Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Gerb 31/10/06 09:19 Page 97<br />

<strong>Track</strong> Technology<br />

<strong>Slab</strong> <strong>Track</strong> <strong>Hits</strong> <strong>The</strong><br />

<strong>Right</strong> <strong>Note</strong> <strong>In</strong> <strong>Basle</strong><br />

<strong>The</strong> Swiss city of <strong>Basle</strong> is using<br />

floating slab track technology<br />

provided by Gerb, Germany, to<br />

protect its favourite concert hall<br />

from vibrations and noise<br />

caused by passing LRVs.<br />

Anitra Green<br />

Regional Editor<br />

THE Steinenberg in <strong>Basle</strong> is one of<br />

the most heavily-used sections of<br />

the city’s light rail network, with<br />

LRVs passing at intervals of one to two<br />

minutes. Because of the wear and tear on<br />

the rails and the consequent risk of broken<br />

rails, the city council has been aware<br />

for some time that the track on the<br />

Steinenberg and on <strong>The</strong>aterstrasse would<br />

have to be totally replaced. At the same<br />

time it decided to install a floating slab<br />

track system at the T-shaped junction of<br />

the two streets to cut noise and vibration,<br />

which has been a problem for the adjacent<br />

concert hall, the Stadtcasino,<br />

for many years.<br />

<strong>The</strong> acoustics of this protected<br />

building are reputed to<br />

be among the finest in the<br />

world, but enjoyment of concerts<br />

is spoilt and recordings<br />

are impossible because of the<br />

frequent rumblings from passing<br />

LRVs. <strong>The</strong> problem has become<br />

even more acute in recent<br />

years due to the use of longer<br />

and heavier LRVs with multiple<br />

axles.<br />

Preliminary work started in<br />

January to build a new underground<br />

service tunnel and reroute<br />

utilities to make room for<br />

the new floating slab track and<br />

adjust the alignment of the<br />

tracks at the junction to provide<br />

a wider curve radius. <strong>The</strong> underground<br />

structure of this area<br />

is complex since there are sections<br />

of the old city wall that<br />

have to be preserved, and part<br />

of the roof of the Birsig tunnel,<br />

which carries a small tributary<br />

of the Rhine, had to be reconstructed.<br />

Work on the main part of job, to remove<br />

the old rails and install the floating slab<br />

track, started on July 4 and took just six<br />

weeks. This was achieved by closing the<br />

entire city centre to light rail traffic and<br />

working seven days a week, with three<br />

shifts round the clock for the first three<br />

weeks, then two shifts. Trams were rerouted<br />

round the city centre and shuttle<br />

buses laid on to provide a replacement<br />

service. <strong>The</strong> work coincided with the<br />

local school holidays to keep disruption to<br />

the transport system to a minimum.<br />

Soaring Temperatures<br />

Unfortunately it proved to be one of the<br />

hottest summers on record, and the heat<br />

caused several problems, particularly for<br />

the workers and the rails. <strong>The</strong> new rails<br />

had to be kept cool by spraying them with<br />

water during the day to try to prevent<br />

them expanding too much, and they could<br />

only be laid at night.<br />

Gerb’s basic floating slab track is like a<br />

bridge supported by springs embedded in<br />

a firm base that isolates the rails from the<br />

substructure. <strong>The</strong> system can be adapted<br />

according to local needs. Rails are fixed to<br />

a concrete slab or ballasted trough which<br />

is isolated from the substructure by individual<br />

elements containing highly elastic<br />

helical steel springs. <strong>The</strong> springs form an<br />

elastic interface with the slab, effectively<br />

isolating the dynamic forces. <strong>The</strong> entire<br />

system is 1.64m deep and is built up in<br />

several stages.<br />

<strong>In</strong> <strong>Basle</strong>, a total of 750 steel cylinders<br />

were installed to house the steel springs<br />

on the concrete slab that forms the foundation.<br />

Concrete was then poured in four<br />

stages, with the foundations for the rails<br />

being separated from the rest by a layer of<br />

special matting, so that any future work<br />

on the rails can be carried out without affecting<br />

the rest of the structure. After the<br />

necessary adjustments to the system and<br />

test running, normal light rail services<br />

were expected to resume punctually<br />

ready for the new school term beginning<br />

on August 14.<br />

<strong>The</strong> springs are designed to last 25<br />

years, which is about the same time as the<br />

new rails. Unfortunately, because of space<br />

limitations, visual examination of the<br />

spring elements is not possible, so it is<br />

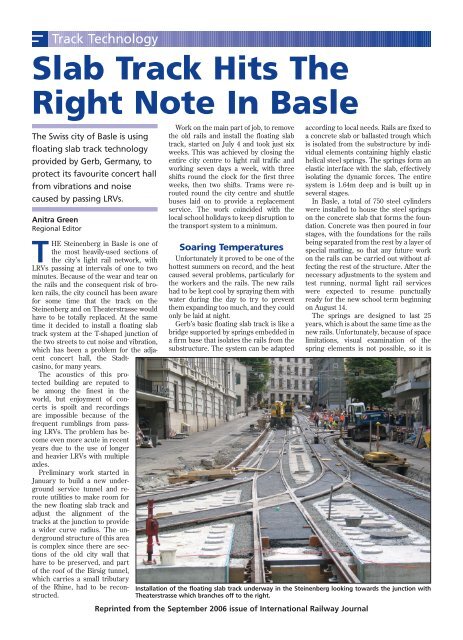

<strong>In</strong>stallation of the floating slab track underway in the Steinenberg looking towards the junction with<br />

<strong>The</strong>aterstrasse which branches off to the right.<br />

Reprinted from the September 2006 issue of <strong>In</strong>ternational Railway Journal

Gerb 31/10/06 09:19 Page 98<br />

Flat elastomer<br />

sealing strip<br />

Surfacing<br />

Hot mixed<br />

aggregates<br />

<strong>Track</strong> Technology<br />

Filler stabilised<br />

with concrete<br />

Wall element<br />

prefabricated<br />

Poured on site<br />

(connecting<br />

reinforcement out<br />

of base plates)<br />

proposed to dismantle some of them from<br />

time to time to monitor their efficiency.<br />

With these measures, the noise in the<br />

concert hall should be reduced by 20-<br />

25dB, which will bring it down to a level<br />

experts say is acceptable. <strong>The</strong> previous<br />

level was around 46dB. <strong>The</strong> authorities in<br />

<strong>Basle</strong> selected this option as being the<br />

Spring elements<br />

cross-section<br />

Asphalt<br />

GERB spring elements<br />

GSI -R2<br />

GERB’S FLOATING SLAB TRACK<br />

Air shaft<br />

Foil as separating layer<br />

best system available today. <strong>The</strong> alternative<br />

would have been a simpler system<br />

only 900mm deep, which although<br />

cheaper would only have reduced noise<br />

levels by 10 to 15dB.<br />

<strong>Basle</strong> city council approved expenditure<br />

of SFr 11.8 million ($US 9.7 million)<br />

for the project. Of this, SFr 4.7 million was<br />

Rail chairs and recesses<br />

cross-section<br />

for preliminary work on the Steinenberg,<br />

and SFr 7.1 million for the installation of<br />

the floating slab track. Another SFr 8 million<br />

is being spent on related works. SFr 3<br />

million is being contributed by a speciallyformed<br />

private foundation. <strong>The</strong> entire<br />

project is scheduled for completion by<br />

February 2007. IRJ<br />

Reprinted from the September 2006 issue of <strong>In</strong>ternational Railway Journal<br />

Air shaft