequencer unit.<br />

Step 4: To calibrate the Slave system select the<br />

CalMounting option, which can be found in the<br />

Quickset menu and select YES.<br />

Step 5: After calibration is done, re-connect the<br />

Slave In cable between the slave system and the<br />

sequencer unit.<br />

Step 6: Repeat steps 1 to 5 for each of the slave<br />

systems connected to the sequencer.<br />

Step 7: Press the RUN button on the sequencer<br />

and all of the slave units. The process is now<br />

complete.<br />

* Note for best performance the sequencer setting<br />

is shown below. Do not adjust these settings.<br />

• On time – 240μs<br />

• Off time – 700μs<br />

24

HI FSH<br />

ON<br />

HI FSH<br />

ON<br />

CAL TEST<br />

ON<br />

1 2 1 2<br />

LO FSL OFF OFF<br />

1 2 3 4 5 6 7 8 9 10<br />

HI FSH<br />

ON<br />

1 2 3 4 5 6 7 8 9 10<br />

CAL TEST<br />

ON<br />

1 2 1 2<br />

LO FSL OFF OFF<br />

1 2 1 2<br />

LO FSL OFF OFF<br />

1 2 3 4 5 6 7 8 9 10<br />

CAL TEST<br />

ON<br />

HI FSH<br />

ON<br />

CAL TEST<br />

ON<br />

1 2 1 2<br />

LO FSL OFF OFF<br />

1 2 3 4 5 6 7 8 9 10<br />

HI FSH<br />

ON<br />

HI FSH<br />

ON<br />

CAL TEST<br />

ON<br />

1 2 1 2<br />

LO FSL OFF OFF<br />

1 2 3 4 5 6 7 8 9 10<br />

CAL TEST<br />

ON<br />

1 2 1 2<br />

LO FSL OFF OFF<br />

1 2 3 4 5 6 7 8 9 10<br />

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

WIRING<br />

MULTIDROP CONNECTIONS<br />

Multidrop GPRS Connection*<br />

SENSITIVITY<br />

DELAY<br />

SENSITIVITY<br />

DELAY<br />

<strong>Hawk</strong>Link<br />

HLRUG6<br />

GPRS modem<br />

A B Gnd<br />

A B Gnd<br />

A B Gnd<br />

Laptop or PC Communications using<br />

PCMCIA card or wired (PSTN) modem<br />

and remote GSM/CDMA connection<br />

with Gos<strong>Hawk</strong> software.<br />

Multidrop Connection Using <strong>Hawk</strong>Link USB*<br />

SENSITIVITY<br />

DELAY<br />

SENSITIVITY<br />

DELAY<br />

A B Gnd<br />

A B Gnd<br />

A B Gnd<br />

White<br />

Blue<br />

Black<br />

<strong>Hawk</strong>link<br />

USB<br />

Laptop or PC Communications using<br />

<strong>Hawk</strong>link USB or RS485 / 232 converter<br />

with Gos<strong>Hawk</strong> software.<br />

Multidrop Connection to PLC/DCS/SCADA*<br />

SENSITIVITY<br />

DELAY<br />

SENSITIVITY<br />

DELAY<br />

A B Gnd<br />

A B Gnd<br />

A B Gnd<br />

PLC / DCS / SCADA for Remote<br />

Communication with Modbus.<br />

* Wiring installation should follow<br />

RS-485 standards for layout and<br />

termination.<br />

25

WIRING<br />

RS 485<br />

1 2<br />

12-30VDC<br />

*<br />

80-265VAC<br />

<strong>Microwave</strong> Smart Switch Series TO<br />

Connect shield to<br />

DC “-” only at this end.<br />

Separate AC power supply<br />

for the GSM module<br />

or<br />

DC power<br />

supply<br />

HAWK UNIT<br />

HAWKLINK GSM - CONNECTING POWER AND COMMS<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

HAWKLINK MODEM TERMINAL BLOCK<br />

B<br />

2 WIRE LOOP POWERED DEVICES<br />

ID 1 ID 2 ID 3 ID 4 ID 5<br />

A<br />

GND<br />

B<br />

A<br />

GND<br />

B<br />

A<br />

GND<br />

B<br />

A<br />

GND<br />

B<br />

A<br />

GND<br />

B<br />

MASTER<br />

A<br />

GND<br />

B<br />

PC POWER NETWORK 12-30VDC 90-265 VAC<br />

A<br />

GND<br />

OUT<br />

IN<br />

B<br />

A<br />

N<br />

L1<br />

<strong>Hawk</strong> Unit<br />

-<br />

MASTER PC POWER NETWORK 12-30VDC 90-265 VAC<br />

B A<br />

Wire Foil<br />

1 2 3<br />

SHIELDED<br />

TWISTED-PAIR<br />

1 2 3<br />

Copper Shield<br />

PVC<br />

Connect shield to<br />

Jacket<br />

DC “-” only at this end.<br />

BOTTOM TOP<br />

COMMS<br />

12-30VDC<br />

PLC CONNECTION STANDARD CONNECTION LOOP POWER CONNECTION<br />

B<br />

PLC A<br />

GND<br />

HAWK<br />

UNIT<br />

1<br />

HAWK<br />

UNIT<br />

2<br />

HAWK<br />

UNIT<br />

Nx<br />

B<br />

A<br />

GND<br />

B<br />

A<br />

GND<br />

B<br />

A<br />

GND<br />

MASTER<br />

B A GND<br />

NETWORK<br />

B A -<br />

NETWORK<br />

B A -<br />

B<br />

A<br />

GND<br />

B<br />

A<br />

GND<br />

B<br />

A<br />

GND<br />

HAWK<br />

UNIT<br />

1<br />

HAWK<br />

UNIT<br />

2<br />

HAWK<br />

UNIT<br />

Nx<br />

LOOP<br />

UNIT 1<br />

MASTER<br />

B<br />

A<br />

B<br />

A<br />

B<br />

A<br />

GND<br />

GND<br />

GND<br />

B<br />

A<br />

B<br />

A<br />

Each terminal block<br />

ID 1 to 5 wired to<br />

individual loop<br />

powered units<br />

ID 1 ID 2 ID 3 ID 4 ID 5<br />

GND<br />

GND<br />

OUT<br />

IN<br />

B<br />

A<br />

GND<br />

B<br />

A<br />

B<br />

A<br />

GND<br />

PC POWER NETWORK 12-30VDC 90-265 VAC<br />

N<br />

MASTER PC POWER NETWORK 12-30VDC 90-265 VAC<br />

B<br />

LOOP<br />

UNIT 5<br />

A<br />

B<br />

A<br />

GND<br />

GND<br />

L1<br />

BOTTOM TOP<br />

26

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

WIRING<br />

TEST TERMINAL FUNCTION SELECTION<br />

The test terminal has two potential modes of operation for Smart Integral units and always<br />

operates in the test input mode for Remote units. Remote units have a separate, failsafe<br />

relay contact, which is always functional.<br />

TEST INPUT MODE<br />

(Test switch must be in ‘TEST’ (ON) position on Smart Integral Units - function always enabled on Remote Units)<br />

Test terminal acts as an input for remote testing of the instrument’s switching function. Used<br />

to check for malfunction of unit from a remote position, PLC, SCADA etc. For more information<br />

see page 29.<br />

TEST INPUT FROM PLC/SCADA/DCS DIGITAL OUTPUT<br />

Terminal Block<br />

PLC / SCADA / DCS Output<br />

Test<br />

OPERATOR CONTROLLED PRESS TO TEST<br />

!<br />

PLC/SCADA/DCS GROUND MUST<br />

CONNECT BACK TO GLADIATOR<br />

GROUND OR DC ‘-’ TERMINALS<br />

Terminal Block<br />

Externally provided<br />

test button<br />

Test<br />

FAILSAFE OUTPUT MODE<br />

(Test switch must be in the ‘OFF’ position - default setting)<br />

!<br />

EXTERNAL PUSH BUTTON GROUND<br />

MUST CONNECT BACK TO GLADIATOR<br />

GROUND OR DC ‘-’ TERMINALS<br />

Test terminal will provide an output which is able to switch an external failsafe relay or PLC/SCADA/DCS<br />

input. During normal system operation this terminal will internally switch a solid state (transistor) output to<br />

ground (or DC ‘-’). If power fails or an internal system failure occurs, the terminal will act as an open circuit.<br />

To switch an external relay<br />

To a PLC input<br />

Test<br />

+12-24Vdc<br />

Coil rating<br />

500mW max<br />

or 50mA max<br />

Relay will turn on during<br />

normal system operation<br />

or off in failed or unpowered<br />

conditions.<br />

Test<br />

27<br />

max 50mA<br />

12-24Vdc<br />

Pull up<br />

PLC<br />

SCADA<br />

DCS Input<br />

Input will detect ‘0’ state during normal system<br />

operation, or ‘1’ in failed or unpowered conditions.

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

SETUP PROCEDURE<br />

FUNCTIONALITY LAYOUT - SMART INTEGRAL SENDER<br />

3<br />

1<br />

4<br />

INT 1<br />

MICROWAVE SENDER<br />

2 3<br />

PRESS<br />

TO TEST<br />

PWR TX<br />

5<br />

REM 0<br />

0 0<br />

1 2 3 4 5 6 7 8 9 10<br />

2<br />

REMOVABLE SENDER TERMINAL BLOCK<br />

DC-IN AC-IN<br />

-<br />

+<br />

N<br />

L1<br />

6<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

7.<br />

8.<br />

9.<br />

10.<br />

7-30VDC 80-260VAC<br />

Terminals 1, 2, 3, 4, 5, 6 not used<br />

1 Smart Integral / Remote mode selection switch (INT/REM)<br />

2 Green LED - power status, continuously on when power supply is OK<br />

3 Red LED - transmitter enabled<br />

4 Pulse rate setting switches (see table below)<br />

Press to test button - interupts signal transmission for system testing.<br />

5<br />

Simulates the effects of breaking of microwave beam.<br />

6 Removable terminal block - plug in type<br />

Switch Settings<br />

INT/REM<br />

1, 2, 3<br />

Sender pulse<br />

rate selection<br />

0 = OFF<br />

1 = ON<br />

Set to INT for Smart Integral types<br />

1 2 3<br />

0 0 0 45 Pulses per sec<br />

0 0 1 44<br />

0 1 0 42<br />

0 1 1 41<br />

1 0 0 40<br />

1 0 1 39<br />

1 1 0 38<br />

1 1 1 37 - Default for INT<br />

The pulse rate may be changed to minimize<br />

the potential for cross-talk if multiple units are<br />

in the same operational area. If cross-talk is<br />

likely to occur, it is strongly recommended<br />

to use Remote type units and employ the<br />

cross-talk prevention schemes for 2 units or<br />

the multi sequence connection for more than<br />

2 units using a separate GMSEQ sequencing<br />

unit. Cross-talk prevention and sequencing for<br />

Remote units are detailed on pages 20 & 21.<br />

28

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

SETUP PROCEDURE<br />

FUNCTIONALITY LAYOUT - SMART INTEGRAL RECEIVER<br />

9<br />

3<br />

6<br />

12<br />

4<br />

SENSITIVITY<br />

signal<br />

HI FSH CAL TEST<br />

ON<br />

ON<br />

1 2 1 2<br />

LO FSL OFF OFF<br />

1 2 3 4 5 6 7 8 9 10<br />

DELAY<br />

1<br />

5<br />

2<br />

8<br />

REMOVABLE RECEIVER TERMINAL BLOCK<br />

RELAY COMMS DC-IN AC-IN<br />

10<br />

7<br />

11<br />

1. NC<br />

2. COM<br />

3. NO<br />

4. Test<br />

A<br />

B<br />

5.<br />

6.<br />

7. +<br />

8.<br />

9. N<br />

10. L1<br />

RS 485 7-30VDC 80-260VAC<br />

-<br />

Functionality Description (bold is default)<br />

1<br />

2<br />

3<br />

4<br />

5<br />

Mounting Calibration switch CAL/OFF<br />

Test input function select TEST/OFF<br />

Relay action selection<br />

switch<br />

FSH - FailSafe High<br />

FSL - FailSafe Low<br />

HI / LO sensitivity switch<br />

LO default. LO = less sensitivty.<br />

Lo for blocked chute detection<br />

Delay Potentiometer (0-20 sec)<br />

(0.1 sec. at minimum position)<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

Sensitivity Potentiometer<br />

Anti-clockwise (low) for blocked chute detection<br />

RED LED: Relay status<br />

ON when relay coil is energised<br />

GREEN LED: Power / Received signal strength.<br />

Brightness varies with strength of received signal.<br />

BLUE LED:<br />

Blinking indicates calibration function is on.<br />

Continuously ON indicates failed calibration.<br />

AC Ground - must be used for<br />

AC powered installations<br />

Removable terminal block - plug in type<br />

12 Signal voltage test point<br />

29

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

SETUP PROCEDURE<br />

SMART INTEGRAL VERSION<br />

!<br />

1. Mount the units in their actual position<br />

1.1 If units are AC powered ensure proper grounding is<br />

connnected to ground screw.<br />

2. Make sure that the material or target is not blocking<br />

the path between sender and receiver.<br />

3. Turn the power on<br />

The green LED on the sender and receiver will stay<br />

on permanently to indicate that power is on. Green<br />

LED on receiver varies in brightness with strength of<br />

received signal.<br />

4. Sender (GMRS): Ensure the REM/INT DIP switch<br />

is selected to the INT position and the remaining<br />

switches (1, 2, 3) are all selected to OFF.<br />

5. Select the required relay action<br />

The Relay can switch ‘ON’ (FSL) or ‘OFF’ (FSH) as<br />

the microwave beam is blocked. Set the relay action<br />

selection switch position depending on your requirements.<br />

FSH is recommended (ordinarily on/energised,<br />

switches off/DEN during blocked conditions).<br />

6. Select the sensitivity<br />

There are two adjustments controlling the sensitivity of<br />

the switch point:<br />

6.1 The ‘HI/LO’ sensitivity DIP switch is used as<br />

the primary sensitivity setting. Select LO sensitivity<br />

for Blocked Chute detection. Select LO If build-up<br />

is expected over sensors or with strongly absorptive<br />

materials or targets. Select HI sensitivity for clean<br />

environments and lighter/less absorptive material or<br />

targets. LO recommended for most applications.<br />

Recommended Settings for<br />

Blocked Chute applications<br />

6.2 The sensitivity potentiometer<br />

Turning the pot fully counter-clockwise factory recommended<br />

for blocked chute applications. If operating<br />

in HI mode set the pot to 12 o’clock. In this mode you<br />

can turning the pot clockwise to reduce the amount of<br />

beam blockage required for switching and vice versa.<br />

7. Select the time delay<br />

Full anti clockwise is minimum (0.1 seconds). Full<br />

clockwise is maximum (20 seconds). Adjust as<br />

required allowing time to avoid possible nuisance trips.<br />

The selected delay will be used for both an ON delay<br />

and an OFF delay.<br />

8. Perform a CAL mount<br />

Do not proceed with this step unless the material or<br />

target position is well beneth the line between the<br />

sender and receiver.<br />

Switch the Mounting Calibration switch on the Receiver<br />

unit to ‘CAL’ (ON) position. The Blue LED will blink to<br />

indicate that mounting calibration is now in progress.<br />

Wait 5-10 sec, then switch the mounting calibration<br />

switch to ‘OFF’ position. The blue LED will switch off<br />

after successfull calibration. If it stays on this indicates<br />

there was a calibration error. If this is the case please<br />

check that the path between sender and receiver is<br />

clear and alignment is correct then try the calibration<br />

again. If mounting calibration was successful the blue<br />

LED should be off and the Green LED should be ON.<br />

9. Switch check<br />

If required block the Sender with a steel plate to check<br />

relay action & time delay. The green LED will dim when<br />

the <strong>Microwave</strong> beam begins to be blocked.<br />

You can also press the ‘TEST’ button on the Sender to<br />

simulate a blocked chute condition and thus trigger the<br />

relay action.<br />

Note: Integral type <strong>Microwave</strong> systems should not<br />

be used for anti collision detection / boom protection.<br />

Contact <strong>Hawk</strong> for information about the remote type<br />

systems.<br />

30

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

SETUP PROCEDURE - REMOTE VERSION<br />

FUNCTIONALITY LAYOUT<br />

REMOTE AMPLIFIER<br />

4<br />

1<br />

1<br />

Calibrate button<br />

2<br />

Run button<br />

3<br />

Down button<br />

4<br />

Up button<br />

5<br />

Relay LEDs 1 and 2<br />

3<br />

RELAY 1<br />

RELAY 2<br />

STATUS A<br />

STATUS B<br />

6 Display (LCD with backlight)<br />

5<br />

6<br />

7<br />

2<br />

7 Status LEDs A and B<br />

- Status A flashes with signal transmission of a unit in<br />

Remote or Master mode.<br />

- Status B flashes with signal transmission of a unit in<br />

Master or Slave mode.<br />

REMOTE RECEIVER<br />

REMOTE RECEIVER TERMINAL BLOCK<br />

TRANSDUCER<br />

8<br />

REMOTE<br />

STATUS<br />

1. 2. 3. 4. 5. 6. 7. 8. 9. 10.<br />

1 2 3 4 5 6 7 8 9 10<br />

9<br />

BROWN<br />

WHITE<br />

BLUE<br />

RED<br />

BLACK<br />

Terminals 1, 2, 3, 9, 10 not used.<br />

8<br />

GREEN LED: Power / Received signal strength.<br />

Brightness varies with strength of received signal.<br />

9<br />

Removable terminal block - plug in type<br />

31

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

SETUP PROCEDURE<br />

FUNCTIONALITY LAYOUT - REMOTE SENDER<br />

3<br />

1<br />

4<br />

INT 1<br />

MICROWAVE SENDER<br />

2 3<br />

PRESS<br />

TO TEST<br />

PWR TX<br />

5<br />

REM 0<br />

0 0<br />

REMOVABLE SENDER TERMINAL BLOCK<br />

1 2 3 4 5 6 7 8 9 10<br />

2<br />

1.<br />

2.<br />

3.<br />

4. BROWN<br />

5.<br />

6.<br />

7. RED<br />

8. BLACK<br />

9.<br />

10.<br />

6<br />

Terminals 1, 2, 3, 5, 6, 9, 10 not used<br />

1 Smart Integral / Remote mode selection switch (INT/REM)<br />

2 Green LED - power status, continuously on when power supply is OK<br />

3 Red LED - transmitter enabled<br />

4 Pulse rate setting switches (settings have no function for Remote units)<br />

5<br />

Press to test button - interupts signal transmission for system testing.<br />

Simulates the effects of breaking of microwave beam.<br />

6 Removable terminal block - plug in type<br />

Switch Settings<br />

INT/REM<br />

1, 2, 3<br />

Sender pulse<br />

rate selection<br />

Set to REM for Remote types<br />

Settings has no function for<br />

remote types.<br />

32

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

SETUP PROCEDURE<br />

REMOTE VERSION<br />

1. Mount the unit in its actual position<br />

(see mounting procedure - pages 12-16)<br />

Make sure that external ground wire is connected<br />

between the outside ground screw on the <strong>Gladiator</strong><br />

housing and the roof/wall/side of the silo/tank/vessel/chute.<br />

(For non metallic tanks make sure that<br />

external ground wire is connected between the<br />

same outside ground screw on the housing and the<br />

general plant ground potential.)<br />

2. Check where the actual level or target is relative<br />

to the sensors<br />

Make sure that the material or target is not blocking<br />

the path between sender and receiver.<br />

UnLock<br />

0<br />

Press<br />

CAL<br />

Press<br />

Press<br />

QuickSet<br />

CAL<br />

App Type<br />

CAL<br />

Press<br />

CAL<br />

Cal Mounting<br />

Yes / No<br />

Press CAL<br />

Yes<br />

Press CAL<br />

Switch Point<br />

75%<br />

Press<br />

CAL<br />

Press CAL<br />

Delay Adjust<br />

2.0S<br />

Press CAL<br />

0.1S<br />

Press CAL<br />

Relay Action<br />

FailSafe Hi<br />

Press<br />

CAL<br />

FailSafe Hi<br />

Press FailSafe Low<br />

Twice<br />

RUN<br />

!<br />

33<br />

3. Ensure that the mode selection switch on the<br />

transmitter is set to REM (OFF). See point 1 page 31.<br />

4. Turn the power on<br />

The display will turn on and the fail-safe relay will<br />

switch. The display will scroll through the following<br />

messages: <strong>Hawk</strong>, Amp SerialNo, Type, Amp Soft<br />

Ver, Device ID, SensorSerial, SensorModel, Sens<br />

SoftVer, Sensor Addrs, <strong>Gladiator</strong> System Amp.<br />

The unit will then go into operational mode displaying<br />

‘Switch’ with a % value. This % value represents<br />

the changing amount of signal loss between<br />

sender and receiver.<br />

5. Simple “1-minute” Setup - Follow the flow<br />

chart<br />

Choose Application Type<br />

Alignment - For Aligning the unit at long range. Unit is set to 1.2V signal (~48% switch<br />

value), move the unit face to get the volt reading high (2.4V will be the maximum<br />

reading or 0% switch value). Calibrate & re-select this mode and repeat till you cannot<br />

improve the alignment.<br />

Blocked Chute - Configures the unit for blocked chute applications<br />

Boom Protection - Configures the unit for anti collision applications<br />

Switch - Allows selection of Sensitivity% for standard switch application.<br />

Density - Special Density measurement mode. See App Types for further information<br />

Cancel Influence of Mounting<br />

Do not proceed with this step unless the material or target position is well beneth<br />

the line between the sender and receiver.<br />

Select ‘Yes’ to start the mounting calibration. ‘Wait’ will be displayed during the<br />

calibration for up to 30 seconds. Unit is now able to cancel the influence of the<br />

mounting. The % reading on the back lit display has been zeroed with the existing<br />

process conditions and the measurement history log has been cleared.<br />

Always calibrate the unit after changing Application type.<br />

Select the Switch point<br />

The output relay will switch at the entered % value. The default value of 76% will be<br />

suitable for detecting most media. For detection of products which are less absorbent of<br />

<strong>Microwave</strong> energy, select a lower % value and vice versa. For highly absorbent materials,<br />

almost any setting will work, but higher % settings will be more immune to build up.<br />

When the level or target falls below the sensors the relay will switch back at half of the<br />

entered switch point % value (when the beam is no longer broken).<br />

Select the Time Delay<br />

Set the time to be used for both switch on and switch off delays<br />

Select the required relay action<br />

The Relay can switch ‘ON’ or ‘OFF’ as the microwave beam is blocked and switch<br />

‘ON’ or ‘OFF’ in response to an instrument failure (see below). Set the parameter<br />

to FailSafe Low or FailSafe Hi depending on your requirements.

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

SOFTWARE MENU<br />

REMOTE AMPLIFIER<br />

ENTERING DATA<br />

All software adjustments are achieved via the four PUSHBUTTONS on the front<br />

panel.<br />

In Run Mode<br />

(A) Press and hold - interrupts normal operations and allows access<br />

to software menu headings.<br />

In Calibrate Mode<br />

(B) Steps into a menu selection to allow editing (down one level)<br />

(C) Saves selected value and moves onto the next menu item.<br />

In Run Mode<br />

(A) Scrolls up through operating diagnostics on display LCD.<br />

In Calibrate Mode<br />

(B) Scrolls up through software parameters when browsing the<br />

menus.<br />

(C) Increases display value when editing a parameter.<br />

In Run Mode<br />

(A) Scrolls down through operating diagnostics on LCD display.<br />

In Calibrate Mode<br />

(B) Scrolls down through software parameters when browsing the<br />

menus.<br />

(C) Decreases display value when editing a parameter.<br />

In Run Mode<br />

(A) Hides diagnostics if they are in view and returns to the standard<br />

running display.<br />

In Calibrate Mode<br />

(B) Steps out of a menu or selection (up one level). Parameter value<br />

will be stored automatically when stepping up.<br />

(C) Returns to running mode from the top level menu.<br />

34

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

FLOW CHART<br />

SOFTWARE TREE<br />

Press<br />

Sensor Value<br />

0.0%<br />

CAL<br />

To Calibrate<br />

Normal Running Display<br />

Press to view unit<br />

operation diagnostics<br />

On first start up there is<br />

no security code protection.<br />

Press<br />

UnLock<br />

0<br />

CAL<br />

Press<br />

Press<br />

Press<br />

To QuickSet<br />

QuickSet<br />

Advanced<br />

flow chart CAL<br />

CAL To Advanced<br />

flow chart<br />

See page 37 See page 38<br />

QuickSet Menu<br />

Advanced Menu<br />

covers all parameters covers less commonly<br />

required for standard used or advanced<br />

setups.<br />

parameters.<br />

Press<br />

RUN<br />

to return to normal operation<br />

35

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

FLOW CHART<br />

DIAGNOSTIC DISPLAYS (Remote type only)<br />

Sensor Value<br />

0.0%<br />

SW On 75.0%<br />

0.0%<br />

SW Off 50.0%<br />

0.0%<br />

Max 99.8%<br />

0.0%<br />

Min 0.0%<br />

0.0%<br />

Delay 0.1s<br />

0.0%<br />

Temp: 22.4C<br />

0.0%<br />

Normal<br />

0.0%<br />

Signal 2.40V<br />

0.0%<br />

Percentage above<br />

which the Relay<br />

will be in State 2*.<br />

Percentage below<br />

which the Relay<br />

will be in State 1*.<br />

}<br />

Max/Min captured<br />

Sensor Value % since<br />

Last history log reset,<br />

or last Cal Mounting<br />

operation<br />

Current switch<br />

delay time<br />

Current temperature<br />

inside housing<br />

(ºCelsius)<br />

Status<br />

Normal / CommRetry<br />

Received Signal strength<br />

The diagnostic displays appear on the<br />

top line of the LCD, after pressing the Up<br />

or Down push button when the <strong>Gladiator</strong><br />

<strong>Microwave</strong> switch is in its normal running<br />

mode.<br />

The diagnostics provide the user with<br />

valuable performance feedback on how the<br />

instrument is performing whilst in operation.<br />

The measured reading Sensor Value (%)<br />

continues to be displayed on the second<br />

line of the LCD during diagnostic viewing<br />

on the top line. Ouput relays will continue to<br />

operate during diagnostic viewing.<br />

Pressing RUN several times returns the unit<br />

into normal operation.<br />

*Switch points are refered to as ‘On’ and<br />

‘Off’ to reflect the most simply understood<br />

performance in FailSafe Low mode. Actual<br />

relay state may be different according to<br />

setting of relay action (see page 19).<br />

CommErr 1 -> unit has lost communications<br />

with the receiver.<br />

Fail 1 - No comms available.<br />

Gain 10.2%<br />

0.0%<br />

Noise 0.04V<br />

0.0%<br />

Current Gain% value.<br />

In Blocked Chute mode this will increase<br />

when product passes in front of the sensor.<br />

The unit has a maximum possible gain% of ~94%<br />

Background Noise received<br />

Remote<br />

0.0%<br />

Device operating mode<br />

Remote/Master/Slave<br />

36

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

QUICKSET MENU<br />

Parameter Description Options<br />

App Type (see next page for<br />

full App Type descriptions)<br />

Select application pre-set.<br />

This automatically configures<br />

the unit to the recommended<br />

settings for each<br />

specificapplication.<br />

Density<br />

Switch<br />

Boom Protect<br />

Blocked Chute<br />

Alignment<br />

Cal Mounting<br />

Switch Point<br />

On Delay Adj<br />

Relay1Action<br />

Lock Code<br />

Note you must perform a<br />

Cal Mount after changing or<br />

selecting App Type<br />

Performs a Cal Mount in<br />

which the unit automatically<br />

configures itself based on<br />

the selected App Type and<br />

the mounting environment.<br />

This is the switch on / off<br />

sensor value % for relay<br />

actions<br />

Set on delay time for the<br />

first relay. If using the 2nd<br />

relay in cleaner / maintenance<br />

mode 1/2 of this<br />

value will be the duration of<br />

the relay timer<br />

Adjust the Relay action<br />

to be energised or de-energised<br />

during normal<br />

operation<br />

Set a lock code to prevent<br />

unauthorised access<br />

Yes / No<br />

Auto - 75% (on) 50% (off)<br />

<strong>Manual</strong> (set in Advanced)<br />

Adjustable in seconds<br />

FailSafe Hi<br />

FailSafe Low<br />

Default 0<br />

37

<strong>Microwave</strong> Smart Switch Series<br />

<strong>Manual</strong><br />

Rev 1.71, Sept 2013<br />

APP TYPES<br />

Software Rev 740 and higher<br />