Milling · Turning - Komet Group

Milling · Turning - Komet Group

Milling · Turning - Komet Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

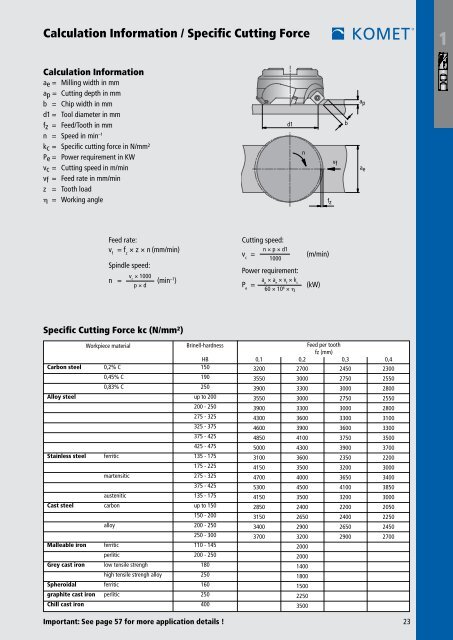

Calculation Information / Specific Cutting Force<br />

1<br />

Calculation Information<br />

ae = <strong>Milling</strong> width in mm<br />

ap = Cutting depth in mm<br />

b = Chip width in mm<br />

d1 = Tool diameter in mm<br />

fz = Feed/Tooth in mm<br />

n = Speed in min –1<br />

kc = Specific cutting force in N/mm²<br />

Pe = Power requirement in KW<br />

vc = Cutting speed in m/min<br />

vf = Feed rate in mm/min<br />

z = Tooth load<br />

= Working angle<br />

d1<br />

n<br />

f z<br />

v f<br />

b<br />

a p<br />

a e<br />

Feed rate:<br />

v f<br />

= f z<br />

× z × n (mm/min)<br />

Spindle speed:<br />

v<br />

n = c<br />

× 1000<br />

(min –1 )<br />

p × d<br />

Cutting speed:<br />

n × p × d1<br />

v c<br />

=<br />

1000<br />

Power requirement:<br />

a p<br />

× a e<br />

× v f<br />

× k<br />

P<br />

c<br />

e<br />

=<br />

60 × 10 6 × <br />

(m/min)<br />

(kW)<br />

Specific Cutting Force kc (N/mm²)<br />

Workpiece material<br />

Carbon steel 0,2% C<br />

0,45% C<br />

0,83% C<br />

Alloy steel<br />

Stainless steel ferritic<br />

martensitic<br />

austenitic<br />

Cast steel<br />

carbon<br />

alloy<br />

Malleable iron ferritic<br />

perlitic<br />

Grey cast iron low tensile strengh<br />

high tensile strengh alloy<br />

Spheroidal ferritic<br />

graphite cast iron perlitic<br />

Chill cast iron<br />

Brinell-hardness<br />

HB<br />

150<br />

190<br />

250<br />

up to 200<br />

200 - 250<br />

275 - 325<br />

325 - 375<br />

375 - 425<br />

425 - 475<br />

135 - 175<br />

175 - 225<br />

275 - 325<br />

375 - 425<br />

135 - 175<br />

up to 150<br />

150 - 200<br />

200 - 250<br />

250 - 300<br />

110 - 145<br />

200 - 250<br />

180<br />

250<br />

160<br />

250<br />

400<br />

Feed per tooth<br />

fz (mm)<br />

0,1 0,2<br />

0,3 0,4<br />

3200<br />

2700<br />

2450<br />

2300<br />

3550<br />

3000<br />

2750<br />

2550<br />

3900<br />

3300<br />

3000<br />

2800<br />

3550<br />

3000<br />

2750<br />

2550<br />

3900<br />

3300<br />

3000<br />

2800<br />

4300<br />

3600<br />

3300<br />

3100<br />

4600<br />

3900<br />

3600<br />

3300<br />

4850<br />

4100<br />

3750<br />

3500<br />

5000<br />

4300<br />

3900<br />

3700<br />

3100<br />

3600<br />

2350<br />

2200<br />

4150<br />

3500<br />

3200<br />

3000<br />

4700<br />

4000<br />

3650<br />

3400<br />

5300<br />

4500<br />

4100<br />

3850<br />

4150<br />

3500<br />

3200<br />

3000<br />

2850<br />

2400<br />

2200<br />

2050<br />

3150<br />

2650<br />

2400<br />

2250<br />

3400<br />

2900<br />

2650<br />

2450<br />

3700<br />

3200<br />

2900<br />

2700<br />

2000<br />

2000<br />

1400<br />

1800<br />

1500<br />

2250<br />

3500<br />

Important: See page 57 for more application details !<br />

23