Milling · Turning - Komet Group

Milling · Turning - Komet Group

Milling · Turning - Komet Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Internal and External Cutting Tools<br />

Cutting Speeds<br />

KOMET has developed an extensive programme of external and internal cutting tools. This<br />

brochure covers the standard design. In addition to these, special tools within this context<br />

can be supplied to suit customers requirements or to suit proposals based on workpieces<br />

to be machined.<br />

KOMET External and Internal Cutting Tools are used on standard lathes, turret lathes, automatic<br />

machines and special machines and also on boring and facing heads and milling<br />

machines.<br />

Because of the simplicity of their design and their high precision and quality, KOMET<br />

<strong>Turning</strong> Tools have an excellent record both at home and abroad. Several decades of<br />

experience have meant that KOMET is always able to supply high quality tools to meet<br />

every customer requirement.<br />

The steel and carbide grades used undergo a constant accurate inspection procedure in<br />

our special Trials Department.<br />

KOMET produce high quality tools for the highest of demands.<br />

High Speed Steel Grades:<br />

KOMET Tools are produced in high speed steel grades F and H.<br />

3<br />

Carbide Grades:<br />

The carbide grades P20 and K10 are supplied as standard for KOMET carbide tools.<br />

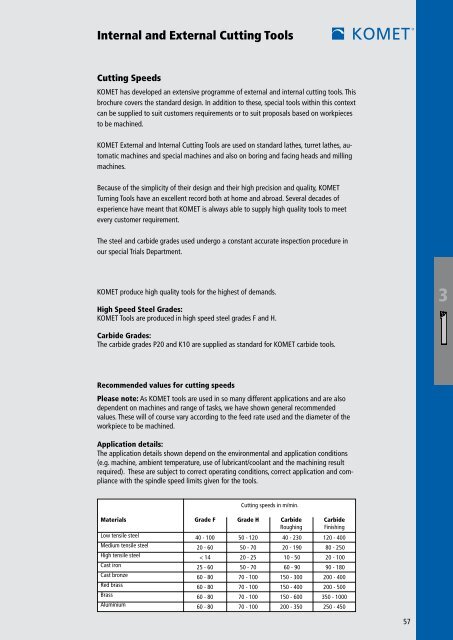

Recommended values for cutting speeds<br />

Please note: As KOMET tools are used in so many different applications and are also<br />

dependent on machines and range of tasks, we have shown general recommended<br />

values. These will of course vary according to the feed rate used and the diameter of the<br />

workpiece to be machined.<br />

Application details:<br />

The application details shown depend on the environmental and application conditions<br />

(e.g. machine, ambient temperature, use of lubricant/coolant and the machining result<br />

required). These are subject to correct operating conditions, correct application and compliance<br />

with the spindle speed limits given for the tools.<br />

Cutting speeds in m/min.<br />

Materials<br />

Low tensile steel<br />

Medium tensile steel<br />

High tensile steel<br />

Cast iron<br />

Cast bronze<br />

Red brass<br />

Brass<br />

Aluminium<br />

Grade F Grade H Carbide<br />

Roughing<br />

40 - 100<br />

20 - 60<br />

< 14<br />

25 - 60<br />

60 - 80<br />

60 - 80<br />

60 - 80<br />

60 - 80<br />

50 - 120<br />

50 - 70<br />

20 - 25<br />

50 - 70<br />

70 - 100<br />

70 - 100<br />

70 - 100<br />

70 - 100<br />

40 - 230<br />

20 - 190<br />

10 - 50<br />

60 - 90<br />

150 - 300<br />

150 - 400<br />

150 - 600<br />

200 - 350<br />

Carbide<br />

Finishing<br />

120 - 400<br />

80 - 250<br />

20 - 100<br />

90 - 180<br />

200 - 400<br />

200 - 500<br />

350 - 1000<br />

250 - 450<br />

57